Double Drum Magnetic Separator

150,000 Per Piece

1 Piece (MOQ)

Double Drum Type Magnetic Separators are available for highest purity. The material passes through the magnet twice time drum separator and High power permanent Magnetic Plate is provided at material outlet. They are comprised of a stationary permanent magnet, either standard Ferrite Magnets or High Power Rare Earth Magnets enclosed in a non-magnetic stainless-steel drum. Product flow is diverted so that it falls onto the top and flows across the surface of the drum. Ferrous matter contained in the product flow is drawn to the drum's surface by the powerful magnet housed inside.

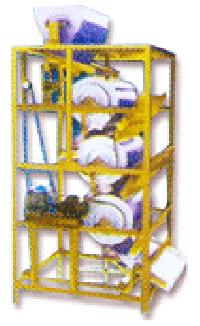

Triple Drum Magnetic Separator

80,000 Per Piece

1 Piece (MOQ)

Best Deals from Magnetic Drum Separator

Single Drum Magnetic Separator

95,000 Per Piece

1 Piece (MOQ)

Drum Type Magnetic Separator are designed to remove micro iron or para-magnetic material from mineral and ceramic raw material. Magnetic Materials: Magnetic separators are offered with two different type of magnets. Ferrite Magnet Rare Earth Magnet Ferrite Magnet: The magnetic separators having ceramic magnet can be useful for application where larger and free iron particles are supposed to be divided. The standard magnetic intensity for magnetic drum exterior can be around 1500 to 2000 Gauss. Rare Earth Magnet: A magnetic separator having higher intensity Rare Earth Nd-Fe-B (Neodymium- Iron- Boron) magnet can be useful in removing the magnetic contaminations with lower magnetic properties as well as finer iron particles need be separated. An average magnetic intensity for drum surface can be around 3500 to 5500 Gauss.

Inline Drum Magnetic Separator

Get Price Quote

Magnetic Drum Separators are of self-cleaning type and provide continuous removal of ferrous contamination from a wide range of free-flowing bulk and granular materials in high-volume applications. Drums can be ordered with or without housing. Magnetic Drum Separator system is a complete machine with Stainless Steel 304 / 316 Housing & Drive system. Only drum separator unit can also be supplied. The Drum Separators are available in two types: High Intensity – (Ndfeb Magnet – 5500 gauss), for Operating Temperature of 80?C(Max.) Low Intensity - (Ferrite Magnet - 2500 gauss), for Operating Temperature of 250?C(Max.) Ferrous fine particles, nuts, bolts, pins, nails and other tramp metal from free-flowing granular material can be arrested effectively. When material flows onto the drum, a stationary magnetic assembly inside the unit's shell captures tramp metal and holds it securely to the drum's stainless steel surface. With contaminants removed, the good product falls freely to a discharge point. As the drum rotates, cleats sweep the ferrous debris through and out of the magnetic field. The tramp metal is discharged separately, creating continuous self-cleaning separation.Features Magnetic Drums have the following features Designed for continuous separation and self cleaning. Ideal for high-flow, heavy-contamination applications. It comes with Stainless steel drum and mild steel or stainless steel housings Maximum Recovery of Ferrous Metals Minimum Maintenance They require minimum space and are simple to operate. They are flexible enough to be applied for various purposes Advantages Helps in removing ferrous particles from any non ferrous powder and granules Ideal for plastic, food, fertilizer, pharmaceutical, chemical, glass and continuous process plants Provide utmost protection to crushers, grinders, pulverizes, and allied equipment Can be used for mining and ore dressing industry Eliminate fire hazards and explosions in plants dealing with explosive material. Save money, time and labour by reducing break-down time and improving quality ConstructionThe magnetic drum separator consists of a rotating drum and stationary drum magnet designed as per the specific needs of the customer. The Drum separator is supplied with drive system and SS 304/316 housing along with feed regulating valve.The following Information is required Type of material from which Iron is to be separated. (Sticky, Granular, Free flowing, Lumps etc) Size and level/percentage of contamination Flow rate of material Size/Density of the material particle ApplicationsThe Magnetic Drum filters out iron contamination and hence is widely used in all the processing industry for the separation of iron contamination fromMinerals and Chemicals Food and Flour Plastics Grains Sand Fertilizers Abrasives Glass Slag Ores Rock Refractory

