Wear resistant rubber liner

3,000 - 30,000 Per Piece

10 Ton (MOQ)

BTo Enhance Productivity & Proficiency of Your Manufacturing Process with Machinery Longevity As a prominent Wear Resistant Rubber Liners manufacturer and supplier, Kedar Rubber offers a comprehensive range of molded and extruded rubber products with the utmost quality and standards. Our premium quality Wear-Resistant Rubber Liners are designed to deliver complete protection against abrasion, corrosion, and impact in different industrial applications. Besides, our liners can withstand critical operational conditions to increase the durability of your equipment and lower maintenance costs. We manufacture products under the stringent watch at each production stage, our liners are best applicable in assorted industries. At Kedar Rubber, we accomplished the bespoke needs of our customers from different industries including cement, mining, aggregate, and many more. For such industries, wear-resistant rubber liners are the necessary component that provides consistent, robust, and cost-efficient protection to their expensive machinery and makes their manufacturing processes safe and efficient. Product Overview Material - Based on tailor-made requirements, liners are manufactured using different material compositions like natural or synthetic rubber, or blended compound. Natural rubber comprises unmatched abrasion resistance and is best for general-purpose applications. Besides synthetic rubbers are applicable where it requires increasing the resistance capacity to maximum temperatures, chemicals, or oils. Dimension & Thickness - The dimensions and thickness vary according to the requirement of protection level. For specific size and shape requirements, liners can mold or cut to complex curves, angles, or shapes to fit the dimensions of your machinery perfectly. Custom Edge Design - In addition, custom edge design helps trouble-free installation of liners and enhances equipment performance. Finishing & Texture - The surface textures and finishes of liners depend on the area of applications. For example, a smooth surface is essential for crucial material flow and prevents build-up. A liner with diamond, ribbed, or other patterns helps reduce material sticking, improving grip, and boosting abrasion resistance. Using customized channels or grooves, it eases the material or fluids flow, reduces wear, and improves efficiency. For different applications, it is required to customize wear-resistant liners like chemical, heat, UV & Ozone resistance. Our consulting team discusses your custom requirements based on the material handled, specific environment, and machinery information. For the precise needs of customers, we proffer prototyping services. In such cases, we allow them to test the liner in their work environment prior to proceeding with production. We assure you that, in the final production stage, we manufacture products that best meet your custom specifications and requirements. Uses Wear Resistant Rubber Liners are widely used in various industries for their different applications. Mining and Quarrying industries – Ball Mills, ore mills, coal mills, and more to enhance equipment life and operation efficiency and performance. Chemical industries – Heat exchangers, coolers, reactors, and other equipment to protect them from wear and corrosion. Cement industries – Hoppers, line mill feeders, and more to protect from the harsh nature of cement dust and other raw materials. Aggregate Industries – Helpful for protecting crushers, conveyors, screens, and other equipment from the endless effect of aggregate materials. Power Industries – Improve reliability and performance of thermal power generators and other equipment.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality, Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

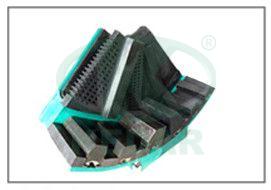

Triangle Head Rubber Liner

3,000 - 30,000 Per Piece

10 Ton (MOQ)

All About Triangle Head Plate The triangle plate at the feed end acts as a start for material to be fed into the ball mill. It can also include a feeding cascade for equal distribution of grinding material into the chamber of the ball mill. The triangle plate at the discharge end includes opening or discharge edges that allow the ground materials to exit from the mill. We supply custom designs of head-end plates based on the bespoke needs of customers by considering the type of their ball mill (grate discharge or overflow). They have unmatched capability to withstand heavy loads and act as shields against wear. They provide efficient material handling that directly impacts operational efficiency, longevity, and performance of the ball mill. The accurately designed head-end plates by considering the ball mill type, material to be ground, grinding media, and other important factors, offer excellent performance with many more benefits including reducing maintenance and downtime. Thus, our best-quality triangle head plates/head liners give several benefits to the ball mill, ensure its smooth operation, and increase the performance, efficiency, and lifespan of the mill.

Material : Rubber

Shape : Triangle

Color : Black

Feature : Good Quality, Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

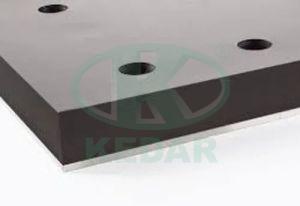

Steel Backed Rubber Liner

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Kedar Rubber is a premier rubber products manufacturing company in India that offers a comprehensive range of products including the best quality steel-backed rubber liners. Our high-performance steel backed rubber liners are essential components for heavy-duty milling applications. The specifically designed steel backed rubber liners give a robust solution for different industrial applications. Combined with steel, they offer utmost durability while rubber delivers cushioning properties. The steel backing increases integrity and enables the liners to withstand higher abrasions and impacts necessary for intense milling processes. They are mainly useful for wet milling processes as the rubber protects steel from corrosion. The rubber layer absorbs vibration and shock and reduces noise levels. The steel backing and rubber combination offers superior wear resistance, and hence extend the lifespan of liners and protect them from frequent damage. This reduces the downtime for replacing liners. Thus, they offer dual performance, ease of use, longevity, and utmost efficiency. They provide more flexibility and strength and are ideal for heavy-duty milling processes. At Kedar Rubber, we deliver custom design solutions for steel backed rubber liners that perfectly fit your mill configurations and operational needs as well as optimize performance for your different processing materials.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality

