vial labelling machine

Suitable to apply accurate Labels on Double Side (Front & Back) of Flat/Oval/Square shaped products having PET, Plastic, HDPE, LDPE, Glass or any other surface. The Machine incorporates latest sophisticated Microprocessor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system. SBSL-120F Sticker Labeling machines are 100% User Friendly, Virtually Maintenance Free and does not require Data Inputs for Label Size. Salient Features: � No change parts for container and label size in standard shaped containers � Single Point on-line Speed Variation control system � Precise Label Placement Accuracy � Built In A.C. Freq. Drive System � Output up to 150 labels per minute. � Fully Stainless Steel Finish including main machine frame

...more

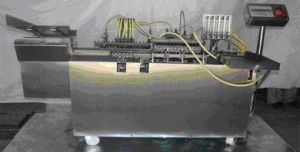

Six Head Ampoule Filling Machine

Keeping up with the latest demands of customers, we, as a trusted Supplier strive to provide quality Six Head Ampoule Filling Sealing Machine. Our company is empowered by a vast distribution network that enables us to reach buyers anywhere and deliver orders on time. Features : Compact GMP model Production output ranging from 60 to 150 ampoules/minute All contact parts made from AISI SS 316 & other Non-contact parts made from AISI SS 304. Ampoule neck centering during gas flushing and filling operations Machine is suitable to fill 1ml to 10ml ampoules with the help of change Parts Possibility of Nitrogen Gas flushing before & after filling

...more

Rotary Bottle Washing Machine

Semi automatic rotary bottle washing machine suitable for 30ml to 1000ml glass bottle glass bottles. machine provides: 4 water & 3 air washes zeneva mechanisam contact parts: ss 316 water tank: total 2 nos (40 ltrs each) pressurised pump: total 2 nos. washing process: automatic loading & unloading: manual out put: 60 to 100 bottle per minute gmp model matt finished

...more

Rotary Ampoule & Vial Washing Machine

Machine provides 4 water washes & 3 air washes complete flexibility with user for washing cycle. all contact parts made out from ss316 entire frame covers & non contact parts made out from ss 304 nozzles enter into the container during washing cycle to meet comp requirement low water consumption quick change over with minimum use of tools. all contact parts with d.m. Water and distilled water of s.s. 316 construction and argon arc welded. the unit built on s.s. Square pipe frame and totally encompassed with s.s. Coverings the washing section is totally covered with acrylic cabinet. all exposed parts are of s.s. 304 or hard chrome plated or brass for corrosion free long life. fixed top nozzles at each washing station ensures external washing of bottles at the same time of internal washing. the flow of washing medias stop during the indexing of chain, saving straight 25% on utilities. the system of solenoid valves and optional tanks, pumps and filters is engineered for long trouble free life & tool proof operation.

...more

pharmaceutical machinery parts

Powder Filling - Liquid Filling - Capping Machines - Labelling Machines - Change of design of machines.

...more

Pharmaceutical Automatic Inspection Machine

Over the years, we have become a high-flying name since our Pharmaceutical Machinery is qualitative and deliveries are time-bound. Ours is a well-established firm located in Ahmedabad(India) and engaged in the business of providing a wide assortment of quality products. Salient Features : Construction AISI S.S. 304 quality. Three step pulley for different speed. Special self-aligning bearings ensure smooth and trouble free operation. Suitable for different type of container. S.S. elegantly matt finished body. Reduction gears ensure jerk free and noiseless operation. Matt Finished body. Optional : Castor Wheel with lock A/c Frequency Drive Acrylic Cover Tray for loading or unloading of container.

...more

pet bottle filling machines

FEATURES: Available in 2 or 4 head models filling range from 5ml to 1500ml.(with the help of different syringes) machine body is constructed in MS and covered by SS sheet. Accurate and continuous filling of all type of free flowing liquid in any shape of container. Filling speed 300 to 1500 fills/ Hr. (Depending on Volume / Viscosity of the Liquid be Filled) Provided with non return valves and HDPE piston rings.

