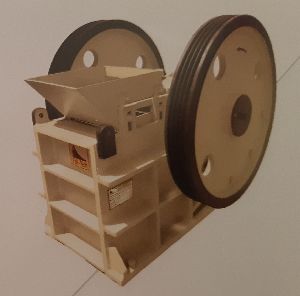

single toggle jaw crushers

75,000 - 300,000 Per Unit

1 unit (MOQ)

We offer single toggle jaw crushers have bearings with grease lubrication have simple construction, easy to maintain and economical. This machine gives higher percentage of fines.

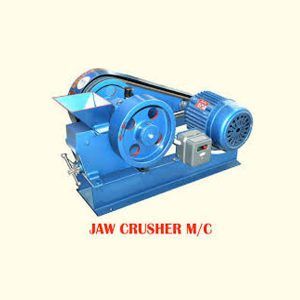

Jaw crusher

Get Price Quote

Details We manufactures two types of Jaw Crusher, Single toggle and Double toggle. Single toggle Jaw Crusher have simple and robust construction with grease lubricated bearings design, which is easy to maintain and economical. This machine gives higher percentage of fines. Double toggle Jaw Crushers has forced oil lubrication with the help of oil pump and nozzles, the machine works with the help of two toggles, so that it’s generates less fines and particles come with sharp edges.

Best Deals from Jaw Crusher

Jaw crusher

Get Price Quote

Apollo jaw crusher modal b1250 250 tph .

Single Toggle Jaw Crusher

Get Price Quote

1 Piece (MOQ)

Single Toggle Jaw crushers are used for primary crushing. Single Toggle Jaw Crusher is designed for exceptionally heavy and continuous applications. Single toggle jaw crushers are provided in heavy and light versions with welded steel housing and a moving jaw in a welded or cast steel version, as well as an eccentric shaft made of high-grade forged steel. Features And Benefits High and constant capacity. High operational reliability. Heavy Duty Forged Crank Shaft. Broad range of application. Easy replacement of wear and spare parts.

Single Toggle Jaw Crushing Machine

Get Price Quote

We are an eminent Manufacturer, Exporter & Supplier of Single Toggle Jaw Crushing Machine from Gujarat, India. Widely used for mining and construction applications, our Jaw Crushing Machine is preferred for its sturdy construction, reliable performance and long service life. Buyers can get in touch with us for purchasing small and bulk orders of Jaw Crushing Machine at affordable rates. Details : Single Toggle Jaw Crusher : is ideally suitable for primary and secondary crusher for material with compression strength less than 320mpa. Jaw crusher is of high crushing ratio, larger capacity, well-distributed final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etc. it is widely used in mining, metallurgy, construction, highway, rail road, and water conservancy, etc. Fixed Body : the main component of the fixed body is rack, which has two manufacturing engineers: carbon steel casting rack and carbon steel plate welded rack. welded rack can achieve the same effect as casting rack through strict quality control and specific process requirements. Rotating Body : it is composed of moving jaw, eccentric shaft, bearings, pulleys and other parts, and it is the main part of the jaw crusher transmission and endurance. Adjustment Device : it is used to adjust the size of discharging mouth and control the discharging granularity. Hongxing jaw crusher has two forms: long wedge type and plunger gasket type with convenient and flexible adjustment, can achieve step less adjustment.

Jaw crusher

500,000 - 5,000,000 Per set

15 Set (MOQ)

Jaw crusher

Get Price Quote

Techno Power engineering is leading manufacturer and exporter of Jaw Crusher in Ahmedabad. Jaw Crusher can crush toughest materials like granite, basalt, iron ore etc. The crushers have gained huge appreciation in the market for their host of qualitative features.A Hinge pin is placed on crushing chamber centerline for crushing without Rubbing, large bearings provided and integral lubrication With the low inertia of the mechanism only a light small diameter flywheel is required.Double toggles provide maximum leverage to long stroke eccentric Pull back and lifter springs automatically compensate for wear. Specifications: Feed Size: 125 mm to 1000 mm Capacity: upto 500 TPH

Jaw crusher

Get Price Quote

We are offering jaw crusher. jaw crushers are used extensively throughout the aggregate and mineral processing industry. There two types of jaw crushers are available single toggle and double toggle. Single toggle jaw crushers have bearings with grease lubrication have simple construction, easy to maintain and economical. Single toggle jaw crusher give higher percentage of fines, hence usually used as primary crushing. In the other side our double toggle jaw crushers has forced oil lubrication with the oil pump and nozzles. It works with the help of two toggles, it generates fewer fines and particles then single toggle and come with sharp edges, therefore they are used mainly for making grits for road, railway track, civil construction etc. Both types of jaw crushers are available in high range of production capacity. These are supposed to be most economical with highest ratio of size reduction. working principle: crush tech, jaw crushers are equipped with one fixed and one moveable jaw plate, both of which support crushing jaw plates in several versions. The motor drives the belt pulley and the belt pulley drives the eccentric shaft to rotate, and make the moving jaw approach and leave the fixed jaw periodically, to crush, rub and grind the materials repeatedly, thus to make the material slower and slower and gradually fall down and finally discharge from the discharge opening. advantage: � jaw crushers are design in single toggle and double toggle � single toggle jaw crushers have bearings with grease lubrication have simple construction, easy to maintain and economical. � single toggle jaw crusher give higher percentage of fines, hence usually used as primary crushing. � double toggle jaw crushers has forced oil lubrication with the help of oil pump and nozzles. � double toggle jaw works with the help of two toggles, it generates less fines and particles come with sharp edges, � both types of jaw crushers are available in high range of production capacity. These are supposed to be most economical with highest ratio of size reduction. application: stones, black trap, basalt, marble, quartz, granite, river gravel, coal, lime stone, mineral ore, making grits for road, railway track, civil construction etc.