Thickness : 5-10mm

Country of Origin : India

...more

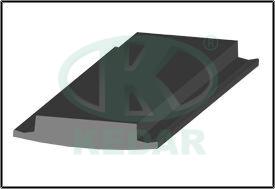

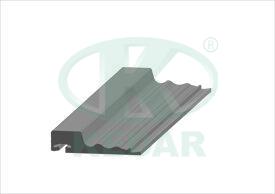

Rubber Shell Plate

3,000 - 30,000 Per piece

10 Ton (MOQ)

Enhance the Overall Performance and Efficiency of Your Milling Processes with Our Best Quality Rubber Shell Plates As a prominent manufacturer and supplier of high-quality rubber products in India, we offer the best quality Rubber Shell Plates for ball mills to improve the overall efficiency and performance of milling processes. Our shell rubber liners are made from high-grade rubber materials. They are specifically designed to protect the shells of ball mills from the corrosive and abrasive effects of the grinding media and processed materials. We offer ball mill shell plate liners based on the customer’s specifications in which design and thickness are vital factors that affect the durability, performance, and operational efficiency of ball mills. We supply flat and radial shell plates with rib, step, or wave designs. Importance of Design and Thickness of Rubber Shell Plates The designs impact the grinding media movement and efficiency of the grinding process. The thickness of the shell plate influences factors like wear resistance and cost. Thick shell plates are highly durable and impact absorption. With reducing thickness, the factors affected are reduction in cost and wear protection. With easy to install, changed, or replacement facilities, we also supply Rubber Shell Plates for ball mills in modular sections helpful for you in drastically reducing downtime and maintenance costs of your processing unit. We offer custom shell plate designs based on soft and hard rock grinding materials needed for your specific application. Flat or Radial Rubber Shell Plates Flat shell plates are useful when requiring uniform wear distribution for less aggressive grinding conditions. Radial shell plates are expensive, but highly durable and offer exceptional performance and grinding efficiency. Based on precise grinding application, cost and performance characteristics are some important factors for choosing the design of ball mill shell liners. For more information or your custom inquiry about Rubber Shell Plates, write to us at kedarrubber@gmail.com or Call Now - 9824444733. Flat Rubber Shell Plate with Taper With increasing thickness of the flat rubber shell plates, they act as a protective barrier that prevents the mill shell from the direct impact of the wear caused by the grinding media and material. This shielding is essential for enhancing the lifespan of the ball mill and preventing structural damage. The taper helps in improving the flow of material and lowering the risk of direct contact between the mill shell and the grinding media ensuring that the rubber shell liner can impact the wear. Due to the improved impact absorption, they lower the waste of energy on mechanical stress and vibrations allowing more energy to be used for the material-breaking process and thus, enhance energy efficiency. The taper controls the grinding media movement inside the mill. The design controls the grinding balls' trajectory ensuring that they tumble well for optimal grinding. This control ensures efficient grinding, reducing consistent particle size and enhancing milling performance. Rubber shell plates are light in weight which makes it easy and efficient to install and remove them. They can fit easily into the mill; thus, they reduce the time to install or replace shell liners. We offer customized solutions to meet the bespoke needs of customers' specifications as per their milling process like the nature and size of grinding material or media required to process. Customizing the rubber shell plates based on the ball mill’s needs boosts performance in different applications. For example, shallower tapers are preferable for smooth material flow and efficient grinding while steeper tapers are useful where higher impact resistance is essential. Rubber Radial Shell Plate with Rib Kedar Rubber offers Rubber Radial Shell Plates with ribs that give extra structural strength to the shell plate. This helps to distribute pressure across the liner evenly. Thus, protect the mill’s shell from damage by preventing excessive wear and downtime. The rib adds reinforcement to the rubber liner, makes it capable of bearing the dynamic forces of processing material and grinding media, and enables it to manage the overall integrity of the mill. The thickness and flexibility are vital factors of rubber shell plates to enhance the absorption and reduce the risk of cracking and deformation of the shell. Thus, the rubber material with a ribbed design works as a shock absorber, shielding the grinding media impact and lowering the direct force effect on the mill shell. The Radial shell plates with rib prolong the lifespan of the liners which in turn reduces maintenance and operational costs and also lower downtime for replacement of liners. They also absorb more vibration caused by grinding media tumbling and thus, reduce overall noise levels in milling operations. Radial ribbed rubber shell plates also efficiently lower the inefficient grinding actions and unwanted noise that make energy-efficient processes cause energy cost reduction. We provide customized solutions for the radial ribbed shell plate based on the specific requirements of our customers. By considering the grinding material type, mill size, and the operating environment, it is necessary to adjust the rib size, angle, and spacing to accomplish the precise grinding requirements and achieve optimal performance.

