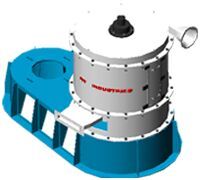

vibro screening machine

Vibro Screens, available in size from 24”to 60”” in diameter with convenient design; maximize screen surface, provide good rate of screening, one to multilevel screens giving desired numbers of predefined portions with absolute separations in various mesh sizes. The equipment also can be supplied with dust cover and other special accessories. Material of construction will be as per requirement of customer.

...more

Vibro Screen Machine

Vibro Screens, available in size from 24”to 60”” in diameter with convenient design; maximize screen surface, provide good rate of screening, one to multilevel screens giving desired numbers of predefined portions with absolute separations in various mesh sizes. The equipment also can be supplied with dust cover and other special accessories. Material of construction will be as per requirement of customer.Majorly used in:Guar Gum, Starch, Cellulose Food, Pharmaceuticals, Chemical, Minerals, etc…

...more

Ultrafine Pulveriser

This is an essential grinding unit for Guar-Gum, CMC, & TKP industries. It gives desired output with required mesh size in continuous and constant manner. This is a must for every plant of its category where uniform fineness is required and it has an advantage of low and easy maintenance. The total assembly has an inlet, Cyclones & dust collectors and entire system is available with various sizes, according to the demand of production of the proposed plant.The Pulverisers are made from 40 to 300 HP and they have a variation in output depending upon the material and desired production. We provide customized design and perfectness in our in-house manufacturing and R &D facilities.

...more

Tray Dryer

This is a batch type Tray dryer suitable for small quantities wet material. It is either in MS or SS. Trays of SS or aluminum ranging from 12– 392 can be supplied according to customer’s requirement. The same is either provided with steam or electrical heating arrangement. Proper insulation is given to minimize heat losses. It has also auto start and cut off facility to maintain optimum temperature in the chamber. It has two to four fans according to trays capacity.

...more

Ss Flaker

1,500,000 Per Piece

1 Piece(s) (MOQ)

Material : MS/SS

Material : MS/SS

Semi-Automatic Centrifugal Siever

Model Number : centrifugal Siever MVI

Automation Grade : Semi-Automatic

Material : SS/MS

Color : Customizable

Phase : 3

...more

Screw Conveyor

The screw conveyors are the most suitable equipments that provide easy way of movement for materials inside the plant and have various sizes, speeds and some arrangements for washing too. They are fabricated in MS or SS material and capacity is designed according to the purpose of their use.

...more

Rotary Valve Feeder

Type : Rotary Valve Feeder

Rotary Table Feeder

Rotary Table Feeders are used in industries, which require the moving or feeding of powder or granular substances. Table feeders are particularly helpful in moving sticky or hard to feed materials. They are also very useful in converting an intermittent batch process into a continuous material feeding process.The amount of material leaving the rotary feeder can be controlled by changing the angle of the discharge plow via a hand wheel or by motor.

...more

Rotary Sieve

The rotating paddles break up soft agglomerates and propel individual particles through the screen while rejecting hard lumps and trash. This makes ease of screening even to the powders that has poor flow ability. A compact appearance, quiet operation, and high output make this rotating screen a highly acceptable for the various applications of the powder screening. These are available in various materials of constructions.

...more

Rotary Air Lock Valve

Rotary valves are useful as one important integral part in material handling system. Rotary airlock valves have a wide application in industry wherever dry free-flowing powders are used. They separate air out of material and transfer the material to equipment in its sequence. Mostly materials are cement, minerals, grains, dust, fly ash, powders, and pharmaceuticals.

...more

Ribbon Blender

This is a universally accepted mixer which is useful for mixing, blending and reaction of solid-solid and solid-liquid materials. They are made in different sizes according to its requirement of application. It has a U shaped trough and a shaft with ribbons is rotating inside it. The ribbons have co-axial supports that provide the strength to the curved arms. The ribbons are designed and fabricated such that the particles inside the shell move freely from one corner to another one and get in close contact with each-other and thereby are mixed very well. Also the close contact enables better reactivity among them.

...more

Reaction Blender

The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of chopper blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

...more

pneumatic flash dryer

Pneumatic Flash Dryer will be effectively used for drying the wet material and convey it. The drying takes place in wide and high vertical tube. The material is sucked into the tube with a negative suction. The hot air is also carried with the material. Cyclones will be attached for the air and material separation. Necessary air lock will be provided with the system.

