Telescopic valve carbon steel

Get Price Quote

Telescoping valves are designed to control the height of liquid within a pond,reservoir, or other holding chamber. In modern sewage treatment facilities, water treatment plant one specific use is to control the level of effluent in settling basins. Also called Decanting Valves or Sludge Draw-off Valves, the assembly consists of a drain tube which can slip up and down inside a stationary vertical pipe. Through a lifting device, the tube is raised and lowered to maintain the desired level within the chamber.

Cast Steel Needle Valve

250 Per Piece

Best Deals from Metal Valves

Forged Steel Valve

Get Price Quote

As a known name, we ensure safe and timely delivery of the orders at any desired Ahmedabad(India). We make sure the ranges of product we offer purchasers with are as per global quality management standards.

Cast Iron Butterfly Valve

Get Price Quote

CAST IRON BUTTERFLY VALVE Dedicated towards bringing forth the finest and premium quality PRODUCT NAME, we are a well-established Supplier in this domain.We always make use of quality raw materials for the production of our products as we comply with all set quality standards.Owing to our excellent connectivity, trusted shipping facilities, we smoothly deliver the product basket to the clientele.Features Easy to install Minimum maintenance Rigid design Flawless finish

Cast Iron Double Flange Sluice Valve

10,000 Per Piece

1 Piece(s) (MOQ)

Cast Iron Globe Valve

Get Price Quote

Size : 12” to 4”,Applications : Water, Steam, Oil & Gas,Temperature : 200° Centigrade in Working Condition,Pressure : 25 Kgcm² in working condition,Design : ISO 5752 Class 150, BS 5159 Table 2, ANSI B 16, BS 21, API 5B,Guarantee : 12 months replacement guarantee.

Forged Steel Globe Valve`

Get Price Quote

Technical Data: Manufacturing Std : BS 5352 Face to Face, End to End : D N Bros. Std. End Connection : Screwed Ends to BSP/BSPT/NPT : Socket Weld Ends to ANSI B16.11 Inspection and Testing Std : BS 6755 (Part-1)

Stainless Steel Relief Valves

Get Price Quote

Cs Globe Valve

Get Price Quote

An important use of GLOBE VALVE is to regulate or throttle fluid flow none to full capacity. They may be operated efficiently with the stem in any position from wide open to fully closed. The changed in direction of fluid flow through the valve produces increased resistance & considerable pressure drop in globe valves. Technical Specification TYPE Globe valve of bolted bonnet loose plug and renewable seat, outside screw and yoke and rising spondle. SIZE 15 mm through 500 mm CLASS 150, 300, 600.

Cast Iron Non Return Valve

2,500 Per piece

10 piece (MOQ)

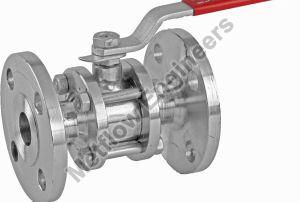

Mild Steel MS Ball Valves

Get Price Quote

100 Piece (MOQ)

Stainless steel Hydrant Valve

2,850 Per Piece

50 Piece(s) (MOQ)

Being a reliable name, we are focused towards delivering exceptional quality range, along with this, we follow strict guidelines and conduct regular quality examinations to ensure quality. We have a strong security system that helps us to make online transactions possible without getting worried about the security. You need to share your details with us and we make sure that the details are kept confidential. Features : Sturdy metal Precision made Dimensional accuracy

3000 PSI Stainless Steel Needle Valve

380 Per Piece

50 Piece (MOQ)

Stainless Steel Double Block and Bleed Ball Valve

Get Price Quote

10 Piece (MOQ)

Carbon Steel Valves

50 - 150 Per Kilogram

2 Metric Ton (MOQ)

SS VALVES

Get Price Quote

We are offering ss valves ( ball valve, knife valve, gate valve, flanged end valve, niddle valve etc.