Material : Rubber

Finishing : Matte Finish

Color : Black

Application : Industrial Use

Thickness : 10-20mm

Country of Origin : India

...more

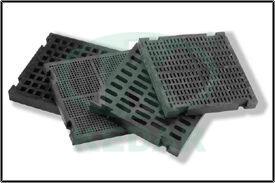

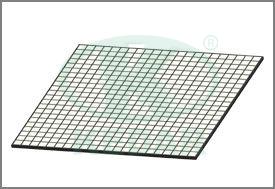

rubber screen

3,000 - 30,000 Per Piece

10 Piece (MOQ)

Kedar Rubber offers High-performance Rubber Screens for Several Industrial Applications Kedar Rubber offers top-quality and durable rubber screens broadly used in ball mills for their assorted applications. Rubber screens are one of the vital components broadly used in different industrial applications. Our high-performance rubber screens deliver excellent wear resistance, reduce noise level and maintenance costs that enhance the lifespan of your mill equipment, and lower downtime. Our heavy-duty rubber screens absorb impact and reduce the force on the mill shell. Besides, rubber screens allow better separation of grinding materials and classify particles reduce the clogging chances and ensure efficient grinding material flow. They also absorb vibrations during milling processes, reduce energy consumption, and thus protect mill structure and enhance operational efficiency. As the best quality rubber products manufacturer in India, we deliver rubber screens tailored to your specific application needs to enhance your milling process effectiveness.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Crack Proof, Heat Resistant, Water Proof

Packaging Type : Paper Box

Thickness : 10-15mm

Country of Origin : India

...more

Rubber Manhole Frame

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Kedar Rubber offers Top-Quality Manhole Frame/Lid Frames for Secure Milling Operations Kedar Rubber Products Private Limited is a renowned rubber manufacturing company in India that delivers highly durable rubber products in India including top-quality manhole frames. It is also known as Lid Frame or Plug Frame. Our manhole frames are popularly used in ball mills which becomes an essential component for secure milling operations. All About Manhole Frame The use of a lid or plug frame is to hold the lid cover during milling operations. A lid or manhole frame with a flanged design supports the lid plug making tight sealing. Moreover, it helps absorb vibrations and protects the mill from wear and corrosion. The robust design and properties of rubber material make it a vital component of the mill for the secure milling process and enhance its lifespan. Its flanged structure makes tight sealing that prevents any leakage of grinding material, dust, or slurry. The plug frame supports bolts or lid plug tightly, thus, preventing leakages even during high pressure and vibrations inside the ball mill. The rubber lid frame makes a dust-tight and airtight seal around the manhole. The flexibility and resilience nature of rubber ensures the plug frame can securely hold the lid plugs. This sealing mechanism is an essential part of safe and trouble-free milling operations. The rubber lining of the manhole frame provides noise reduction, abrasion resistance, and corrosion protection. Thus, the rubber manhole frame gives a cushioned, safe grip and reduces the possibility of untying the lid plug. Reducing mechanical stress on the structure of the mill or surrounding components, the lid frame minimizes the risk of damage to the lid itself lowering the downtime for repairing. This makes the milling process efficient and non-interrupted.

Material : Rubber

Shape : Square

Application : Industrial Use

Feature : Rust Resistance

Thickness : 10-50mm

Country of Origin : India

...more

Rubber Lifter bar

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Kedar Rubber Lifter Bar – Make Your Milling Process Efficient & Smooth with Our Utmost Quality Lifter Bar Kedar Rubbers offers high quality rubber products including the best quality Lifter Bars (Radial and Trapezoidal), which are essential components of ball mills. Our top-quality lifter bars play an important role in making grinding processes efficient by improving the grinding media and materials' tumbling action. Thus, the key functions of lifter bars are to lift the grinding media and materials that ease the movement, protect the mill shell, reduce the noise level, and enhance the grinding & milling efficiency. Selecting the right dimensions and designs of lifter bars can significantly impact the performance and cost-effectiveness of the milling process. Uses Our lifter bars comprise excellent resilience and wear resistance and are broadly used in different milling applications in industries, such as Mining, Metal, Cement, and Ceramic where it is required to deal with hard ores or abrasive materials. At Kedar Rubber, we deliver radial and trapezoidal lifter bars based on precise customer specifications (design, height, angle, radius, etc.). We provide the best quality lifter bars according to the customized needs of your milling processes to lift and drop the grinding media.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality, Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

Rubber Center Circle

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Kedar Rubbers offers High-Quality Center Circles Enable Stable and Supportive Ball Mill Operations Kedar Rubber Products Private Limited is a renowned Indian Manufacturer and Supplier of the best quality rubber products including the most durable center circles. Our high-performance central circle plays a crucial role in protecting or supporting the head plate giving stability to the mill components necessary for stable milling operations. The center circle also known as the central rubber liner is an important component of the rubber lining system in the ball mill. During high-speed milling operation, when the grinding material and media collide with the head plate around the central zone, the rubber central circle helps absorb impact energy and prevents wear. In the ball mill, the central region is extended to align with the head plates and other components and hence, the central circle balances the movement and makes it efficient. Moreover, aligning with the head plates, the center circle fills the gaps and thus, makes a smooth transition of the grinding media and material near the central region of the ball mill. This makes it possible to run smoothly and prevents material from getting stuck or misaligned grinding media. This rubber liner reduces the direct contact between the mill components and grinding media and lowers maintenance costs and excessive wear during milling processes.

