Liquid Filling Machine

Get Price Quote

This type of filler is best suited for liquids with very thin viscosities that do not change with ambient temperature or with batch variation. This machine is also suited for applications where recirculation of the liquid in the fluid path is not desirable. Although this type of filler is used predominantly on products that do not foam, foam may be limited and controlled by subsurface/bottom-up-fill capability. EXAMPLES: Water, solvents, alcohol, specialty chemicals, paint, inks, corrosive chemicals i.e. acids and bleach ADVANTAGES: This is the most economical type of filling machine for a limited range of applications. It is especially well suited for corrosive chemicals.

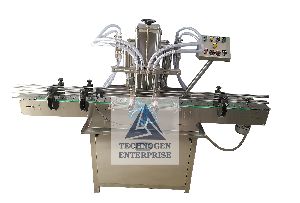

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

SALIENT FEATURES + 1% Filling Accuracy on single dose. Rigid vibration free construction for trouble free performance. S.S elegantly matt finished body. Elegant and easy control panel for total control on operation. Minimum charge overtime, from one size to another container or fill size. Automatic washing of conveyor belt[ optional. No container No filling system – to avoid spillage. Pneumatic control bottle stopper. cGMP Model.

Best Deals from Liquid Filling Machinery

Automatic Soda Bottling Plant

1,150,000 Per Piece

Milk Filling Machine

Get Price Quote

1 Unit (MOQ)

Flavoured Milk Filling Machine The Milk Filling Machine is a cutting-edge solution for 200-ml glass and PP bottles with up to 120 bottles per minute output speed. Key Features Precision Filling Technology: Our milk bottling machine ensures accurate and consistent filling of milk bottles with minimal product waste. User-Friendly Interface: Our milk bottle fillers feature an intuitive interface for easy operation and control. The user-friendly design enables quick setup and adjustment for a smooth production flow. Versatility in Bottle Sizes: Our machines fill various bottle sizes efficiently. Whether you are filling small or large milk bottles, our equipment adapts to your specific needs. Robust Construction: High-quality materials and components are used for reliable performance with minimal downtime and high-quality production. Tailored Solutions: Harikrushna Machines understands that every dairy operation is unique. Therefore, we offer tailored solutions per requirement, ensuring a perfect fit for your production line. Compliance with Industry Standards: Our machines adhere to the highest industry standards and regulations, ensuring that your milk packaging process meets all necessary quality and safety requirements.

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

2 Head Servo PLC Liquid Filling Machine

260,000 Per Piece

1 Piece (MOQ)

2 Head Servo PLC Liquid Filling Machine Are you looking for good quality 2 Head Servo PLC Liquid Filling Machine for your company? If yes, we at Purvaj Pharma Machinery can serve your needs with the delivery of the best quality products and services. We are engaged in the Manufacturing and Exporting of high-quality Industrial Machinery. Our machines work flawlessly for filling up bottles of Shampoos, Shower gel, lotions, liquid soap, oils, dishwashing liquid detergent, honey, syrups, beverages, and pharmaceutical & chemical liquids. Our machines are highly efficient and powerful to complete the job within the fastest time possible. Contact us now for more information.

Two Head Vial Liquid Filling Machine

100,000 - 500,000 Per piece

1 Piece (MOQ)

Automatic Vial Filling And Bunging Machine

1,500,000 Per piece

1 piece (MOQ)