...more

Packing Conveyor Belt Machine

We also manufacture 90 /180 degree Turn conveyors, which are designed to take heavy loads upto 100kg and speed variation from 0 - 45 mtr/min. The system design is: Modular Assembly Low running noise Positive belt guidy system Sturdy frame work Belt change within 30 minutes Smooth product transfer The application of systems is for conveying food, pharmaceutical, mechanical, plastic, soup & detergent. The conveyor design mainly used to link up the system for space saving.

...more

Packing Belt Conveyor

We are the most promising name, involved in supplying Packing Conveyor. Sited in Ahmedabad(India), we guarantee safe side deliveries of consignments in a time limited period. Salient Features : Available in S.S./M.S. model. Available as per your require speed, length, height & width. Structure is made of S.S. 304/M.S. 32mm square pipe with matt finish/painted. Table top is made of S.S.304 16 gauge sheet with matt finish. Conveyor Belt is supplied with 3 speed pulley. Special Self-aligning bearing ensure smooth and trouble free rotation of the Roller. Conveyor belt is used as PVC coated canvas belt/endless rubberized belt. The Reduction Gear Box provides jerk less & noiseless performance for long time.

...more

Multi Jet Ampoule & Vial Washing Machine

All thanks to our smart inventory management owing to which safe and quick deliveries are furnished by us. Ours is a well-established firm located in Ahmedabad(India) and engaged in the business of providing a wide assortment of quality products. Salient Features : Positive & pressurised jets through washing needle for pressure cleaning at minimum usages of Washing Media. Sound design concept of pressure tanks for reverses & continuous supply of washes medias Both internal & external washing ensuring absolutely & continuous ampoule & Vial after sequential washing. Acrylic top cover for clear view of washing events taking place in the machine. On-line poly carbonates housing with P.P. replaceable filter cartridge of 10 microns for water & 5 microns for air for best possible washing. All contact parts of washing media & compressed are of S.S 316 or HDPE of Poly carbonate or P.P. In the event of acrylic cover lifted during cycle operation, the machine will automatically stop and re-start from the point when cover is pushed down.

...more

Vial Washing Machine

Positive & pressurised jets through washing needle for pressure cleaning at minimum usages of washing media. sound design concept of pressure tanks for reverses & continuous supply of washes medias both internal & external washing ensuring absolutely & continuous ampoule & vial after sequential washing. acrylic top cover for clear view of washing events taking place in the machine. on-line poly carbonates housing with p.p. Replaceable filter cartridge of 10 microns for water & 5 microns for air for best possible washing. All contact parts of washing media & compressed are of s.s 316 or hdpe of poly carbonate or p.p. in the event of acrylic cover lifted during cycle operation, the machine will automatically stop and re-start from the point when cover is pushed down.

...more

Label Counting Machine

Features for Label Counting Machine :- High Speed With Capacity Of Counting Upto 1500 Labels Per Minute. 5.7" Touch Screen Display For Control Like Direction Change. Ability To Count Pre-Determined Label Quantity. Printout Facility To Maintain Record Of Exact Counted Labels. Compliance With cGMP. Compact And Sturdy Structure. Simple Controls For Ease To Operation.

...more

LABEL BATCH CODE PRINTING MACHINE

Working: Automatic feeding by slant magazine allows labels to a polished stainless steel feed wheel, The Label is picked up by rubber and it is fed to a timing chain, which carries the label under the printing head. Printing head is having a type block where individual types can be composed, or rubber stereos can be fixed on a block of half cylinder piece. No make ready or skill is involved, as the rubber backup cylinder evens out the impression. Oscillating distributor roller spreads ink evenly shaded unbroken, fully to the ink roll. All shafts of Stainless Steel materials, rotate in sintered bronze bushing (oil-less bushes). Other major parts are also stainless steel material. FULL GMP MODEL IS ALSO AVAILABLE. MAIN FEATURES: Automatic feeding, nice and quick adjustments, easy controls, accurate registering, uniform impressions, high output 250 labels/min. Specification: Model FOR LABELS FOR CARTONS Over All Dimension 820 X 415W X 490H 870 X 765W X 625 H Speed 125, 180, 250 Label/Min 125, 180, 250 Carton/Min Label Size 20 x 40 mm to 150 x 200 mm 75 x 25 to 325 x 175 mm Weight Approx 75 Kg. Approx 125 Kg. Power 0.25 HP / 1440 RPM / 414V,3 Phase OR Single Phase 0.25 HP / 1440 RPM / 414V,3 Phase OR Single Phase