Material : Rubber

Shape : Round

Color : Black

Application : Industrial Use

Feature : Good Quality, Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

Rubber Buffer Ring

3,000 - 30,000 Per Piece

10 Ton (MOQ)

As one of the leading manufacturers and suppliers of rubber products in India, Kedar Rubbers offers the best quality products and services for the bespoke application needs of vertical industries. Our range of rubber products includes the high-quality filler ring known as filler segment liner, filler block, or segment ring. They are broadly used in ball mills to serve multiple purposes precisely for enhancing mill efficiency, internal shell protection of the mill, and to improve wear resistance. This modular-type sectional lining system is used to fill gaps and make milling operations smooth mainly used in industries such as cement, mining, and other heavy industrial processes. All About Filler Ring/Segment Ring Filler segment liners or filler rings are the liner’s sectional parts and are mainly used to fill the space between other liners and larger segments. We design filler blocks based on the design requirement of ball mills to fit the liners securely within the shell to lower the irregular surfaces and spaces. This helps overcome inefficiencies in grinding processes and protects mill shell parts from impact forces and abrasive. It makes the grinding media motion-controlled and consistent enables uniform interaction with the grinding material and enhances energy efficiency by reducing dead zones. This modular filler segment liner or segment ring can easily be installed, repaired, or replaced. This helps to reduce maintenance costs and downtime significantly. Many filler blocks are specially designed to act as shock absorbers to minimize vibrations and impact caused by the grinding media’s dropping action. Thus, the filler ring or filler segment liner is one of the essential components of the ball mill that protects the structural components of the mill, enhances efficiency, decreases operational cost, and enhances lifespan and milling efficiency.

Material : Rubber

Finishing : Matt

Color : Black

Application : Industrial Use

Feature : Best Quality

Packaging Type : Box

Country of Origin : India

...more

Manhole Plug

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Make Your Ball Mill Operation Safe and Efficient with Our Highly Durable Manhole Cover/Lid Plug As the best quality rubber products manufacturer and supplier in India, Kedar Rubber delivers manhole covers with the utmost quality and durability. Manhole cover also known as lid plug or manhole plug is an important part of ball mill widely used in different industries for its various benefits. It is used as a protective removable cover that seals the access port or manhole (feed and discharge) of the ball mill. The lid plug covers the manhole tightly to prevent leakage of slurry, dust, or grinding material and offers a safe and closed grinding environment. During milling operation, the manhole cover provides close and tight sealing necessary to withstand the harsh internal pressure and heavy vibrations. At Kedar Rubber, we manufacture top-quality manhole covers that offer operational efficiency, durability, and safety. The properly fastened manhole plug reduces the accidental risk of spillage or opening. Thus, it ensures safe milling operations which is vital for the protection of workers. The manhole cover protects the mill from wear and tear and enhances the lifespan of equipment. It becomes easy to remove or refit the lid plug and makes the maintenance process easy and quick. We supply manhole covers as per requirement of our customers based on their custom specifications with different shapes, like square and round. We offer lid plugs for the feed and discharge edges of the ball mill. We ensure utmost testing and quality checks for flexibility and toughness, temperature tolerance, abrasion and corrosion protection, and accurate sealing properties to withstand high-speed milling operations.

Material : Rubber

Shape : Round

Application : Industrial Use

Pattern : Dotted

Thickness : 1-10mm

Country of Origin : India

...more

Impact Resistant Rubber Liner

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Give Your Ball Mill a Protective Shield with Our Highly Durable Impact Resistant Rubber Liners/Impact Pads As the best quality rubber products manufacturing company in India, Kedar Rubber delivers the most durable Impact Resistant Rubber Liners for ball mills. Impact Resistant Rubber Liner also known as Impact Liner or Impact Pad is one of the important components of ball mills used in vertical industries from mining to cement. Our top-quality impact liners are manufactured using abrasion-resistant rubber that effectively reduces the wear on the mill shell, feed, and discharge end and absorbs shock. It improves the cascading action of grinding media and reduces vibration and noise. Our impact pads are corrosion-resistant and suitable for wet milling applications across different industries like cement, mining, chemicals, and others. The key function of impact-resistant rubber liners is to absorb the impact of the grinding material and media during the milling process when they collide with the surface of the ball mill. These impact pads are designed to shield the impact force and protect the internal shell of the mill from wear and damage. Thus, they protect the mill’s surface, reduce downtime, and expand the lifespan of the ball mill. Made from highly abrasion-resistant rubber compounds, these impact liners prevent the formation of scratches, grooves, and other damage caused by the pressure between the mill surface and the grinding media. Impact liners are efficiently used as cushions in ball mills to protect the internal structure of the mill from wear, reduce noise, absorb impact force, and optimize material flow. Thus, it makes the milling operation efficient. At Kedar Rubber, we supply custom-designed impact-resistant rubber liners based on our customers' requirements for their specific milling applications.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality, Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

head discharge lifter bar

3,000 - 30,000 Per piece

10 Ton (MOQ)

Kedar Rubber Delivers Best Quality Head Lifter Bars/Discharge Lifter Bars for Efficient Grinding Processes Kedar Rubber offers the best quality Head Lifter Bar and Discharge Lifter Bar widely used in ball mills. These bars are set on the ball mill’s feed and discharge side walls between the two head plate rubber liners. They are fitted in the mill with a clamp block, nut, and washer. They lift grinding media in the mill and prevent feed and discharge grinding media from escaping outside the mill. Based on the requirement of the ball mills, they are made from rubber or aluminum sections. The discharge lifter bar helps in material flow and reduces the over-grinding of material. Moreover, the precise design of the head/discharge lifter bars helps regulate how efficiently the ground material exits the ball mill. This makes sures the steady flow of the desired particle size of the material to the next stage of classification or processing. Thus, they enhance the efficiency of ball mills in addition to noise reduction, control material handling, and efficient grinding.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality, Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