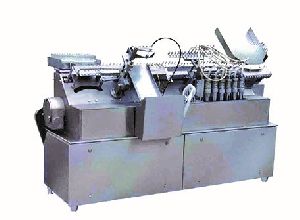

Ampoule Filling and Sealing Machine

Get Price Quote

The High Speed Ampoule Filling and Sealing Machine is majorly used for filling and sealing of glass ampoules of all types. The Ampoule Filling Machine is essentially designed for the purpose of usage in industries like biotech, pharmaceutical, cosmetic and chemicals. Multi Pack Machinery offers standardized solutions as well as customized machinery as per the requirement of a particular customer. The machine is built using slant travel of the ampoules during the filling and sealing processes. This helps in taking care of diverse types of ampoules that vary from each other in terms of thickness or dimensions etc. The sterile ampoule filler sealer is built of stainless steel with matt finish on it. The large mouth of the machine enables the user to clean the ampoule filler sealer with ease. The electrical control panel is made in a pendant style to ensure safety is taken care of at every point Has a compact GMP modelling Production output varies from 30 to 150 ampoules per minute Every part is made of high quality stainless steel The machine is ideal to fill 1 to 20 ml ampoules No ampoule and no filling system is adopted Ampoule centering of neck is done while the operations of flushing and filling are carried out Nitrogen gas flushing possibility Full accessibility to every part ensures that the machine can be easily cleaned and maintained Pre warming station exists Minimum change over time is required

VOLUMETRIC VIAL BOTTLES FILLING MACHINE

Get Price Quote

Automatic volumatric vial bottles filling machine is working on the volumetric principle. The machine consists of diving nozzles. The machine is made up of stainless steel matt finish body. It is compact and versatile. HOW IT IS SIMPLE AND QUICK : There is a twin pneumatically operated stopper system with feed below and filling nozzles. The conveyor belt moves the container to the filling nozzles. The reciprocating nozzles and stopper system can match for centering of the container below nozzles, to avoid the wastage of the liquid. The nozzle goes upwards from the bottom level to minimize the foaming. The fill size can easily set with a hexagonal bolt, below the syringe. THE FEATURES : Very much accurate, ±1% filling accuracy. Vibration free construction Error code display The platform is provided with drain tray round it, and drip tray under the conveyor The perfect pneumatic arrangement for bottle stopping The conveyor gear box, motor and pneumatic cylinders are provided with the safety guard. To prevent from the short circuit and over load, the MCB is given. For the voltage fluctuation and short circuit in A/C frequency drive there is inbuilt protection, with machine No bottle no filing system Trouble free performance with low maintenance Easy control panel Low friction wear surface, smooth and noiseless conveying. It takes minimum time to change the apparatus The bottle height gauge is adjustable for the quick and easy setting The height of the conveyor belt is adjustable to align with other machine of the line No container no cap arrangement The single A/C drive is synchronizing the platform turret and capping bowl, conveyor and star wheel. The conveyor, star wheel and platform turret is synchronized by the single motor. The S.S. matt finished body S.S. cladding or hard chrome plating of all exposed parts. The UHMW-PE guide profile for low friction wears surface. It is self lubricating leads smooth and noiseless conveying. Depending on the gauges and size of caps, the sealing pressure can varied Noise level and power consumption are very low SPECIAL FEATURES : The washing system of automatic chain for the conveyor belt There is afloat tank( holding tank) with or without stirrer In-built pre-inspection Nitrogen flushing Acrylic cabinet The cover of the conveyor is of acrylic UTILITY REQUIREMENT : Electrical Supply : Three Phase + Neutral + EarthingElectrical Load : 2 KWAir Pressure : 6 bar pressure 0.5 CFM

Glass Vial Liquid Filling Rubber Stoppering Machine

215,000 - 2,850,000 Per Piece

1 Piece (MOQ)

Glass Vial Liquid Filling & Rubber Stoppering Machine is suitable for Round Vials with maximum speed of 240 Vials per minutedepending on nature of Liquids, Vial Neck Size, Fill Volume and Rubber Stopper size. Machine construction in fully Stainless-Steel finish including machine frame structure. Machine with built-in Turn Tables at In-feed and Out-feed with individual drives to match the speed of incoming and outgoing vials for smoother operation. All parts coming in contact with Liquids and Rubber Stoppers are made from SS 316 Materials. Machine also available with vaccumetric type Rubber Stoppering System. Special Features: Total Controls on your figure tips. Servo based filling volume adjustment. Easy to adjust filling volume from PLC screen. Easy to maintain and changing spare part, changing format form for different vial sizes. Suitable for the filling Volume of 2ml to 100ml. Volume adjustment by pic controls. Provision of Manually fine volume adjustment Higher accuracy with higher speed due to servo control continuous motion. Provision of half and full stoppering. Inbuilt Scrambler &Unscr ally or fully stopper filled vials. Vial filling machine shall be equipped with eject collect tray for un stopper Vials. Provision for inert gas purging – pre and post the filling. Rejected without stopper vial shall be store in a safe condition, Vial filling machine shall perform the following functions. Vial half stoppering. Nitrogen purging (pre and post fill). Fallen vial eject, no stopper ejects. Ambler with rejected vial collect facility. Rigid vibration free construction for trouble free performance Pick and place type stoppering machine Vial filling machine shall be equipped with pumps with an accuracy of 0.5 on the fill volume. Suitable for Plain as well as Slotted Stoppers, with the help of change parts High Precision manufactured Syringes (2 Nos.) Servo Motor driven Syringes