...more

Inspection Table

We make sure; our products are produced using top grade materials sourced from reliable vendors only. If you are interested in obtaining Inspection Table at market leading prices, we are its responsible and responsive suppliers. Specifications : 8 feet Length Output - Up to 250 Container / minute Number of Operator - Six (3 x 2, two side seated) Power Characteristics - 220 Volts, Single Phase, 0.5 HP, 50 Hz. Machine Dimension - 2440 mm (L) x 760 mm (W) x 1325 mm (H) Case Dimension - 2616 mm (L) x 915 mm (W) x 1420 mm (H) Net Weight - 225 Kgs. 16 feet Length Output - Up to 150 Container / minute Number of Operator - Four (2 x 2, two side seated) Power Characteristics - 220 Volts, Single Phase, 0.5 HP, 50 Hz. Machine Dimension - 1830 mm (L) x 760 mm (W) x 1325 mm (H) Case Dimension - 2080 mm (L) x 915 mm (W) x 1420 mm (H) Net Weight - 200 Kgs.

...more

Dry Powder Filling Machine

Automatic Vial Powder Filling Machine is suitable to fill injectable powder into vials. The precision built welded steel frame is encompassed with stainless steel sheets with access doors for servicing the machine. All parts coming in contact with container, powder and rubber stopper or exposed to the atmosphere are made of stainless steel for long life. This machine is available in two different models. Automatic Vial Powder Filling Machine,KPFR-120 provide output of 30 to 120 vials per minute, on other side Automatic Vial Powder Filling Machine, KPFR-240 provide production output of 60 to 240 vials per minute. Salient Features Compact cGMP model Machine provide production output up to 240 vials/minute �No Vial, No Filling� system eliminates wastage of costly powder Multiple Dosing System High Volumetric Filling Accuracy of ± 1% of uniform density Injectable powder can be ensured by setting the depth of piston in the port of powder wheel Built-in Rubber Stoppering Unit saves lot of space in the Sterile Area & reduces the length of Laminar Flow Individual drive for the filling & sealing to match the speed of filling & sealing All motors are provided with appropriate contractors and relays for the protection against any overload or jamming Safety clutch system to avoid Vial breakage Variable Frequency Drive for speed control All contact parts are easily removable for mandatory Autoclaving/ Sterilization Digital counter for counting production output Process Operation The sterilized powder is stored in powder hopper is agitated by pair of mechanical agitators for maintaining consistency and uniform bulk density. The powder wheel having eight ports rotates at the pre determined speed below the powder hopper with practically no clearance. Powder wheel consist of Piston in each port and behind the powder wheel vacuum plate is provided there is no clearance between powder wheel and vacuum plate due to back spring pressure.

...more

Double Head Dry Syrup Powder Filling Machine

With meticulousness, hard work and commitment, our organization has developed in order to become a reputed trader in Ahmedabad(India). Stern quality checks, frequent examinations and perfect packaging, we make certain that the range is as per the industrial standards. Features : No Bottle - No Fill System All contact parts made of Ss316 and Nylon/HDPE material with easy removal system for Cleaning Machine construction in SS304 material A. C. Variable Frequency Drive Speed Control Filling Accuracy of +/- 1% to 3% depending on powder at controlled humidity below 0% Rh Built in Turn Tables with Separate Drive for speed control Heavy Duty Mounting system for Powder Wheel for Trouble Free long term operations

...more

Automatic Bottle Liquid Filling Line

Operation : The central conveyor belt brings the bottle from the capping machine conveyor. These bottles are automatically bifurcated on the two adjoining conveyor belts and further on the side tables for operator sitting on either side of the table. The operator sin turn pick up the bottles and visually inspect the bottles in the alternate white and black background to check for any particles in the liquid filled, sealed and breakage of bottle. After inspection the bottles are placed in the central track. Salient Features : Designed as per cGMP - Current Good Manufacturing Practices compliance A machine structure is made from AISI 304 with matt finish. High-speed visual inspection with high output. Length can make as per customer requirement. PVC black & white board as per GMP norms Belt drives through gear motor with variable frequency drive. Provides guide for chain of UHMW self lubrication. Adjustable height of conveyor belt, to align with other machine of the line Self-alignment bearing for easy maintenance.

