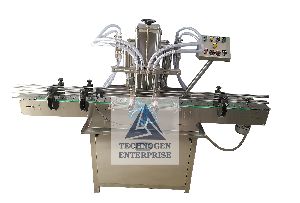

Automatic Liquid Filling Machine

Get Price Quote

As a dependable name, we source raw materials from the well-known providers who are certified. Thus, we guarantee only quality-approved products at customer's end. Owing to our expertise in the domain, we are able to supply excellent quality Automatic Liquid Filling Machine at very reasonable price. Features : Filling Accuracy on Single dose. Rigid vibration free construction for trouble free performance. S.S. elegantly matt finished body. Elegant and easy control panel for total control on an operation. Minimum change over time , from one size to another container or fill size. Reciprocating Filling nozzle with the self-centering device to avoid foaming. The unit is made compact & versatile -as per GMP norms. No container No Filling system to avoid Spillage. Synchronized A.C. drives for conveyor & main drive. Model no DALF- 100 (4 head) DALF-150 (6 head) Output/hour- 2500 to 6000 3500 to 9000 Electric motor - main machine 1 hp / 440 volts / 3 phase / 50 (four wire) conveyor 0.5 hp / 440 volts / 3 phase / 50 (four wire) Container size ø 30 mm to ø 100 mm, maximum height 210 mm Fill size 10 ml. To 500 ml. (with the help of required change part) Overall dimension 2035mm (l) x 1050mm (w) x 1400mm (h)

Automatic Liquid Filling Machine

Get Price Quote

Our Liquid Packing Machine is manufactured using high grade stainless steel, well known for its noiseless operation and negligible maintenance. Moreover, we provide customization as per the specific requirement of the clients inorder to meet their needs. We are also counted as the best exporter of Pouch Packaging Machine in India

Best Deals from Liquid Filling Machinery

Automatic groundnut oil filling machine

295,000 Per piece

packing Mineral Water Machine

Get Price Quote

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Automatic Six Head Liquid Vial Filling Machine

Get Price Quote

SBLFRS Automatic 6 Head vial filling with Rubber Stoppering Machine is a compact model used for filling and rubber Stoppering of Inject able liquid into vials. The incoming dry vial (sterilized) are fed through the Unscramble and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of S.S. 316 construction and both, glass as well as S.S. syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided for ’’No Vial, No Filling’’ operation. Syringes are mounted on eccentric block and driving through bottom main gear box. Volume can be either increased or decreased by increasing or decreasing stroke length of piston as per filling size. Syringes is having non return valve for sucking and delivering situation to avoid volume variation. Liquid will reach to filling nozzles through silicon transparent pipe. Nozzle will be having Up and Down movement with help of cam mechanism and it will come down when vial will be hold by star wheel for filling operation and starts filling when it starts to move up and after completion of filling operation, star wheel delivers four/six vials together on conveyor for rubber Stoppering operation. Stoppering unit consist of Star wheel, Vibrator unit and Bowl. The sterilized/autoclaved rubber stoppers stored in the vibrator bowl moves vertically to the rubber stopper chute. The vial is hold firmly by star wheel, which will be in continuous rotary motion and vial which is coming from filling unit get in to star wheel and move in rotary direction along with star wheel, during movement it will pick up the rubber stopper from the exit end of the chute and rubber stopper will be pressed by fix pressing roller, which is spring loaded. Then vial further move on conveyor and collected on out feed star wheel for next sealing operation.