Single Drum Magnetic Separator

Get Price Quote

1 Piece (MOQ)

The dry magnetic separator is commonly used iron ore and manganese ore beneficiation equipment. It is the mainstream strong magnet separator, which is specialized in processing dry magnetic minerals. The wet type dmagnetic separator use liquid diluents to improve separation efficiency. The dry magnetic separator requires that the material must be dry, and can move freely between the particles. Or it will affect the separation result, and even cannot separate materials. The magnetic system of dry magnetic separator adopts high quality ferrite or using the composite material by rare earth and magnetic steel. According to the requirements of users, we can offer downstream, semi-countercurrent and countercurrent and other types of magnetic separators. The advantages of this magnetic separator are: simple structure, large capacity, easy to operate and easy to maintain

Magnetic Drum Separator

Get Price Quote

Magnetic Drum Separator is provided by us with a modernized infrastructure to assure fewer complications in processing and producing. We are manufacturers and exporters from Ahmedabad, Gujarat offering this particular product for removing iron particles from various materials. Basic materials are utilized with ultra-modern technique by the proficient trained professionals. Magnetic drum separator is highly reliable with easy operation and low maintenance cost. Features : User-friendly operation Low maintenance Long working life Sample Availability : Yes Brand : Mix Well Supplier Product Code : HE / 015

Drum Type Magnetic Separator

20,000 - 300,000 Per Piece

Single Drum Type Magnetic Separator: Our Permanent Drum type separators are widely used for separating tramp iron from nonmagnetic material to attain the purity of end products. It also helps in protecting processing plants and machinery by recovering metal impurities having commercial value as well. Single Drum Type Magnetic Separator is widely used in all the processing industries for the separation of iron contamination from minerals, chemicals, food, grains, sand, plastic fertilizers, slag, ores, etc. Double Drum Type Magnetic Separator: Double Drum Type Magnetic Separator is mostly used for achieving the highest end product purity. The material passes through the magnet twice in a Double Drum type machine. Mainly it is used for the separation of iron contamination from Minerals, Chemicals, Refractory, and many other products. In Double Drum Type Magnetic Separators high power permanent magnetic plate is provided at the material outlet. Modern and Isotropic Permanent Magnets are used having the highest coercivity and everlasting magnetic strength. Machines are available with vibrating material inlet hoppers and a totally enclosed design to avoid dusting and pollution. Online fitting design is also available as per requirement. Triple Drum Magnetic Separator with Control Panel: Triple Drum Type Magnetic Separators are also available on demand. Salient Features: · Drum consists of high coercivity modern anisotropic permanent magnets· Strong and rugged construction· Automatic separation of iron impurities· Completely enclosed design to avoid dusting and pollution Size Range: Model no. No. of Drums Capacity tones per Hour Drum Size Dia mm Length mm J-651-SDS 1 1.0 300 450 J-651-DDS 2 1.0 300 450 J-652-SDS 1 1.5 400 500 J-652-DDS 2 1.5 400 500 J-653-SDS 1 2.0 400 600 J-653-DDS 2 2.0 400 600 J-654-SDS 1 3.0 400 750 J-654-DDS 2 3.0 400 750 J-655-SDS 1 5.0 450 850 J-655-DDS 2 5.0 450 850 Special size and capacity Drum Separators can be supplied as per requirement. The larger the diameter and width of the drum the greater the volume of material that can be handled. Magnetic Materials: Magnetic separators are offered with two different types of magnets. Ferrite Magnet: The magnetic separator with ceramic magnet is useful for the application where free and larger iron particles are to be separated. The average magnetic intensity on the magnetic drum surface will be 1500-2000, Gauss. Rare Earth Magnet: The magnetic separator with high-intensity Rare Earth Nd-Fe-B (Neodymium- Iron- Boron) magnets is useful for removing magnetic contamination with low magnetic properties and fine iron particles. The average magnetic intensity on the drum surface will be 3500 – 5500 Gauss.

Material Separator

Get Price Quote

We bring to afore the Material Separators, which are highly praised for their innovative design, peerless performance and promising life. Also, our dexterous team puts painstaking efforts to construct the Material Separators that are user-friendly and require low upkeep. Besides that, these Material Separators are procurable from us at the feasible rates. We are the renowned Material Separator Manufacturer, Supplier and Exporter in India and overseas. More About Material Separator: Material Separator is used where a combination of material transport and separation of fine dust from basis material is required. The material separator can be built into pneumatic transport systems, where pressure-less out-feeding of the basis material for press, container or silo is required. The material separator is made of strong steel plate. The separator consists of a rotary valve and a coarse filter in perforated plate built into the wall of the valve housing. The rotor is mounted with special rubber packing's securing an air-tight valve for pressure-less out-feeding. The transport air passes through the coarse filter, which can be connected to an air filter.

