WET MAGNETIC SAPARATORS

The wet magnetic drum separator (known as NTS) is used to remove very fine magnetisable components from low concentration, low-viscosity liquids. NTS is mainly used by metal processing industry and for the treatment of pre-concentrates extracted from high gradient magnetic filter. About 90% of the very fine magnetisable components can be separated as sludge. Features such as stainless steel housing and powerful neodymium iron boron magnets are standard. General Principles:The liquid flows through a semi-circular separating chamber beneath a stainless steel drum to which the magnetisable particles are attracted. The strong, high-gradient magnetic field is created by a cylinder consisting of permanent magnetic discs positioned within the drum. These special permanent magnets generate particularly high field gradients which are necessary for successful separation, as is the need with all Magnetic-Separators.For recovering Magnetic/Ferro-silicon in dense media plants and iron ores, wet drum separators are mainly used. They remove contamination from the product stream, increasing product purity and plant productivity. In the applications where the product purity is most essential, the wet drum separators can use powerful Rare Earth Magnets, which can remove very fine and weak contaminants even from dense materials. Features:(1) Wet drum magnets have high magnetic recovery and discharge. (2) The feed slurries recover the magnetic. (3) It is available in single or multiple drum applications.(4) Recover magnetic solids in as clean as a magnetic concentrate. (5) Permanent magnet assembly eliminates coil burn-outs(6) The magnet/pole elements are bolted to a mild steel shaft. (7) The drum is made from thick stainless steel for long service life.(8) Wet drum separators are available in different configuration like single drum, double drum and multiple drum. In double drum two separators are arranged back to back with a common feed back. Applications:(1) Glass industry(2) Chemical industry(3) Plastic industry(4) Mining industry(5) Food industry (6) Pharmaceuticals industry(7) Foundry industry Buyers Advantage:Buyers have the following advantages:(1) The separator provides minimum wear on the cylinder.(2) The materials are returned to the feed point automatically.(3) It has the high magnetic solid discharge(4) It can also handle heavy magnetic load. (5) Wet drum separator has wide industrial usage.

...more

Suspension Magnets

KUMAR Suspension atype Magnets are useful for products carried by the Conveyor belt.Suspension Type Magnets use is recommended for low contamination products. If the frequency of the impurities is very much, it will make a layer shunting magnetic field. Hence, the equipment required frequnet cleaning. Over band type Magnetic Separator is recommended for this type of application. The principal applications are for processing of bulk products such as Culets, Glass, Cofee, Cereals, Minerals, Coal and Sugar etc.,INSTALLATIONKUMAR magnets can be installed at the end of belt above the head drum (Image-1) or across the Conveyor belt (Image-2).Toavoid disturbances to the magnetic field, in both cases, the magnetic parts must be placed below the surface of the magnet.The installation shown in Image-1 is recommended for high speeds. Due to trajectory of the products and the fact that it is then fluidized, separation is more efficient.

...more

RARE EARTH TUBE MAGNETS

are Earth Tube Magnets are used to eliminate Iron contamination from Liquids or dry bulk materials for quality Control Check. Magnetic Tubes are available in standard length i. e. 150mm to 400mm with solid, Threaded or with studded ends, as per specific requirements of the clients.

...more

Rare Earth Magnets

Kumar Industries, a supplier of “KUMAR” Rare Earth neodymium magnets for education, industry and engineering. We specialize in providing strong high-quality neodymium-iron-boron (NdFeB) magnets at low prices. Our neodymium magnets are made with the most advanced magnetic materials. New Resellers : We are contemplating actively recruiting new resellers for our “KUMAR” Rare Earth Magnets. If you have a retail store or an online presence with complementary products, we encourage you to contact. Small accounts are welcome. Extencive Selection Magnets :We carry a wide range of shapes and sizes of neodymium magnets. All our stock of magnets is of Grade N40 sintered neodymium-iron-boron plated in nickel.Rare Earth Magnets can be customized according to your request. Any shape or size can be ordered. If you have any questions, please, do not hesitate to ask us. We will design a magnet that will be exactly as per your requirement.NdFeB Magnet:Neodymium Iron Boron (NdFeB) magnets , a sort of Rare Earth magnet, has the high remanence, high coercive force, Maximum energy and is easily formed into various sizes, shapes. So they have been widely used in commercially available fields. Manufactured by sintering, compression bonding, injection molding, and extrusion. The sintered form holds the highest energy product of up to 48MGOe, while the bonded form holds a lower energy product of up to 10MGOe. Further more the majority of NdFeB magnets are anisotropic and can only be magnetized in the orientation direction.