Automatic Ampoule Filling Machine

Get Price Quote

Semi Automatic Liquid Filling Machine

Get Price Quote

4 Hard Automatic Liquid Filling Machine

Get Price Quote

Backed by a team of diligent members, we are one of the outstanding Manufacturers and Suppliers of 4 Hard Automatic Liquid Filling Machine. Made from authenticated components and high grade steel, Hard Automatic Liquid Filling Machine is known for its flawless design, smooth functioning and long service life. We are trusted by our clients for competitive prices and capability of delivering all orders in the set time frame.

Liquid Filling Machine

Get Price Quote

Gained prominence in the industry as a reliable organization, we are engaged in providing Automatic Liquid Filling Machine. Widely demanded in food processing, beverages and dairy industries, our offered filling machines are provided in various specifications. These machines are delivered timely to gain maximum client-satisfaction. Features: Trouble-free operations Longer service life Energy efficient design Salient Features: ± 1 % Filling accuracy on single dose Rigid vibration free construction for trouble free performance S. Elegantly matt finished body Drain tray around machine platform Pneumatic vial stopping arrangement MCB for overload protection, and prevention against short circuit Machine Speed varies with A/c frequency drive Technical Specification: Model No. SVILF-40 SVILF-60 SVILF-100 Number of Nozzles 2 Nos. 4 Nos. 6 Nos. Output/Hour 700-2400 2400-3600 3600-6000 Fill Size 5 ml to 1000 ml Electric Specification: 0.5 HP/ 220 Volts / 50 Hz Height of Conveyor: 750mm to 850mm adjustable

Automatic Liquid Filling Machine

220,000 Per Piece

1 Piece(s) (MOQ)

Semi Automatic Liquid Filling Machine

Get Price Quote

Supported by a well-organized network and dependable resources, we have developed as a reputed supplier of Semi Automatic Liquid Filling Machine. We are one of the respected names in the market of Ahmedabad(India) and are offering amazing deals on our products. Salient features : S.S. Elegantly matt finished body. Simple Design. Easy to operate. Low Power Consumption & Maintenance Free. Highly Accurate Range - 5ml. to 1000ml. Speed -300 to 1500 containers / Hour depending on volume / viscosity of the liquid to be filled. Packing Material - Bottles, Jars & Pouches Rigid vibration free construction for trouble free performance

Semi Automatic Bottle Filling Machine

200,000 - 300,000 Per piece

Ampoule Filling and Sealing Machine

Get Price Quote

Heavy duty base with robust construction off S.S. matt finished body Ampoule Filling & Sealing machine is specially designed for ampoule drawing, filling and sealing combined equipment for injections In this machine, belts / reciprocating agitators are provided in the feeding station. The filled ampoules in the sealing station are spun by rotating pinions of

