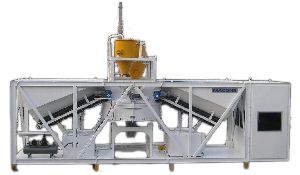

Wet Mix Plant

wet mix plants are manufactured with best of the components and accessories. The unique design features makes it most efficient in terms of operational costs, and ensures close control of the quality of output. Available in fixed or variable speed drives, the plant is well equipped with adjustable gates at its bins. The design of twin shaft pug mill ensures fast, continuous & homogenous mixing of aggregates & additives. Besides, the surge hopper arrangement allows discharge into trucks without shutdown & spillage.

...more

Wet Mix Macadam Plant

wet mix plants are manufactured with best of the components and accessories. The unique design features makes it most efficient in terms of operational costs, and ensures close control of the quality of output. Available in fixed or variable speed drives, the plant is well equipped with adjustable gates at its bins. The design of twin shaft pug mill ensures fast, continuous & homogenous mixing of aggregates & additives. Besides, the surge hopper arrangement allows discharge into trucks without shutdown & spillage.

Feature : Available in 120/160/200/250/300/350 TPH Capacity.

...more

Vertical Silo

Salient Features • Available in 20/30/40/60/80/100 ton capacity. • Horizontal and vertical screw conveyor with hopper arrangement for silo feeding system. • Seamless pipe for feeding material in silo. • Aeration System at bottom of cone & with other necessary filaments.

...more

Transit Mixer

Salient Features • Available in 6 cubic meters capacity. • Driven by Kirloskar Air Cooled Diesel Engine Model 494 with hydrostatic transmission and oil cooler. • Mounting on Ashok Leyland Taurus / Tata 2516 OR any other equivalent truck chassis. • Fully imported oil bath planetary gear system is proven when traveling in rough terrain with full power of the engine required. • Harden rollers increase the reliability of the performance. • Cover provides safety and protection against dirt. • The drum and spirals are made of highly wear resistant steel so that it increases stability and reduces the wear out. • More Economic in transporting concrete thanks to MACONS larger volume of drum with more water line capacity. • Operation is user-friendly. • Excellent quality of materials and components gives long life with less economy. • The design of devices allow concrete consistently with high speed. • Constant discharges of concrete. • High mixing capacity and maximum discharge output thanks to the optimal position of the spiral blades in the drum. • Fully Imported Hydraulic Pump, Motor and Oil Cooler. • Efficient and reliable after sale-service, round the clock. Technical Specification

Type : Hydrostatic Transmission with Oil Cooler

...more

Semi Mobile Concrete Batching Mixing Plant (MASM)

Salient Features • Available in 20/25/30 m3/hr. capacity • Mixer PAN type, for continuous mixing. • Replaceable liner Tiles and Tips in to the mixer. • Inbuilt Water and Additive tank. • Fully Automatic plant with Electronic weighing of aggregate/sand/water/cement. • Loading of aggregates / sand Hoppers by wheel loader / conveyor manually. • Civil Foundation work is not required as fully containerized plant. • Easy transportation & shifting. • Compact and Economical design. • Easy installation and put into operation. • Remarkably cost efficient. • Plant operation is very silent, in a clean surrounding. • Least maintenance of plant, due to less wear & tear of parts. Optionals • Online Printing System. • Discharge Belt Conveyor. • Fly Ash Feeding System. • Cement Storage Silo. • Computer SCADA System with Software. • Touch Screen with provision of USB for data back up. Technical Specification

...more

Self-Loading Transit Mixer

Salient Features • Available in 1/1.2/2/2.5/3.5/4 m3 Capacity. • Operation is user friendly. • Excellent quality of materials and components gives long life with less economy. • The design of devices allow concrete consistently with high speed. • 4 Wheel drive & 4 wheel steering. • 180° reversible driving post. • Electronic weigh batching unit. • 35% Gradeability. • Efficient and reliable after sale – service round the clock. • Manufactured under license from “DUMEC S.R.L.” Optionals • Extra Chute. • High Pressure Washing System. • Printer. • Slewing Drum Arrangement. Technical Specification

...more

Self Loading Concrete Mixer

Available in 11.222.53.54 m3 Capacity. Operation is user friendly. Excellent quality of materials and components gives long life with less economy. The design of devices allow concrete consistently with high speed. 4 Wheel drive & 4 wheel steering. 180° reversible driving post. Electronic weigh batching unit. 35% Gradeability. Efficient and reliable after sale – service round the clock. Manufactured under license from “DUMEC S.R.L.”

