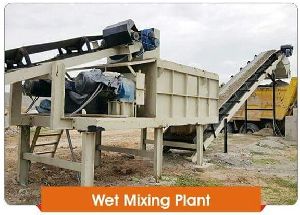

Wet Mix Plant

Get Price Quote

We are a well-known name as Wet Mix Plant Manufacturer and Supplier in Ahmedabad, Gujarat. The Wet Mix Plants that we offer are precisely engineered in compliance with the industry set norms by the professionals. The Wet Mix Plants can be availed from us in different models with production capacities of 100 tph, 160 tph, 200 tph and 250 tph. Higher capacity plant can be offered against specific requirement. Cold Aggregate Feeder Bins Single Deck Vibratory Screen Charging Conveyor Twin Shaft type Pug mill Mixture Mix Material Output Conveyor Storage Silo Water Pump Control Panel Control Cabin

Road Paver With Long Needle Vibrator Machine

2,600,000 Per Piece

1 Piece (MOQ)

Best Deals from Milling Machine

Rotary Table Machine

Get Price Quote

We manufacture a wide range of rotary table machine, processing plant equipments including rotary tables , used in automatic conveyorised systems such as powder filling line, inspection unit, liquid filling line etc. Rotary tables have unique drive mechanism and fully modular design that ensure high performance and ease of operation. Available in varied diameter and height and can be custom made as per the specific requirements of clients. Salient features: - unique drive mechanism - fully modular design - disc size to suit customer requirements - hight adjustment to in-line with conveyor belt

PLC Surface Grinding Machine

Get Price Quote

Pre-Milling Full Automatic Edge Banding Machine

1,750,001 - 1,800,000 Per Piece

1 Piece (MOQ)

Power Floater

Get Price Quote

The company is enlisted among the topmost Manufacturers, Exporters and Suppliers of Power Floater in Ahmedabad. We have a team of highly experienced engineers who use the latest techniques to fabricate it. Energy efficient, lightweight, excellent performance are some of the main attributes of our Power Floater. We make available floater with different technical specifications as per the requirement of buyers. We believe in delivering Power Floater within the stipulated time. Features : Top quality Long lasting Fine finishing Specification : Power Supply : 415 volts, 3 Phase, 50 Hz Power : 2.25 KW/ 3 HP/ 2 HP Rated Current : 5.0 A Output Speed :80/120 rpm Max. Reach : 2.7 Mtr. Max. Wt. with Floating disk : 110 Kg. Outer Diameter : 914 mm Blades Diameter : 815 mm Disk Diameter : 900 mm

Wet Mix Macadam Plant

Get Price Quote

The tradition of providing automation excellence in Road Construction Machinery, CAPIUS has designed & engineered their Wet Mix Macadam Plant for achieving homogenous mix material to prepare base and sub base in Road Construction Projects. Wet Mix Macadam Plant from Capious for base and sub base production provides higher productivity with close control on quality of mix and production costs. Manufacture from a rich experience of supplying around 100 plus installations across the globe.

paper mill machinery

70,000,000 Per Unit

1 Unit (MOQ)

N K R Engineers Pvt. Ltd. – Ahmedabad was established with an objective to offer tailor made optimum solutions in the field of Pulp and Paper Industries.

Road Cleaning Machine

Get Price Quote

The company is chiefly engaged in the manufacturing, exporting, and supplying of Road Cleaning Machine in all over the globe. The Road Cleaning Machine efficiently cleans the sand from the road through powerful high pressure air blower. The Road Cleaning Machine is known for saving time, labor, as well as bitumen. Specifications Trolley with pneumatic tyre Honda company make engine Blower with heavy duty impeller Supporting solid tyre with standard accessories

Communiting Mill Machine

Get Price Quote

HOW IT IS BETTER The S.S. cladding on base, S.S. belt guards and S.S. cover on motor are the main components of the machine. There is no painted surface on the top of the table. The screw, guide rods and motor rails are chrome plated. The single operator can handle the machine, because of the very less down time as only beaters assembly will have to be reversed for making t knifr to impact The fixed bearers assembly is provide The shaft and beaters are of stainless still