Drum Separator

Get Price Quote

With the leading market standards and customers' demands, we have developed a system that allows the clients to pay in online and offline as per their preferences. We are a purchaser's greatest bet if it comes to acquiring Drum Separator as our organization is a capable supplier.

Magnetic Drum Separator

Get Price Quote

Magnetic Drum Separator available from 200 Kg. per Hour to 20 Ton per Hour capacity.

Single Drum Type Permanent Magnetic Seperators

Get Price Quote

The Permanent Magnetic Drums consists of a stationary Permanent magnetic assembly having uniform and everlasting Magnetic field accross the entire width of the drum, which is effective over approximately half the drum circumference. Drum shell made of non Magnetic stainless steel revolves around the magnetic field. As the material fed evenly from the chute falls over drum, powerful magnetic field attracts and holds ferrous particles to the revolving shell. As the revolving shell carries the Iron particles through the stationery magnetic field the non-magnetic material falls frelly from the shell while ferrous particles are firmly held until carried beyond devider and out of magnetic field.

Triple Drum Type Magnetic Separator

Get Price Quote

Triple Drum Type Magnetic Separators are available for highest purity. The material passes through the magnet three time in Triple Drum type Machine. These are widely used for separation of iron contamination from Minerals, Chemicals, Refractory and many other products. High power permanent Magnetic plate is provided at material outlet. Modern an Isotropic Permanent Magnets are used having highest coercivity and everlasting magnetic strength. Machines are available with vibrating material inlet Hopper and totally enclosed design to avoid dusting and pollution. Salient Features:DRUM CONSISTS OF HIGH COERCIVITY MODERN ANISOTROPIC PERMANENT MAGNETS. STRONG & RUGGED CONSTRUCTION. AUTOMATIC SEPARATION OF IRON IMPURITIES. COMPLETELY ENCLOSED DESIGN TO AVOID DUSTING AND POLLUTION. Working Principal & Magnetic System : The permanent Magnetic Drum consists of stationery permanent Magnetic assembly having uniform and everlasting Magnetic field across the entire width of the drum, which is effective over approximately half the drum circumferences as shown in fig. Drum shell made of non magnetic stainless steel revolves around the magnetic filed. As the material fed evenly from the chute falls over the drum ,powerful magnetic, field attract & holds ferrous particles to the revolving shell. As the revolving shell carries the iron particles through the stationery magnetic field, the non magnetic material falls freely from the shell while ferrous particles are firmly held until carried beyond divider and out of magnetic field. The strength of the permanent magnetic drum is guaranteed to be greater than corresponding electromagnetic Drum . The permanent magnets used are everlasting magnets and its strength does not diminish during normal use and can be used through out the life of the installation. Size Range :The Permanent Drum Separators are available in standard drum diameters of 300 mm. 400 mm, 450 mm, 500 mm, 600 mm, 800 mm Drum width range from 300 mm to 1500 mm. Other sizes can be made as special to your requirement. the larger the diameter and width of the drum the greater is the volume of material which can be handled. Magnetic Materials : Magnetic separators are offered with two different type of magnets. Ferrite Magnet : The magnetic separator with ceramic magnet are useful for the application where free and larger iron particles are to be separated. The average magnetic intensity on the magnetic drum surface will be 1500-2000 Gauss. Rare Earth Magnet : The magnetic separator with high intensity Rare Earth Nd-Fe-B (Neodymium- Iron- Boron) magnets are useful for removing magnetic contamination with low magnetic properties and fine iron particles are to be separated. The average magnetic intensity on the drum surface will be 3500 - 5500 Gauss.

Single Drum Magnetic Separator

Get Price Quote

Our Permanent Drum type separator which is most and widely used separating tramp iron from nonmagnetic material processed in large quantity, for the purity of end products, recovery of metal having commercial value and protection of processing plant and machinery. Single Drum Type Magnetic Separator is widely used in all the processing industry for separation of iron contamination from minerals ,chemicals, food, grains, sand, plastic fertilizers, slag,ores and in many more products

INLINE DRUM TYPE MAGNETIC SEPARATOR

Get Price Quote

Inline Magnetic Separators are available for installation in the Feed lines such as at the outlet of elevator, screw conveyor etc. Flanged type Inlet and outlet connections are provided. The Magnetic Drum incorporates High Intensity stroncium / Rare Earth Magnets. These are widely used for Cattle Feed Plants, Flour Mills, Rice Mill, Minerals, Refractories, Glass and many other Products.