...more

RARE EARTH MAGNETIC PLATE

Rare Earth Magnetic Plates are developed for installation in feed Chutes or for suspension over the flow of material for eradication of weak magnetic and or fine iron impurities. They are widely used by food, Chemicals, Minerals or Ceramic Slips and glazes etc. Rare earth Chutes (Channel Type Magnet) are also suitable for custom Built requirements

...more

Rare Earth Magnetic Grids

Rare Earth Magnetic Grids are developed for installation in Hoppers, Feed Holes and Duct etc. The Grids Comprise of Rare Earth Tubes assemblies in single, Double or Multiple bank as required by the clients and can be supplied in square circular or any other size to suit the requirement of the customers.

...more

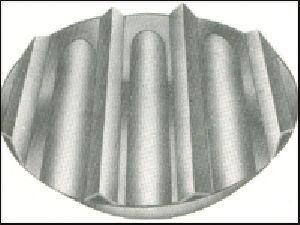

rare earth magnetic drums

Rare Earth Magnetic Seperators can be used in processing industry for removal of weak magnetic or fine iron impurities from Minerals, Refractories, Food Products, Glass, Slag, Ores etc.

...more

power magnets

These are available in various size and capacity and is the most handy device for separating Iron from nonferrous scrap, plastic or any other material. Following size are available.

...more

Permanent Magnetic Separator

KI Permanent Drum Type Magnetic Separator is most useful non electric separator for separating tramp iron from non magnetic material processed in bulk quantity for the purity of end products recovery of metals having commercial value end protection of processing plant and machinery. These are widely used in all the processing Industry for separation of iron contamination from minerals, chemicals food , flour, plastics, grains sand, cement fertilizers, abrassives, glass slag, ores rock and many other products.

...more

Permanent Magnetic Drum

The permanent Drum Separators are available in standard drum diameters of 300 mm, 400 mm & 450 mm. Drum length range from 300mm to 1200mm. Other sizes can be made as special to your requirement. The larger diameter and length of the drum the greater is the volume of material Which can be handled. Working Principle & Megnetic System :-The Permanent Magnetic Drum consists of a stationary Permanent Magnetic assembly having uniform and everlasting Magnetic field accross the entire width of drum, which is effective overapproximately half the drum circumference as shown in Fig.Drum Shell made of non Megnetic stainless steel revolves around the magnetic field. As the material fed evenly from the chute falls over the drum, powerful magnetic field attracts and holds ferrous particles to the revolving shell as the revolving shell carries the Iron particlesthrough the stationary magnetic field the non-magnetic meterials falls frelly from the shell while ferrous particles are firmly held until carried beyond devider and out of magnetic field.The strength of the permanent magnetic drum is guaranteed to be greater than corresponding electromagnetic drum, The Permanent magnets used are everlasting magnets and its strength does not diminish during normal use and can be used through out the life of the installation.

...more

Parmenent Magnetic Pulley

“KUMAR” manufacture a wide range of Rare Earth and Ferrite Magnetic Pulleys. These Pulleys are widely used to remove tramp iron mixed with the material moving on a conveyor belt. The permanent magnetic pulley is dual-purpose equipment used for protection of crusher Jaws or other machinery and also for purification and concentration of magnetic material from the mines. It has the widest application in food, chemical, ceramic, paper, coal handling, foundry operation and mining industry. The magnetism in a Permanent Magnetic Pulley is generated by internal assembly of magnets enclosed in non magnetic Stainless Steel shell. The steel shaft is extended on both sides. One side is provided with Key-way. The Pulleys have a face width of 50 mm to 100 mm more than the belt width. The magnetic strength of the pulley depends on the diameter and also quality of magnets used. Pulleys with Rare Earth Magnets can handle depths up to 300 mm. Pulley width is determined by width of conveyor belt to be used. Diameter depends on depth of material and speed of the conveyor. It can be designed to suit customer’s specific application.The magnetic Drum pulley replaces the drive pulley at the end of conveyor belts. In view of the wide variety of conveyor belt types, the drum pulley are supplied made to measure and ready for installation. As the figure clearly show, the magnetic head roller extracts the iron particles from the material flow and carries them to the underside of the belt where they are removed and collected. Head roller magnets for conveyor belt are supplied in permanent magnets.Features:(1) 304 stainless steel faces.(2) Removable mild steel shaft.(3) Four hub styles.(4) Flat face.(5) Keyway and set screws. Options:(1) Taper locks(2) Crowned face(3) Fixed shaft(4) Lagging(5) Stainless steel shaft

