Wear resistant rubber liner

3,000 - 10,000 Per SET

1 SET (MOQ)

- Material - Based on tailor-made requirements, liners are manufactured using different material compositions like natural or synthetic rubber, or blended compound. Natural rubber comprises unmatched abrasion resistance and is best for general-purpose applications. Besides synthetic rubbers are applicable where it requires increasing the resistance capacity to maximum temperatures, chemicals, or oils. - Dimension & Thickness - The dimensions and thickness vary according to the requirement of protection level. For specific size and shape requirements, liners can mold or cut to complex curves, angles, or shapes to fit the dimensions of your machinery perfectly. - Custom Edge Design - In addition, custom edge design helps trouble-free installation of liners and enhances equipment performance. - Finishing & Texture - The surface textures and finishes of liners depend on the area of applications. For example, a smooth surface is essential for crucial material flow and prevents build-up. A liner with diamond, ribbed, or other patterns helps reduce material sticking, improving grip, and boosting abrasion resistance. Using customized channels or grooves, it eases the material or fluids flow, reduces wear, and improves efficiency. Uses Wear Resistant Rubber Liners are widely used in various industries for their different applications. - Mining and Quarrying industries – Ball Mills, ore mills, coal mills, and more to enhance equipment life and operation efficiency and performance. - Chemical industries – Heat exchangers, coolers, reactors, and other equipment to protect them from wear and corrosion. - Cement industries – Hoppers, line mill feeders, and more to protect from the harsh nature of cement dust and other raw materials. - Aggregate Industries – Helpful for protecting crushers, conveyors, screens, and other equipment from the endless effect of aggregate materials. - Power Industries – Improve reliability and performance of thermal power generators and other equipment. For more information about our best quality Wear Resistant Rubber Liner and other products, write at ______________ or call us at ______________.

Outer Diameter : 1000mm

Type : Wear Resistant Liner

Certificate : ISO9001:2008

Length : 1000 To 2000 Mm

Color : Black & Green

Material : Ceramic

Application : Finishing & Texture

Machine Type : Longevity

...more

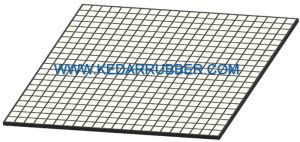

Shell Plate liner

3,000 - 10,000 Per NOS

10 PIECE (MOQ)

Flat or Radial Rubber Shell Plates Flat shell plates are useful when requiring uniform wear distribution for less aggressive grinding conditions. Radial shell plates are expensive, but highly durable and offer exceptional performance and grinding efficiency. Based on precise grinding application, cost and performance characteristics are some important factors for choosing the design of ball mill shell liners. For more information or your custom inquiry about Rubber Shell Plates, write to us at kedarrubber@gmail.com or Call Now - 9824444733. Flat Rubber Shell Plate with Taper With increasing thickness of the flat rubber shell plates, they act as a protective barrier that prevents the mill shell from the direct impact of the wear caused by the grinding media and material. This shielding is essential for enhancing the lifespan of the ball mill and preventing structural damage. The taper helps in improving the flow of material and lowering the risk of direct contact between the mill shell and the grinding media ensuring that the rubber shell liner can impact the wear. Due to the improved impact absorption, they lower the waste of energy on mechanical stress and vibrations allowing more energy to be used for the material-breaking process and thus, enhance energy efficiency. Rubber shell plates are light in weight which makes it easy and efficient to install and remove them. They can fit easily into the mill; thus, they reduce the time to install or replace shell liners. We offer customized solutions to meet the bespoke needs of customers ' specifications as per their milling process like the nature and size of grinding material or media required to process. Rubber Radial Shell Plate with Rib Kedar Rubber offers Rubber Radial Shell Plates with ribs that give extra structural strength to the shell plate. This helps to distribute pressure across the liner evenly. Thus, protect the mill’s shell from damage by preventing excessive wear and downtime. The rib adds reinforcement to the rubber liner, makes it capable of bearing the dynamic forces of processing material and grinding media, and enables it to manage the overall integrity of the mill.

Material : High Manganese Steel

Color : Black

Application : Deck Plate

Length : 1000 To 2000 Mm

Certificate : ISO9001:2008

Type : Wear Resistant Liner

Thickness : 10-15mm

Country of Origin : India

...more

Abrasion Resistant Rubber Liners

3,000 - 10,000 Per NOS

1 PIECE (MOQ)

As a premium rubber products manufacturing company in India, Kedar Rubber delivers high-quality rubber products including abrasion-resistant rubber liners. We accomplished the bespoke needs of different industries for their custom specifications. Abrasion Resistant Rubber Liners play a vital role in maintaining the durability and performance of ball mills. In industries such as mineral, cement, chemical, and others the abrasion-resistant rubber liners are widely used to shield the ball mill’s shell from wear and tear due to the friction and impact of the grinding material and media during the milling process.