Fixing & Fastener Set

3,000 - 30,000 Per Set

10 Ton (MOQ)

Kedar Rubber delivers fixing hardware/fastener sets essential to assembling ball mill liners and other components. As a renowned manufacturer and supplier of high-quality rubber products in India, our range of products also includes high-quality fastener sets such as bolts, nuts, sliders, rubber washers, spacers, and other fixing hardware based on bespoke needs of our customers for their milling applications. Our highly durable and best quality fixing hardware is useful to ensure proper liner attachment, prevent damage, and enhance milling performance. We provide customized solutions for high-grade abrasion-resistant and high-tensile welded or loose studs or bolts for ball mills. Our washers and nuts are compatible with the bolts. We offer the most durable liner bolts necessary for attaching ball mill rubber liners to the shell and head of the grinding mill. Fastening hardware including bolts or studs is useful to protect the structural components of the ball mill so it can withstand the harsh force during the grinding processes of ball mills. Other components include Torque Wrenches for tightening bolts accurately. A spacer reduces liner distortion during high temperatures milling processes and maintaining precise gaps between multiple liners or liners and the mill shell.

Material : Stainless Steel

Surface Finishing : Polished

Usage : Industrial Use

Size : 0-15mm

Packaging Type : Carton Box

Packaging Size : 10 Pieces Set

Specialities : High Quality

Country of Origin : India

...more

Discharge Cone

3,000 - 30,000 Per piece

10 Ton (MOQ)

As the prominent Indian manufacturer and supplier of the best quality rubber products, Kedar Rubber offers custom design solutions for discharge cones broadly used in ball mills for different applications. In the ball mill, the discharge cone is located at the end part from where the ground material comes out. It impacts the flow of grinding material, energy efficiency, and durability of milling in addition to the product quality. Hence, the cone-shaped or conical design discharge cone prevents blockages and allows optimal segregation of finely ground materials. Thus, it plays a vital role in prolonging the mill's lifespan and improving its performance. All About Discharge Cone for Ball Mills Once the particles of the processing material reach the desired particle size, the discharge cone allows them to exit from the ball mill. The conical shape prevents clogging and controls a constant material flow; hence it makes it possible to reduce blockages that interrupt the milling process. The discharge cone in the ball mill also helps reduce wear resistance on mill liners. It withstands abrasions that occur due to the grinding particles when moving through the ball mill by making the smooth & uniform material flow. Thus, it reduces energy consumption for pushing material out from the ball mill and makes the process energy efficient. We provide custom design solutions to supply discharge cones as per the type of your ball mill discharge such as overflow discharge or grate discharge. Both types of discharge cones help regulate the flow of grinding materials and improve mill performance. Based on the needs of different industries like mining, ceramics, or others, the discharge cone design can be customized. Based on the type of grinding material, the durability of the cone is required, so that it can withstand the abrasive nature of the material. The conical design selection in some ball mills is necessary to enhance internal motion and better mixing of the material and ensure uniform material grinding throughout the process. For more information or your custom inquiry for the best quality discharge cone for ball mills, write to us at kedarrubber@gmail.com or Call Now - 9824444733.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality

Country of Origin : India

...more

Corrugated Rubber Liner

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Increase Operational Efficiency, Durability, and Cost-effectiveness of Your Processing Units using Our High-Performance Corrugated Rubber Liners At Kedar Rubber Products Pvt Ltd, we manufacture and export top-quality rubber products, including Corrugated Rubber Liners. Our premium quality corrugated rubber liners are specifically designed to protect your precious machinery, like ball mills. Our high-performance corrugated rubber liners protect machinery from abrasion, wear, and impact from aggregate materials. Thus, they expand the lifespans of machinery and increase the productivity of your processing unit. Uses of Our Corrugated Rubber Liners Our protective rubber liners are widely used in different industries for aggregate, mineral, and mining processing, and material handling applications. The reason for using a corrugated pattern of rubber liners is to enhance flexibility and capability of wear resistance and shock absorption. The flexible nature of rubber material when combined with the corrugated design, works as a shield for the equipment and prevents their structural damage. Benefits of Our Corrugated Rubber Liners Impact Resistance – Our premium quality corrugated rubber liners are an ideal option for ball mills where mining materials drive at high speed and cause high impact force that might damage your equipment. Our rubber liners with corrugated designs give shields and decrease the impact force of mining materials, preventing equipment from wear and tear and thus, useful in increasing the lifespan of machinery. Noise & Abrasion Resistance – In the mining and mineral industry, machinery often gets damaged due to the abrasive nature of materials. Our corrugated rubber liners are specifically designed to protect the machinery from the wear and tear effect of aggregated materials. The corrugated rubber liners absorb the energy from force and thus reduce the noise level and make the working environment safe and comfortable. Reduce Dusting Process – One more reason for using corrugated rubber lining in the mining industry is that it prevents the deposit of fine or sticky materials due to its uneven surface that eases the material flow. Thus, there are fewer chances of downtime, generally caused by material blockages. Cost-efficient – Kedar rubber corrugated rubber lining products provide many benefits to your processing units, like extending the service life of your machinery, reducing electricity expenses, repairs, and maintenance, and cutting downtime. We conduct thorough research of your custom requirements by considering important factors like types of materials and compositions based on the application environment, choosing ideal liner thickness based on specific application requirements, depth and pattern of liners by evaluating material flow, and many others. For your custom inquiry or more information about our best quality corrugated rubber liners, write to us at kedarrubber@gmail.com or Call Now - 9824444733. At Kedar Rubber, We Never Compromise the Quality of Our Products.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality, Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

