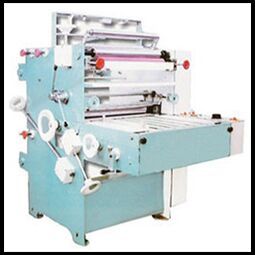

Extrusion Lamination Plant

Get Price Quote

1 Piece(s) (MOQ)

We are offering poster paper lamination, extrusion lamination plant. remica extrusion lamination plant for poster/chromo paper lamination with sandwich

Both Side Bopp Sandwich Lamination Plant

Get Price Quote

01 Set(s) (MOQ)

We are offering both side bopp sandwich lamination plant. fuma multi-function extrusion coating laminating machine is developed continuously by ourselves, based on our production experience of more than fifteen years. It is characterized by advanced technique, reliable quality, easy to operate, and high automation, which is used widely in the industries of chemical, petrochemical, cement, sugar , salt, grain and wheat, animal feed, commodity items, metallurgy and mining and general purpose packaging, storage and transportation of many kinds of materials. The line uses pp or pe as raw material, through the flow-casting coating and lamination technology, achieving single-sided double-sided coating or paper-plastic lamination with substrates (plastic woven fabric), to produce coated or laminated products. The line is equipped with advanced electrical and mechanical devices throughout the whole production flow from substrate unwinding, lamination to winding, to achieve single control and group control. The dual-station unwinder uses automatic web guiding control for substrates, and brakes for surface tension control of substrates, achieving pneumatic splicing and non-stop roll changing. The laminator is equipped with preheating roll (optional) for preheating and drying of substrates. Laminating roll, silicon rubber roll and press roll are of dual-interlayer forced water cooling structure, with excellent cooling effect. The dual-station winder adopts constant-tension surface friction winding, pneumatic transverse cutting, roll changing without shutdown, and equipped with adjustable edge-trimming device, edge-strip blowing device, and length counting device.

Best Deals from Lamination Plants

extrusion coating laminating plant

Get Price Quote

Extrusion Coating Lamination Plant

950,000 Per Units

1 Units (MOQ)

extrusion lamination plants

Get Price Quote

extrusion lamination plants have been developed for ldpe / pp extruded film lamination on woven sacks / knitted bags, woven fabrics, bopp, paper, aluminium foil, pre-printed bopp, non wovens, jute, tarpaulins, geo textiles & many other applications.. salient features :- extrusion lamination and coating plants with high speed high production upto 200mts/min for flat and clircular woven fabrics. Sandwitch lamination of printed bopp. Polyster, paper, jute, non-wovens, cotton fabrics, woven sacks, fabrics, aluminium foils and tarpaulins. our highest selling, proven and versatile high speed high production extrusion lamination plants for laminating, woven sacks, jumbo bags and fibc fabrics, sandwitch lamination of bopp/polyster , cpp, paper and aliminium foils, now available with mixtrude ™technology

Adhesive Coating Lamination Plant

3,251,000 Per Piece

1 Piece (MOQ)

Tandem Lamination Plant

Get Price Quote

The offered Tandem Lamination Plant manufactured using premium quality raw materials and cutting edge technology under the guidance of a skilled expert. Pioneer manufacturer, exporter and supplier of the Tandem Lamination plant in Ahmedabad, India. This Lamination plant is available in various sizes, design according to customized specification. For ensuring its functionality our quality expert thoroughly tests this tandem lamination plants against numerous parameters to meet the Industry standards. Additionally, we are offering this Tandem Lamination plant to clients at cost-effective prices. FEATURES OF TANDEM LAMINATION PLANT: Hassle free performance High quality Cost effective Lower power consumption Less maintenance

Paper Lamination Plant

5,200,000 Per Piece

Paper Lamination Plant

Get Price Quote

Paper Lamination Plant We put forth a range of extrusion coating Lamination Plants, which find wide application in areas like cotton cloth, hessian cloth, aluminum foils, HDPE woven Fabric for bags, Tarpaulin and paper lamination. } It comprises a nitrated screw and barrel made out from special nitro alloy steel, which ensures longer life and trouble free operations.It is equipped with PID temperature controller and helical gear box with inbuilt thrust bearing. Other distinguishing features of the lamination plant are as follows: Coating width up to maximum 18 feet Higher production capacities ranging from 100 kg/hr to 350 kg/hr (Depending upon the application) Super fine coating as per required square meter Center winder or surface type winder system Special winder facilities that make 2 meter fold from 4 meter laminated cloth AC frequency drive with synchronized system

Extrusion Coating Lamination Plant

Get Price Quote

Extrusion Coating Lines (Lamination Plant) : For coating thin layer of polyolefin's (Mainly LDPE / PP) on substrates like Paper, Cotton Cloth, Woven fabrics, jute fabric, Aluminum foil, BOPP film, Polyester film, etc. Tandem Lamination Plant For coating Circular Woven fabric, for producing multi layer laminates up to 2 layers along with the various substrates like Paper, Aluminum foil, Polyester film etc.