Country of Origin : India

...more

RUBBER LID FRAME FOR MANHOLE

5,000 - 25,000 Per Piece

2 Piece (MOQ)

The use of a lid or plug frame is to hold the lid cover during milling operations. A lid or manhole frame with a flanged design supports the lid plug making tight sealing. Moreover, it helps absorb vibrations and protects the mill from wear and corrosion. The robust design and properties of rubber material make it a vital component of the mill for the secure milling process and enhance its lifespan. Its flanged structure makes tight sealing that prevents any leakage of grinding material, dust, or slurry. The plug frame supports bolts or lid plug tightly, thus, preventing leakages even during high pressure and vibrations inside the ball mill. The rubber lid frame makes a dust-tight and airtight seal around the manhole. The flexibility and resilience nature of rubber ensures the plug frame can securely hold the lid plugs. This sealing mechanism is an essential part of safe and trouble-free milling operations. The rubber lining of the manhole frame provides noise reduction, abrasion resistance, and corrosion protection. Thus, the rubber manhole frame gives a cushioned, safe grip and reduces the possibility of untying the lid plug. Reducing mechanical stress on the structure of the mill or surrounding components, the lid frame minimizes the risk of damage to the lid itself lowering the downtime for repairing. This makes the milling process efficient and non-interrupted.

Brand Name : Kedar

Material : Rubber

Finishing : Polished

Color : Grey-black

Condition : New

Application : Chutes,Hopper,Mills

Type : Wear Resistant Liner

Size : Internationally Accepted tolerance will be applicable on rubber parts each side size (ex. size x

...more

Manhole Covers

3,000 - 10,000 Per piece

1 piece (MOQ)

At Kedar Rubber, we manufacture top-quality manhole covers that offer operational efficiency, durability, and safety. The properly fastened manhole plug reduces the accidental risk of spillage or opening. Thus, it ensures safe milling operations which is vital for the protection of workers. The manhole cover protects the mill from wear and tear and enhances the lifespan of equipment. It becomes easy to remove or refit the lid plug and makes the maintenance process easy and quick. We supply manhole covers as per requirement of our customers based on their custom specifications with different shapes, like square and round. We offer lid plugs for the feed and discharge edges of the ball mill. We ensure utmost testing and quality checks for flexibility and toughness, temperature tolerance, abrasion and corrosion protection, and accurate sealing properties to withstand high-speed milling operations. For more information or your custom inquiry for our highly durable Manhole Cover/Lid Plug/Manhole Plug, write to us at kedarrubber@gmail.comor Call Now - 9824444733

Brand Name : kedar

Material : RUBBER

Shape : Round

Color : Grey

Condition : New

Application : Industrial

Size : Internationally Accepted tolerance will be applicable on rubber parts each side size (ex. size x 0.0

Feature : Highly Durable

...more

lifter bar

3,000 - 10,000 Per NOS

20 PIECE (MOQ)

Our lifter bars comprise excellent resilience and wear resistance and are broadly used in different milling applications in industries, such as Mining, Metal, Cement, and Ceramic where it is required to deal with hard ores or abrasive materials. At Kedar Rubber, we deliver radial and trapezoidal lifter bars based on precise customer specifications (design, height, angle, radius, etc.). We provide the best quality lifter bars according to the customized needs of your milling processes to lift and drop the grinding media. For more information or your custom inquiry for ball mill lifter bars, write to us at kedarrubber@gmail.com or Call Now - 9824444733.

Material : High Manganese Steel

Color : Black

Application : Side Bar

Machine Type : longevity

Outer Diameter : 1000mm

Length : 1000 To 2000 Mm

Certificate : ISO 9001:2015 ISO 14001:2015 ISO 45001:2018

Type : Wear Resistant Liner

...more

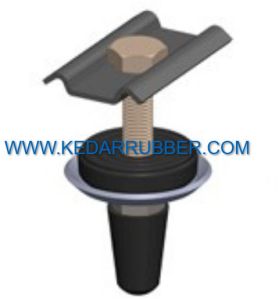

Fixing hardware

500 - 10,000 Per piece

Our highly durable and best quality fixing hardware is useful to ensure proper liner attachment, prevent damage, and enhance milling performance. We provide customized solutions for high-grade abrasion-resistant and high-tensile welded or loose studs or bolts for ball mills. Our washers and nuts are compatible with the bolts. We offer the most durable liner bolts necessary for attaching ball mill rubber liners to the shell and head of the grinding mill.Fastening hardware including bolts or studs is useful to protect the structural components of the ball mill so it can withstand the harsh force during the grinding processes of ball mills. Other components include Torque Wrenches for tightening bolts accurately. A spacer reduces liner distortion during high temperatures milling processes and maintaining precise gaps between multiple liners or liners and the mill shell. We design all types of fixing hardware/fastener sets based on the application needs of ball mills as per specifications given by customers. Our quality fixing hardware helps in trouble-free liner installation necessary to resist wear and tear, reduce noise, and make milling processes efficient.

