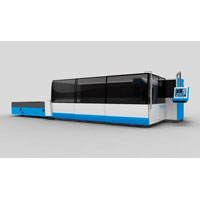

Laser Cutting Machinery

Get Price Quote

1 Piece(s) (MOQ)

We are offering laser cutting machinery. Laser cutting machinery works on the principle by heating the material at the focal point of the focused laser beam above its melting point. The resulting molten material is ejected either by a coaxial gas jet or the induced vapor pressure, thus forming the cut kerf. Laser cutting machinery is applied for different kinds of materials like stainless steel, mild steel, and aluminum etc. Where it require precise, fast and force-free processing. Lasers create narrow kerfs and thus achieve high-precision cuts. Compared to alternative techniques like die cutting, laser cutting machinery is cost-efficient already for small-batch production. Application of laser cutting machinery is as follow: 1) job & machine shop application 2) automotive industries 3) aerospace industries 4) metal profile art work 5) machine manufacturer 6) sheet metal application 7) fabrication work 8) defense advantage of laser cutting machinery: 1) co2 sealed slab laser technology. 2) laser pre-mix gas bottles not required. Saves cost and space. 3) no pre heating required prior to start. 4) 48 months pro rata warranty. 5) after refilling your warranty extends to another 48 months (same as new machine) 6) low operating cost (160 rs. Per hour approx.) 7) no moving parts, less maintenance. 8) low standby power consumption. 9) we provide meniscus focusing lenses.

Portable Fiber Laser Marker Machine

Get Price Quote

Features of Laser Marking Machine Emma EMMA laser provide a fast, flexible and efficient way to permanently mark a wide variety of materials such as, metals, plastics, ceramics and silicon.EMMA lasers are commonly used for identification and traceability marks such as serial numbers, date codes, manufacturers info, material flow, barcodes, 2D data matrix, logos, graphics & more.EMMA fiber lasers can be easily integrated into tabletop marking system automated manufacturing cells, and customized multi-axis machine tools. Depending on the specific application requirements. Features• First and last pulse equally useable.• Bitmap marking compatible.• High repeatability/stability design.• Status monitoring and safe shut down.• High speed marking (MHz repetition rate). • Long using time : the average using time more than 80000 hours.• Good Stability and free maintenance : No need to Maintenance for laser device.

Best Deals from Laser Marking Machine

FIBER LASER TECHNOLGY

Get Price Quote

Fiber laser marking is a technique which uses computer-controlled laser beam to leave permanent mark on the surface of various kinds of object. The working principle of fiber laser marking machine is to use light amplication to cause chemical effect or burn part of the material to mark letters, symbols, bar codes, and other graphics on an object. Fiber laser marking machine is mainly composed fiber laser, laser scanning galvanometer and controller. The fiber laser has the advantages of small size, high quality beam, no maintenance and etc. The output center wavelength of fiber laser is 1064 nm and the life time is around 100,000 hours. Compared with other king of lasers, fiber laser has a long life. Advance Features1. Can mark both metallic and nonmetallic materials, especially those materials with high hardness, high melting point or brittle materials.2. High processing speeds, low operation cost, constant high quality and durability of the results, high flexibility in automation. Laser marking is a perfect choice for mass production.3. Laser marking is non contact type of marking so it doesn't produce stress on the materials. It will not alter the physical properties of the materials processed.4. Laser is a clean and safe process as it is chemical-proof, water-proof, oil, grease & fuel proof.5. As the laser beam spot size (after focusing) is small, the heat-affected zone is much smaller, thus allowing it to achieve fine processing that other conventional methods cannot.6. Laser Marking is a flexible process as one can mark texts, alphanumeric, logos, bar codes, graphics, images, 2D data matrix code, etc.7. It is a user-friendly and cost effective marking solution as virtually no consumables.8. Laser marking enhances the aesthetical & monetary value of products by making it more attractive & eye catching ApplicationsLaser marking machine is widely used in most kind of products in different industrials, such as integrated circuit chip, computer accessories, industrial bearings, watches and clocks, electronic and telecommunication products, aerospace parts, auto parts, home appliances, hardware tools, molding, wire and cable, food packaging, jewellery, and etc.

Fibre Laser Marking machine (EVAN 20)

Get Price Quote

1 Piece(s) (MOQ)

Features of laser marking machine evan evan laser provides a fast, flexible and efficient way to permanently mark a wide variety of materials such as metals, plastics, ceramics, silicon etc. features • first and last pulse equally useable • bitmap marking compatible. • high repeatabilitystability design. • status monitoring and safe shut down. • high speed marking (mhz repetition rate). • long using time : the average using time more than 100000 hours • good stability and free maintenance : no need to maintenance for laser advice high quality gray scale marking technical specifications of laser marking machine evan 20 model no. : evan-20 laser average output power : 20 w wavelength : 1064 nm power adjustment : 0 to 100 % cooling : air cooled min. Line : width min. 0.03 mm (depend on material) max. Speed : max. 10000 mms (max. Linear speed) marking depth : 0.01~0.3mm (depends on material) min character height : 0.5mm marking range : 145 mm x 145 mm(standard) optional : 175 x 175 mm & 300 x 300 mm supporting format : support plt, dxf, bmp file etc., using shx ttf character storage directly marking area : 145 x 145 (standard) 175 x 175 300 x 300 (optical) single pulse energy (mj) : 1 to 20khz repetition frequency range : 20-80 khz output power stability : < 3% beam quality(m2 ) : < 1.5 pulse width(ns) : < 130 to 20 khz power supply : dc 24 volt ac 220 volt max power consumption : 200 watt

Laser Engraver Machine

250,000 - 300,000 Per Piece

Cnc Glass Cutting Machine

3,500,000 - 4,500,000 Per piece1

1 Piece (MOQ)

Metal laser cutting machine

Get Price Quote

Metal laser cutting machine, Metal Cutting Machine, Water Jet Cutting Machine

worldcut laser cutting machine

Get Price Quote

worldcut laser cutting machine, Solvent Inkjet Printer, cnc engraving

Laser Machine

Get Price Quote

Laser Machine, Printing Machine, metal marking machine

Laser Cutting Machine

Get Price Quote

Laser Cutting Machine, water jet cutting, AC Drive > MFDDTB3A2 (5KW)

Fiber laser cutting machine

Get Price Quote

Fiber laser cutting machine, CNC PLASMA CUTTIG MACHINE

Laser Welding Machines

Get Price Quote

Laser Welding Machines, Laser Marking Machine, laser marking service

Laser Engraving Machine

Get Price Quote

Laser Engraving Machine, Cutting Plotter Machine, metal marking machine

Plasma Cutting Machine

Get Price Quote

Plasma Cutting Machine, Double Shaft U Mixture Machine