Combo & Combined Liner with Rib

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Kedar Rubber Products Private Limited is a leading manufacturer of rubber products including high-performance combo liners / combined liners for ball mills. Our top-quality combo liners give several benefits such as wear resistance, cost efficiency, and energy efficiency. Manufactured using high-grade rubber and compound materials, our combined liners with ribs comprise impact abrasion, noise reduction, and durability with high strength wear resistance. This helps extend the lifespan of the ball mill and improve the overall efficiency of the grinding process. Our best-quality combo liners for ball mills are a superior choice for industries such as mining, metal, cement, chemical, power, and others. All About Our Combo Libers/Combined Liner with Rib Combo liners are hybrid lining systems that combine lifter bars and shell plates to provide unmatched durability and performance to ball mills. The combined liner with rib effectively manages the material flow within the ball mill, reduces dead zones, and increases the grinding efficiency. The combo liner with lifter bar and shell plate helps create the best trajectory for the grinding media movement and ensures an efficient and smooth grinding process. It enables better particle size distribution and improved quality of grinding materials. They are popularly used in various industries for different applications as a modern alternative to liners based on the mechanical specifications of the equipment. The key functionality of composite liners/combined liners with ribs is that they protect the inner surface of ball mills from damage and impact by the direct force of grinding material and media. Our high-quality combo liners used for various industrial applications are specifically designed using combined multiple layers of high-grade compound materials that provide robustness and versatility. At Kedar Rubber, we offer combo liners/combined liners with ribs based on the bespoke needs of our customers. It requires several things to consider, such as the speed and diameter of mills, as larger ball mills need robust combo liners. Other factors that need to be considered are the type and properties of processing material and the size and shape of grinding media that influence the design of combo liners.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

chute liner

3,000 - 3,000 Per piece

10 Ton (MOQ)

Protect Your Chute Surface from Impact and Sliding Abrasions Using Our Best Quality Chute Liners Kedar Rubbers offers a comprehensive range of the best quality rubber products including highly durable Chuter liners. Made from high-grade composite material, our rubber chute liners give the utmost performance and longevity. They are used as protective coverings in the ball mill installed in the feed and discharge chutes. Besides, they reduce wear and tear due to the continuous impact of grinding material moving through the chute. Our highly durable chute liners are designed to withstand abrasive conditions and protect the mill components from corrosive materials. Thus, by reducing damage, they enhance operational efficiency and minimize maintenance costs. The key functionality of chute liners in ball mills is to protect the chute surface from impact and sliding abrasions, reduce noise, enable smooth grinding material flow, and minimize the possibility of blockages. With the capability to absorb vibrations and shocks due to the hammering effect of the material, chute liners are fixed in a hopper to protect the mill structure and other components of ball mills. At Kedar Rubber, we deliver high-performance chute liners that are widely used to enhance the efficiency and lifespan of ball mills.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality, Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

Ceramic Embedded Rubber Liner

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Make Your Milling Processes Cost-effective and Efficient with Our High-Performance Ceramic Embedded Rubber Liners Kedar Rubber offers the utmost quality rubber products, including ceramic embedded rubber liners widely used for various industrial applications. As a leading Indian rubber products manufacturing company, Kedar Rubber maintains excellent quality and standards of its products after thorough testing and quality checks at each production stage. Our Ceramic Embedded Rubber Liners are most suitable for industries such as mining, cement, minerals, and many others for ball mills to grind and milling materials. These liners enhance the longevity and performance of the ball mills as combining the rubber resilience and ceramic material’s hardness and wear resistance offers many benefits. The benefits include shock absorption, minimized impact damage and noise levels, increased energy efficiency, cost-effectiveness, and many others. At Kedar Rubbers, we proffer customized ceramic embedded rubber liners tailored to your specific milling requirement by understanding operational conditions, mill size, and other essential factors for optimal fitting and excellent performance. You can increase the grinding efficiency of your ball mill using our unique designs for better grinding material flow and consistent product quality.

Material : Rubber

Application : Industrial Use

Feature : Good Quality, Wear Resistant

Thickness : 5-10mm

Country of Origin : India

...more

buffer line segment ring

3,000 - 30,000 Per Kilogram

10 Ton (MOQ)

Kedar Rubber, The Prominent Indian Rubber Products Manufacturer offers The Best Quality Filler Rings/Filler Segment Liners As one of the leading manufacturers and suppliers of rubber products in India, Kedar Rubbers offers the best quality products and services for the bespoke application needs of vertical industries. Our range of rubber products includes the high-quality filler ring known as filler segment liner, filler block, or segment ring. This modular-type sectional lining system is used to fill gaps between head plate and cell plate and make milling operations smooth mainly used in industries such as cement, mining, and other heavy industrial processes. Thus, they are broadly used in ball mills to serve multiple purposes precisely that enable enhancing mill efficiency, internal shell protection of the mill, and to improve wear resistance. All About Filler Ring/Segment Ring Filler segment liners or filler rings are the liner’s sectional parts and are mainly used to fill the space between the cell plate and head plate. We design filler blocks based on the design requirement of ball mills to fit the liners securely within the shell to lower the irregular surfaces and spaces. This helps overcome inefficiencies in grinding processes and protects mill shell parts from impact forces and abrasive. It makes the grinding media motion-controlled and consistent enables uniform interaction with the grinding material and enhances energy efficiency by reducing dead zones. This modular filler segment liner or segment ring can easily be installed, repaired, or replaced. This helps to reduce maintenance costs and downtime significantly. Many filler blocks are specially designed to act as shock absorbers to minimize vibrations and impact caused by the grinding media’s dropping action. Thus, the filler ring or filler segment liner is one of the essential components of the ball mill that protects the structural components of the mill, enhances efficiency, decreases operational cost, and enhances lifespan and milling efficiency.