Liquid Filling Machine Nozzle

3,500 Per Piece

Automatic Liquid Filling Capping Machine

Get Price Quote

Automatic Liquid Filling Inner Plugging Screw Capping Machine This automatic system comprises of a 3 stages indexing mechanism to perform a sequence of operations for Filling, Inner Plugging and Screw Capping. The unit is fabricated on rigid MS structure and cladded with SS Sheet to meet GMP requirements. All three operational stations are housed in a common acrylic cabinet to provide safe working zone. The unit is made compact & versatile with three operational stations of Filling, Inner Plugging and Screw Capping on a common center star wheel adjoined with in feed & out feed S.S. slat conveyor. Filling station consists of two / four reciprocating nozzles for peristaltic pump assisted dosing. Inner Plugging station consists of vibratory inner plug feeding device and pneumatic plug pressing unit along with pneumatic cap placement mechanism. Screw Cap sealing station consists of Vibratory screw cap feeding device along with and cap screwing unit with Rotary heads. Main drive, conveyor drive, servo capping drive & servo filling is synchronized PLC. Operation : Empty vials moving on the conveyor is fed to the center star wheel where all the operations of filling, plugging & screw capping will be performed in an indexing mechanism. Vial moves under the filling station and full dose of solution is filled in two stages under both the nozzles. Then it moves for the further operation of plugging where inner plug comes from bowl(s) through chute & being placed on the vial while it stops under the pneumatic plug-placing device, which operates in pair (in case of MPAFPC-100). Screw cap comes from the separate cap bowl through chute(s) and being placed in pair (in case of MPAFPC-100) on the plugged vial at next stop. Further moves under the capping heads where capping is done in pair (in case of MPAFPC-100) according to the pre set torque. Filled vials duly plugged & capped move on to out feed conveyor then. Salient Features : A very compact & versatile equipment for 3 in one operation. Unique for small volumes filling for Eye/Ear/Nasal drops. Smooth & efficient Filling-Inner Plugging & Screw Capping operations in one star wheel. Elegant matt finish body with acrylic enclosure on operational zone. Designed for low noise & maintenance less operation. Peristaltic pump assisted filling ensures accuracy of + 0.5 %. Pneumatic inner plug pressing & cup placement. All contact parts made of SS 316. Screw capping heads is designed to apply adequate torque. No bottle, No plug, No cap - machine stop system. Equipped with torque limiter to protect indexing mechanism. No bottle - No fill, No plug - No cap, No bottle - No plug system. PLC base operation.

SIngle Head Piston filler Juice filling machine

45,000 - 100,000 Per piece

1 piece (MOQ)

mineral water packing machines

Get Price Quote

Our range of products include Mineral Water Plant such as Packaged Drinking Mineral Water Plant, Reverse Osmosis Systems, Turnkey Project Mineral Water Plants, Reverse Osmosis Plant, Water Treatment System, Semi Auto Blow Moulding Machine and many more items. We are offering best quality Mineral Water Plant to our customers. Easy usage, durability, less maintenance, reliable performance and automatic as well as manual operation are some of the attractive features of the offered plants. These plants help in purifying and treating water and make it free for drinking. Quality management team has experts who check and evaluate this mineral water plants to guarantee its perfect functioning.

Ampoule Filling Machine

Get Price Quote

We offer our clients with ampoules Filling and Sealing Machine that is fabricated as per the industrial standards. ampoules Filling and Sealing Machine are available with in-built safety features for long term reliable operation. Further, ampoules Filling and Sealing Machine are also provided in customized specifications to meet the varied needs of the clients. Our range includes the following:- We are instrumental in offering automatic six head ampoule filling and sealing machine, model � ahfs-6. These are highly appreciated by our clients for the sealing pre mechanism and for the feature of no ampoules no filling. We offer precision engineered automatic four head ampoule filling & sealing machine, model ahfs � 4. automatic four head ampoule filling & sealing machines are manufactured using high quality components and are offered in customized solutions as per the needs of the clients. Further, automatic four head ampoule filling & sealing machine are available with a. C. Frequency drive that provides speed control for digital counter. In addition, we offer these with the pre sealing mechanism, which does not require ampoules or filling.

Automatic Volumetric Liquid Filling Machine

Get Price Quote

cGMP Vial Powder Filling Machine

Get Price Quote

Semi Automatic Liquid Filling Machine

Get Price Quote

Two Head Ampoule Filling Machine

Get Price Quote

Offers two head ampoule filling machine, two head ampoule sealing machine, ampoule filler sealer, single head ampoule filling machine, four head ampoule filling machine, six head ampoule filling machine, eight head ampoule filling machine, Ampoule Vial Jet Washing Machine, Ampoule Labeling Machine, Ampoule Inspection Machine by manufacturer and exporter of ampoule filling & sealing machine in Ahmedabad, India, Adinath International.