...more

Pin Mill

Pin Mill is designed for finer mesh grinding of different materials, which are heated during grinding. The RPM of machine is varying from 2000 to 5000 depending on material to be pulverized. The output mesh size is also variable from material to material. This is an ideal solution for size reduction for foodstuff. It is available with water-cooling jacket on special requirements. Uniform output & easy to operate and maintain are the distinctive features of Pin Mill. Application In:Food, Pharmaceutical and chemical industry.

...more

Nauta Mixer

Nauta Mixer is Ideal mixer to mix various small lots to make uniform one lot or to mix many large proportions of powders to a uniform product. This should be perfect choice. The Nauta mixer offers low operative cost than any other types of mixers. A planetary rotating screw near the wall of cone not only mixes the powders but also breaks the lumps. Silent equipment offers you trouble free operation. The sizes of Nauta mixer available are 500 liters to 20000 liters.Application In:Food, Pharma, Chemical, Minerals, Guar Gum / Starch / Cellulose etc.

...more

Impact Pulverizer

An extra heavily constructed machine designed to pulverize even rocks and minerals of medium hardness. fineness, ranging among 100 mesh to 300 mesh (150 to 50 microns) and in some cases even 500 mesh. Non concrete foundation - frame with AVM pads may be provided. The equipment is suitable for medium hard minerals, chemicals, bulk drugs, coal, paints, dyes and pigments, herbs, seed, etc.Application In:Guar flour, tamarind kernel powder and their derivatives. Cellulose and starch derivatives, to grind pulses and cereals, chemicals, feed and minerals.

...more

Guar Gum Powder Plant

The Guar Powder Plant has a typical role as the raw material of Guar-Gum Powder.It is very important to select guar split in this process. The spilt is screened to clean it and then soaked to pre-hydrate it in a double cone mixer. The Pre-hydrating stage is very important because it determines the rate of hydration of final product. The soaked splits, which have reasonably high moisture content, are passed through a flaker. The flaked guar split is ground and then dried. The powder is screened through rotary screens to deliver required particle size. Oversize particles are either recycled to main Ultra fine or reground in a separate regrind plant, according to the viscosity requirement.This stage helps to reduce the load at the grinder. The soaked splits are difficult to grind. Direct grinding of those generates more heat in the grinder which is not desired in the process as it reduces the hydration of the products. Through the heating, grinding, and polishing process, the husk is separated from the endosperm halves and the refined Guar Gum split is obtained. Through the further grinding process, the refined Guar split is then treated and converted into powder.The split manufacturing process yields husk and germ called "Guar Meal", widely solid in the international market as cattle feed. It is high in protein and contains "Oil and Albuminoids ", about 50%in germ and about 25% in husks. The quality of the food grade guar gum powder is different grades and qualities of guar gum by particle size, the viscosity generated with a given concentration, and the rate at which that viscosity more slowly, They may achieve a reasonably high viscosity, but will take longer to achieve. On the other hand, they will disperse better than fine mesh, all conditions being equal. A finer mesh, like a 200 mesh, requires more effort to dissolve. The plants supplied by us are capable of most of the grades of Guar Gum from split.M. V. Industries can provide the machinery for derivatives and Modified of Guar Gum.