Width : 1000MM

Size : 2000

Brand Name : Kedar

Material : Metal

Finishing : Polished

Color : Silver,Black

Application : Request To User Update Us Product Application, Working Temperature

Length : 2000mm

Feature : Fine Finished,Durable

Type : Door Hinges

Thickness : 250mm

Appearance : Antique

Certifications : ISI Certified

Country of Origin : India

...more

Combined rubber liner

3,000 - 10,000 Per NOS

10 PIECE (MOQ)

Combo liners are hybrid lining systems that combine lifter bars and shell plates to provide unmatched durability and performance to ball mills. The combined liner with rib effectively manages the material flow within the ball mill, reduces dead zones, and increases the grinding efficiency. The combo liner with lifter bar and shell plate helps create the best trajectory for the grinding media movement and ensures an efficient and smooth grinding process. It enables better particle size distribution and improved quality of grinding materials. They are popularly used in various industries for different applications as a modern alternative to liners based on the mechanical specifications of the equipment. The key functionality of composite liners/combined liners with ribs is that they protect the inner surface of ball mills from damage and impact by the direct force of grinding material and media. Our high-quality combo liners used for various industrial applications are specifically designed using combined multiple layers of high-grade compound materials that provide robustness and versatility. At Kedar Rubber, we offer combo liners/combined liners with ribs based on the bespoke needs of our customers. It requires several things to consider, such as the speed and diameter of mills, as larger ball mills need robust combo liners. Other factors that need to be considered are the type and properties of processing material and the size and shape of grinding media that influence the design of combo liners.

Country of Origin : India

Thickness : 250mm

Type : Combined Rubber Liner

Certificate : ISO9001:2008

Length : 1000 To 2000 Mm

Machine Type : Longevity

Application : Combo Liner

Color : Black

Material : High Manganese Steel

Outer Diameter : 1000mm

...more

Ceramic Embedded Rubber Liner

3,000 - 10,000 Per Piece

1 Piece (MOQ)

These liners enhance the longevity and performance of the ball mills as combining the rubber resilience and ceramic material’s hardness and wear resistance offers many benefits. The benefits include shock absorption, minimized impact damage and noise levels, increased energy efficiency, cost-effectiveness, and many others. At Kedar Rubbers, we proffer customized ceramic embedded rubber liners tailored to your specific milling requirement by understanding operational conditions, mill size, and other essential factors for optimal fitting and excellent performance. You can increase the grinding efficiency of your ball mill using our unique designs for better grinding material flow and consistent product quality.

Type : Rubber Liners

Pattern : Plain

Feature : Longer Durability And Smooth Functioning

Application : Industrial

Color : WHITE AND BLACK

Shape : Cylindrical

Material : Rubber

Brand : Kedar

Thickness : 250mm

Country of Origin : India

...more

Ball Mill Rubber Liner

500,000 - 1,500,000 Per SET

1 piece (MOQ)

Uses of our Ball Mill Rubber Liners Our highly durable and high-performance rubber linings are essential components to install in the ball mills due to their unmatched benefits including maintaining the material quality being processed. Ball mills are effectively used in various wet grinding applications in different industries such as mining and mineral processing, ceramics, metal, cement, and several more. Benefits of our Ball Mill Rubber Liners Kedar Rubbers offers the best ball mill rubber liners for the bespoke needs of industries including metal, minerals, and many others. Our best rubber liners for ball mills offer unmatched benefits as follows. Enhanced Grinding Efficiency – Our wet grinding liners optimize the grinding media motion, lower the electricity consumption and thus increase production speed and grinding performance. Lowered Wear and Tear – Our highly durable rubber liners for mills have resistant properties to wear and corrosion, which is useful in increasing the liner’s service life and drastically decreasing maintenance costs. Reduction in Noise Level – Our rubber liner helps ball mills reduce noise levels to create comfortable and safe work environments. Trouble-free installation, maintenance, and replacement – Our rubber liners for ball mills are highly flexible and lightweight enabling installation or replacement efficiently and quickly which in turn reduces downtime. At Kedar Rubber, We Never Compromise the Quality of Our Products. Looking for cost-efficient and top-quality rubber liners Call Now: 98244 44733 Write us at kedarrubber@gmail.com for more information or custom inquiries about our best-quality ball mill rubber liners.

Application : For Grinding Materials

Power : 6-9kw

Automatic Grade : Manual

Condition : New

Color : Black

Driven Type : Mechanical

Brand Name : Kedar

Material : High Grade

...moreBe first to Rate

Rate ThisOpening Hours