Automatic Four Head Vial Filling and Rubber Stoppering Machine

Get Price Quote

AUTOMATIC High Speed LIQUID Vial Filling & VACUUM Rubber Stoppering Machine MODEL: AHVF 4, 6 & 8 Description: High Speed Automatic Vial Filling & Rubber Stoppering Machine suitable for the filling & rubber stoppering of glass vials. Our Automatic Vial Filling & Rubber Stoppering Machine is widely uses in SMALL & large volume injectable preparations. Machine consist automatic feeding, filling, bunging & ejection system all complies as per cGMP requirements. Automatic Vial Filling & Rubber Stoppering Machine can be attached to Vial Washing Machine and Vial Cap Sealing Machine in order to complete online Sterile Vial Filling Line. Machine complies as per GMP requirements. Our standard machine equipped with stainless steel piston pump for the liquid filing, further we can also provide peristaltic pump for higher filling accuracy upon specific customer request. Salient Features: • Suitable for the filling Volume of 2ml to 250ml. • Piston pump/Peristaltic pump aseptic filling. • Filling with accuracy of ±0.5-1% • Filling with accuracy of ±0.5-1%. • All Contact Parts Made from S.S 316L & framework by S.S. 304. • ariable A.C. frequency drive for speed adjustment. • Digital Vial Counter for counting production output. • In-feed Turn Table/ Unscrambler for automatic feeding of objects. • On-line Mechanism. • “No Vial - No Filling” system. • “No Vial - Machine Stop” system. • IQ/OQ documentation can be provided Process Operation: The incoming dry vial (sterilized and siliconised) are fed through the unscrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of S.S. 316 construction and both, glass as well as S.S. syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided for 'No Vial-No Filling' operation. Syringes are mounted on eccentric block and driving through bottom main gear box. Volume can be either increased or decreased by increasing or decreasing stroke length of piston as per filling size. Syringes is having non return valve for sucking and delivering situation to avoid volume variation. Liquid will reach to filling nozzles through silicon transparent pipe. Nozzle will be having Up and Down movement with help of cam mechanism and it will come down when vial will be hold by starwheel for filling operation and starts filling when it starts to move up and after completion of filling operation, starwheel delivers six vials together on conveyor for rubber stoppering operation.

Liquid Vial Filling Machine

Get Price Quote

Juice Filling Machine

Get Price Quote

. This is a versatile filling machine can be used for water, fruit juice, liquid tea, liquid coffee, food coloring, milk and many more products to fill. Our liquid fillers are designed to handle all types of containers such as glass, metal, plastic. We offer filling machines with advance technology and advance features to our worldwide global clients.

