Cone Blender

Get Price Quote

The Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. All the contact parts made out of stainless steel of required grade by customer. Two third of the volume of the Cone Blender is filled to ensure proper mixing. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc.

Hand Operated Baby Mixer Machine

Get Price Quote

Best Deals from Kitchen Appliances

Double Cone Blender

235,000 - 1,250,000 Per Piece

1 Piece (MOQ)

Ribbon Blender

25,000 - 500,000 Per piece

1 Piece (MOQ)

V Blender machine

Get Price Quote

OPERATION : The “v” blender machine is efficiently mixes the dry powders homogeneously. It is a versatile and flexible machine doing lubrication process of the dry powders. For the proper mixing, the blenders are filled up to two third of the volume of the blenders. The “v” shape of the container is very suitable for the proper mixing. The blenders can be used for the various applications in pharmaceutical, food, chemical and cosmetic products. Because of the “v” shape of the blender, the requirement of the RPM is not more and better result for the lubrication of the granules. It is suitable for the materials like powder and granules. THE FEATURES : Easy loading and unloading Easy cleaning Low maintenance The hand wheel facility is given for the manual rotating. In standard model, the general structure and safety guards are made of mild steel and colored In GMP model it is fabricated with the S.S. 304 and polished to the matt finish OTHER FACILITIES : vacuum loading flame proof drive motor flame proof starter the contact parts manufactures from S.S. 316 l (instead of S.S. 304)

Double Cone Blender

Get Price Quote

1 Piece(s) (MOQ)

Reaction Blender

Get Price Quote

We offer reaction blender. The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

ribbon blander

Get Price Quote

Check out our comprehensive array of Ribbon Blander that is price tagged reasonably. We are one of the sought after Manufacturers, Suppliers and Exporters of the Ribbon Blander from Gujarat. Made of stainless and mild steel, these Ribbon Mixers are not only durable, but, also assure speedy and uniform mixing of ingredients. We appease the global demands by furnishing the Ribbon Blander in various capacities.

grinder mixer

Get Price Quote

Moisture free blending and compounding with additives in different controlled temperatures Process control timer switch to set and monitor process Provision for on line additives or pigment adding facility and breather valves on the lid Thermo couple to monitor temperature Optional Pneumatic controlled powder discharge and lid opening arrangement Sturdy construction Stainless steel vessels (corrosion resistant) Twin jacket for heating and cooling Timer control for energy saving, Heavy duty bearing housing for trouble free working

Ribbon Blender

560,000 Per Piece

Ribbon Blender

Get Price Quote

We are offering ribbon blender we have a state-of-the-art manufacturing facility, which helps us providing our clients with ribbon blenders. Ribbon blenders available size from 200 mm diameter to 2500 mm diameter in mild steel & stainless steel.

Cone Blender

Get Price Quote

All type of Blenders are available for Mixing i.e. Octagonal Shape, V Shape, Double Cone, Cage, Cone & Ribbon Blender in the MOC of Contact Parts S.S.316.

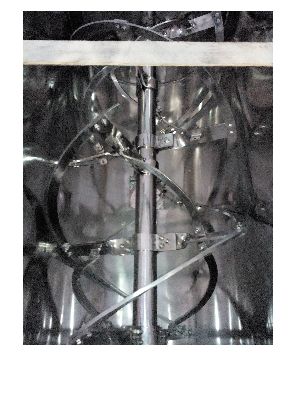

Double Cone Blender

100,000 - 300,000 Per Piece

1 Piece(s) (MOQ)

Silent Features : The conical shape at both end enables uniform mixing and easy discharge The cone is statically balanced which protects the gear box and motor from any excessive load. Powder is loaded into the cone through a wide opening and discharged through a butterf Depending on the characteristic of the product, paddle type baffles can be provided on the shaft for better mixing, uniform blending and de-agglomeration Flame proof electricals can be provided as optional. Dust free bin charging system ensures minimum material handling.

