Metal Roll Forming Machine

Get Price Quote

1 Piece (MOQ)

Plate Bending Machine

250,000 - 1,000,000 Per piece

We are manufacturing & supplying of 3 roll & 4 roll pyramid type mechanical & hydraulic double pinching plate bending machines.

Best Deals from Metal Forming Machine

CNC Syncro Press Brake Machine

Get Price Quote

CNC Synchro press brakes are designed to give more accuracy and better productivity. The controller has a facility to program the various jobs with complex bending sequence on screen. The CNC Control is used for Three Axis Control or more. The program gives facility to bend different bending degrees; different back gauge positions & different open positions. It has a facility to save different programs and it can be reloaded as & when required. The back gauge consists of Flip-top Fingers, Ball Screw & Linear Bearing along with drive. The machine can be equipped with some high-end optional accessories like, Back gauge Axis X1, X2, R & Z Anti- Deflection units Special profile Hardened Dies & Punch Product Features World class dedicated controller from Delemor Cybelec. 3 or more axis control i.e. ram axis Y1,Y2 & Back gauge axis x. Bend angle & Depth Mode program. Highly Precise press brake scale for Y1, Y2 axis. Close loop proportional hydraulics for ram synchronization. Zero leak sealing of hydraulic cylinders. Hardened & ground Multi “V†Die & Punch. Manual Anti deflection unit in punch. Quick release die clamps. Highly Precise proportional valve to control accurate beam movement. The power pack is supplied by Hoerbiger / Bosach –Germany. Back gauge consist of hardened & ground ball screw, liner motion bearings and AC servo drive for accurate position up to 0.05 mm.

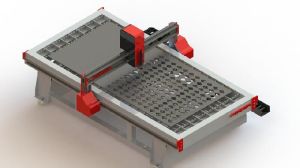

Cnc Plasma Cutting Machine

100,000 Per Units

CNC Press Brake Splendid Machine

Get Price Quote

Plate Bending Machine

500,000 Per Piece

CNC Syncro Press Brake Machine

Get Price Quote

Product features world class dedicated controller from delemor cybelec. 3 or more axis control i.e. Ram axis y1,y2 & back gauge axis x. bend angle & depth mode program. highly precise press brake scale for y1, y2 axis. close loop proportional hydraulics for ram synchronization. zero leak sealing of hydraulic cylinders. Product Features World class dedicated controller from Delemor Cybelec. 3 or more axis control i.e. ram axis Y1,Y2 & Back gauge axis x. Bend angle & Depth Mode program. Highly Precise press brake scale for Y1, Y2 axis. Close loop proportional hydraulics for ram synchronization. Zero leak sealing of hydraulic cylinders. Hardened & ground Multi “V†Die & Punch. Manual Anti deflection unit in punch. Quick release die clamps. Highly Precise proportional valve to control accurate beam movement. The power pack is supplied by Hoerbiger / Bosach –Germany. Back gauge consist of hardened & ground ball screw, liner motion bearings and AC servo drive for accurate position up to 0.05 mm.

CNC Aluminum Letter Bending Machine

625,000 Per Piece

1 Piece(s) (MOQ)

Cnc Plasma Cutting Machine

850,000 Per Piece

Cnc Plasma Cutting Machine

755,000 Per Piece

Gantry plasma cnc cutting

Get Price Quote

1 Piece(s) (MOQ)

corner crimping machine

Get Price Quote

Cnc Angle Punching Machine

Get Price Quote

Main drive Motor, Electric control panel with INCH & SINGLE CYCLE AUTO OPERATION, Stroke adjustment rod with Limit Switch, Punch & Die Adaptor, Sheet Punching. Angle Punching.

Cnc Plasma Cutting Machine

1,100,000 Per Piece

We are the main supplier of this product.

cnc plasma flame cutting machine

150,000 Per Piece

1 Piece (MOQ)

Gantry cnc plasma cutting machine

1,100,000 Per Piece

Cnc Bending Machine

2,700,000 Per Piece

Cnc Punching Machine

Get Price Quote

The COMPACT punching machine from Boschert is the perfect machine for the first-time user of CNC punching technology. User-friendly graphic programming, high quality with low cost, small floor space requirements.

Cnc Plasma Cutting Machine

Get Price Quote

Performance and Features of CNC Plasma Cutting Machine PL 1325 CNC Plasma Cutting machines are widely used for cutting Stainless Steel, Aluminum, Iron, Galvanized sheet, Titanium plate, M.S. plate for signs, architectural components, fabrication units etc.Plasma Source : Mehta has selected the Hyperthem (U.S.A.) as our preferred plasma source. Hypertherm is the world leader in plasma cutting technology and has proven to be consistent, reliable products for all levels of production demandsTorch Height Controller (THC) : The Torch height control system ensures that the cutting torch stays at the right height from the work piece. THC helps to increase the life of consumable like nozzle and improves cutting quality.Fume Extraction Bed : Plasma bed is fabricated by metal sheet with specialized water bed system which is helpful to fumes.

Cnc Plasma Cutting Machine

600,000 Per Piece

1 Piece(s) (MOQ)

Aqcor Inc. Designed and manufacturer of CNC Plasma cutting machines, CNC Routers, CNC Laser cutting machines, CNC Glass cutting machines and CNC engraving machines. The requirements for the CNC machines are from different branches of different manufacturing industries. These include the automotive industry, advertising, glass industry, medical, research & development and research institutions, the mechanical engineering, electrical engineering, fabrication industry, panel building, pharmaceutical industry, the food industry, the ship manufacturing industry, aerospace, architecture, jewelry crafts, prototyping, engraving, schools, museums, universities and many other institutions and industries from around the world.

