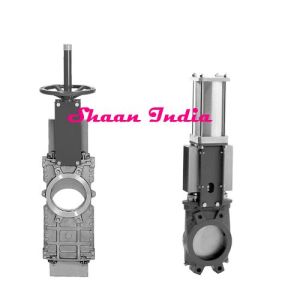

Knife Gate Valves

3,000 - 300,000 Per piece

6 Piece (MOQ)

Knife Edge Gate Valves

Get Price Quote

10 Piece (MOQ)

Best Deals from Knife Gate Valves

Knife Edge Gate Valve

Get Price Quote

100 Pieces (MOQ)

Mild Steel Knife Edge Gate Valve

9,000 Per piece

10 piece (MOQ)

Carbon Steel Knife Edge Gate Valve

700 Per Piece

5 Piece(s) (MOQ)

Pulp Valves

2,500 - 150,000 Per Piece

1 Piece (MOQ)

Metflow Engineers is one of the acknowledged pulp valve exporters and manufacturers in India. Quality being the major concern of our organization, we keep a stringent check on the production, packaging and delivery processes. Therefore, our esteemed customers regard us as one of the best plug valve suppliers in India. Designed and developed using the best quality material, we pack them meticulously to ensure hassle-free deliveries. In addition to this, we make sure that only premium material is used for packaging. Metflow Engineers is a key supplier in many pulp and paper industry manufacturers. Our industrial-grade valves fit the pulp and paper requirements and satisfy many standards. The pulp and paper industry demands the most reliable and strongest flow control valves and actuators. Get the best products from our company. Contact us and get the products from us today.

Knife Edge Gate Valve

2,500 - 5,000 Per Piece

1 Piece (MOQ)

Knief Edge Gate Valve

50,000 - 500,000 Per Piece

10 Piece (MOQ)

KNIED EDGE GATE VALVE As being well established global engineering services, we offer Actuation and Modulating Type Knife Edge Gate Valve of high quality. It is generally used to maintain constant flow in the production line. Our provided range of valves efficiently regulates air pressure. In some industrial applications, it is necessary to prevent back flow in order to suspend or to eliminate contamination. In the industries like food and beverages and also in dairy industry, high level of precautions is taken for the processing of the products. In the process plants, these valves play significant role for automation. To provide customize solution with most suitable valve, we have adopted all latest techniques. Our valves are been constructed under strict observance. International norms and conditions are stringently followed. In order to obtain highly accurate result, our offered range of the Actuation and Modulating Type Knife Edge Gate Valve is built to perform well under critical plant conditions.

Knife Edge Gate Valve

3,250 Per Piece

10 Piece (MOQ)

The Knife Gate Valves we manufacture have a strong construction and are highly durable. These products have high tolerance for heat and pressure. These products perform their operations of controlling the flow of liquid and gases very effectively. The manufacture of these products involves use of high quality raw materials acquired from reliable vendors. These products are further sent for a number of quality checks as we want to provide our customers high quality products. We provide these quality products at a very competitive price. Features : Low maintenance Rugged construction Precise design

Knife Edge Gate Valves

3,000 Per Piece

1 Piece (MOQ)

Knife Edge Gate Valve

2,800 Per Piece

1 PIECE (MOQ)

Pulp Valve

Get Price Quote

Valvequip Engineering Corporation is one of the acknowledged plug valve manufacturers in India. Quality being the major concern of our organization, we keep a stringent check on the production, packaging and delivery processes. Therefore, our esteemed customers regard us as one of the best plug valve suppliers in India. Designed and developed using the best quality material, we pack them meticulously in order to ensure hassle free deliveries. In addition to this, we make sure that only premium material is used for packaging.