Stainless Steel Globe Valve

9,500 - 9,550 Per Piece

Forged Steel Flanged Piston Check Valves

1,900 Per Piece

1 Piece (MOQ)

Cast Iron Butterfly Valve

400 - 700 Per PIECE

5 Piece (MOQ)

Cast Iron Plug Valve

1,500 Per Piece

10 Piece (MOQ)

Cast Iron Open Body Pinch Valves

Get Price Quote

Pinch valves, offered by our company, are the modified version of laboratory pinchcock in which rubber sleeve is protected under the casting made of cast iron. The main advantage of Pneumatic Pinch Valves is that the fluid passing from it does not come in contact with its metal parts except the sleeve. This property makes it corrosion resistive against the action of various fluids. Open Body Pinch Valves assure the smooth flow of water like pipeline and their collar sleeve eliminates gasket. Pinch valve is user friendly and can be operated easily as compared to other wheel operated valves. This valve allows positive control over flowing media because of its in between stoppage that gives desired throttling. These pinch valves are extensively used for handling corrosive slurry, liquid with solid suspensions, abrasive media, and many others. We offer pinch valve in best application range with flange as per BS, DIN, ASA & IS dimensions, and ranging between 15mm to 300mm. We are known widely as one of the proficient Pinch Valves Exporters and Suppliers. General Features & Highlights Seat Less & Glandless ValvesField Replicable Elastomer Sleeve.Elastomer Sleeve Having Four Reinforced LugsFlanged Ends & Drilled to Din, Ansi, Bs-10, Is, Etc.this Valve Incorporates allthe Design Modifications Based On Our Experience & is of Study Construction to Handle Abrasive Corrosive Media. BRIEF DETAILS OF PINCH VALVE Pinch Valve is a Seat less & Glandless valve.Pinch valve is a modified version of laboratory pinchcock. A rubber sleeve is protected under a cast iron casting.The fluid passing through do not come in contact with either body covering or any other metal parts of the valve except the sleeve.Hence the body and other metal parts are almost permanently not subjected to the corrosive action of the fluid.The flow through the valve is straight and full as that of a pipeline, when the valve is fully open. Further, the collar of the sleeve eliminates gasket.The valve is simple hand wheel operated of rising wheel type. Therefore the operation of the valve is just simple as other wheel operated valve.The in-between stoppage will allow the desired throttling. Thus the valve offers positive control over flowing media. Applications Pinch valve finds its best application in handling corrosive slurry, abrasive media, liquid with solid suspensions and many others, which are difficult to handle with seat valve. Range The flange of the pinch valve can be supplied in accordance to BS, DIN, ASA & IS dimensions The range for the valve is from 15 mm TO 300 mm. Actuation The valve can be supplied with Electrical and pneumatic actuation. Operating Manual OF PINCH VALVE THE PINCH VALVE is a modified version of the laboratory pinchcock. A rubber sleeve is protected under a Cast iron or Aluminum split body casting. The valve is a simple hand wheel operated of rising wheel type. The operation of the valve is same as other hand wheel operated valve, it closes when moved in clockwise direction and opens when moved in anticlockwise direction. The in-between stoppage will allow the desired throttling. Thus the valve offers positive control over flowing media. The flow through the valve is same as that of a pipeline, when the valve is in fully opened condition. Further, the rubber sleeve eliminates the need of a gasket. PRELIMINARY PRECAUTION On receipt of the valve please check the position of the valve, as it is advisable to keep the valve in fully opened condition. Also check the position of the travel limit nut, if found loose then tighten the set screw of the nut. INSTALLATION The valve can be installed without any gasket unless it is required for some specific purpose. Tighten the nut of the flanges evenly & equally, but avoid too much tightening. After installation check the free movement of the upper & lower pinching bar by opening & closing the valve. The valve is then ready for the service it is installed for. MAINTENANCE If the valve is found leaking through the seat after sometime even though in fully closed condition, then set the travel limit nut by just taking it 1 or 2 threads above & then tighten. This will allow more room for traveling of rubber sleeve & ensure the valve to zero leakage. This problem sometimes occurs when the sleeve is slightly worn out, when used under abrasive condition. Further, The Rubber sleeve of the valve up to 2” (50mm) have a single lug on either side and it goes into the hollow passage of the pinching bar where it is fixed with the lug clamping screws. In the higher sizes above 2” the sleeves have two lugs on either sides and is fitted overlapping the pinching bar. DISMANTLING THE VALVE & REPLACING THE RUBBER SLEEVE When the rubber sleeve is ruptured or totally worn out then it is to be replaced with a new one. In this case first dismantle the valve by following the instructions. Remove the hand wheel.Open the Tie Bar nuts.Disconnect the spindle from the Horseshoe connection and remove it completely with the bridge.REMEMBER not to temper the set screw of the yoke bush, unless if required it should be completely tight.Open out the nuts & bolts of the split body of the valve.Remove the screw of the lugs from both the pinching bars.Now fit the new rubber sleeve & reverse the operation to assemble the complete valve. NOTE It is advisable to keep a spare rubber sleeve for maintenance purpose, considering the self life of the Rubber as six months when packed & stored in dark. The Pinch valves should be stored in fully open condition only. We also offer complete spares of the valves, but request you to place your order a week in