Automatic Ampoule Filling Machine

Get Price Quote

The sterilized ampoule tray can be directly loaded in to slant hopper of the unit. The synchronized star wheel Delivers ampoules, one by one on moving eccentric ampoule rack in single or two's or four's. During the stoppage of rack sequentially pre-gassing Filling, post gassing, pre heating (for single and double head only) and final Sealing/annealing is achieved. At the end to the rack, optional synchronized pusher Pushes out ampoules in to tray in vertical position. The basic unit fitted with parts suitable for any size of Ampoule and any one fill size syringes. In the event of change over of each size of Ampoule, following change parts are required. The filling system includes filling syringes, made from stainless steel, pre & post gassing arrangements as well as mechanical "No Ampoule, No Filling" device. Filling is affected by aspirating filling product through the syringes, passing it by positive displacement through the non return valves, filling tubes and filling needles in to the ampoules. Fine setting of each filing syringe is possible. The machine is suitable for filling range from 1 ml to 20 ml. "No ampoule, No filling" system is advantageous to save the costly filling liquid. The sealing station is composed of the ampoule revolving station, sealing burners as well as draw-off jaws. The regulations of burner flames are made easier with the knob. The machine can be easily inspected and better accessed from the both the sides. The driving and controlling elements are protected from splinters, product spillage and jets of water. All the parts coming in contact with the filling liquid are made out of stainless steel 316 and can easily be cleaned and sterilized. The ampoules which are to be treated are fed from ampoule sterilization boxes to an inclined charging hopper. Alternatively, customer can make arrangement for feeding the ampoules directly from sterilized tunnel. Through the charging hopper the ampoules are passed in to ampoule feeding Wheel, which in turn transfers the ampoules positively to the ampoule carrying rack. Ampoules at a time are transported to the various processing stations. The ampoule carrying rack carries the ampoules at an angle of 52 degrees to the vertical, stroke wise. Two centering racks lift the ampoules from behind out of ampoule carrying rack for inert gas treatment and filling and sealing operation. The precision transport system ensures exact centering of ampoule necks at each working station. At the filling station, ampoules are filled accurately, at a time depending on no. of syringes. Filling is affected by aspirating filling product through the syringes, passing it by positive displacement through the non return valves, filling tubes and filling needles, in to the ampoules. Filling in the stationery position and exact centering of necks at the filling and gassing stations guarantees filling without moistening ampoules necks and uniform, safe closures. The sealing station is composed of the ampoule revolving station, burner station as well as draw off jaws. In the ampoule revolving station, the ampoules are rotated round its longitudinal axis. At sealing station, the ampoule necks are gripped by the draw off jaws and sealed when adequate plasticity of glass has been reached, the glass splinters are collected in the waste box.

Perfume Filling Machine

Get Price Quote

The filler is equipped with advanced technologies for Italy Costas fillers.It is safe and easy for operation.The machine is having quick filling speed.It is having large filling capacity. The machine is used to fill chemicals, fire fighting products and agricultural chemicals like perfumes, pesticides, hair oils, lubricants, antiseptics and LPG etc. Multipack is applicable for the outer clawing type capping of international universal 1 inch air valve caps. It is characterized by security, easy operation, high capping speed, excellent capping quality and tightness etc.

Automatic Liquid Filling Machine

Get Price Quote

APPLICATION & PROCESS : Automatic Volumetric Liquid Bottle Filling Machine works on volumetric principle with syringe & piston & nozzle. It is used to fill liquid in bottle in pharmacy, food, dairy, agro chemicals and Beverages industries. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Drives unit with syringe & piston, Reciprocating Nozzle with self-centering devices & No container No filling system arrangement is standard features of the machine. The main drive of the machine and conveyor drive consist of gear motor with synchronized variable drive. Containers moving on S.S.304 Slat conveyor from turn table or washing machine, feed below the filling nozzles through a settable twin pneumatically operated stopper system. The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. Liquid suck by syringe & piston assembly and fill in bottle through nozzle. Filling doze can be adjustable by eccentric drive block. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards slowly from bottom level of bottle towards neck during filling. SALIENT FEATURES : Designed as per cGMP - Current Good Manufacturing Practices compliance All contact parts AISI 316 & non contact parts AISI 304. Filling dose easily set by dosing block & pin. No Container - No fill system to prevent spillage of material. Rigid vibration free construction for trouble free performance. +_1% filling accuracy on single dose. Minimum change overtime, from one size to another container or fill size. UHMW-PE guide profile for SS slat belt provides smooth noiseless & frictionless working. Bottle stopper arrangement by Pneumatic system. Synchronizes filling drive with conveying drive with VFD. Drain tray around machine platform. Drip tray under the conveyor. OPTIONAL FEATURES : Flame proof Electricals. Automatic chain washing system for conveyor belt. In-built pre-inspection. Acrylic cabinet. Pre/post Nitrogen flushing arrangements. Float tank (Holding tank) with or without stirrer.

Drinking Water Packaging Machine

Get Price Quote

Manufacturers and exporters of bottle filling machine, automatic filling machine, liquid filling machine, drinking water filling machine, oil filling machine.