...more

Road Kerbing Machine

Salient Features Front & Rear hydraulic cylinder for adjusting Kerb height. Fully Imported needles vibrators to ensure compact & easy concrete flow. Fully imported hydraulic kit and micron system for longer life. � Fully Imported Slope, Steering and Grade sensors. � Maximum mould size is 600m height x 800mm width � The machine can lay on Wetmix Layer & DBM Layer, as well as Reinforcement and Gutter Section � Hydraulic tilting inlet chute for easy maintenance and accessibility to engine and hydraulic parts � Rigid construction of main chassis, fabricated from rolled steel sections. � Dust proof lockable operator console. � Mould boxes are designed for quick change. Standard Accessories � Fuel Gauge, Amp, Meter, Temperature Meter, Engine pressure gauge. � Front and rear light, Horn, Reflectors etc. � Set of tool kit, Grease gun, Piler, Screw driver etc. � Cushioned operator�s seat. � String line wire tensioning device. � String line with rod and clamp. Technical Specification

...more

mobile concrete plants

Available in 1215182025m3hr. capacity. Mixer – PAN type, for continuous mixing. Mixer having Electronic load Cell type weighing system. Loading of AggregateSand Hoppers by Wheel loader Conveyors Manually. Inbuilt Water and Additive tank. Fully Automatic Electronic operation with integrated PLC PC Control and Remote function. Plant can be erected & commissioned within two days. Entire plant can be transported in single 40 feet trailer. Rigid construction of main chassis; fabricated from rolled mild steel material. Replaceable liner Tiles and Tips in to the mixer. Fully automatic plant with Electronic weighing of Agg.SandWaterCement. PLC based control panel with integral computerized batch controller accommodates 99 different mix recipes. Maximum weighing accuracy. Plant only requires Electric Power Supply, Water Piping, AggregateSand feeding. Easy transportation & shifting by toeing also.

...more

Mobile Concrete Batching Plant

Fully Automatic Electronic operation with integrated PLC PC Control and Remote function.Rigid construction of main chassis; fabricated from rolled mild steel material.Replaceable liner Tiles and Tips in to the mixer.Fully automatic plant with Electronic weighing of Agg.SandWaterCement.PLC based control panel with integral computerized batch controller accommodates 99 different mix recipes.

...more

Mobile Concrete Batching Plant

Salient Features • Available in 12/15/18/20/25m3/hr. capacity. • Mixer – PAN type, for continuous mixing. • Mixer having Electronic load Cell type weighing system. • Loading of Aggregate/Sand Hoppers by Wheel loader/ Conveyors/ Manually. • Inbuilt Water and Additive tank. • Fully Automatic Electronic operation with integrated PLC / PC Control and Remote function. • Plant can be erected & commissioned within two days. • Entire plant can be transported in single 40 feet trailer. • Rigid construction of main chassis; fabricated from rolled mild steel material. • Replaceable liner Tiles and Tips in to the mixer. • Fully automatic plant with Electronic weighing of Agg./Sand/Water/Cement. • PLC based control panel with integral computerized batch controller accommodates 99 different mix recipes. • Maximum weighing accuracy. • Plant only requires Electric Power Supply, Water Piping, Aggregate/Sand feeding. • Easy transportation & shifting by toeing also. Optionals • Online Printing System. • Discharge Belt Conveyor. • Fly Ash Feeding System • Cement Storage Silo • Computer SCADA System with software. • Touch Screen with provision of USB for data back up. Advantages • Very slim and compact design. • Plant can be erected & commissioned within two days. • Remarkably cost efficient. • Plant operation is very silent & with clean surrounding. • Very fewer maintenance of plant, due to less wear and tear parts. • Complete plant can be transported in one 40 foot trailer. Technical Specification

...more

Mini Dumper

Mini dumper 3 cylinders Water Cooled Diesel Engine. Hydrostatic 2 Speeds transmission.Power assisted with power steering.Fixed drive seat with protection roof.

Feature : Available in 2/2.3/2.5/2.75/3/5/10/16 ton capacity.

...more

kerb paver machine

Salient Features Front & Rear hydraulic cylinder for adjusting Kerb height. Fully Imported needles vibrators to ensure compact & easy concrete flow. Fully imported hydraulic kit and micron system for longer life. � Fully Imported Slope, Steering and Grade sensors. � Maximum mould size is 600m height x 800mm width � The machine can lay on Wetmix Layer & DBM Layer, as well as Reinforcement and Gutter Section � Hydraulic tilting inlet chute for easy maintenance and accessibility to engine and hydraulic parts Rigid construction of main chassis, fabricated from rolled steel sections. Dust proof lockable operator console. Mould boxes are designed for quick change.