Semi Automatic Powder Filling Machine

325,000 Per Piece

Automatic Flowmetric Lubricant Oil Filling Machine

Get Price Quote

Semi Automatic Powder Filling Machine

145,000 Per Piece

1 Piece(s) (MOQ)

Water Bottle Packing Machine

Get Price Quote

We as a manufacturer, supplier and exporter of the Grouping machine provide comprehensive solution correlated with the packaging machinery, packaging tools and packaging materials bring forth highly efficient and continuous operation packing equipment configured by considering the thermal shrinkage property of the packaging film. Our water bottle packing machine is a good example of the implementation of advanced technology, which complies with all international standards. The machine is fully automatic in which array, aggregate and alignment of the bottles is achieved by automatic operation. In the water bottle packing machine bottles are counted by lines and rows as a preset, packed with the film and at last pass through heating tunnel where thermal shirking take place by heating, cooling and forming. The long term experience in the packaging domain enables us to produce the advanced technology based water bottle packing machine equipped with third generation sealing cutter which ensures even and longer life sealing. Furthermore adopting air circulation technology, we ensure heat insulation, high accuracy for controlling temperature and absolute packaging. The whole process of the bottle packaging machine is automatic, but to meet the requirement and budget, we offer a customization option and deliver the machine as per the customer’s specification at the leading industry rate. Core Features of Water Bottle Packing Machine: High speed perfect finishing low maintenance sturdy construction Note: We as a packaging machine manufacturer, supplier and exporter from India accept specifications from you, if any, and manufacture Water Bottle Packing Machine with your preferences at the best possible price as well as assist to determine the best machine for your application and budget.

Water Cup Filling Machine

Get Price Quote

Automatic Liquid Filling Capping Machine

Get Price Quote

Automatic Liquid Filling Inner Plugging Screw Capping Machine This automatic system comprises of a 3 stages indexing mechanism to perform a sequence of operations for Filling, Inner Plugging and Screw Capping. The unit is fabricated on rigid MS structure and cladded with SS Sheet to meet GMP requirements. All three operational stations are housed in a common acrylic cabinet to provide safe working zone. The unit is made compact & versatile with three operational stations of Filling, Inner Plugging and Screw Capping on a common center star wheel adjoined with in feed & out feed S.S. slat conveyor. Filling station consists of two / four reciprocating nozzles for peristaltic pump assisted dosing. Inner Plugging station consists of vibratory inner plug feeding device and pneumatic plug pressing unit along with pneumatic cap placement mechanism. Screw Cap sealing station consists of Vibratory screw cap feeding device along with and cap screwing unit with Rotary heads. Main drive, conveyor drive, servo capping drive & servo filling is synchronized PLC. Operation : Empty vials moving on the conveyor is fed to the center star wheel where all the operations of filling, plugging & screw capping will be performed in an indexing mechanism. Vial moves under the filling station and full dose of solution is filled in two stages under both the nozzles. Then it moves for the further operation of plugging where inner plug comes from bowl(s) through chute & being placed on the vial while it stops under the pneumatic plug-placing device, which operates in pair (in case of MPAFPC-100). Screw cap comes from the separate cap bowl through chute(s) and being placed in pair (in case of MPAFPC-100) on the plugged vial at next stop. Further moves under the capping heads where capping is done in pair (in case of MPAFPC-100) according to the pre set torque. Filled vials duly plugged & capped move on to out feed conveyor then. Salient Features : A very compact & versatile equipment for 3 in one operation. Unique for small volumes filling for Eye/Ear/Nasal drops. Smooth & efficient Filling-Inner Plugging & Screw Capping operations in one star wheel. Elegant matt finish body with acrylic enclosure on operational zone. Designed for low noise & maintenance less operation. Peristaltic pump assisted filling ensures accuracy of + 0.5 %. Pneumatic inner plug pressing & cup placement. All contact parts made of SS 316. Screw capping heads is designed to apply adequate torque. No bottle, No plug, No cap - machine stop system. Equipped with torque limiter to protect indexing mechanism. No bottle - No fill, No plug - No cap, No bottle - No plug system. PLC base operation.

Automatic Volumetric Liquid Filling Machine

Get Price Quote

4 Head Automatic Volumetric Liquid Filling Machine

225,000 - 275,000 Per Nose

1 piece 2,75,000/-IRS. (MOQ)

Packaged Drinking Water Filling Machine

Get Price Quote

Manufacturer & exporter of Automatic Liquid Filling Machine & Automatic Electronic Filling Machine. Our product range also comprises of Semi Automatic Liquid Filling Machine and Volumetric Liquid Filling Machine. Gained prominence in the industry as a reliable organization, we are engaged in providing Automatic Liquid Filling Machine. Widely demanded in food processing, beverages and dairy industries, our offered filling machines are provided in various specifications. These machines are delivered timely to gain maximum client-satisfaction.

Oil Filling Machine

500,000 Per Piece

Automatic Sharbat Filling Machine

250,000 Per Piece