Stainless Steel Spring Washer

Get Price Quote

1000 Piece (MOQ)

Steel Washer

40 - 70 Per Kilogram

Best Deals from Metal Washer

SS plain washer

Get Price Quote

rotary bottle washer

Get Price Quote

The Multipack Rotary Bottle washing Machine is compact and highly efficient machine with elegant look. This multi functional multi featured machine meets the GMP requirements of washing for glass and plastic bottles. The machine operates on the Rotary principle with "GENEVA" mechanism and requires manual loading and unloading of bottles.

Rubber O Ring

5 Per Piece

100 Piece (MOQ)

Tab Washer

Get Price Quote

Plain Washer, Plain Big OD Washer, Plain Small OD Washer, Spring Lock Washer, Spring Washer Heavy Duty, Tooth Washer, Serrated Star Washer, Tab Washer with One Tab, Tab Washer with Two Tab.

Stainless Steel Washer

250 Per Kilogram

100 Kilogram (MOQ)

Full Gear Coupling

Get Price Quote

We are main supplier of this product.

Full Gear Coupling

Get Price Quote

Range:-full gear coupling sfg-100 to sfg-119 as per our catalogue or made as per customers requirement against their drgs. Half gear coupling shg-100 to sfg-110 as per our catalogue or made as per customers requirement against their drgs. Related to coupling we also make rigid coupling, break drum couplings etc.

Frp Air Washer

Get Price Quote

he basic components of an air washer system are a chamber that contain a series of spray nozzles, an eliminator section that removes water from the air that is exiting the air washer and a sump which catches both the sprayed water droplets and the water that was collected by the eliminators. The spray section will either add moisture to the air or dehumidify the air, while washing solid particles out of the air. The eliminator section in many cases is a "W" or a series of "W"s in shape. This section, forces the air to contact the eliminator components, which in turn knocks down water droplets and air borne solids. The sump is the collection basin for the system. The washed out solids, lint, dust, and water all collect in this area. FUNCTIONS OF AN AIR WASHER: 1. Cool the air.2. Humidify the air. 3. Dehumidify the air. 4. Clean the air of particles. 5. Hyperionize the air. HUMIDIFICATION BY AN AIR WASHER: Humidification is accomplished by using the recirculating spray water, washing preheated air with the spray water, and by heating the spray water. In general, the humidification of the air occurs as the humidity of the outside air decreases. This allows the water from the sprays to entrain in the low humidity air and increase the humidity of the washed air as it leaves the system for the plant. The heating of the spray water or the heating of the air prior to the air washer creates a condition that allows the air passing to the plant to hold a higher level of moisture. The amount of moisture that is required for the plant use will dictate the degree that the air or spray water will need to be heated. An air washer will humidify the air during the seasons when the outside air is low in humidity. This is usually during the late Fall, Winter and the early Summer, or in arid climates. The reason that the air is humidified, is to create the proper condition for the operation of the plant. In the production of Textiles, Electronics, and other related industries, where the humidity of the air is crucial for the air quality and material production, the air washer will balance the required humidity of the plant air by humidifying the air during the dry seasons, and dehumidifying the air when the air conditions are more humid than the plant requires. During the humidification process, the water in the air washer will cycle up solids in the same manner as a cooling tower. For this reason, the air washer is to be treated in basically the same manner as a cooling tower would be, that has the same water characteristics. The only differences in the chemical treatment program are based on the unique operating characteristics of an air washer, which are addressed in other sections of this report. DEHUMIDIFICATION BY AN AIR WASHER: Dehumidification occurs when the water that is spraying from the nozzles is cooler than the wet bulb temperatures of the incoming air. In this case, the incoming air is moist and contains a higher level of moisture than the plant requires. By spraying this air with colder water, the incoming air is cooled down. This cooling process also removes moisture from the incoming air. Dehumidification usually occurs during the hotter more humid months of the late Spring, Summer, and very early Autumn. During the period of time that the air washer acts as a dehumidifier, the air washer will take on the water that has been stripped from the air. This effect causes the dissolved solids level in the air washer to drop. It also creates a surplus of water in the air washer system that is removed from the air washer through the system overflow. As the solids level in an air washer drops, the Langelier Index will also drop. The index is used to indicate the tendency of the system water to be either scale forming or corrosive. During CLEANING THE AIR WITH AN AIR WASHER: Air is cleaned by an air washer when particulate matter impinges on the wetted surfaces of the eliminator blades. Air is also cleaned, when the sprayed water generates enough ionization to neutralize the charges on the particles in the service area so that they can be dropped out into the sump as they are drawn through the air washer. The cleaning of the air will remove lint, oils, and other airborne particles from the air. This builds up the level of the solids in the water which must be removed either from over flow or bleed. Chemical treatment can improve particle removal and prevent nozzle clogging from excessive solids build up. AIR HYPERIONIZATION: As the water droplets are broken up at the nozzles, ionization occurs. This places a charge on the water droplet which allows it to attract charged particles that are in the air. This will allow the removal of any of the airborne solids from the air. It can also cause the build up of charges in the air that exits the air washer. These charges can cause static electricity to build in the air, which can cause textile processing problems if not neutralized by an antistat treatment program. RECOMMENDED AIR WASHER MAINTENANCE: Air washer systems should be inspected regularly to insure that wetted components are free of dirt, WE ALSO HAVE