...more

Magnetic Separator

Supension Type Permanent Over Band Magnetic Separator are develioped to remove tramp metal from the product carried by vibratory feeders, belt, or inclined planes. These are mainly used to safeguard machine such as shedders, Crushers, others and to remove ferrous particles and purify the end products (Industries such as coal Mines , Foundries, Cement Works, food, Sponge Iron< Glass, Char Coal, Chemical and Domestic waste recycling Plants)These Permanent Over band Magnetic Separatora are used for an automatic removal of ferrous contamination. For other purposes, fixed permanent Suspension Type Magnets are more suitable. Applications :Several types of separators are developed to operate at pre determined working space over the conveyor i.e. 100,150,200,250 and 300 mm. while choosing the over band, the speed of the belt, the nature of the product, its density, its granulometry and size of the particles, which have to be extracted are the main parmameters to be taken into consideration.Construction :2 "U" Section pieces are fitted on the magnet by fastening ears and are supporting bearings of drums and the drumd are enuipped with shafts mounted on removable hubs. All the bearings are equipped with stakes for tightening the belt. reduction gear coupled Electric Motor/Geared Motors by vee belts drives the belt.Magnet Unit : This Magnet is developed from high Intensity Stroncium Ferrite Rare Earth Magnets and guaranteed to give full magnetic power in the entire life span of installation. One Non Magnetic Stainless Steel Plate is supplied to cover the poles of the magnet. No need for electrical supply or maintenance.Installation :These Magnetic separator can be installed either inline over the terminal head pulley (Image-1) or transversal to the Conveyor (Image-2). For both cases, it is required to foresee Non-magnetic products under the magnetic fileld. Most suitable position is inline (photo-1) over the head pulley. The material being conveyed is in vitual suspension and tramp iron is therefore more readily extracted. Good results are obtained by combining a permanent Megnetic over and with permanent Magnetic pulley at discharge end.

...more

Magnetic Plate

Permanent Magnetic Plates are used for separation of tramp iron found in Tea. Tabacco, Coffee, Cocoa, Milk Powder, Chemicals etc. They are available in both flat and curved shapes and could be installed either above or along the passage of materials flow. They are provided with Clamps and could be located on the conveyor of carrying such materials ideally, they are located 30 mm above the layer of material flow. These plates are constructed with high energy permanent magnets plated in a magnetic circuit. They are extensively used in CTS Tea machinery and in Biscuit stacking machines. They are available in various sizes as per the requirement.

...more

Magnetic Floor Sweeper

This ideally used to collect the iron scrape from the workshop floor. Magnetic Plate with cover, wheels and Handle in three different sizes are available.

...more

magnetic coolant seperator

The Coolant fluid with iron dust particles falling by gravity to the inlet of the seperator from the precision machine tools such as Grinders, Milling Machines, Automats etc. The coolant with iron impurities come into contact with Magnetic Drum and extracts all iron particles.The Magnetic drum is kept clean at all times by a spring steel blade scrapping along the circumference.A Rubber roller squeezes the sludges gathered to ensure that no coolant is wasted. SPECIFICATIONS :-• A sturdy welded Stainless Steel/M.s Frame.• A Magnetic drum enclosed in stainless steel Drum having extra powerful Magnets with uniform Magnetic field all along the circumference.• A neoprene rubber roller with covered bearings.• A spring steel blade with adjustments for efficient scrapping of the sludge.• An electric motor working 440 Volts with a reduction gear revolving the drum at about 10 RPM.We give below the standard models manufactured by us. However, custom made coolant seperators can also be manufactured as per specific req.

