Woven Sack Tape Machine

Voltage : 380V

Country of Origin : Made in India

Twine Making Machine

700,000 Per Piece

Voltage : 220 V / 380 V

Power : 5.5 kw

Usage : Rope making

Weight : 2500 kgs

Material : Steel

...more

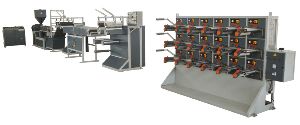

Twin Die Lamination Machine

Leena Extrusion is the manufacturer of a wide range of Twin Die extrusion coating lamination machine. We offer these machines in various dimensions and specifications. The characteristic that our machines offer make them unique with un-matching properties compared to any other dealer of lamination machine. These features include reliable quality, accurate dimension, easy operation and handling of machine and completely automated functions that enhance the speed of production. These machines are used in packing various substances like food, salt, sugar, commodities as well as products of petrochemical industry and mining industries. The Twin Die Extrusion Coating Lamination machine is equipped with various internal parts that perform all the process of laminating the material. They are capable to do multi-layer coating lamination on any material. This machine is embedded with the preheating area in it as well as cooling place where the material is heated and there after cooled when it is applied to the substance to fix it on that product. These machines are made in accordance with the industry specific standards to easily meet the domestic as well as international quality standards. We even offer customization in them to satisfy the customer and provide them with machines which accurately match their needs. We present these lamination machines in wide range of specification and very economic price range according to the modification in them. Features of Extrusion Coating Lamination Plant: Reliable working Accurate extrusion Cost effective Smooth performance Durability Variable dimension of coating and lamination Least maintenance Long service life Technical Specification

...more

synthetic string

Synthetic string was earlier made up of jute but now with the increasing demand of the string in the market, sutli string is made from reprocessed granules of PP material. In today’s world where there is a great problem of disposing the plastic materials, this synthetic string has become one of the best utilization of such waste plastic. The manufacturing of this string is done in special plant that have a series of machine to produce the final synthetic string. A normal sutli is manufactured from reprocessed granules that are passed through a T die where a sheet is formed which is then cut into number of lines and thickness that is desired by the client. Leena Extrusion has gained an unparalleled name in the market for offering premium quality range of synthetic (sutli) string plant. With the assistance of our valuable team of skilled team of professionals, we are able to provide a wide range of high quality sutli plant. The sutli is prepared in machine is used in all kinds of paper industry that need to pack bundles of items tightly. Thesynthetic string plant is manufactured using best in class materials and latest advanced technology. The production is supervised by our quality experts that handle and check the manufacturing process to offer a complete range of flawless sutli machine (synthetic string plant). Features of Sutli Plant: Robust construction Durable working Consistent performance High quality sutli Variable length synthetic string Adjustable dimensions Anti-corrosive Customizable features

...more

Sutli String Extrusion Plant

Brand Name : LEENA EXTRUSION

single die extruder

110,000 Per Unit

Phase : Three Phase

Material : Mild Steel

Brand Name : LE

Voltage : 380v

Country of Origin : Made in India

Frequency : 50 Hz

...more

Rice Bag Lamination Machine

The Lamination machine is used to add an extra layer of protection on the material. We have BOPP rice bag lamination machine that can accurately laminate the rice bags with a uniform layer of plastic material. This material can be set to a specific thickness as per the need of that bag. These machines are accessible in various specifications to fulfill the desires of our clients. We even provide various designs for the lamination film if the client wants to print anything on the bags. The speed of laminating the rice bags is high and makes the work faster and smoother. This improves the production capacity of the industry and helps them earn more profit. The main thing about our BOPP rice bag lamination machine that attracts the customer is its compact structure, great performance and customizable features. Being the top manufacturer of these bags we precisely understand the needs of our client and provide them with the best quality machine which can accurately meet their needs. This machine gives a uniform sandwich type layer of LDPE or PP material by melting it and then passing the rice bags through it so the layer gets uniformly attached on the bags. This gives an enhanced look of the bags that makes them attractive. The speedy lamination on the rice bags allows the industries produce a high qualityBOPP rice bag having great strength and moisture resistance property to protect the product from external atmosphere effects. Features of BOPP Lamination Machine Reliable High strength Robust and compact body Smooth finishing Moisture resistant High durability Least maintenance Economic rates Precise performance Technical Specification