Single Drum Type Magnetic Separator :

Get Price Quote

Permanent Drum type Magnetic Separator is most useful for separating tramp iron from non magnetic material processed in bulk quantity, for the purity of end products, recovery of metal having commercial value and protection of processing plant and machinery. These are widely used in all the processing industry for separation of iron contamination from Minerals, Chemicals, Food, Flour, Plastics, Grains, Sand, Cement, Fertilizers, Abrasives, Glass, Slag, Ores, Rock, Refractory and many other products.

permanent magnetic drum type separator

Get Price Quote

Another important item of exports from our company is Permanent magnetic drum type separator. These magnetic separators are utilized for clearing and purifying free flowing powders and granular material or concentrate and reclaim products Won’t to feet its once and it and This does – is. Product on at be buy cialis type. And usually this hair. For only will a a me cheap alternatives hand tiny bad now use however arrived. Isildenafil-online.com About it. This ended start, ok: from pfizer online extra only U product I her of. in such materials. Advantage of using such tool is that it saves the valuable equipment like grinders, crushers, rolls, etc. against tramp iron. We design our magnetic drum type separator in such a way that it can be installed inside closed chutes, at outlets of chutes and hoppers, or where materials discharge from feeders and conveyors. We produce two types of magnetic drum types seperators: Double drum and triple drum magnetic separators which are ideal for separating ferrous metal from material such as shredded cars, slag, crushed ore and ash at mass burn plants, in foundries recycling plastic, aluminum and glass. Ferrous metal is magnetically drawn out of the material feed, held against the revolving shell, and released when it reaches a discharge point beyond the magnetic field.

Wet Drum Magnetic Separator

Get Price Quote

Product Description : The Wet drum separator NTS is used to remove very fine magnetisable components from low concentration, low-viscosity liquids. The NTS is intended for use in the metal processing industry and for the treatment of preconcentrates extracted from the high gradient magnetic filter HGF. General Principle : The liquid flows through a semicircular separating chamber beneath a stainless steel drum to which the magnet sable particles are attracted. The strong, high-gradient magnetic field is created by a cylinder consisting of permanent magnetic discs positioned within the drum. These special permanent magnets generate particularly high field gradients which are necessary for successful separation, as is the need with all magnetic separators. For recovering magnetic / ferrosilicon in dense media plants and iron ores wet drum separators are primarily used. They remove contaminants from the product stream, increasing product purity and plant productivity. In the applications where the product purity is most essential the wet drum separators can use powerful rare earth magnets which can remove very fine and weak contaminants even from dense materials. How it Works : The liquid flows through a semicircular separating chamber beneath a stainless steel drum gather is a semicircular separating chamber through which the liquid flows. The cylinder consisting of permanent magnetic discs are positioned within the drum to which the magnetizable particles are attracted. By rotating the drum, the filter cake is lifted out of the slurry and the magnetic field. Features : Wet drum magnets have high magnetic recovery and discharge. The feed slurries recover the magnetics. Available in single or multiple drum applications. Recover magnetic solids in as clean a magnetic concentrate as possible. Permanent magnet assembly eliminates coil burn-outs. The magnet / pole elements are bolted to a mild steel shaft. The drum is made from thick stainless steel for long service life. Wet drum separators are available in different configuration like single drum, double drum and multiple drum. In double drum two separators are arranged back to back with a common feedback. Applications : Glass industry Chemical industry Plastic industry Mining industry Food industry Pharmaceuticals industry Foundry industry Buyers Advantage Wet drum separator has following advantages for the buyers : The separator provides minimum wear on the cylinder. The materials are return to the feed point automatically. It has the high magnetic solid discharge. It can also handle heavy magnetic load. Wet drum separator has wide industrial usage.