...more

Liquid Trap Magnets

Liquid Trap Magnets are those engineering device that removes ferrous tramp from liquid processing and conveying lines. Liquid magnetic traps separators provide magnetic protection for liquid lines and processing equipments. They preserve product purity by removing small contaminants. They protect against tramp iron and other ferrous fine contaminations. It consists of powerful magnets to capture finest possible contaminants. Magnetic configuration ensures maximum exposure of contamination to the high intensity tubes without any obstruction to liquid flow. Types:Based on the configuration and the types of contaminants they capture, the liquid tramps are of following types:Cartridge-Style Liquid Traps: For non fibrous fluids cartridge-style liquid traps are ideal. These types of separators are utilized where the size of the contaminants is few diameters and pose no risk of clogging. When the liquid is forced towards the tightly spaced grid, the contaminants come in the effect of magnetic field, which is extracted from the liquid flow by powerful Rare Earth Magnets. The contaminants are held on the cartridge surfaces, which is later removed.Magnetic Liquid Traps- Single Plate:Single plate magnet style liquid traps are effective and efficient in removing ferrous particles from viscous and fibrous liquids and liquids containing large suspended solids. The contaminants are thrusted to the magnetic plates where they are held. The magnetic field is strong enough to trap and protect the tramp materials from the wiping action of the liquid flow. The cleaning is done by removing the plate magnets from the housing and wiping the ferrous tramp to the edge of the plate, where it can easily be brushed away. Magnetic Liquid Traps- Dual Plate:Dual plate magnet has diverter that creates a smooth flow pattern that protects fragile products from damage. The diverter also divides the product flow over two plate magnets. Thus even the flow rate is higher the dual plate traps can effectively handle it easily. The flow rate can be slowed thereby giving more magnetic protection. Also more contaminants are exposed to the magnetic field in the dual plate magnetic liquid traps.Specifications:(1) The liquid trap magnets are equipped with powerful Rare Earth Magnets of high-intensity there by capturing even the minutest ferrous fines.(2) The trap magnets come in different forms like single plate, dual plate cartridge's type etc.(3) They are easy to mount and operate. (3) The liquid trap magnets are housed in stainless steel structure.(4) The entire flow of the liquid is covered by the cartridge in cartridge liquid magnets which creates strong magnetic force and capture the tramp iron and ferrous particles. Applications:(1) Food industries(2) Pharmaceutical (3) Chemical product flows (4) Rubber industries (5) Plastic industries

...more

Lifting Magnets

Type KI-706 LM / WC is the most handy , efficient and economical device to separate iron contemination from Foundry scrap, sand & plastic granuls. Made from High coercivity permanent magnets most useful for foundry Plastic Industries & Scrap dealers Size of the magnetic plate is 135 mm (w) x 170 mm (L) x 27 mm height.

...more

INLINE DRUM TYPE MAGNETIC SAPARATOR

Inline Magnetic Separators are available for installation in the Feed lines such as at the outlet of elevator, screw conveyor etc. Flanged type Inlet and outlet connections are provided. The Magnetic Drum incorporates High Intensity stroncium / Rare Earth Magnets. These are widely used for Cattle Feed Plants, Flour Mills, Rice Mill, Minerals, Refractories, Glass and many other Products. Salient Features: (1) Drum consists of High Coercivity modern Anisotropic Permanent Magnets. (2) Strong & Rugged construction. (3) Automatic Separation of Iron Impurities. (4) Completely enclosed design to avoid dusting and pollution. Rotary Drum Magnetic Saparator:Abstract:Solid waste incinerator fuel is pre-classified by passing it through a hollow rotating cylindrical drum which has magnetic extensions called flights protruding from the inside of the drum wall along its length. The drum may also have a first set of non-magnetic flights towards one end protruding further from the wall toward the center or axis of the drum. Then a second non-magnetic portion on the other side of the magnetic flights along the length of the drum. The magnetic flights attract particles and material subject to magnetic attraction. The ends of the first set of non-magnetic flights towards the middle of the length of the drum are preferably shaped or rounded somewhat lengthwise. A scraper assembly preferably having two material removal channels or chutes in addition to a scraper blade, may be arranged to extend into an exit end of the drum. The scraper blade removes magnetic or iron particles from the magnetic flights as the drum rotates. These are carried out of the drum via a first of the two channels, with the non-magnetic non-combustibles being carried out via a second channel.

...more

Hopper Magnets

Kumar Hopper Magnets provide an efficient magnetic filtering to any hopper-fed injection moulding, blow moulding, extruders, cattlefeed plants, flour mills rice mills etc. Made up of high corecivity, permanent magnets sealed in non magnetic tubes they provide better magnetic filtering due to their high magnetic flux density. They are designed to fit in any size of hopper. No need to make any cumbersome attachment or alteration to fix it in your hopper. Easy to clean and no maintenance, cost Makes it really a very convenient and reliable filter,providing constant magnetic protection at a low cost to your equipment and preventing expensive shut downs and delays.