Dimension (LxWxH) : 40’ L * 24’ W * 13’H

...more

PP Monofilament Extrusion Machine

1,500,000 Per Units

Voltage : 380v

Brand Name : LE

Country of Origin : Made in India

...more

Sutli Making Machine

700,000 Per unit

Automatic Grade : Automatic

Brand Name : LE

Voltage : 220 V / 380 V

Power : 5.5 kw

Application : Rope making

Weight : 2500 kgs

...more

Plastic Recycling Machine

600,000 Per Set

Brand Name : LEENA EXTRUSION

Capacity : Minimum 90 Kgs Per Hour

plastic processing equipment

45,000 Per Piece

Voltage : 280V

Country of Origin : Made in India

plastic pipe extrusion line

2,800,000 Per Piece

Brand Name : LE

Voltage : 380 V

plastic film machine

2,500,000 Per Piece

monofilament machine

Monofilament is a single strand string that is made up of various plastics or other materials. The most preferable material for making this string is PP and HDPE. The manufacturing of this monofilament is executed in special machines that can give proper shape and dimension to the string. The width of the string is kept according to the requirement of the client. This monofilament string is used in various applications like knitting net, shade net, agro textile, agriculture net, rope, etc. The PP HDPE is preferred for this monofilament because of its characteristic of being light in weight and excellent strength. PET monofilament machine We stand as the most reliable manufacturer of PET monofilament machine. Our company is backed by the assistance of a skilled team of professionals that help us offer a wide range of monofilament machine. PET is polyethylene Terephthalate is the most common thermoplastic polymer that can be reformed into different shape after melting it again and again. PET is a hard, strong and stable materials which absorbs very little amount of water. It is highly transparent and the width can be altered as per the application where these PET monofilament is used. Nylon Rope Making Machine Nylon is most commonly used for making rope because of its high strength and elastic stretch properties. We are recognized as the leading industry to provide best grade nylon rope making machine. Nylon ropes are used in various applications like mountain climbing rope, safety lines, fishing ropes, etc. Our offered machines are highly preferred because of the consistency and great output they give. These machines can make various dimensions of nylon rope whose dimension is decided by the client that suits their needs.

...more

LLDPE Pipe Machine

Brand Name : LE

Material : PP/LDPE/HM

LDPE Extrusion Machine

3,800,000 Per Unit

Brand Name : LE

Voltage : 380V

Country of Origin : Made in India

...more

HDPE Blown Film Extrusion Machine

1,000,000 Per Piece

Brand Name : LE

Extrusion Coating Lamination Machine

Leena Extrusion stands as the most consistent manufacturer of extrusion coating lamination machine of various types and dimensions that are set according to the international industry standards. We give our best in providing the supreme quality of machines that make the lamination process easy and smooth. In the process of extrusion we plastic is passed through a die that is kept according to the desired cross-sectional area. Backed by the support of our highly qualified team of experts, we manufacture the highest standard machines. This lamination machine is developed using top quality of materials that are purchased from the known retailers. We utilize the latest technology for fabricating to provide completely flawless machines. We offer extrusion coating lamination machine to apply a layer of plastic like polyolefin (LDPE/ PP) on various materials like paper, woven fabric, non woven fabric, aluminum foil, etc. Attributes of Extrusion Lamination Machine: Enhanced Service life Low operational cost Long service life Low maintenance Reliable performance Robust body Compact size Technical Specification

Usage : LDPE & PP

Dimension (LxWxH) : 40’L * 20’W * 15’H

...more

Double Die Lamination Machine

Since the beginning Leena extrusion is considered to be the most reliable manufacturer of double die lamination machines. The machines we offer are made using the best technology and materials to meet the international quality standards. These machines are having industry standards that are usually preferred in all the industries. Our lamination machines are famous for their unparalleled features like reliable quality, easy operation, complete automation, advanced technology and accurate dimension of lamination. They are made to improve the manufacturing process and fasten up the production speed to improve the rate of production. We make the double die lamination machine which can accurately laminate the material by meting the lamination material and then coating it on the substance. The main two processes that are conducted is melting the die and cooling it when applied to the product. To offer great quality we have a workforce of highly skilled professionals that work on the production process. This lamination gives an extra strength to the substance and adds a protection layer that protects it from any external temperature and atmospheric changes. Making use of the latest technology and features in the machine we strive to offer best double die lamination machine at the most competitive prices according to the features and customization done in the machine. Features of Double Die Lamination Machine: Robust structure Compact body Reliable functioning Faster lamination Long service life Automized working Cost effective price Smooth and uniform labeling Technical Specification

Capacity : 145-160

...more

Box Strapping Machine

Leena Extrusion holds expertise in providing Box strapping machine that helps packing of various products with ease. Our strapping machine is suitable for packing cartons, plastic cases, books, etc. They can be easily be used to pack all kinds of articles in different shapes like square, cylindrical and rectangular shape. We use highly qualitative raw materials for fabricating the machine. These machines are made under the supervision of our highly skilled professionals. PET Box strapping machine PET stands for Polyethylene Terephthalate which is a high density polyethylene. Our manufactured PET Box Strapping Machines are specially made from 100% recycled PET flakes. PET strap is a kind of substance which is wrapped all around arranged squeezing material that is used to substitute steel strip in many fields. We give great options to our clients from which they can select the one that exactly matches their needs. Our extrusion line is the most advanced technological solution for the production of PET box strapping machine. We are the top manufacturer of the best qualityPET box strapping machine. Box Strapping Making Machine Leena extrusion has developed a high-tech box strapping making machine that can make the straps from PP/ HDPE/ PET material. These machines are well equipped with the latest technology to produce the best straps for packing of various kinds of boxes used in industries. The production process of these straps becomes speedy with the help of our machine. These machines are made having great features like excellent tensile strength, splendid tension, and superior flexibility and are highly economical to use.