...more

Horizontal Silo

MACONS introduces the Horizontal silo for storage of Cement of other bulk material for construction purpose. The horizontal silo is fabricated from mild steel plate shaped as to ensure to drop the material into horizontal screw conveyor located in the low part of the bin. The horizontal screw conveyor extracts the material in to inclined screw conveyor and discharge the material over a height of 4.2 mt. The horizontal silo provides with control panel for horizontal screw conveyor, inclined screw conveyor and vibrators, manually via push buttons and also automatically during batching out of pre-set quantity of cement from the silo. The weight indicator provides the display of net weight of cement in the silo. It also allows quick and accurate calibration of the load cells. The pre-set quantity of cement can be automatically batched out on loss – in – weight basis through a single push button operation on the panel. The same can also be done manually by independently operating all the dosing devices via push buttons provided on the control panel. The bin with accessories is supported on electronic load cells, which transfer the load on to a suitable framework. The framework is provided with manually operated off loading legs. The Horizontal silo is provided with vibrators to facilitate the flow of material, loading pipe, relief pipe, pressure relief valve and man hole. Salient Features • Available in 20/30/40 Ton Capacity. • Load Cell Weighing System with electronic instruments. • Electric Control Panel • Horizontal Screw Conveyor • Inclined Screw Conveyor • Manually operated off loading legs. • Set of vibrators to facilitate the flow of the material • Loading Pipe, Relief Pipe, Pressure Relief Valve. • Man Hole. Optional • Rear Mounted dust Filter

...more

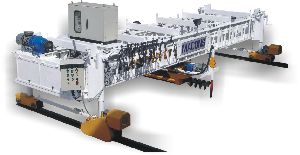

horizontal concrete batching plant

Salient Features • Concrete Batching / Mixing plant available in 45 to 240 m3/hr. capacity. • Aggregate stored by Inline Bins. • Aggregate weigh is suspended on Four “S” type load cells, gives higher accuracy. • Independent weighing system for Aggregate/Cement/Water & Additive. • Fully Automatic-Electronic operation with PLC/PC Control. • Required installation time is very less, due to Modular design. • Available with Single Shaft / Twin Shaft / PAN / Planetary type Mixers. • Reliable, Fast and Accurate Electronic Weighing System for major inputs. • Full service, technical support and spares back-up. Optionals • Cement / fly ash storage & conveying system from 20 to 200 MT capacity. • Microwave Moisture Meter. • Computer SCADA System with software. • Radial Conveyor Belt for Agg. Feeding Technical Features

...more

Dumper

Salient Features • Available in 2/2.3/2.5/2.75/3/5/10/16 ton capacity. • 3 cylinders Water Cooled Diesel Engine. • 4 wheel drive traction. • Hydrostatic 2 Speeds transmission. • Power assisted with power steering. • Hydraulic Skip tipping. • Fixed drive seat with protection roof. • Manufactured under license from “DUMECS.R.L”.

...more

concrete paver

Salient Features • Light weight construction for easy erection and transportation from site to site. • User Friendly, fast and accurate control. • Advanced energy efficient electric drive system with step less speed control. • The Special under carriage consist of a spreader auger to spread the concrete to level. • Finishing Roll bracket equipped with vibrator to achieve better finishing. • The Forward and reverse motion of the machine is controlled by electrically operated bogie. • Adjustable carriage movement with variable speed drive. • Pin connected main frame available in length 1220mm, 1830mm, 2440mm, 3660mm

...more

Concrete Mixing Plant

Concrete Batching Mixing plant available in 45 to 240 m3hr. capacity.Aggregate weigh is suspended on Four “S” type load cells, gives higher accuracy.Fully Automatic-Electronic operation with PLCPC Control.Available with Single Shaft Twin Shaft PAN Planetary type Mixers.Reliable, Fast and Accurate Electronic Weighing System for major inputs.

Capacity : 15

...more

Concrete Kerbing Machine (MKM) Series

Salient Features • Front & Rear hydraulic cylinder for adjusting Kerb height. • Fully Imported needles vibrators to ensure compact & easy concrete flow. • Fully imported hydraulic kit and micron system for longer life. • Fully Imported Slope, Steering and Grade sensors. • Maximum mould size is 600m height x 800mm width • The machine can lay on Wetmix Layer & DBM Layer, as well as Reinforcement and Gutter Section • Hydraulic tilting inlet chute for easy maintenance and accessibility to engine and hydraulic parts • Rigid construction of main chassis, fabricated from rolled steel sections. • Dust proof lockable operator console. • Mould boxes are designed for quick change. Standard Accessories • Fuel Gauge, Amp, Meter, Temperature Meter, Engine pressure gauge. • Front and rear light, Horn, Reflectors etc. • Set of tool kit, Grease gun, Piler, Screw driver etc. • Cushioned operator’s seat. • String line wire tensioning device. • String line with rod and clamp. Technical Specification