...more

high intensity roller type magnetic separator

KUMAR have Developed High Intensity, High Gradient, Permanent Magnetic Roller Seperators with the indigenous Technology. This technology can be successfully used in Industrial Minerals applications. The Technology involves high energy Rare Earth Neodym Permanent Magnetic Roll Assembly, Which is developed and assembled under strict quality control and specification to generate unsurpassed Magnetic Field Gradients. Under this high Intensity Magnetic Field, weekly Magnetic Contamination can be easily removed effectively. Operating Method :A Short conveyor belt envelopes the Magnetic Roll and tensioning the Ideal Roll. An efficient Feeder discharges material on the Belt. The Ferro Magnetic and Para-magnetic particles adheare to the Belt while the non-magnetic particles flow freely off the end of the Conveyor. Features : Magnetic Rolls are available in 65, 75 & 100 mm dia and widths upto1200mm . There are three different Magnetic Strengths i. e. 8000 Gauss, 20,000 Gauss and 22,000 Gauss. The Roll is driven by a 0.5 HP, variable speed DC/AC geared Motor drive adjustable from 0 to 100 RPM. For the purpose of Feeding, Vibratory Feeder with Control is Provided. The Machine is Provided with Abrasion resistant endless conveyor Belts of 0.8mm thickness.Applications :Kumar Machines are most suitable for various types of Industrial Minerals applications i. e. Abrasive, Refractory and Ceramic Raw Material beneficiation, Alumina, Silica, Carbide, Magnestic, Quartzite, etc. Glass Raw Materials, Clean Silica Sand, quartz, Feldspar, Dolomite etc., Ultra High Purity Quartz Cleaning, Graphite Upgrading, Mangenese Orebenification, Bauxite Upgrading, Diamond ore benification, Selective Separation of Garnet / Ilmenite/Rutile, Zircon, Benification of Iron ore, Recovery of Metals from Slag, Removal of Ferro Silicatge from Limestone, Megnesite etc.Testing Facilities : Please feel free to ask for Free Demonstration by testing 5/10 Kgs of any material, at our Works.

...more

grill Magnets

KUMAR” Permanent Magnetic Grids (Grill Magnets) are designed primarily for fitting in Hoppers for removal of small particles of ferrous metal from free-flowing powders and granular materials when processed. Magnetic Grills manufactured to any size or shape, they are simply placed in or below hoppers, in closed chutes, floor openings, catch bins, and other locations. Open Grate Magnets are available in round, square, and rectangular shapes to fit your equipment. These grids encased totally in stainless steel for rigorous handling are often used in hoppers in the plastics industry. For an even higher level of protection, double and triple banked grids can be manufactured. All grids are available with either ferrite or powerful rare earth magnets that are recommended for fine ferrous particles such as rust etc. Easily installable highly effective and consistent performance magnetic surfaces can be easily cleaned manually. Standard grids have 25mm (1 inch) mesh can be manufactured to any size or shape double or triple banked grids available. Powerful Rare Earth (Neodymium iron boron) magnets available for fine particles.

...more

Ferrite Magnets

KUMAR FERRITE MAGNETS are very hard, but more brittle and more prone to cracks and chipping on the edges and corners. They are characterised a very high normal and intensive coercive force, but rather a low residual induction and are virtually free form self-f-Demagnetisation. They possess a very high electrical resistivity which makes them ideally suited for high frequency applications. The following shapes of ferrite magnets are available : Rings, Rectangulars, Square, Segments, Discs, Cylindricals, Plasto-ferrite / Rubber Sheet / Strips, etc. Any other shapes and sizes, not available in the country at present, could be supplied in accordance with the client's requirement. Our factory is well equipped with latest sophisticated machinery catering to the need for - (1) Magnetic Chuck, Separators, Grills, Holding Systems, etc.(2) Magnetos, DC Motors, Stepper Motors, Generators, etc.(3) Moving coil Instruments, Magnetic Door Catches, Magneto Theropy.(4) Loud Speakers, Horns Public Address System etc.(5) Fabricators, Automobiles, Auto Switches, Coupling Oil Filters etc.(6) Magnetic / Strickers/Boards, Laboratories & Schools(7) Conveyors, Trollies, Gifts & Novelty Items, Televisions(8) Computers, Refrigerators & Relays. Our Products were lunched in the market only 4 year back and have earned a high reputation in terms of quality and timely supply. Our magnets are fully guaranteed for its best performance. However, minor defects like hair line cracks, chipped edge or corner which are unavoidable due to nature of material. These defects are acceptable only, if they do not change the magnetic performance of the piece. Kumar magnets has carved out an unique place for itself at the forefront of magnet technology - with a reputation for the highest quality standards reliability and dependability of timely supplies-and the creditability that goes with it. the confidence that has been generated, thus, will be our springboard into the future - into more challenging vistas calling for the highest technical ingenuity and the most prudent resource management. Partners in each others growth through a commonality of interests. DISC MAGNETS are also available in isotropic material which do not have any specific directions, they can be magnetised by any one of the 3 axes. Isotropic Disc Magnets are available from 4.00 mm to 50.00 mm diameter and their varying heights.