Brass Needle Valves

Get Price Quote

We are engaged in offering superb quality Brass Needle Valves. Our Needle Valves are designed with utmost precision using pristine brass and modern technology. They are stringently tested on various parameters to ensure hassle free functioning. Brass Needle Valve has a small port and a threaded, needle-shaped plunger and allows precise regulation of flow. These valves find wide usage in flow metering applications. We take up and fulfil bulk orders of Brass Needle Valves owing to our highly efficient production capacity.

Forged Steel Gate Valves

2,000 Per

1 Piece(s) (MOQ)

Forged Steel OS & Y Type 1 Globe Valve

2,000 Per Piece

Stainless Steel Dairy Valve

Get Price Quote

10 Piece (MOQ)

Stainless Steel Check Valve

130 Per Piece

100 Piece (MOQ)

Forged Steel Gate Valve

Get Price Quote

We are offering forged steel gate valve, jupiter controls valves forged steel gate valves are bolted bonnet, outside screw and yoke type, rising stem design. Jupiter controls forged valves body and bonnet made from high quality forgings. Jupiter controls offer forged steel gate valves in size 12” (dn15) to 2” (dn50) to suit various critical, non-critical applications and pressure rating in 800 class. Jupiter controls forged steel gate valve manufacturing range covers regular port and standard port both types of valve. Regular port gate valves have fast delivery or ready stock, for standard port gate valve do manufactuing on order basis. jupiter controls offer forged steel gate valve in wide range of body materials like astm a 105 - forged carbon steel, astm a 182 f 304304l316316l - forged stainless steel 304304l316316l, astm a 182 f 1122 - alloy steel to suit industrial application. Jupiter controls forged steel gate valves are available under any third party inspection also. For high pressure & temperature application stellited f6 face seat & gate available. Forged gate valve available is threaded end, socket weld end, butt weld end and flanged end connection. For flanged end forged gate valve flanges will be a welded with a valve body not integral forged. In haryana manufacturer trading & exporter of wide range of industrial forged steel gate valves rising stem forged steel gate valve (regular port) non-rising hand wheel, bolted bonnet forged gate valve (regular port)

Brass NRV

Get Price Quote

LCB series brass non return valve manufacturer by lubi valves. Construction from forged brass body. Suitable for both oil and water applications

Mild Steel Ball Valves

Get Price Quote

Reckoned for our extensive array of products, we efficiently serve our customers from Ahmedabad(India). In order to deliver flawless range of products, we keep stern check on the product development, storage, packaging and delivery.

Cs Globe Valve

Get Price Quote

Simex put forward the broad assortment of globe valves which are suitable for throttling as well as shut-off applications. Let’s have take some idea about it.. What is the globe valve??? Its structure and applications… The Globe Valve is widely used and suitable for On Off or Regulating fluid flow. Main single seating in globe valves is parallel to line of flow and the flow pattern is offset type, not a straight line through flow as gate valve or ball valve. This design affords a better closure than a gate valve. The change in direction of fluid flow produces increased resistance and considerable pressure drop. Because the flow is directed against the disc in a symmetrical fashion, there is very little wear on the valve parts and is one of the easiest valves to repair