pet glass mould

100,000 - 1,000,000 Per 1-10

this is the six cavity glass mould hot runner glass mould 1.2083 din steel material mould base plate is c45

Industrial Insert Molding Services

Get Price Quote

Advance your industry with our Industrial Insert Molding Services. Seamlessly integrating inserts into molded components, we enhance strength and functionality. Our skilled team specializes in diverse sectors, crafting solutions that meet rigorous standards. From automotive to electronics, we ensure precision, durability, and streamlined production. Elevate your manufacturing process with our insert molding expertise, where innovation meets integration, creating robust and efficient components that drive progress in your industry.

Best Deals from Molding Machine

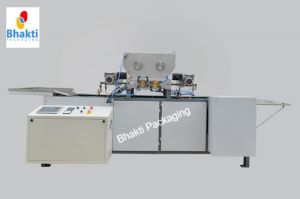

Paper Cutlery Moulding Machine

136,000 Per Piece

1 Piece (MOQ)

Application of Paper Cutlery Moulding Machinery Hotels Food and Beverage Factory Restaurant Home Use Food Industries

BLY 2020G Rubber Molding Machine

2,500,000 - 2,600,000 Per piece

1 Piece (MOQ)

Plastic Bottle Blow Mould

18,000 Per Set

1 Piece (MOQ)

Die Mould Laser Welding Machine

1,250,000 - 1,500,000 Per piece

1 Piece (MOQ)

Mini Injection Molding Machine

625,000 Per Piece

1 Piece(s) (MOQ)

We are one of the leading Manufacturers and Suppliers of high grade Mini Injection Molding Machines, suitable for molding small plastic parts. It saves the moulding cost, die cost, and requires less floor space. Mini Injection Molding Machine is widely used for molding all kinds of plastic. It is available at highly reasonable prices. Optional Features Air ejector systemHydarualic ejector system multi strokeCore pulling arrangementMotorized mould height adjustmentSelf lubrication bushesManual and auto lubrication systemHour counterMould lifting arrangementWater batteryDynamic barrier screwTio2 coating screwReturn line magnetic oil filterHeating insulation coverCeramic heaterSensitive low pressure mould systemHydraulic guard systemEnergy saving electro proportional control hydarualic system with plcHopper dryerHopper loader Attributes Low power consumptionHigh efficiencyEasy to install

roto moulds

Get Price Quote

ROTOPLAST is based at Ahmedabad and manufacturer & exporter of different types of Rotomoulding Moulds in SS, MS Aluminum and CNC machined rotomoulds. Our professional experts are guiding to carry out the manufacturing process. High Production Efficiency Strong Built & Reliable Structure Optimal Cooling Cycle Time

SE-6060 CNC Mould & Die Making Machine

825,000 Per Piece

1 Piece(s) (MOQ)

Auto Mould - Woodworking Machine

Get Price Quote

Designed for mass production of straight & angular mouldings. Built for rugged durability Single and Double Auto Mould models are available. Work table can be tilted for angular moulding and V-notch table helps for moulding on square work piece. Model No. J-505, J-507 Standard Accessories :- Moulding block 2 no. each of 1.5" & 3" length (for J-507), Moulding block 1 no. each of 1.5 & 3" (for J-505), motor pulley, motor fixing plate, washers set. moulding V-block & toolkit

STAINLESS STEEL HOPPER FOR VERTICAL INJECTION MOLDING MACHINE USE

5,850 - 6,950 Per piece

1 Unit (MOQ)

Chocolate Moulding Machine

650,000 Per Piece

1 Piece (MOQ)

Features : Plant Build with duly powder coating strong Mild Steel Square Pipe. Inner partitions, where the product may have chance to contact are made with SS 304. Mould Pre-heater Depositor: Depositor tank build with SS 304, Aluminum head two Rotary Slides, with 20 or 40 no’s of pistons. One set of Nozzle plate suitable to required product. Vibration Section Hot Water circulation System for Depositor and aluminum head. HMI 7”s PLC Grams Adjustable By Touch Screen

bi axial rotomoulding machine

Get Price Quote

We have gained recognition as an eminent enterprise, devotedly engaged in manufacturing a broad range of Bi Axial Rotomoulding Machine.Description:We have come with newest making Bi-axial Rotomoulding Machine and Auxiliary Machineries for Plastic Industries. The company brings the world class information of Bi-axial Rotomoulding Machine and Rotomoulders in India.The Process: Rotational molding process is different as compared to other plastic processes.In the complete process, first the mold is loaded with raw material in resin from. The loaded mold is then shifted in to hot air oven where it is oriented and rotated at suitable low speed. As the molten resin gets properly heated oriented, it adheres to the mold's inner surface until completely fused. Then the mold is moved to the air, water or the both to slowly reduce the temperature when the mold is still in bi-axially rotating mode. Finally, the mold is dismantled to get the finished roto-molded product and is then again reloaded for next cyclic process.Salient Features:Most efficient in fuel and energy consumption compared to other types of machinesVery consistent product quality due to smooth bi-axial rotational, highest production due to lowest cycle timeUniform heating of the mould with forced air circulation in heating chamberUniform distribution of material of hence possible to produce tank with lesser weightBest compatibility in market due to lowest production cost per tank.Lowest rejection rate due to sound and proven technologyClean and silent operation of machineFlexibility to produce double and triple layer tanksAC variable drive for all minor and major axes for minute and accurate speed controlControl panel is equipped with ac drives, digital indicators, temperature controllers, timers and advance automation circuit for entire process control and all necessary safety features.