...more

Guar Gum Plants Machinery

The plant has been configured and designed in such a way that minimum work force will require. The guar split will be fed in to the pneumatic system to feed in to the turbo screen. The turbo screen is suggested at the high of plant. The screening will be employed for the removal of foreign matter. This screened material will be stored in a storage hopper. The guar splits will fall from the screens by gravity to the storage hopper, which is configured below the screen. From storage hopper material can be taken in to double cone mixer as and when required by gravity for the prehydrating of guar splits. All the prehydrated guar split will be sent to the hopper of Flaker at a time by gravity.Machinery Capacity: As per Requirement Pneumatic System Split cleaning Split washer Double Cone Mixer Water Tank Flaker Machine Flakes Dryer Boiler Heat Exchanger Pneumatic Flash dryer line Blower, Cyclone, Dust collector with accessory Rotary Siever Nauta Mixer (Conical Blender) Misc. Pipe-lines Ribbon Blender Our grinder is proposed for the grinding of crushed guar splits. This grinder has abilityto grind the material without generating too much heat. Material will be fed into the dryer.Oil will be the media to convey the heat and deliver to the air.This hot air will take the material into thedryer line where actual drying will take place. Attached cyclone system will separate the material and hot air. To heat the oil Thermic boiler will be used.The material will be screened through centrifugal screen. Material passing through the screen will be again screened through turbo screens as additional control. This material will be sold as a premium product. Oversize of the centrifugal screen will be screened through turbo screen to separate another grade in terms of particle size followed by additional screening. The oversize will be screened through another turbo screen to separate another grade. Oversize will be passed through another grinder. The material will be passed through another screen. Oversize will be recycled to the same grinder.Final material coming out from all the screens will be sent separately by gravity in to the Nauta mixer for the blending and to make a uniform lot. The products will be tested and packed.The plant can be operated by 2 skill workers in a shift. The loading/unloading and the packing of the final product can be done on contract basis.PROCESSThe indicative process of manufacturing guar gum (Food grade) is as under.The guar split will be purchased from the guar seed processors. Selection of the split is a critical in the business. Various parameters of split selection has been derived by the client and will be purchased on that basis for the processing. The split will be screened to clean and then will be soaked to prehydrate in a double cone mixer. Prehydrating stage is crucial in the process as it derives the rate of hydration of the final product.The soaked splits, which has reasonably high moisture content, will be passed through Flaker to take them. This stage helps to reduce the load at the grinder. The soaked splits are difficult to grind and direct grinding of those generates to much heat in the grinder which is not desired in the process as it results in insoluble or reduced hydration of the product.Both the material will be as a different grade and will be packed separately.Quality of the guar gum powder-food grade is defined from it’s particle size, rate of hydration and the microbial in it.

...more

guar gum plant

In Guar-Gum industry, a Flaker is considered as a heart of the plant. It presses the hydrated split between two moving rolls and the split grains are elongated into flakes, which enables to stretch the fibers and makes them soft and easily grind-able and thereby helps to increase the viscosity of Guar-Gum and output of Ultrafine Pulveriser.

...more

guar gum machinery

The plant has been configured and designed in such a way that minimum work force will require. The guar split will be fed in to the pneumatic system to feed in to the turbo screen. The turbo screen is suggested at the high of plant. The screening will be employed for the removal of foreign matter. This screened material will be stored in a storage hopper. The guar splits will fall from the screens by gravity to the storage hopper, which is configured below the screen. From storage hopper material can be taken in to double cone mixer as and when required by gravity for the prehydrating of guar splits. All the prehydrated guar split will be sent to the hopper of Flaker at a time by gravity.

...more

Flaking Machine

A Flaker is made of 2 or 4 rolls among which one side is stationary and the other single roll or two rolls are moving.It continuously keeps the pressure on the rolls to provide optimum force on them to flake the split to a maximum extent.

...more

Flaker machine

In Guar-Gum industry, a Flaker is considered as a heart of the plant. It presses the hydrated split between two moving rolls and the split grains are elongated into flakes, which enables to stretch the fibers and makes them soft and easily grind-able and thereby helps to increase the viscosity of Guar-Gum and output of Ultrafine Pulveriser. A Flaker is made of 2 or 4 rolls among which one side is stationary and the other single roll or two rolls are moving. It is available with Hydraulic Power-Pack: a hydraulic system which generates the pressure by circulating oil from the oil-chamber and narrow conduits up to the plunger inside the cylinder and it can work in reverse direction too. It continuously keeps the pressure on the rolls to provide optimum force on them to flake the split to a maximum extent.

...more

Double Cone Mixer

This is a unique mixer which has 2 cones on the ends and cylindrical in the middle portion. It has two supporting legs. The shaft is moving with the cone by a motor and pedestal support which is mounted on legs. Both the cones have lids which can be opened or closed for loading and unloading. The double cones and cylindrical body is made of stainless steel. D.C. Mixer has two major functionsa. Mixing of the ingredients kept inside the chamber, andb. Hydration of the Guar splitIn guar-gum industry, the D.C. Mixer plays important role as it gives better result in fast hydration which enables to get better flaking, soft pulverising and high viscosity of the powder to be produced.

...moreBe first to Rate

Rate ThisOpening Hours