Material : Rubber

Color : Grey

Application : Industrial Use

Feature : Good Quality

Thickness : 10-20mm

Country of Origin : India

...more

Radial Lifter Bar

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Kedar Rubber Lifter Bar – Make Your Milling Process Efficient & Smooth with Our Utmost Quality Lifter Bar Kedar Rubbers offers high quality rubber products including the best quality Lifter Bars (Radial and Trapezoidal), which are essential components of ball mills. Our top-quality lifter bars play an important role in making grinding processes efficient by improving the grinding media and materials' tumbling action. Thus, the key functions of lifter bars are to lift the grinding media and materials that ease the movement, protect the mill shell, reduce the noise level, and enhance the grinding & milling efficiency. Selecting the right dimensions and designs of lifter bars can significantly impact the performance and cost-effectiveness of the milling process. Uses Our lifter bars comprise excellent resilience and wear resistance and are broadly used in different milling applications in industries, such as Mining, Metal, Cement, and Ceramic where it is required to deal with hard ores or abrasive materials. At Kedar Rubber, we deliver radial and trapezoidal lifter bars based on precise customer specifications (design, height, angle, radius, etc.). We provide the best quality lifter bars according to the customized needs of your milling processes to lift and drop the grinding media. For more information or your custom inquiry for ball mill lifter bars, write to us at kedarrubber@gmail.com or Call Now - 9824444733. All About Radial Lifter Bar – Installation, Functionality, and Design With the foolproof installation of radial lifter bars, they enhance the working efficiency of ball mills. They are installed alongside the inner edges of the mill shell normally parallel to each other. The vital factors necessary to consider for perfect installation are secure attachment and accurate alignment, which make certain that the installation performs effectively and prevents imbalance or excessive wear. As the mill rotates, the radial lifter bar lifts and moves the grinding media and material in a radial direction (from the bottom of the ball mills to the top). This movement efficiently mixes and grounds the charge, continuously. Thus, the ball mill grinding efficiency and impact are enhanced with such lifting actions that help to cascade the grinding media. Radial lifter bars are specifically designed for ball mills that support clockwise or anticlockwise rotation (which depends on the direction of rotation and design specified for the ball mills). Thus, radial lifter bars support both clockwise and anticlockwise rotation helping in increasing the lifespan of ball mills. The design and angle of the radial lifter bars are vital factors for their efficient performance. Lifter bars' orientation with the mill’s rotation direction is necessary to consider for optimal grinding efficiency. Accurately designed lifter bars make certain that the grinding media gets the precise trajectory to grind the material resulting in the desirable particle size. Our Radial lifter bars give consistent grinding with uniform lifting and dropping action of the grinding media. They reduce the overall time for grinding processes, improve performance, and become a cost-efficient solution for ball mills. Trapezoidal Lifter Bars The trapezoidal profile plays a vital role in making the grinding process efficient by influencing the movement of grinding media and material in the ball mills. They improve the lifting action using higher and angled edges that give an aggressive lifting angle compared to rectangle lifter bars. It allows lifting the charge towards the up direction within the mill and then letting the balls and material drop from the top of height to create higher impact pressure. Thus, such actions make the grinding process more efficient for breaking down material. Besides trapezoidal lifter bars boost the dropping motion necessary for properly mixing and uniformly distributing the grinding media and material throughout the ball mill. Thus, it well-manages the motion that improves the milling process by increasing the contact between the material and balls which results in reducing particle size consistently. They require less time to process significant amounts of material. All About Lifter Bars - With & Without Metal At Kedar Rubber, we provide lifter bars with and without metal based on the tailor-made needs of customers as per their milling applications. Lifter Bars with Metal Lifter bars with metal are best applicable in ball mills for their utmost durability, and capability to withstand the intense wear and impact due to abrasive and hard material grinding, thus offering primary grinding benefits. They can manage abrasive materials and high-impact forces. The superior lifting capability of metal lifter bars enables maintaining a continuous and effective trajectory for the ball mill’s grinding media. This improves the quality of the products, grinding performance, and higher materials. Lifter Bars without Metal With some characteristics like energy efficiency and noise resistance, Lifter bars without metal are best applicable for fine and secondary grinding applications of ball mills. As made from rubber, non-metal lifter bars reduce energy consumption as they decrease the load on the motor. They are suitable for regrinding (secondary) grinding, where they require low-impact force and minimize wear and tear. Thus, lowering the operating cost and increasing the lifespan of equipment.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality, Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