Trash Bin rotational Mould

40,000 Per Unit

Automatic Chocolate Moulding Machine

Get Price Quote

Our domain expertise has enabled us to offer an excellent collection of Automatic Chocolate Moulding Machine that is widely used in food processing industry for wrapping the chocolates. Our offered wrapping machine is widely acknowledged among our clients for its high productivity in less energy consumption. In addition to this, offered wrapping machine is available in various customized specifications as per clients' requirements. Our provided wrapping machine is available at industry leading prices in the market - Automatic Chocolate Moulding Machine Chocolate Melting Tank Cooling Tunnel PEE 05 Fully Automatic Chocolate Moulding Machine The Pooja Equipments & Engg.Details : Depositing system provides our customers with a simple production method for me filled chocolates are the two hoppers of the machine are filled with cr me and chocolate the weight of the centre and chocolate are then selected on graduate scales. These weights may be varied while the machine is running or as required. Different moulds can quickly be accommodated by changing the depositing plates and then making the necessary weight adjustment. The plant will produce chocolate bars, both solid and me filled, with a wide variety of centers and shapes. Two colour items with or without me can also be produced on this time. Retrofits to other makes of moulding machines also available. With a Changeover of piston block assembly and distribution plates, you can then do solid pieces with inclusions or solid chocolate slabs with inclusions up to 50%. Typical inclusions would be crispies, broken nuts, whole nuts, raisins, broken caramel, colored lentils to name but a few of the products used in our machines worldwide. Basic Information : Products : Chocolate Block, Center filled Chocolate Weight : Approx. 7 Ton Chocolate Company Name : Pooja Equipments & Engineering Location : Odhav, Ahmedabad, Gujarat Item Code : PEE-05

Auto Moulder Machine

500,000 Per Piece

Vacuum Rubber Compression Molding Machine

1,500,000 Per Unit

1 Unit (MOQ)

Precise Counter Profile

259,000 Per Piece

1 Pcs (MOQ)

(Reverse Moulding Machine) Perfect Counter Profile Cut with reference to tenon in a single operation Get Different sizes and designs with easy spindle adjustments General Features Selection of cutters can accommodate all the necessary sizes and designs Pneumatic clamping, manual feeding on linear bearing slide and machine settings are operator friendly.

Rotational Moulding Machine

Get Price Quote

We are leading manufacturer and exporter of 3-arm and 4-arm bi-axial rotomoulding machine to our premium clients across the india and overseas.this machine is developed after extensive research and study of industry norms and as well as client requirement and the technical specifications detailed by them.

pvc dip moulding

10 Per Piece

Ring plunger set

1 - 1,000 Per piece

1 piece (MOQ)

Injection Point Machine

Get Price Quote

PVC Y Strainer Mould

Get Price Quote

Blow Mould

Get Price Quote

Abiding by ethical norms of the industry, we are engaged in manufacturing and supplying a broad array of blow molds. Offered blow molds are manufactured by utilizing high grade raw material that are sourced from the trusted vendors of the industry. Moreover, to ensure the precise design of offered blow molds, we make use of modern machinery and latest technology. While carrying out the manufacturing process of offered blow molds, we strictly adhere to international quality norms.

rotational molds

Get Price Quote

We are engaged in manufacturing and supplying a wide range of rotational molds. Rotational molds are made in a wide range of sizes. They normally consist of molds, an oven, a cooling chamber, and mold spindles. Molds are typically manufactured from stainless steel or aluminium. This allows for variable thicknesses in the walls of the product. The aluminum addition to the steel provides more heat capacity, causing the melt-flow to stay in a fluid state for a longer period. Features: long serving life high efficiency precisely designed

Plastic Glass Mould

Get Price Quote

Pet Blow Molding Machine.

Get Price Quote

With the use of advanced resources, our technical team manufactures superior quality range of Semi Automatic Pet Blow Molding Machine. These are known for their best quality, performance and huge application in the industrial sectors. Our products are highly strong, rust free, easy to operate, long functional and are offered at the nominal market price range. Semi-auto pet blow moulding machines are the most cost-effective solution for mass production of jars and bottles for small and medium scale factories. The machines are also designed for the production of big jars and containers. There are two types of semi automatic pet blow moulding machine Specifications : Ensures extremely uniform heating for pet performs, superior molding performance and minimum product defects. Offers two functions in a single machine by simply changing the mold from single to double cavity mold. Advanced PLC control system with a use-friendly panel and time-control precision of PLC up to 0. 01 second. Heating zones can be adjusted to meet production variations.quipped with special designed air storage unit. Heating tubes are adjustable in any direction such as up or down, forward or backward to suit various perform sizes and shapes.Full-time stabilized heating system. Heating temperature and speed are adjustable according to sizes and features of performs. Independent temperature Control for different heating lamp to get ideal preform heating results. The stretch shaft is located on the mold center for convenient operation and adjustment and rigid structure. Superior air tightness for high-pressure blowing upgrades molding performance. Steady operation, negligible trouble and easy maintenance. Operated easily without special training. Requires little base space, suitable for small to medium size factories. Negligible waste rate of finished bottle.

Wax Injection Machine

Get Price Quote

Calibrated Digital Temperature Controller to keep wax at a consistence injection Temperature.

Pvc Fitting Mould

Get Price Quote

Plastic Vertical injection molding machine

Get Price Quote

Vertical scruw type injection ,horizontal height pressure hydraulic clamping ,lorge ld ratio for homogenous optimum melt for all type of engineering plastics ,robust clamping force and parallelism platen for fiash proof mulding, fully microprocessor controller; mold memory , programmable speed and pressure controlling thru plc.