disc spring washer

30 Per Piece

Dal Washer

Get Price Quote

Moong dal (Green Gram) and Chana dal (Chick Peas or Chick Pea) are very popular in the Chinese, Indian and Pakistan cuisine and are increasingly consumed as deep-fried snacks.Our Dal washing machine are manufactured by fabricate using solid and superior quality of stainless steel 304. We have been efficiently able to offer to our customers this range of Dal Washing Machine. The dal washer machine has been made to process high quality and completely hygienic mung dal, moong dal (Green Gram) and Chana dal (Chick Peas or Chick Pea snacks. Moreover, these machines are fitted with reduction gear box. Complete stainless steel body of these machines is widely appreciated by the clients. Operating Principle of Dal washing machine The spacialized paddles are positioned to move the material in opposing lateral directions as well as radically. The paddle design is generally employed where friable materials are being washed.Dal washer consists of several elements: a centrally mounted horizontal shaft that rotates within a cylindrical container, paddleswashing elements that are attached to the centrally mounted shaft, special openings at the top for feeding materials, manually tilt able tank operated, inside a cylindrical conduit and a complete drive unit. Due to continuous improvements, we reserve the rights to alter and/or amend dimensions/design without prior notice.The figure for capacities given are for guideline only may very force case to case and depending many factors.

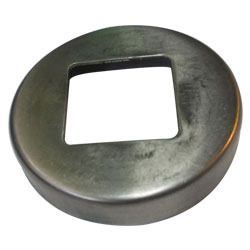

SS Flat Square Washer

Get Price Quote

Lifts Washer

Get Price Quote

We fulfill the requirement of Elevator/Lifts Washer for Collapsible Gate that is used in various industries and research organization for fitting of various nuts and bolts. These Elevator/Lift Washers are widely demanded for salient attributes like easy operation, high performance and durability. We do complete quality and performance measure inspection of these Elevator/Lift Washers before supplying these to our esteemed clients ensuring all Instruments re working well. Available in Size:It ia available in 16mm O/D – 6.5mm I/D – 8.5mm (H).

Full Gear Coupling

Get Price Quote

FLEXIBLE GEAR COUPLINGS are distinguised by their MECHANICAL FLEXIBILITY and compensation of MISALIGNMENT of the connected shafts automatically without any loss of transmitted power during running. These coupling ensure greater flexibility because of their well designed tooth formation generated by INVOLUTE system to ensure uniform toothe PROFILE AND PITCH.