Multi Mill Machine

Get Price Quote

Vacuum Dewatering System

Get Price Quote

10 Set(s) (MOQ)

Multi Mill Machine

80,000 - 150,000 Per Number

10 Piece (MOQ)

Pharma Machinery & Spares Multi Mill are the efficient and compact unit. This equipment is used in the Pharmaceutical industry for compunction i.e. particle size reduction. This is necessary to achieve size reduction as well as an output of uniform size before subsequent operations. The unique feature of Multi Mills is that it can be used inline between two equipment conveniently. For example in the pharmaceutical industry, it is widely used at the outlet of Rapid Mixer Granulator and directly discharge in FBD Bowl for producing by RMG. The uniform granule size results in faster and uniform drying. Other Details: Multispeed drive for various product grinding. Easy dismantling and cleaning Low energy consumption SALIENT FEATURES :• Suitable for Dry Granulation / Pulversing / Shredding & Chopping of Materials.• Multi Speed Drive for Various Product Grading.• Easy Dismantling & Cleaning.• Output 20kg To 400kg / HR Depend upon Machine Model, Characteristic of Product & the Screen Size.• Easy Maneuverability with the help of Castor Wheels.• Beaters 8 to 12 nos. with Knife / Impact Edge & 2 Scrapper Blades.• Rotor Speed - 750 / 1500 / 2100 / 3000 RPM Approx.MULTI MILL is designed to utilise the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to control the particle reduction. Material fed in to the processing chamber moves to the periphery and passes through the screen radially and tangentially. Finally the processed material gets collected in to the container kept below the processing chamber.

Walk Behind Vibratory Rollers

98,000 - 99,900 Per Piece

1 Piece (MOQ)

Lab Multi Mill Machine

110,000 Per Piece

1 Piece (MOQ)

Communiting (CAD) Mill Machine

Get Price Quote

Communiting Mill Machine Manufacturer In India.. We are one of the largest Pharmaceutical Machinery Manufacturer from India, Communiting Mill Machine is used in Granulation Department for making granules, and Communiting Mill Machine is most widely used in the Pharma Industry. We can get maximum kegs. Per hour depending on the product and sieve we used. * Varies according to product characteristic, rotor Speed and Screen type. APPLICATION: It has been specifically designed for wet and dry granulation, pulverization or dispersion of products or ingredients found in the pharmaceutical, Chemical and food industries. It is also finds application in Cosmetics, confectionery, Fertilizers, Insecticides, detergents and Electrolux Industries etc. DESCRIPTION: Latest improvements in design make this unit a truly GMP model and Versatile in operation & maintenance. Unit consist of quality hopper, feed throat and processing chamber with beaters assembly , heavy duty motor, star delta starter with overload relay, three speed step pulley, suitable screen , S.S. cladded base having tubular legs with castors, optional jacket for the feed throat and processing chamber for cooling A wide range of screens is available for various process needs Technical Specification

Ball Mill Machine

Get Price Quote

HP to 100 HP and above { 5 Kg to 10 tons Capacity Continue Ball Mill }, Direct Gear Drive , Counter Gear for load reduction. MS + MS SS Coating + SS + jacketed. Pigment Colors - Minerals & Ores - Chemicals Technical Products Dyestuffs - Fertilizer - Insecticides - Pesticide.

Mini Rice Mill Machine

Get Price Quote

Colloid Mill Machine

Get Price Quote

Unique for small volume micronization. Modified design of stator-rotor assembly. Totally leak proof design. Easy to dismantle for cleaning and maintenance. Available in plain, water jacketed & flame proof options. Special design colloid mill working principle facilitates adjustment of grinding gap by an exterior screw by means of handle even during operation. Extended bearing housing specially designed to facilitate fine adjustments of bearing clearances or backlash to avoid metal to metal contact of rotor and stator. This unique design provides smooth and consistence all round performance and long life of rotor and stator. Salient Features:- Colloid Mill - Pharmaceutical Milling, Colloid Mill Machine Unique for small volume micronization. Modified design of stator-rotor assembly. Totally leak proof design. Easy to dismantle for cleaning and maintenance. Available in plain, water jacketed & flame proof options. Special design facilitates adjustment of grinding gap by an exterior screw by means of handle even during operation. Extended bearing housing specially designed to facilitate fine adjustments of bearing clearances or backlash to avoid metal to metal contact of rotor and stator. This unique design provides smooth and consistence all round performance and long life of rotor and stator. The colloid mill machine is used as herbal extractor machine, in food processing, and pharmaceutical lab also.

