screen vibrator

FEATURES Least Blinding: Screen blinding can be limited to more prominent degree by Multi plane activity Vibtation control. Longer screen Life: Screen fabric is collected with uniform strain on extraordinarily composed work outline. The firmly screening surfaces vibrate inflexibly without flexing of wires, for the most part decreasing screen wears and expanding screen life. No transmitted vibration: No uncommon deck or establishment is required to utilize this Screening framework. ADVANTAGES Favorable position Secluded outline structure. Space sparing. Decrease in material misfortune. Better alternative to limit tidying. Process improvement Better use of fundamental and scrap material Simple operation and upkeep Flexibile plan according to custom prerequisite. Cost control by reusing scrap material according to application Better and predictable item quality because of immaculate screening. Better Polution control Application Areas Polymers, gums, Plastics, PPLDPE, LDPE, RPVC, Food Industry : Salt, Tea, Fertilizer, Effluent, Detergent powder, Edible Oil, Biscuit, Abrasives, Bulk Drugs, Cattle bolster, Ceramic Industry, Metal Powder, Agro and seed Processing, Master clusters, Paper and Pulp Industry, Pharmaceuticals, Spices and minerals, Petrochemicals, Rotomolding and reprocessed granules, Pesticides and Insecticides, Paints and powder covering, Talcom powder, Ayurvedic solution, Cosmetics, Chemicals, Carbon and graphite, Chocolate, Dehydrated nourishment, Dry organic products, Dyes and shades, Engineering, Flour plant and foundry, Guar gum, Grains, Refactory, Glass dots, Metal powder, Tea, Slurry, Rubber.

...more

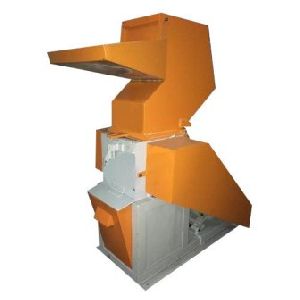

SCRAPE GRINDER

FEATURES Hearty and Heavy steel development body, Operation at less vibration. Enduring and upkeep free operation. Higher yield at low power utilization. Simple evacuation of screen for cleaning. Extensive variety of models for better determination. Rotory blades composed with scissors cut activity and powerful slicing edge to guarantee viable crushing. Granulating blades are produced using extraordinary compound steel and solidified for longer existence with simple alteration office. Side encouraging connection for channels and material stacking can be offered as discretionary. Granulating screen, top opening ,sustaining connection are intended for simple opening ,support and change. Exceptional composed Rotor sort processor reasonable for crushing of assortment of materials including Injection Molded articles, Blow Molded articles, Rotational formed, Pipes, and so forth. APPLICATIONS Blow formed articles like jugs, Jerry jars, drums, jars.etc. Infusion Molded empty articles like cans, wicker bin, cupboards, and so on. Rotational Molded Articles, piece of Plastics tanks. Funnels from channels dia 20 mm to 200 mm OD,

...more

PVC Pulveriser Machine

PVC Pulveriser Machine manufacturer PVC Pulveriser machine manufacturer in Ahmedabad, Gujarat and all over the india since 2001. Operation PVC Pulveriser machine manufacturer Finish Robust and exceptionally solid structure for sound and vibration operation. Attractive sort vibrating feeder for uniform and controlled bolstering of material. Primary Grinding circle of unrivaled review material for longer life. Exceptionally viable water cooling framework for Blade, Mill body and Bearing lodging. Temperature checking of Disk Mill and in this way simplicity of control on bolster rate. Vibratory Roller screen for fine re-beating obviously materials. Powder covered Electrical board with clean evidence development furnished with all wellbeing highlights and controls. All segments and purchased outs parts are of presumed and dependable make PVC Pulveriser machine manufacture. Finish Design with adaptability and perform fine pvc Pulverizing machine manufactuer in ahmedabad, gujarat and all over the india. of extensive variety of plastics materials like PE, RPVC, ABS, PC and other warmth delicate materials. Plate and plant body PVC Pulveriser machine manufacturer The circle is produced using reviewed material tried quality and progressively PVC Pulveriser machine manufacture adjusted for smooth running. Review windows (2 nos.) Are given on both side of factory body for outwardly checking the circle hole and help the hole setting. A few choices are accessible to disentangle the cleaning procedure. Long administration life of the circles between resharpenings. Features PVC Pulveriser machine manufacturer Cooling: For process body, bearing lodging and plant entryway for better outcome. Bearing lodging: Bearing lodging water cooled. Metal locator: High efficeincy container magnet give the m/c. To recognize the metallic consideration parts from the polymer. Alternatively, PVC Pulveriser machine manufacture metal indicator sensor will be given on ask. Bolstering: Feeding container demonstrating low level pointer. Auto stumbling framework available in the event of over-burden nourishing. Fundamental engine ampere and sustaining gadget synchronized to abstain from stumbling of engine due to over bolster Violent wind: Our cyclonic framework is very much intended for simple cleaning. With pack channel (on request)arrange ment of PVC Pulveriser machine manufacture. Container loader: Pneumatic container loader will give on ask. Execution: Uniform molecule measure for better dispersion Ideal material dissemination Homogeneous material if there should arise an occurrence of shaded powders. Low vitality utilization and high throughput PVC Pulveriser machine manufacture. Powder temperature observing gadget . Diagram :PVC Pulveriser machine manufacturer Kunti machine is satisfied to present PVC Pulverizer Machine manufacturer itself as a main assembling unit occupied with the matter of npu/k-10 demonstrate pulveriser. The scope of pulveriser is accessible from 30 kgs/hr to 500 kgs/hr. For various application, any place a powder item is required. Application : PVC Pulveriser machine manufacturer Run of the mill uses of npu/k-10 pulverisers are the crushing varietes of these granulated material including high and low thickness plastics like: PVC Pulveriser machine manufacture Ldpe (16 mama 400 ipcl review for material and wire covering), Lldpe, hdpe (26500 dependence review for ace group) Lldpe (36ra 0345 ipcl review) Rpvc, pc, abs, eva,ps, and so forth. pvc pulverizing machine is used in above application area.

...more

Plastic Tank

Loft Tank

ice box

House Hold Drum

Dustbin

Commercial Vertical Tank

Chemical Tank

axial machines

Agglomerator

The Agglomerator works in “clumps” and the handling chamber is stacked earlier and amid the procedure. The high-vitality cutting edges shred the plastics stacked material and press it under the rotor because of its plan. The grinding warms being created amid the operation . which warms up the plastics material up to the preparing temperature. At this temperature the material turns out to be very thick. In this manner frosty water is infused into the procedure which makes the material densify. This Agglomerator are additionally outstanding with other wording names like Film compactor, Film densifier, Film washer, Turbo washer.

...more

Shuttle Rotomolding Machines

Pick it for high volume generation (past 15000L/4000USG) Furnished with machine controls and vital interlocking Furnished with security gadgets and pointers and cautions Chip based machine control board with show Discretionary PLC for finish mechanization Condition benevolent burners appropriate for LPG/CNG/Duel Fuels Alternatively configuration warming chamber for vitality productive warmth exchange to the molds for quick and short process duration Extraordinary protection material for better workplace. Straight arm with four shape singular bearer for uniform thickness. Inbuilt shape situating and adjusting office Office to include Extra station for higher creation

...moreBe first to Rate

Rate ThisOpening Hours