Ribbon Blender

Get Price Quote

Ribbon blender is used for uniform, homogeneous and quick mixing of powders and semi-wet materials of different densities by specially designed helical ribbon agitator. It can be used for Pharmaceutical, Food, Chemical, Dyestuffs & Pigment etc. For Pharmaceutical Industries, Ribbon Blender is called as Mass Mixture. Uni-Mech manufactures Continuous type and Batch type Ribbon Blenders. Uni-Mech also designs Ribbon Blenders for Chemical Reactions with Heating & Cooling applications. Ribbon Blender Design Range : Capacity range: 5 liters to 15000 liters Material of Construction: Various grades of Stainless Steel, Mild Steel, Hastelloy (cGMP model is also available). Special Features : Homogeneous Mixing Dust Free Operation Easy Handling & Operations Top Charging & Bottom Discharge through Butterfly Valve / Sliding Gate

Ribbon Blender

Get Price Quote

Hot Water Boiler

Get Price Quote

500 Kg Double Cone Blender

150,000 Per Piece

1 Piece (MOQ)

octagonal blender machine

325,000 Per Piece

1 Piece (MOQ)

Smoke Tube water wall Membaren Type Steam Boiler

1,000,000 Per Piece

J.D.ENGINEERS is manufactured with Water cum Smoke Tube design that makes it doubly advantageous. It provides a water-cooled furnace which is paneled to prevent heat loss. The tall shape of the furnace provides sufficient residence time for complete combustion of fines & volatiles and reduces the carry over. The vertical configuration of evaporative tubes enables better circulation of steam. A boiler quality strip provided in between the water wall tubes makes the furnaces leak-proof The large sized drum makes available greater steam-water interface area thus ensuring Dry Steam. Features Optimum thermal efficiency due to higher combustion volume & large grate area. Minimal radiation losses due to water membrane wall mounted on furnace. Minimum maintenance required due to less refractory work. Better response to fluctuating steam load as large water & steam holding capacity. Dry steam due to large steam to water interface area. MULTI -FUEL OPTIONS Coal, lignite, wood and all type of agro waste. FIRING OPTIONS Manual firing FBC - Over bed feeding FBC - Under bed feeding Pneumatic firing Dumping grate Pulsating grate Reciprocating grate Travelling grate

Ribbon Blender

380,000 Per Piece

1 Piece(s) (MOQ)

The Mahavir ribbon blender are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. The dimensions and configuration of the ribbons in ribbon blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. The design of the Mahavir ribbon blender can in corporate features required for a customer's product or process such as: wear resistance, corrosive resistance, vacuum filling and discharge arrangements, special shaft seals, heating/cooling jackets. Ribbon blender is available in sizes 100-8000 litters in Stainless Steel 304, Stainless Steel 316 and Mild Steel Construction.

ribbon blander

Get Price Quote

Where a fine blending or mixing of material, with uniform output is required Ribbon Blenders are the best. The equipment is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 10000 litre. The design of the equipment also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. These blenders are also available with all contact parts of Stainless Steel. Construction : M.S. / M.S. - S.S Coating / S.S / Jacket Ribbon Blender Models Available : MS Blender MS. SS Coating Blender Jacket Blender Till Till Blender Ideal For: Mineral & Others Chemical Technical Products Dyestuffs Pigments Colours Fertilisers Metal Separation Insecticides / Pesticides

Horizontal Ribbon Blender

Get Price Quote

Horizontal Ribbon Blender gives very best result for combining of dry powdered & granules as a result of design and form of the mixing ribbon and product jar. It can provide for Pharmaceutical, Meal, Chemical and Cosmetic products etc. The HORIZONTAL RIBBON BLENDER is a proficient and resourceful blending machine and is very useful for homogeneous mixing of dry granules & powders. Roughly about two third of the volume of the container of Horizontal Ribbon Blender is filled to make certain that it is mixed properly. The Horizontal Ribbon Blender Manufacturer offers the most excellent outcome as far as mixing of dry powder and granules is concerned because of the design and shape of the container. It is very apt for Pharmaceutical, Food, Chemical and Cosmetic products processing. Material charged via the top part port/ports are put on the top cover to charge the material. It also aids in venting the air. A discharge valve is given at the bottom part at center of the container. The discharge height can be altered according to the necessity, thus the material is discharged in the extra container directly. Thus there is zero material handling time needed for discharge and the operation is totally dust free. We produce brilliant quality of Horizontal Ribbon Blenders and our product is very apt for mixing, grinding, granulation and homogenizing procedures. Features: The shape of container along with mixing stirrer allows sufficient continuous movement towards powder / granules result in good quality. All contact elements of Horizontal Ribbon Blender are created from SS 304/SS 316 top quality material Maximum care may be taken to ensure safe operation in the Horizontal Ribbon Blender Inching service for stirrer regarding discharge of materials Full cover at the top side of the container Discharge height as per client requirement Operating panel provided for safe operation of Horizontal Ribbon Blender Centrally located material Discharge valve Dust proof top cover with window provided