Liquid Filling Machine Nozzle

Get Price Quote

Liquid Filling Machine Nozzle

Inline Liquid filling machine

Get Price Quote

Competencies » Total CGMP model » Frame Made from SS-structure. » Sleek sturdy and compact design » Fully Automatic machine » All controls from panel » Left to right and right to left options available » PLC-HMI touch screen Features » No bottle no fill arrangement » No Bottle change parts required » Bottle is centered under the Nozzle » Bottom-up filling for foaming liquid » In bottom up filling, Nozzle is inserter in the mouth of bottle and are slowly lifted to original position. » Top filling for other liquid » Liquid is dispensed to bottle from nozzle » Very high dosing accuracy due to piston dosing method » Parts can be easily declamped / clamped for quick cleaning and changeover » Completely fail safe design Accessories » Flow controller » Liquid tank » Pre/post Check weigher » Pre/post Inspection unit Utilities » 415V, 3-phase, 50hz electric supply » Electric load:- 2HP » Air:- 1 CFM @ 4 to 6 kg/cm2 FEATURES » Synchronisation with nitrogen purging. » Electronic level controller and pneumatic product in feed control » Model with peristaltic pump/servo motor » Monoblock machine for Screw capping/ROPP capping APPLICATION » To fill liquid in Plastic/Glass bottles and simultaneously seal them with Screw/ROPP cap » Machine series-A suitable to fill 5ml to 250ml » Machine series-B suitable to fill 250ml to 1000ml » Bottle Diameter:- 30mm to 80mm » Bottle height:- 50mm to 150 mm

Liquid Filling Machine

75,000 Per Piece

SOLVENT BASED FILLING MACHINE

Get Price Quote

SOLVENT BASED (LIQUID) FILLING AND SEALING MACHINE Basically machine is designed for filling and sealing solvent base ink cartridge. One of the main features of this machine is it does not have any air presence in cartridge. Usually these sealed cartridges are used in flex hoarding. Solvent pour through glass flax mounted on the top of Machine to pre-formed pouch which also mounted in the machine. Finally filled ink pouch sealed after press the foot switch with zero air presence. ALSO KNOWN AS INK POUCH PACKING MACHINE

Bottle Liquid Filling Machine

Get Price Quote

We are engaged automatic Liquid Filling Machine manufacturer and exporter in Ahmedabad, Gujarat, India. Liquid Filling Machine is used for filling of liquid products in a wide range of consumer packs with highly accurate volumetric displacement pump based system, ensuring high speed and easy changeover. Being a quality oriented organization, we are engaged in manufacturing, exporting and supplyingLiquid Filling Machine that is used for filling liquid in containers, bottles, etc. Offered machine is manufactured at our advanced manufacturing unit under the guidance of our deft professionals using the finest quality components and contemporary technology. It is suitable for filling of shampoos, lotions, syrups, sauces and oils. We offer the provided Liquid Filling Machine in differed specifications to meet the variegated requirements of our clients at rock-bottom prices.

Ampoule Filling Machine

Get Price Quote

We offer precision engineered Automatic Four Head Ampoule Filling And Sealing Machine. These ampoule filling machines are manufactured using high quality components and are offered in customized solutions as per the needs of the clients. Further, these are available with A. C. Frequency drive that provides speed control for digital counter. In addition, we offer these with the pre sealing mechanism, which does not require ampoules or filling. The machine built on principle of Slant travel of ampoules while filling and sealing. to take care of wide variation of ampoule neck dimensions, thicknesses and ovality of available in globe ampoules.

Liquid Filling Machine

Get Price Quote

We are offering liquid filling machine. we are leading supplier and exporter of liquid filling machine - semi automatic filling machine - auger filler machine - automatic liquid filling machine - pouch making machine - votator - capping machine - labelling machine - induction sealing machine

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

SALIENT FEATURES + 1% Filling Accuracy on single dose. Rigid vibration free construction for trouble free performance. S.S elegantly matt finished body. Elegant and easy control panel for total control on operation. Minimum charge overtime, from one size to another container or fill size. Automatic washing of conveyor belt[ optional. No container No filling system – to avoid spillage. Pneumatic control bottle stopper. cGMP Model.