...more

Drawer Magnets

Drawer magnets consists of a row, or most commonly, rows of round magnetic tubes that are assembled into drawers. Drawer Magnets are recommended for fine cohesive materials such as magnesium oxide, zircon powder, fly ash, aluminum, gypsum, lime, powdered sugar, cornstarch, flour & pulverized minerals and ceramics. This type of ferrous metal removal unit can be fitted simply in existing pipe line or outlet of various equipments like pulverizes blenders, & classifier or any other outlet location. In standard type each unit comprises to permanent magnetic grids mounted one above the other. System with multiple grids is available for special application. The grids are easily removable for cleaning. The drawer is fitted with flanges at outlet. As standard the magnetic rods consisting hard ferrite ceramic magnets or high intensity rare earth magnet is fitted in a sturdy steel housing. Model with stainless steel grids and housing can be supplied if required. The drawer magnets are available with either Ferrite Magnets or with High Intensity Rare Earth NdFeB Magnets. Types:Based on the sizes, configurations and the working capacities, drawer magnetic separators are classified as: Heavy Duty:Heavy duty drawer are useful for optimum magnetic separation in tough processing conditions like ambient temperature and humidity, bridging, abrasion, corrosion or galling. There are special coating on the drawer's tubes that prevents sticking problems associated with certain products and processing conditions. Due to this the cleaning operations becomes even easier. The cleaning can be accomplished both manually and automatically. Large TubeIn larger drawer magnets Rare Earth Magnetic tubes are incorporated for optimum ferrous metal separation on difficult flowing products such as flour, powdered sugar and other products with a tendency to bridge. The placement of larger tubes below steep angled diverters that prevent product from bridging or building up on the tubes. Since the spacing between the tubes are larger it allows the product to flow freely through the housing.Manual CleanFor low levels of tramp metal contamination, manual clean drawer magnets are ideal. The Magnetic tubes are located on the alternating centers of the tubes. The trapped materials can be removed with the help of shop rag or gloved hand.Self-CleaningIn difficult locations Self-cleaning Magnetic Drawer is considered as suitable. Through the toggle switch the operator can easily clean the assembly from a remote location.FeaturesFollowing are the features of the drawer magnets:(1) The drawer magnets can be fitted simply in existing pipe line or outlet of various equipments like pulverizers, blenders etc. (2) Generally each unit comprises of permanent magnetic grids mounted one above the other.(3) For special applications there are systems with multiple grids.(4) The grids are easily removable for cleaning. (5) Normally the ferrite or rare earth and NdFeB magnets are used in the drawer magnets.(6) Certain types of drawer magnets handle a wide range of separation tasks in gravity conveying systemsApplicationsThe drawer magnets can be applied in following areas:(1) Mining industries(2) Pharmaceuticals industries(3) Food processing industries(4) Industries dealing with powdery substance(5) Cement, gypsum and other types of small scale industries.

...more

DOUBLE Permanant Magnetic Separator

Double Drum Type Permanant Magnetic Separator :Specification : With reduction gear, l HP 3 Phase Electric Motor to drive the drum at a speed of 15 RPM, Vibrating Tray fixed in between Hopper and Drum extra high power permanant magnetic plate at bottom side & Machine complete with close body. Special modifications can be made as per requirement of the customer.

...moreBe first to Rate

Rate ThisOpening Hours