Hydraulic Milling Machine

400,000 Per Piece

Comminuting Mill

Get Price Quote

Salient Features Versatile machine for particle size reduction and grinding operation Beaters assembly is in a separate pillow blocks for ease in maintenance. Very less down time, as only beaters assembly will have to be reversed (and not the complete chamber) for making it knife to impact forward or vice-versa which can be done by operator. Swing type beaters assembly is provided as a standard supply which increases the output by 10 to 30% and is easy to clean. Water jackted chamber is also available of demand. Beaters are made from HCHC material with hard chrome plating. Beaters assembly is dynamically balanced which reduces vibration and noise level and increases bearing life. Castors are provided for mobility and brakes can be applied for fixing machine at one place. Flame proof electrical can be provided on demand at extra cost

communiting mill

Get Price Quote

PRISM Lab Scale Comminuting Mill has been designed for wet and dry granulation, pulverizing and dispersion of products for pharmaceuticals, chemicals, Cosmetics, Confectionery, Fertilizers, Insecticides, Detergent and food industries etc. Built on advance engineering principles the machine consists of Hopper, throat hopper, processing chamber, beater assembly, sieve, heavy duty motor, overload starter, back frame and rigid structure with castors. The comminuting chamber having simple to use features, the reversible comminuting chamber having simple to use features, the reversible comminuting chamber consists of blades with knife and impact edges. The knife edges come in use for granulating, chopping, cutting and sizing while impact edges are preferred for grinding, pulverizing, blending and mixing. The dynamically balanced rotor mounted on pillow back at outside of the chamber with effectively sealed in a fabricated housing. All Contact parts of AISI Stainless Steel 316 Quality, All Non contact parts of AISI Stainless Stele 304 Quality, Easy and simple to change knife to impact forward vice-versa, Dynamic balanced beater assembly bearings are in a separate pillow block at outside chamber.

Ball Mill Grinder Machine

Get Price Quote

We are working with a pool of professionals who are diligent at their work and make sure that the offered lot is packed in high quality material and timely dispatched. Our products are the most sought after in the market, as they are specifically made as per global and domestic quality managements systems. Features: Precision made High strength Industrial application

Wet Mix Macadam Plant

Get Price Quote

1 Piece(s) (MOQ)

PIN MILL / SUGAR PIN MILL / SUGAR MILL MACHINE

300,000 Per Set

1 Set(s) (MOQ)

Communiting Mill Machine

Get Price Quote

We have marked a distinct position in the market by providing high quality range of Communiting Mill Machine. Our offered machine is manufactured using quality approved components and innovative technology under the stern vigilance of adroit professionals in tune with predefined industry norms. To meet the varied requirements of the patrons, we offer this machine with high performance at a pocket friendly price. Features :- Excellent performance Easy handling Less maintenance How it is Better :- The S.S. cladding on base, S.S. belt guards and S.S. Cover on motor are the main components of the machine There is no painted surface on the top of the table The screw, guide rods and motor rails are chrome plated The single operator can handle the machine, because of the very less down time as only beaters assembly will have to be reversed for making knife to impact The fixed bearers assembly is provide The shaft and beaters are of stainless still

Wet Mix Plant

Get Price Quote

We are the main supplier of this product.

Thermoplastic Road Marking Machine

Get Price Quote

Utilizing state-of-the-art packaging tools and superior grade supplies, we pack our products and help them remain protected from external damages. Furthermore, the packages are labeled properly for information. We can be entrusted for delivering the orders within the promised time frame as we have sophisticated transportation facilities.

wet mix plants

Get Price Quote

Our PE (Stationary) & MDM (Mobile) series offer customers the industry's finest & proven technical solution, latest generation process controls and automation together with total installation and site support, aimed to delvier precisely mixed quality asphalt productively and profitably. PE design team facilitates custom built asphalt plants to meet specific site demands and requirements. Available in capacity ranging form 35 to 120 TPH output in different models. In continuing the tradition of providing automation excellence in Road Construction Machinery, PE has engineered their Wet Mix Macadam Plant for achieving homogenous mix material to prepare base and sub base in Road Construction Projects. Designed to confront the toughest job site requirements and maximum reliability and uptime, PE WMM plants have robust structure and quality precision. Motivated to meet specific customer requirements, PE WMM Plants raging from 100 to 125 TPH can be tailored as needed. Cement stabilization (CTAB) system and other accessories can be provided as per requirement.

Wet Mix Macadam Plant

2,250,000 - 3,150,000 Per Unit

1 Piece (MOQ)

Wet Mix Plant