Bill Mill Rubber Filler Block

3,000 - 30,000 Per Kilogram

10 Ton (MOQ)

As one of the leading manufacturers and suppliers of rubber products in India, Kedar Rubbers offers the best quality products and services for the bespoke application needs of vertical industries. Our range of rubber products includes the high-quality filler ring known as filler segment liner, filler block, or segment ring. They are broadly used in ball mills to serve multiple purposes precisely for enhancing mill efficiency, internal shell protection of the mill, and to improve wear resistance. This modular-type sectional lining system is used to fill gaps and make milling operations smooth mainly used in industries such as cement, mining, and other heavy industrial processes. All About Filler Ring/Segment Ring Filler segment liners or filler rings are the liner’s sectional parts and are mainly used to fill the space between other liners and larger segments. We design filler blocks based on the design requirement of ball mills to fit the liners securely within the shell to lower the irregular surfaces and spaces. This helps overcome inefficiencies in grinding processes and protects mill shell parts from impact forces and abrasive. It makes the grinding media motion-controlled and consistent enables uniform interaction with the grinding material and enhances energy efficiency by reducing dead zones. This modular filler segment liner or segment ring can easily be installed, repaired, or replaced. This helps to reduce maintenance costs and downtime significantly. Many filler blocks are specially designed to act as shock absorbers to minimize vibrations and impact caused by the grinding media’s dropping action. Thus, the filler ring or filler segment liner is one of the essential components of the ball mill that protects the structural components of the mill, enhances efficiency, decreases operational cost, and enhances lifespan and milling efficiency.

Material : Natural Rubber

Color : Black

Application : Industrial

Feature : Good Quality

Thickness : 5-10mm

Country of Origin : India

...more

Ball Mill Rubber Liner

3,000 - 30,000 Per piece

10 Ton (MOQ)

Enhance the Productivity and Lifespan of Your Mills Using Our High-Quality Ball Mill Rubber Liners At Kedar Rubber Pvt. Ltd., we deliver premium quality ball mill rubber liners manufactured using high-grade materials to protect the shell life of the ball mill and enhance grinding efficiency. We have an in-house research laboratory for testing materials and utilize cutting-edge tools and technology to manufacture high-quality rubber products that give the utmost durability, performance, and productivity. We utilize branded and best-quality raw materials to deliver high-performance rubber liners for ball mills. The key properties of rubber, like, Abrasions, Corrosion & Noise Resistance, Lower Weight, Elasticity & Resilience, Design Flexibility to make customized shapes, and several more make it the most popular material for manufacturing mining mill liners. Uses of our Ball Mill Rubber Liners Our highly durable and high-performance rubber linings are essential components to install in the ball mills due to their unmatched benefits including maintaining the material quality being processed. Ball mills are effectively used in various wet grinding applications in different industries such as mining and mineral processing, ceramics, metal, cement, and several more. Benefits of our Ball Mill Rubber Liners Kedar Rubbers offers the best ball mill rubber liners for the bespoke needs of industries including metal, minerals, and many others. Our best rubber liners for ball mills offer unmatched benefits as follows. Enhanced Grinding Efficiency – Our wet grinding liners optimize the grinding media motion, lower the electricity consumption and thus increase production speed and grinding performance. Lowered Wear and Tear – Our highly durable rubber liners for mills have resistant properties to wear and corrosion, which is useful in increasing the liner’s service life and drastically decreasing maintenance costs. Reduction in Noise Level – Our rubber liner helps ball mills reduce noise levels to create comfortable and safe work environments. Trouble-free installation, maintenance, and replacement – Our rubber liners for ball mills are highly flexible and lightweight enabling installation or replacement efficiently and quickly which in turn reduces downtime. Why Kedar Ball Mill Rubber Liners? Our ball mill rubber liners comprise the utmost characteristics to withstand complex conditions and make the processes swift, cost-effective, and efficient. They lower the operational cost of overall processes in ball mills by reducing downtime, minimizing liner wear, and enhancing energy efficiency by easing the friction between the liner and grinding media. In addition, our mining rubber liners are helpful in quickly discharging materials and reducing wear and tear. Thus, making mass production efficient and enhancing the mill's lifespan. We provide accurate guidance to choose the best rubber liners by considering the abrasive nature of your processing materials and provide customized liners that efficiently withstand the abrasion and impact. We also consider essential factors like the speed and size of the mills, grinding materials, and others for supplying customized rubber liners that double your productivity.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality, Wear Resistant

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...more

Abrasion Resistant Rubber Liner

3,000 - 30,000 Per Piece

10 Ton (MOQ)

Kedar Rubber offers the Best Quality Abrasion Resistant Rubber Liners to Enhance the Lifespan and efficiency of Ball Mills As a premium rubber products manufacturing company in India, Kedar Rubber delivers high-quality rubber products including abrasion-resistant rubber liners. We accomplished the bespoke needs of different industries for their custom specifications. Abrasion Resistant Rubber Liners play a vital role in maintaining the durability and performance of ball mills. In industries such as mineral, cement, chemical, and others the abrasion-resistant rubber liners are widely used to shield the ball mill’s shell from wear and tear due to the friction and impact of the grinding material and media during the milling process. Our most durable abrasion-resistant liners of rubber can withstand the ball mill’s harsh environment. These rubber liners are fitted into the ball mill shell’s interior area. Besides, their functionality to absorb vibrations and impacts enables stress reduction on the mill structure. The corrosion-resistant nature of rubber enables protecting the mill from chemical damage. By offering wear protection, our abrasion-resistant rubber liners absorb the energy impact, and by reducing wear on the mill shell, it enhances the operational efficiency and lifespan of ball mills.

Material : Rubber

Color : Black

Application : Industrial Use

Feature : Good Quality

Pattern : Plain

Thickness : 5-10mm

Country of Origin : India

...moreOpening Hours