...more

Bottle Inspection Conveyor System

SS pipe structure Speed control through ACVFD Direct gear drive Reduction gear ensures noiseless and jerk free movement of chains Length can be modified as per the requirement Bigger size of magnifying dome allows inspection of larger size containers UHMW self-lubricating guides below chains to reduce friction Adjustable height of conveyor belt to align with other machine of the line Technical Specification: Model -100 -150 Direction of Movement Left to Right Output / Minute* Up to 100 Up to 150 Number of operator One (1 x 1, One side seated) Two (1 x 2, Two side seated) Dome Diameter 250 mm (1 Nos.) Electric Specifications 0.5 HP/220 V/50 Hz Height of Conveyor 860 ± 50 mm Input Specifications Container Size Round Diameter : � 22 mm to � 100 mm Respective Height : 58 mm to 240 mm Flat / Square Length : 15 mm to 100 mm Width : 10 mm to 50 mm Height : 58 mm to 240 mm Utility Requirement Electric Supply Single Phase + Neutral + Earthing Electric Load 0.5 KW

...more

Bottle Cap Sealing Machine

The automatic single head cap sealing machine is manufactured from welded steel frame, enclosed with stainless steel sheet. The conveyor belt is used to move the feed containers. The containers are placed in the star wheel. Then containers are set below the sealing head which is in the subsequent indexing part. The delivery chute of cap feeding bowl, deliver the cap on the bottle. The body and neck of the container are positioned below the rotating head. The threading and sealing is performed perfectly by the sealing head. The conveyor, star wheel and the platform turret are operating by a single motor.The height of the conveyor belt is adjustable to align with other machine of the line. S.S. cladding or hard chrome plating of all exposed parts.S.S. matt finished body.The bottle height gauge is adjustable for quick setting For the different container diameter, no need to change the parts.Head movement is by the motor.Noise level and power consumption is very low.In built control panelThe self lubricating profile for S.S. slat chain. No bottle no filing system The conveyor, star wheel, platform turret and capping bowl are synchronizing by the synchronized A/C drives. For the different gauges and sizes of caps, the sealing pressure is varied. UTILITY REQUIREMENT : Electrical Supply : One Phase + Neutral + Earthing Electrical Load : 0.75 KW TECHNICAL SPECIFICATION : Model -60 Output/Hour* 1000 to 3000 bottles. Direction of Movement Left to Right No. of Sealing Head 1 Nos. Electrical Specification** Main Motor Cap Feeding Bowl 1 HP / 415 Volts / 50 Hz. 300 Watt, Magnetic coil Height of Conveyor** 860 mm to 910 mm Machine Dimensions** 1525 mm (L) x 850 mm (W) x 1900 (H) Approx. Case Dimensions 1750 mm (L) x 1100 mm (W) x 2250 (H) Approx. Net Weight 350 Kgs. Approx. Gross Weight 550 Kgs. Approx. Change parts required (A) Container: Star Wheel, Back Guide,

...more

Automatic Volumetric Liquid Bottle Filling Machine

To ensure utmost satisfaction of the buyers, we make sure that the delivery schedule should be properly maintained. Headquartered in Ahmedabad(India), we are acknowledged for providing excellent products domestically. Details : Depends on container size, Fill size, Neck diameter of container, and container, and nature of liquid etc. We can supply as per customer requirements.With help of change parts.