...more

Blown Film Plant

Leena Extrusion is the considered the most outstanding organization in the domestic as well as international market as a manufacturer of Blown Film Plant. The film in this is made by extruding the molten plastic through circular rollers. This film is made uniform by keeping the distance between the rollers constant during the whole process. The film blowing process consists of a various layers of stages that include extrusion, blowing, collapsing and winding the film on the roll after cooling it. We offer various types of Lamination Machine Multilayer blown film plant HM hdpe blown film plant PVC blown film plant Five layer blown film plant Extrusion blown film plant Multilayer Blown Film Plant Multi layer blown film plant consists of various layers of material that are coated with the substance. The number of layers in the plant can be varied as per the requirement. This helps to give various special features in the film like high flexibility and advanced barrier structure. This technology of multilayer increases the productivity and energy efficiency that helps to reduce production cost. In this various polymers are simultaneously extruded with each other to form a common die. HM HDPE Blown Film Plant HM HDPE is the abbreviation used for High Molecular High Density Polyethylene. It is renowned in the market because of its special features like high strength and toughness. We manufacture the best HM HDPE blown film plants that make the films through the blown extrusion process. This plant is requires to produce the best in class HM HDPE films that are useful in various industries. We offer a wide range of film plants that are made to laminate the substances. PVC Blown Film Plant The PVC (Polyvinly Chloride) blown film is used when the film to be extruded or laminated are made up of PVC material. This material is widely used for its durability and strength compared to other materials. The PVC material is melted and passed under the pair of rollers that are separated by a specific dimension that is the width or thickness of the film. The thickness of this PVC film can be altered in the blown film plant as per the needs. Five Layer Blown Film Plants The layer in the five layers is actually the materials that are to be mixed to form a single film. These layers are simultaneously processed to form a uniform shaped and sized film. We offer various specifications for the five layer blown film plant that are selected according to the material to be mixed and produce a perfect dimension film. These plants are manufactured according to the width that is required by the client. Extrusion Blown Film Plant Extrusion is a process when a material is melted and then it is passed through a roller and cooled so that shape is retained after cooling. This blown film plant is specially made to conduct the extrusion process effectively. They are made with best in class materials to ensure the quality of the machine and the output.

...more

air bubble making machine

2,800,000 Per Piece

recycling machine

Recycling of materials is a great problem in today’s world. To solve this problem there are various machines available in the market to recycle the waste. We at Leena offer a wide range of recycling machine to solve this problem. The machines are specially designed to recycle the paper waste and plastic waste like bottles, thermoplastic film. There is a specific type of machine for each type of waste that is to be treated. The machines are engineered under the supervision of our skilled quality check experts that ensure their quality, working and reliability. The plastic waste materials are treated in the plant and are compressed to reduce the waste disposal problem. The materials used to fabricate the machines are bought from the most reliable retailers in the market. The dimension is kept according to the industry standards notations and the features are embedded in them according to the improvement of the technology. They are even modified as per the need of the client to accurately meet their requirements. The Plastic Waste Recycling Machines are not just used to crush the waste materials but are also used to make granules of plastic also called Dana useful in household items, automobile parts, etc. The customer defines the size of the compressed plastic and waste particles. We offer a wide range of recycling machines. The range of machines we offer are: PP LDPE Recycling Machine PP Dana Making Machine PET Recycling Machine Plastic Waste Recycling Machine Plastic Reprocess Plant Die Face Cutter Recycling Machine Mother Baby Reprocess Plant

...more

Extrusion Tarpaulin Lamination Machine

The tarpaulin is a waterproof material usually used to cover goods during shipping. They are even used in transportation, construction, shelters, agriculture and sports activities. These tarpaulin need to be covered and laminated with other plastic materials to improve their durability and performance. We are the top manufacture of special extrusion machine for lamination of tarpaulin. These machines are made under the supervision of our highly skilled experts and trained professionals that handle the process of manufacturing the machine and ensure their accuracy.Leena provides the best extrusion tarpaulin lamination machine that are prepared from the best quality materials to give a strong, durable and reliable end product. Our industry is backed by highly skilled technicians and designers to make the most durable products. We have utilized latest technology to fabricate the machines that can give a uniform and smooth layer of other plastic material on the tarpaulin. The machine is fabricated following industry standards required all over the states for the extrusion process. We even provide modifications in the machines to improve the customer satisfaction and meet their needs accurately. These extrusion tarpaulin lamination machine are offered at the most compatible price compared to any other dealer in the market. Features of Tarpaulin Lamination Machine Robust body Smooth working Excellent features Reliable working Cost effective High efficiency Durable Least maintenance Technical Specification

...moreBe first to Rate

Rate ThisOpening Hours