Plain Washers

Get Price Quote

We manufacture our range of Plain Washers in different size options, dimensions, and finishes to suit different industrial applications. These are in high demands in the competitive market owing to their dimensional accuracy, high tensile strength, abrasion resistance, flawless finish, and durability. Our range of Plain Washer is quality tested on well defined parameters by our team of quality controllers. We also manufacture different types of washers as well i.e Tab Washers, Heavy Duty Washers, Tooth Washers, etc. To satisfy our clients fully, we also provide them with testing certificate. Our plain washers are also available in customized forms and at market competitive price Stainless Steels Material Grade : 304, 304B, 309, 310, 316, 316B, 317, 317L, 321, 347, 401, 416, 430 & 501. Diameter : M6 to M72 Duplex & Super Duplex : UNS31803,S32750. Diameter : M6 to M72 Hastelloy : Hastelloy C-276, Hastelloy C-22. Diameter : M6 to M72 Exotics : 904L, A-286, Alloy20, Alloy50, NitronicAlloys50, Titanium. Diameter : M6 to M72 Nickel Alloys : Inconel600, 601, 625, 718, 750, 800/800H, 825, 925, Monel 400, 405, K-500 & Nickel 200. Diameter : M6 to M72

rotary bottle washer

Get Price Quote

The Bhagwati Rotary Bottle washing Machine is compact and highly efficient machine with elegant look. This multi functional multi featured machine meets the GMP requirements of washing for glass and plastic bottles. The machine operates on the Rotary principle with GENEVA�¢ mechanism and requires manual loading and unloading of bottles.

Plain Washer

0 - 1 Per Piece

Stainless Steel Washers

Get Price Quote

Lock Washer

24 Per Piece

Stainless Steel Washers

Get Price Quote

We are offering Stainless Steel Washers. we provide a broad array of stainless steel washers, which procured from reliable manufacturers from all over india. these are manufactured according to the din 125 specifications and are offered by us in a variety of material grades and sizes. variants : plain (punched) washers spring washers square section flat section availability : sizesm2 to m36 material gradesss 304ss 316ss 310ss 321 attributes : available without burrsnon-corrosive high stress bearing resistant to wear and tear perfect gripping action bright finishing required with bolts for : packing gripping.

Stainless Steel Plain Washers

5 - 10 Per Piece

100 Piece (MOQ)

Full Gear Coupling

Get Price Quote

1 Piece (MOQ)

SS Plain Washers

Get Price Quote

SS plain washers are available in ss 304 , ss 316 & ss 202 grades. SS plain washers are available in various thickness. SS Plain washers are available in various guages [ 10 guage , 12 guage , 14 guage , 20 guage , 22 guage ]. SS Plain washers available in range from : 2mm to 56 mm. SS washers are available in tailor made sizes as per client requirements.

Stainless Steel Washer Making Machine

1,000,000 Per Piece

Duplex Steel Washer

Get Price Quote

100000 Pieces (MOQ)

Plain Washer

Get Price Quote

We have positioned ourselves as a major manufacturer, supplier, and exporter of an immense range of plain washer in India.

Stainless Steel Washer

152 Per Kilogram

100 Kilogram (MOQ)

Stainless Steel Bolts

Get Price Quote

Form of industrial Bolts:Stud bolts, hex head bolts, socket hexagon head screw anchor bolts, u-bolts, j bolts, mushroom head square neck bolts, t- head bolts, wing screw bolts, eye bolts, eye bolts, foundation bolts, structural bolts. Specifications: Stainless Steel Standards: Astm / Asme A/Sa 193 / 194 Stainless Steel Grade: B 8 (304), B 8C (Ss 347), B 8M (Ss 316), B 8 T (Ss 321), A 2, A 4 Duplex Steel Standards: UNS No.S 31803, S 32205. Nickel Alloy Standards: Astm / Asme Sb 160 / 164 / 425 / 166 / 446 / 574 / 472 Nickel Alloy Grades: Uns 2200 (Nickel 200) / Uns 2201 (Nickel 201), Uns 4400 (Monel 400), Uns 8825 (Inconel 825), Uns 6600 (Inconel 600) / Uns 6601 (Inconel 601), Uns 6625 (Inconel 625), Uns 10276 (Hastelloy C 276), Uns 8020 (Alloy 20 / 20 Cb 3) Alloy Steel Standards: Astm / Asme A/Sa 193 / 194 Gr. Alloy Steel Grades: B 6, B 7/ B 7M, B 16, 2, 2Hm, 2H, Gr 6, B 7, B 7M.

Stainless Steel Bolts

Get Price Quote

Stainless Steel Bolts, Stainless Steel Rods, Industrial Fasteners