...more

Automatic Vial Powder Filling Machine

For ensuring quality products at buyer's end, we check each and every product at diverse stages including production, packaging and delivery. Obtain the extensive array of products from our well-established inventory located in Ahmedabad(India). Salient Features : Compact cGMP model Machine provide production output up to 240 vials/minute “No Vial, No Filling” system eliminates wastage of costly powder Multiple Dosing System High Volumetric Filling Accuracy of ± 1% of uniform density Injectable powder can be ensured by setting the depth of piston in the port of powder wheel Built-in Rubber Stoppering Unit saves lot of space in the Sterile Area & reduces the length of Laminar Flow Individual drive for the filling & sealing to match the speed of filling & sealing All motors are provided with appropriate contractors and relays for the protection against any overload or jamming Safety clutch system to avoid Vial breakage Variable Frequency Drive for speed control All contact parts are easily removable for mandatory Autoclaving/ Sterilization Digital counter for counting production output

...more

Automatic Vacuum Type Volumetric Injectable Powder Filling Machine

Customers can place bulk as well as urgent orders with us and we can assure timely & safe delivery of the same. Placed in Ahmedabad(India), is capable of catering to local as well as domestic markets without any hassle. Semi Automatic Rotary Bottle Washing Machine : Output - 40-80 Vials/Minute for single dose. 20-40 Vials/Minute for double dose. Fill Size - 50 mg to 1.5 grams with the help of two different powder wheels and dipending on the neck diameter of the containers. Accuracy - ±1 % for uniform density and free flowing powder at controlled humidity level below 30%. Dimension - 1585 mm (L) x 750 mm (W) x 1600 mm (H) Net Weight - 400 Kgs.

...more

Ampoule Filling Machine

Technical Specifications are as below: Equipment : Ampoule Filling Sealing Machine Model : KFS-100 Optimum output 80 to 90 Ampoule/min. Overall dimensions : 1200 mm L * 1070 mm W * 965mm H Electric Power Supply : 440V. 3 Phase,1H.P Ampoule Size : Min. 9.5mm Dia to Maxi. 17mm Dia (1ml to 5ml) Construction details : The equipment consist of Hopper with loading Tray at infeed, Filling & Sealing station Loading tray : SS 304 Table top : SS 304 Change Parts : Star Wheel & Needle Ampoule Collection : Collect in Trays

...more

Automatic Six Head Ropp Capping Machine

We are backed by a modern transportation facility that ensures safe delivery of the orders at required destinations. Our team members inclusive of quality auditors make complete quality analysis of the product before final dispatch. Salient Features : No cap no sealing arrangement. Single motor synchronizes conveyor, star wheel & platform turret. Adjustable height of conveyor belt. Sealing pressure can be varied to suit different gauges and size of caps. Specially designed hopper is provided to increase storage capacity of bowl. Low noise level, low power consumption. Star wheel is equipped with safety clutch for automatic stoppage of machine in case of jamming / overloading.

...more

Products Manufacturing Exports & Imports

We are specialized manufacturer & Exporter of machineries for Pharmaceuticals, Food, Herbal, Beverages, Cosmetics, Pesticides, Chemicals and House hold products Ranging from Automatic Liquid Filling Machine, Automatic Screw Capping / Sealing Machine, Automatic Wet Glue Labeling Machine, Automatic Sticker Labeling Machine Suitable for different types & sizes of bottles / containers.

...more

PHARMACEUTICALS MACHIENERY

Ampoule Filling line � Vial Injectable Filling line - Dry Powder Filling line - Washing machines -Syrup Powder Filling machines �Oral Liquid Filling machines - Capping Sealing machines - Online Inspection Machines � Wet Glue and Sticker Labeling machines -Turn Tables - R & D Type machines.

...more

MASSAGE FOR ALL CUSTOMERS

PLEASE SEND YOUR VALUE SERVICES FOR BUYING MACHINES PLEASE DIRECT CALL & CONTACT NOW. OUR MAIL : hiteshkailash@gmail.com & Contact No : 9426078188 - 9825578818 - 98250 18210 please give your best value time us. thanking you, HITESH MEVADA.

...moreBe first to Rate

Rate ThisOpening Hours