Sand Casting Heavy Duty Slurry Knife Gate Valve

Get Price Quote

The company holds expertise in manufacturing, exporting and supplying high grade Sand Casting Heavy Duty Slurry Knife Gate Valve. The Sand Casting Heavy Duty Slurry Knife Gate Valve, offered by us, facilitates flexible pressure assisted two-piece rubber sleeve system which allows valve to cycle in heavy slurries without sticking. The sleeves of our Sand Casting Heavy Duty Slurry Knife Gate Valve can be easily replaced without disassembling the valve. In addition to this, the bi-directional full port flow reduces pressure drop and turbulence, thus minimizing wear. The open bottom of our Sand Casting Heavy Duty Slurry Knife Gate Valve allows for the purging of large solids, and solids in higher concentration. The purging of solids stops when the gate is in the full open or closed position. Our Sand Casting Heavy Duty Slurry Knife Gate Valve is highly appreciated by the clients for high strength, durable life and resistance towards corrosion. Features : New and replaceable upper seal design is not only packing less, which eliminates the need for periodic adjustment, it is also a self lubricating system and is rechargeable without valve disassembly Open bottom allows for the purging of large solids, and solids in high concentration Bi-directional shutoff Sleeves are available in a variety of materials to handle abrasion, and chemical application Flushing plate option allows for periodic cleaning of the lower discharge vent and allows flushing as needed Two-Piece Rubber Sleeve System : Port pressure provides assistance by forcing the sleeves against the opposing sleeve or the gate, depending on the position, to provide greater sealing force. Face rings allow the valve to cycle under maximum flow conditions up to a maximum differential of 150 psi10 bar. Seats are self gasketing and are compatibility with raise face.Flushing Cover Bonnet : Flushing Bonnet attached to the bottom flange to capture any discharge during cycling. This option also allows for periodic cleaning of the lower discharge vent and can allow flushing as needed. It has a bi- directional shut – off design.

Knife Edge Gate Valve

Get Price Quote

Pulp Valve

2,150 Per Piece

5 Piece (MOQ)

UNI Directional Knife Edge Gate Valve Lug Type Wheel Operated

6,500 Per Piece

10 Piece (MOQ)

Knife Edge Gate Valve

Get Price Quote

Knife Edge Gate Valve is the specific design. This design ensures minimum contact between the parts of the Valve, Reduces the Wear & Tear. The high-performance Knife Gate Valves feature. Non-Sliding Motion, Avoid Sliding Contact between Body & Gate allow flushing of media form the Valve interior. A wide variety of hardened trim options are available on Gate, Seat and Wear Ring. Batten edge of the Gate (Knife-Edge) allows the tight shut off even when solid particles settles at the bottom of the Body. The valves are regularly used for applications to handle, pulp in pulp mill, slurries, powder such as coal, ash, dry and wet powder in power houses, pneumatic conveying systems, dust collecting systems and material handling equipment’s. For liquid slurries and fiber applications with low-allowable leakage the valves are most commonly used. Pneumatic, Manual, Gear and Hydraulic equipment devices are provided for operation of the Valves. For elevated mounting, chain driven Valves are also provided. Our product range covers valves of sizes up to 36” [900mm] and ASME classes up to 150, PN 10 and PN 16. Based on customer requirements, valves in different pressure classes, larger sizes and other materials are also offered. We manufacture this Valve according to MSS SP – 81 designing and manufacturing standards. Uni-directional Type Knife Gate Valve Bi-Directional Type Knife Gate Valve Square & Rectangle Type Knife Gate Valve Fabricated Type Knife Gate Valve

Knife Gate Valve

2,000 Per Piece

Knife Gate Valve

Get Price Quote

20 Piece (MOQ)

Knife Edge Gate Valve

4,000 Per Piece

2 Piece(s) (MOQ)

Application:- Pulp & Paper For half a century, �K.I� Engineered Valves has been a proven supplier of quality valve products designed specifically for the pulp and paper industry. Year after year, we�ve designed and engineered products and features uniquely adapted to pulp and paper processing. These valves substantially reduce downtime and maintenance costs and consistently outlive their payback period. Through testing and application, we continue to solve countless problems associated with pulping, bleaching, dewatering, recovery, papermaking, and recycling. Our valves are designed to provide long life in an industry where life expectancy of equipment is exceedingly low. Mining "K.I� is leader in fluid handling with 50 years of design, manufacture and fabrication of engineered valves with specific expertise in slurry applications. Mining customers depend on KIRIT IIEngineered Valves for consistent reliable delivery, cost effective solutions, and after sale support. We approach each customer�s requirements with the certainty that we have the right product to fit their most challenging valve application. Better valve performance in mining and processing of metals and minerals Less unscheduled maintenance downtime Improved plant performance and pipeline reliability Safety for operators General Industry �K.I� Engineered Valves provides valve solutions for a wide range of general industry applications. Industrial Gate valves have been used to solve problems associated with corrosive, erosive and abrasive media in such industries as steel production, pickling, and plating. Gate valves can be found in many applications in water and wastewater treatment, including chemical treatment, filtration, and sludge handling. The industrial Gate valve has been the valve of choice for demineralized water systems for the past 40 years. Oil and Sand