Lamination Plant

Get Price Quote

This is the most important extrusion machinery for extrusion coating and lamination work. The extrusion coating lamination plant is used in various industries for lamination like paper, fabric, jute, aluminum foil, polyester etc. for effective and efficient coating and lamination. Lamination Plant is used in wide spectrum of plastic processes to form a continuous profile and plastic products. We are engaged in offering a wide array of Extrusion Lamination Plants. These plants are designed & developed in line with the set industry extruders. Further, our offered plants are tested stringently on the basis of several parameters that ensure their flawlessness. Our products are fabricated under the strict supervision of our diligent quality controllers. These lamination plants are find wide application in areas like cotton cloth, hessian cloth, aluminum foils, HDPE woven Fabric for bags, Tarpaulin and paper lamination. Features: Accurate in design Resistant to corrosion Durable Cost effective

Extrusion Coating Lamination Plant

Get Price Quote

We are one of the eminent manufacturers and exporters of a comprehensive range of extrusion coating lamination plant manufacturer india, extrution machines for pvc and pp that is specially designed to cater to the requirements of various industries, where high productivity is required. Manufactured as per international quality standards & norms, our range is widely appreciated by the clients due to its durability, reliability, accuracy, high performance, low maintenance, high efficiency and sturdy construction. Available at industry leading prices, our range can be customized as per the specifications given by our esteemed clients.

Extrusion Lamination Plant

Get Price Quote

Extrusion lamination plant indigenously developed using unique and latest technology. Machine with better business sense upgraded quality of extrusion system with high productivity, long durability, great efficiency and top performance to meet customers expectations.Remica Lamination Plants for Tarpoline food packaging, non-food packaging, pharmaceuticals, etc. OPTIONAL ITEMS: 1. Ancher coater2. Tension control on unwinder and rewinder through lode cell.3. Sandwich lamination unit.4. Web aligner.5. Pre heating rollers.6. Turn bar arrangement,7. Matt finish chill roller etc. APPLICATION : 1. LDPE coating on HDPE woven fabric/paper/sandwitch and jute.2. PP coating on PP woven fabric.

Extrusion Coating Lamination Plant

4,200,000 Per Piece

1 Piece (MOQ)

Extrusion Coating Lamination Plant

Get Price Quote

Wide range to cater different lamination application of HDPE & PP Woven Fabric, BOPP Film, Paper, Aluminum Foil etc. Optimum product costing due to high productivity with less power consumption Nitrided screw and barrel made out from special nitro alloy steel for long life and trouble free operations Helical gear box with inbuilt thrust bearing Uniquely designed coat hanger type 'T' die with uniform flow distribution Manual lever type screen changer Load cell based auto web tension control in unwinder Heavy duty safety chucks with airshaft Web aligner unit Crease removal banana roller Lamination unit forwardreverse & updown arrangements Centre type, surface type & turret type winding options Microprocessor based PID temperature controller Synchronization of all AC motors

Extrusion Lamination Plant

Get Price Quote

Looking For 25 KgHr. Extrusion Coating Lamination Plant, We are looking for 1500 mm width extrusion plant with T die and two unwinders.

HDPE Tarpaulin Lamination Plant

4,450,000 - 45,000,000 Per Piece

Extrusion Coating Lamination Plant

Get Price Quote

With the support of our excellent professionals, we have been able to offer extrusion coating lamination machine. This lamination machine is developed using top quality material and progressive technology in tandem to universally verified standards. Besides our offered lamination machine is highly demanded by our clients for its long operational life. It is characterized by advanced technique, reliable quality, easy to operate, and high automation, which is utilized broadly in the enterprises of chemical, petrochemical, cement, sugar, salt, grain and wheat, animal feed, commodity items, metallurgy and mining and general purpose packaging, storage and transportation of many kinds of materials. extrusion coating lamination machine is an appropriate solution for producing exceptionally thin coating layers made of PP, LDPE. This lining material will then be added to packaging components like woven sacks, giant size bags, aluminum foil, cotton and jute fabric bags, etc. Leena Extrusion is a foremost extrusion coating lamination plant manufacturer and our lamination plant will remain a revenue making investment as the machine components are made of reliable and quality materials. With the industry’s most versatile equipment platforms, we deliver cost-effective extrusion coating packages to support construction, consumer products and packaging industries.

Extrusion Coating Lamination Plant

Get Price Quote

Coating Width : 4 feet to 16 feet Bag Tarpolin, Paper Lamination With & Without Turn bar attachment & Sandwhich attachment Optional : Turret Type Winder or Surface Winder,auto winder

Extrusion Lamination Plant

Get Price Quote

Lamination line material adds superior protection for products when they are packed. Extrusion coating lamination plant is a suitable solution to produce very slim lining layers made of PP, LDPE. This lining material will them be added to packaging components like woven sacks, giant size bags, aluminum foil, cotton and jute fabric bags, etc. Ocean Extrusions is a leading extrusion coating lamination plant manufacturer and our lamination plant will remain a revenue making investment as the machine components are made of reliable and quality materials.

Paper Lamination Plant

Get Price Quote

Paper Lamination Plant, Extruder Machine, Cold Aggregate Bin Feeders

Extrusion Coating Lamination Plant

Get Price Quote

Extrusion Coating Lamination Plant, Box Strapping Plant

Extrusion Coating Lamination Plant

Get Price Quote

Extrusion Coating Lamination Plant, Hdpe Tape

Lamination Plant

Get Price Quote

Lamination Plant, Pvc Pipe Plant, Pp Film Plant, Injection Moulding Machines

Paper Lamination Plant

Get Price Quote

Paper Lamination Plant, Piston Valves, Piston Valves, Paper Lamination Plant

Extrusion Coating Lamination Plant

Get Price Quote

Extrusion Coating Lamination Plant, Granule Dryer, extrusion die

Lamination Plant

Get Price Quote

Lamination Plant

Extrusion Coating Lamination Plant

Get Price Quote

Extrusion Coating Lamination Plant, air bubble sheet plant, Agglomerator

Lamination Plant

Get Price Quote

Lamination Plant

Extrusion Lamination Plant

Get Price Quote

Extrusion Lamination Plant, PP Tubing Plant, Plastic Granule Mixing Machine