Octagonal Blender

Get Price Quote

Operation: The Octagonal Blender Is An Efficient And Versatile Blending Machine For Mixing And Lubrication Process Of Dry Granules Homogeneously. Two Third Of The Volume Of The Cone Blender Is Filled To Ensure Proper Mixing. The Octagonal Blender Gives Best Result For Granules Due To Very Slow Speed And Octagon Shape Of Container. It Can Be Used For Pharmaceutical, Food, Chemical And Cosmetic Products Etc. In Octagonal Blender The Granules Comes From All Sides Due To The Octagonal Shape Of The Product Container, Hence Requirement Of RPM Is Less. Suitable Mainly For Crystalline & Granular Type Material. This Type Of Material Gets Sufficient Continuous Movement Due To Their Shape If Container Have Only Slow Movement And Will Results In Good Quality Of Blending / Lubrication Of Granules. Special Features: Octagonal Blender Contains Following Main Features uitable For Dry Mixing Of Products In Granule Form. Easy For Loading And Unloading Of Material. Easy For Cleaning. All Contact Parts Are Made Out Of SS 304 / SS 316 Or SS 316 L Quality Material, As Per Customer Requirement. The Octagonal Shape & Slow Speed Of Rotating Gives Sufficient Continuous Movement To The Granules Result In Good Quality. Simple Design Requires Minimum Maintenance. General Structure & Safety Guards Made Out Of Mild Steel & Colored In Standard Model And Made Out Of SS 304 & Polished To The Matt Finish In GMP Model. Maximum Care Has Been Taken To Ensure Safe Operation Of The Unit. Bigger Size Batch At Low Power Consumption. Other Options Available: We Offer Following Other Option For Octagonal Blender Buyers Contact Parts Made Out Of SS316 Instead Of SS304. Flame Proof Drive Motor Along With Flame Proof Starter. Vacuum Loading Facility For Material Charging. Cylindrical Container With Cone For Material Charging. Contact Parts Are Made Out Of SS316 / SS304 Material. Inside & Outside Surfaces Of Contact Parts Will Be Polished To The Mirror Finish. Gear Box: - Standard Make Starter: - D.O.L.

Reaction Blender

Get Price Quote

The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

v cone blender

225,000 - 785,000 Per Piece

1 Piece(s) (MOQ)

gravimetric blender

200,000 - 700,000 Per NOS

1 Nos (MOQ)

octagon blender

Get Price Quote

In keeping with our theme of client satisfaction, we are offering Octagonal Blender. Octagonal Blender is considered to be high effective blending machine. It could efficiently mix dry granules and apply lubrication process with ease. This Octagonal Blender is proven for its reliable performance. Owing to its octagonal shape, it could easily process large volume of material in comparison to V and double coned blenders.

Industrial Blender

150,000 - 7,500,000 Per Piece

1 Piece (MOQ)

Electric Ovens

Get Price Quote

Double Cone Blender

Get Price Quote

The double cone blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as healthcare, food, chemical, cosmetics, detergents, fertilizers and plastics. Product Description Ideal for Mixing of powder and homogeneous lubrication of granules. Double cone blender is provide safety guard with limit switch interlocked to motor For higher capacity model. Available capacity 5 kg. to 1000 kgs. Automatic loading & unloading facilities provided. All parts made it S.S material is used for ss304 / 316 / 316L. It can be used to pharmaceutical,food,chemical and cosmetic product