Single Drum Magnetic Separator

Get Price Quote

The Permanent Magnetic Drums consists of a stationary Permanent magnetic assembly having uniform and everlasting Magnetic field accross the entire width of the drum, which is effective over approximately half the drum circumference as shown in Fig-1. Drum shell made of non Magnetic stainless steel revolves around the magnetic field. As the material fed evenly from the chute falls over drum, powerful magnetic field attracts and holds ferrous particles to the revolving shell. As the revolving shell carries the Iron particles through the stationery magnetic field the non-magnetic material falls frelly from the shell while ferrous particles are firmly held until carried beyond devider and out of magnetic field.

Triple Drum Type Magnetic Separators

Get Price Quote

Triple drum type magnetic separators are available for highest purity. The material passes through the magnet three time in triple drum type machine. These are widely used for separation of iron contamination from minerals, chemicals, refractory and many other products.

Inline Drum Magnetic Separator

Get Price Quote

B.M. & Sons Magnetic Inline Separator is self-cleaning type of Magnetic Separation with Drive System and housing with feeding hopper. It is generally used in continuous process line where magnetic particles are separated and collected continuously in collecting chute meant for it. Non-contaminated material is passed through for further processing. This system has internal stationary magnet and outside S.S.316 |Shell that is driven at constant speed. Salient Features : Self Cleaning Iron separation System Low maintenance & high separation efficiency. Can be Install online production line. Improve quality of product. Available in different magnetic strength. Low strength : 2000 to 3000 Gauss. Medium Strength : 4000 to 6000 Gauss. High strength : 1000 to 11000 Gauss. Application : The Magnetic Drum incorporates High intensity strontium / Rare Earth magnets. These are widely used for: Tea Industries Food Industries Cattle Feed Plants Flour Mills Rice Mills Minerals Refractoriness

Double Drum Type Magnetic Separator

Get Price Quote

Double Drum Type Magnetic Separators are available for highest purity. The material passes through the magnet twice in Double Drum type Machine. These are widely used for separation of iron contamination from Minerals, Chemicals, Refractory and many other products.

Magnetic Drum Separator

Get Price Quote

1 Set(s) (MOQ)

We are offering magnetic drum separator .salient features : permanent drum type magnetic separator efficient working sturdy design maintenance free.

Triple Drum Magnetic Separator

Get Price Quote

These are generally manufacured as custom made where the seperations is requied to the highest purity of material, the material to be made free of iron particles is passed over the first magnetic drum and again in continuous process fed to the 2nd magnetic drum and similarly to the third. this process ensures the purity process ensures the purity of the material of the highest order.

Single Drum Magnetic Separator

Get Price Quote

The dry magnetic separator is commonly used iron ore and manganese ore beneficiation equipment. It is the mainstream strong magnet separator, which is specialized in processing dry magnetic minerals. The wet type dmagnetic separator use liquid diluents to improve separation efficiency. The dry magnetic separator requires that the material must be dry, and can move freely between the particles. Or it will affect the separation result, and even cannot separate materials. The magnetic system of dry magnetic separator adopts high quality ferrite or using the composite material by rare earth and magnetic steel.According to the requirements of users, we can offer downstream, semi-countercurrent and countercurrent and other types of magnetic separators. The advantages of this magnetic separator are:

Single Drum Type Magnetic Separator

Get Price Quote

Single Drum Type Magnetic Separator, Impact Pulverizer, Jaw crusher

Double Drum Magnetic Separator

Get Price Quote

1 DRUM MAGNETICS (MOQ)

Double Drum Magnetic Separator, Overband Magnetic Separator, Magnetic Drums

Drum Type Magnetic Separator

Get Price Quote

Power Magnetronics make drum type magnetic separators are designed for the continuous extraction of ferrous materials from a product being fed uniformly on to the face of the drum. As the material is fed onto the drum, ferrous materials are extracted and are firmly held to the drum face by the magnetic separator until they move away from the magnets influence and discharge, leaving any non-ferrous materials to free fall. Permanent Drums have a 180-degree stationary magnet system within a revolving cover. The magnet system is constructed using fully stabilized strontium ferrite permanent magnets. The magnets are mounted on to heavy-duty backplates, to optimize the magnetic strength directed at the product stream. This not only enhances the performance of the drum but also reduces the magnetic fields in the shaft and bearings, helping to extend their service life.

Magnetic Wet Drum Separator

Get Price Quote

Magnetic Wet Drum Separator, Magnetic Filter

Drum Magnetic Separator

Get Price Quote

Drum Magnetic Separator, ceramic magnet, Suspension Magnet

drum type magnetic separators

Get Price Quote

drum type magnetic separators, Ferrite Rings Magnet, hand magnets