Jaw crusher

Get Price Quote

Jaw crusher

Get Price Quote

We are offering jaw crusher.

Jaw crusher

Get Price Quote

Jaw Crusher manufactured by us is known for the robust structure and output driven quality. These Jaw Crushers are used in many industries like Mining, Chemical, Coal, Construction and many similar places. The use of Jaw Crushers makes the crushing of stone easy. Our Jaw Crushers are known for low power consumptions and powerful motors used to run them. These Jaw Crushers have high capacity and they require low maintenance. Our Jaw Crushers produce less noise and are vibration resistant in nature. Highlights Less noise Vibration resistantLow power consumption.

Jaw Crusher Laboratory Type

Get Price Quote

Laboratory Jaw Crusher is designed to speed up the crushing of aggregate, ores, minerals, coal, coke, chemicals and other similar materials. Its compact and of rugged construction is advantageous for general laboratory or small pilot plant operations. IntroductionTwo jaws of manganese steel are provided in the jaw crusher. The moveable jaw produces two blows for every revolution, thus reducing over sizing to a minimum. A combination of forward and downward and strokes with a rocking action exerts pressure on the coarse material to pass through the jaws. A hopper is provided at the top for feeding materials. The smooth jaws ensure a uniform product and easy cleaning is possible.

Jaw Crusher Laboratory

Get Price Quote

Introduction Laboratory Jaw Crusher is designed to speed up the crushing of aggregate, ores, minerals, coal, coke, chemicals and other similar materials. Its compact and of rugged construction is advantageous for general laboratory or small pilot plant operations.wo jaws of manganese steel are provided in the jaw crusher. The moveable jaw produces two blows for every revolution, thus reducing over sizing to a minimum. A combination of forward and downward and strokes with a rocking action exerts pressure on the coarse material to pass through the jaws. A hopper is provided at the top for feeding materials. The smooth jaws ensure a uniform product and easy cleaning is possible. Max Size of feed 50mm (approximately) Product discharge Size of feed 6mm to 18mm (adjustable) Capacity 80kG/hr (approximately - based on material) Operation On 440 volt, 3 Phase, 50hz, A.C. supply with 3H.P. Electric motor motor, a starter ' v ' belt pulley drive and mounting

Pew Jaw Crusher

Get Price Quote

PEW series Jaw crusher features big crushing ratio, reliable operation, easy maintenance and low operating cost. It is the new generation product designed and produced by SKD , basing on our 30 year’s crusher production experience and the latest design conception. It does be one high efficiency and low cost crushing machine. Features Of PEW Jaw Crusher V-shaped structure crushing cavity is able to meet a big feeding. Movable jaw assembly adopts a high-quality steel casting and heavy eccentric shaft has also adopted forging billet for processing. Use of finite element analysis technology helps to reach both light weight and high reliability. Equipped with wedge adjustment devices, enable to realize automatic control and stepless adjustment. Application Of PEW Jaw Crusher Jaw crusher is widely used in various materials processing of mining &construction industries, such as it is suit for crushing granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral &rocks.

Mobile Jaw Crusher

Get Price Quote

Portable mobile jaw crusher is developed according to novel series stone crushing equipment’s design idea, the adaption of ship form structure lowers the chassis; reduce the weight and volume of the plant; and makes it easy for turning and transportation; the fashionable design and standardized mass production fully meet customers' requirements.

Jaw Crusher Machine

Get Price Quote

Single Toggle Jaw Crusher

Get Price Quote

Two series of Jaw Crushers are available. Single toggle and Double toggle type. Single toggle Jaw Crushers have bearings with grease lubrication have simple construction, easy to maintain and economical. Single toggle Jaw Crusher give higher percentage of fines, hence usually used as Pre Crusher. Double toggle Jaw Crushers has forced oil lubrication with the help of oil pump and nozzles. Since it works with the help of two toggles, it generates less fines and particles come with sharp edges, hence used mainly for making grits for road, railway track, civil construction etc. Both type of Jaw Crushers are available in high range of production capacity. These are supposed to be most economical with highest ratio of size reduction. Application: Stone, Coal, Various Minerals, Ores etc.

Jaw Crusher Machine

Get Price Quote

Jaw Crusher Laboratory Type

Get Price Quote

Laboratory Jaw Crusher is designed to speed up the crushing of aggregate, ores, minerals, coal, coke, chemicals and other similar materials. Its compact and of rugged construction is advantageous for general laboratory or small pilot plant operations. IntroductionTwo jaws of manganese steel are provided in the jaw crusher. The moveable jaw produces two blows for every revolution, thus reducing over sizing to a minimum. A combination of forward and downward and strokes with a rocking action exerts pressure on the coarse material to pass through the jaws. A hopper is provided at the top for feeding materials. The smooth jaws ensure a uniform product and easy cleaning is possible.

Jaw crusher

Get Price Quote

We are offering jaw crusher. Ours is an eminent organization, engaged in manufacturing and supplying jaw crusher. Offered jaw crusher is used for crushing material and is developed in adherence with the guidelines laid in the industry to attain highest benchmarks of quality. Driven by motor, our offered machines are offered to our customers at industry leading prices. features: reliable operation easy maintenance low operating cost specifications: capacity(th): 140-260th electric motor power: 110kw Features: Our jaw crusher has Simple structure and reliable operation Easy maintenance and low operating cost Rugged Steel Body Jaw Plates of Wear-Resistant Manganese Steel Special Steel Eccentric Shaft with Heavy -Duty Double-Toggle Attachment Superior load distribution Spray Oil Lubrication System Guarantees safe operation at high speeds. Requires lower horse power cheaper squirrel cage Maximum Crushing Range-13MM to 62MM