Cnc Plasma Bevel Cutting Machine

Get Price Quote

Cnc Plasma Cutting Machine

1,050,000 Per Piece

CNC Plate Bending Machine

Get Price Quote

NC Plate Rolling Machine NC Plate Bending Machine working principal CNC Plate Bending Machine is a kind of fully automatic Plate Rolling Machine. INFORCE Machines are equipped with advanced technological features. The Rolls move up and down hydraulically. Top roll is able to generate opening and closing of swing arm automatically from a control panel. The control panel system is submitted with CNC and NC options. Our NC Plate Bending Machines, minimize the loss of time, and expand productivity with many other optional features. Our Sheet Bending Machine has extremely strong bodies precisely machined on CNC machines and with welded accurately. Our NC Plate Rolling Machine is supplied with self-aligning roller bearing, it reduces the friction force. These technological features made us stand with the high head as a reliable NC Plate Bending Machine Manufacturers in India, and other countries. CNC Plate Rolling Machine Features CNC Plate Bending Machine Features : Digital Readouts to Check the roll position NC Controller automatic stop the roll at the limit set Bottom rolls are hydraulically driven independently. Color LCD Display of roll positioning Can be operated by touch panel & keyboard Movable operating desk with user friendly interface Automatic swing arm opening for finished part removal. Self aligning Spherical roller bearings on all 3 roll shafts. Hydraulic Drive Motor Emergency Stop Switch to stop machine during operation Heavy duty reinforced welded steel frame. CNC Plate Bending Machine standard Accessories NC & CNC Options as control panel HMI With Color Display Linear Motion Guideways Movable Operating Desk with Touch Pad & Keyboard Solid Rolls of EN 8/9 with material test certificates Epicyclic Planetary Gearbox for extra torque Spherical roller bearings on all 3 roll shafts. M C B to protect machine against short-circuit and over-loading. Emergency Stop Switch is fitted on control panel to avoid any Accident. NC Plate Rolling Machine Optional Accessories Hardened and ground alloy steel rolls. Material Feeding Table Side support for bending large diameter shells Hydraulic top support for large diameter shells. Automatic Sheet Feeding System Auto Sheet Alignment System Auto Ejection system for removing bending parts NC Plate Bending Machine Price NC Plate Rolling Machine Price There are many advantages of NC Plate Bending Machines. Thanks to the user friendly interface with simple, convenient and precise operation, you can obtain high production efficiency. The main advantage of NC Plate Bending Machine is it requires very less manpower. Only single operator can perform the jobs of large diameters in approx half the time compared to conventional machines. NC Plate Rolling Machine Price in India and other countries are depending up on the following factors. The maximum working width of the machine Maximum plate thickness bending capacity The level of automation and accessories supplied with the machine. As a dependable Sheet Bending Machine manufacturers in India, we assure you the most competitive price. We also provide tailor made solutions as per your requirements and to best suit your budget.

CNC Steel Sheet Shearing Machines

Get Price Quote

Channel Letter Bending Machine

450,000 Per Piece

1 Piece (MOQ)

Plate Bending Machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering Mechanical Plate Bending Machine.

Channel Letter Bending Machine

Get Price Quote

AUTOMATIC BENDING MACHINE Fully functional, which has combined both the plate and profile processing. This system integrated the most convenient switching function of material and cutter, the design of double slotting cutter and double bending tools can easily deal with stainless steel, galvanized sheet, aluminum plate and aluminum profile and other materials processing. Now the machine is the highest rate of return on investment in the market A13ESW Planer Full Function Bending Machine Double bending tools bending system, special designed bending tools and the tools edge, capable of bending with plate and profile. Better choice for small angle and radian bending. Double-cutter slotting, using plane cutter for Galvanized sheet and Stainless steel, using milling cutter for Aluminum plate and Aluminum profiles. Continual rolling press feeding, fast and precise, continual respond, shorten the time of feeding. The close-loop control from length encoder and system itself, makes possible to avoid the material slipping. AT1 Advance Full Function Bending Machine Double knife alternating bending system, according to the change of internal and external arc, automatically switch to bend the bending tool, reverse bending tool automatic income tools library, to avoid the phenomenon of intervention bending tools forming angle, for small arc of the small angle of the molding performance is very good. Under the same platform have the processing ability of profile, plate and profile processing without the need to replace the hardware Double cutter double drive slotting system, Planer cutter and milling cutter of combination configuration, The system is based on the processing of different materials to drive the slotting tool, no manual intervention tool switching procedure. Rolling continuous feeding system, Rapid and sensitive, continuous response. The pressure can be adjusted according to the change of material, which can avoid the occurrence of indentation and sliding material. The setting of the double feeding support avoids the change of feeding track, and ensures the smooth input of the material. processing without the need to replace the hardware.

Cnc Shearing Machine

Get Price Quote

The bending process in metals, especially sheet metals has to be carried out in a highly technical way. One of the technologies that are employed for cutting sheet metals is the sheering process which is processed in terms of applying shear stress of high force to the material. A shearing machine is one that helps to shear or cut metal sheets of different sizes and thickness. The shear strength has to be definitive in accordance with the metal portion that needs to be cut down. In general the cutting and bending processes on metal sheets are applied to obtain programmed sizes of metals pieces form the large sheets of metal. Shearing is carried out with the help of making two bladed meet gradually from the two sides of the metal sheet wherein, determining the angular specification of the blades will help in getting the desired shape of the sheet to be cut. In addition, other types of specific machines such as press brakes are also employed for shearing and bending metals for different industrial operations.

Mild Stee CNC Plasma Cutting Machine

700,000 Per Unit

Cnc Shearing Machine

625,000 Per Units

1 Units (MOQ)