...more

concrete kerbing machine

Front & Rear hydraulic cylinder for adjusting Kerb height. Fully Imported needles vibrators to ensure compact & easy concrete flow. Fully imported hydraulic kit and micron system for longer life. Fully Imported Slope, Steering and Grade sensors. Maximum mould size is 600m height x 800mm width The machine can lay on Wetmix Layer & DBM Layer, as well as Reinforcement and Gutter Section, Hydraulic tilting inlet chute for easy maintenance and accessibility to engine and hydraulic parts, Rigid construction of main chassis, fabricated from rolled steel sections. Dust proof lockable operator console. Mould boxes are designed for quick change.

...more

Compact Series Concrete Batching Plant

MACONS introduces MAC Model, especially designed for the production of concrete at sites where the quality, flexibility and performance are key features to consider. The flexibility of this plant begins in the different arrangements available. Four types of mixer models can be selected with a broad range of models: Single Shaft Mixer, Twin Shaft Mixer, PAN type Mixer and Planetary Mixer. The main advantage of this plant is that it doesn’t require large foundations and others civil constructions. The time and money can be saved by easy transportation, assemble and disassemble when plant is shifting from one site to another site. The constitution of the plant is made in welded construction of steel profiles. The complete structure is shot blasted before the primary coat of paint being implemented. There are two coats of paint of the color is being applied. Including elements like stairs, balconies, pavements, discharge mouths of the aggregates bins to resist to the attacks of the weather situations. It’s easy to disassemble, transport and assemble again. In one week we assemble your plant in a new site producing concrete, saving you time and money. Salient Features • Available in 25 to 135 m3/hr. capacity. • Compact and economically designed. • Heavy duty structure. • Plug-on & Operate” concrete batching plant. • Less space required because of its compactness. • Civil Foundation work is very fewer as compact design. • Negligible owning & operating cost. • Longer life of wear & tear parts. • In-built control cabin. • Especially quick erection & commissioning. • Inbuilt pipeline of water, additive and pneumatic. • Tilting type control cabin for easy transportation. • One operator can run the plant. • Single Shaft and Planetary Mixer Available on request. Optional • Cement / fly ash storage & conveying system from 20 to 200 MT capacity. • Microwave Moisture Meter. • Computer SCADA System with software. • Radial Conveyor Belt for Aggregate Feeding Technical Specification

...more

Compact Concrete Mixing Plant

Salient Features • Available in 30/45m3 / hr. Capacity with Pan type mixer. • Skip Bucket is driven by single two speed geared motor with single brake. • External glass cabin for inspection of entire operation. • Independent weighing system for cement, water & additive • Fully Automatic – Electronic operation with PLC / PC Control. • Available with Radial Dragline / Star Bins / Inline Bins. • Compact & Slim design • Sturdy fabricated skip hoist track. • Heavy duty PAN type mixer for continues mixing. • Mixer discharge done by powerful hydraulic cylinder. • Replaceable Tiles and Tips in to the mixer. • Aggregate weigher is suspended on four shear beam type load cells, gives higher accuracy. • Ample space on platform with protective railing for easy maintenance. • Three side glass cabin for Radial Scrapper operator for extensive view. • Maximum weighing accuracy. • Completely close conveying system for cement to ensure absolutely no wastage. • Full Service Technical Support & Spares Backup. • Simple & Economical Foundation. Optionals • Cement / fly ash storage & conveying system from 20 to 200 MT capacity. • Chemical Additive dosating system. • Online / Offline Printing system. • Computer SCADA System with adequate software. Technical Specification

...more

apollo wet mix plant

MACONS wet mix plants are manufactured with best of the components and accessories. The unique design features makes it most efficient in terms of operational costs, and ensures close control of the quality of output. Available in fixed or variable speed drives, the plant is well equipped with adjustable gates at its bins. The design of twin shaft pug mill ensures fast, continuous & homogenous mixing of aggregates & additives. Besides, the surge hopper arrangement allows discharge into trucks without shutdown & spillage. Available in 120160200250300350 TPH Capacity. Modern Wet Mix Technology. Designed For Domestic International Market. Modular Design For Containerized Transport. Easy To Operate. Highly Accurate Aggregate Feeders.

...moreBe first to Rate

Rate ThisOpening Hours