Pulp Valve

Get Price Quote

10 Pieces (MOQ)

Knife Gate Valves

Get Price Quote

We are offering knife gate valves, jupiter controls knife gate valves is greatly appreciated for its cost effectiveness. This series is developed with an aim to enhance customer's profitability and satisfaction. features knife gate valve is one of the most preferred industrial valves. It is featured with minimum contact between moving parts of the valves. In this type of valve, a gate is practically held between layers of gland packing without touching the body parts during most of its travels. the seating is accomplished with a non-sliding motion aided by jams located in the body. Avoiding sliding contact between gate and body permits this valve to handle abrasive particles present in the media much better than conventional designs. This valve is named 'knife' because of the beveled bottom edge of the gate. It allows positive closure of the gate even when solid particles settles at the bottom of the body. In abrasive media, deflection cones are used to avoid direct impingement of the media on the seat surface. Besides this, sometimes hard facing of seat part is also used, which involves stelliting of the seat or gate or complete intruding of body as well as gate. Another feature is the purge connection which allows the flow of suitable fluids at pressures higher than line pressure in order to clean seating surfaces (body purges) and packing area (chest purges). This helps in minimizing abrasive wear and tear during opening and closure of valve. Knife gate valves are excellent hopper isolation valves with their ability to cut through flowing powders and close by dislodging any material in the seating area. Specially designed to tolerate differential thermal expansion of its parts without affecting its functions, this valve is an ideal choice for handling high temperature media,

Knife Edge Gate Valve

5,000 - 50,000 Per Piece

Knife Gate Valve

1 Per piece

1 piece (MOQ)

If you are looking for Industrial Valves please contact us

Knife Edge Gate Valves

3,000 Per Piece

1 Piece (MOQ)

Electric Actuator Operated Knife Gate Valves

Get Price Quote

With our fast delivery network, we can easily meet expected delivery deadline of the clients. So, what are you waiting for, place orders now! We are backed by a well-structured and capacious storage unit wherein we store the entire lot in a secured manner. Moreover, we ensure complete security of the stored items. Electrical Actuator Details: Manufactuator - Cair Euromatic Automation Pvt.ltd. Brand / Model- Cair / Atm-in Characteristic - On-off Type With Integral Starter Unit Controller Power Supply- 415v Ac, 50 Hz Housing & Cover- Cast Iron Enclosure - Water Tight Ip 67 Ambient Temperature- -10°c ~ 50°c Torque Switches- 2 X Spdt Limit Switches- 2 X Spdt Stall Protection- Current Trip Provided With Starter Unit Indicator - Continuous Position Indicator Manual Override- Provided Integral Starter Unit Details: Selector Switch - Open / Stop / Close. Selector Switch - Auto / Manual Or Local/remote. Indicating Lamps - Open / Close / Error. Enclosure - Ip 67 Weather Proof & Dust Proof. Blinking Led Lamp Indication During Open/close Operation. | Red - Fully Open | Green - Fully Closed. Automatic Phase Rotation Correction And Phase Loss Protection. 24v Dc Voltage Level Is Applied For Remote Control. Easy And Flexible User Connection Way. Non-penetrate Local Control Switch With Hall Effect Device To Improve Water Proof Feature. Five Passive Contacts To Indicate The Working Status Of The Electric Actuator And Facilitating The Monitoring Of The Electric Actuator By Dcs System. Operating Mode Select Switch Can Be Locked With Ordinary Lock To Prevent Improper Operation. Details Size - ½” to 12” MOC - CI/ WCB / CF8 / CF8M Seals - Metal to Metal / NBR/ PTFE Pressure - Upto 2 Kg/cm² (Above on req) Temp. - Upto 80°C / 220°C Ends - Lugged / Flanged type

Knife Edge Gate Valves

9,500 Per Piece

1 Piece(s) (MOQ)

Pulp Valve

3,500 Per Piece

Knife Gate Valve

Get Price Quote

1 Piece (MOQ)

Knife Edge Gate Valves

3,200 - 40,000 Per Bag

4 Bag(s) (MOQ)