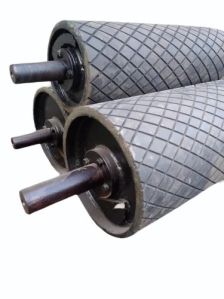

Conveyor Tail Pulley

3,500 - 22,000 Per Piece

500 Piece (MOQ)

APPLICATION The belt conveyor tail pulley can be used as take-up pulley, snub pulley, and bend pulley. The primary function of the tail pulley is to redirect the returning conveyor belt and provide tension. It helps maintain proper belt tracking and ensures that the belt remains under tension to prevent slack. It can be used in industries of mining, quarry, power plant, sand plant, cement, coal, port, steel, etc FEATURES Tail Drum Pulleys You can get belt conveyor traditional tail drum pulleys with high abrasion resistant rubber or ceramics covered. The diameter of tail pulley is smaller than driving pulley. It is installed at the tail of belt conveyor to change the direction of conveyor belt. Winged Tail Pulleys You can get heavy duty wing pulley, spiral wing pulleys, chevron wing pulleys, herringbone wing pulleys. Wing type tail pulleys are often installed as a method to reduce the risk of belt damage from the entrapment of lumps of material between the belt and the pulley. Belt Conveyor Tail Pulley (Return Pulley) Belt Width 500-2800mm (19-110.2 inch) Pulley Length 500-3200mm (19-125.9 inch) Diameter 200-1800mm (7.8-70.8 inch) Standard ISO9001:2008, CEMA, DIN, TUV, etc. Working Life More than 30,000 hours. Surface Flat Rubber Lagged, Ceramic Lagged, Diamond Rubber Lagged, etc. Main Material Carbon Steel Shell The selection and design of the tail pulley should be tailored to the specific requirements of the conveyor system, including factors such as load capacity, belt tension, and environmental conditions. Length of conveyor Tail pulley depends on the width of conveyor Belt. You can get Tail pulleys with hot vulcanized rubber lagging, plain or grooved, as required by client. ..

Jacquard Pulley

Get Price Quote

We are considered as the most trusted, Jacquard Pulley Manufacturer, Exporter and Supplier of excellent quality Jacquard Pulley. The Jacquard Pulley, we offer, is widely used in all types of jacquards like BONAS,STAUBLI,MULLER,GROSSE,VAN DE WIELE 7 for high speed needle lom jacquards. The Jacquard Pulley is a light weight and compact pulley that incorporate a proper direction,Our jacquard pulley wheel are designed to save breakage of lower upper cordshigh class material used in whole process. All ranges of jacquard pulley we have a complete set of jacquard pulley with upper lower belts for all make of jacquards. Any size of upper lower cords made.

Best Deals from Mountaineering Gear

Aluminium Timing Pulley

525 Per Piece

5 Piece (MOQ)

HTD Timing Belt Pulley

500 - 8,000 Per piece

1 Barrel (MOQ)

Key features of HTD timing belts include: Tooth Profile: HTD belts have a trapezoidal tooth profile, which offers a larger contact area with the pulley and distributes the load more evenly compared to other tooth profiles. Material: HTD timing belts are typically made from rubber with reinforcement fibers such as fiberglass or aramid to provide strength and flexibility. Applications: HTD timing belts are commonly used in various applications, including automotive engines, industrial machinery, robotics, and other systems that require precise timing and power transmission. Advantages: The design of HTD timing belts allows for smoother engagement, reduced noise, and enhanced power transmission efficiency compared to some other belt types. Maintenance: Like any other component, timing belts require periodic inspection and replacement according to the manufacturer's recommendations. If a timing belt fails, it can lead to severe engine damage due to the misalignment of the crankshaft and camshaft. Remember that proper maintenance and replacement of the timing belt are essential to prevent engine damage and maintain the proper functioning of the machinery or system it's used in. If you have specific questions about HTD timing belts or their applications, feel free to ask!

Timing Pulley

360 - 45,000 Per Piece

100 Pieces (MOQ)

transmission belt pulley

100 Per Piece

1 Piece(s) (MOQ)

Complete range of Transmission belt pulleys that meet highest quality standards. It includes Classical, HTD, Metric in various sizes, with or without taper/keyless bushings with different width diameter, materials, torque, shapes & drives for almost all kinds of machineries.

Single Groove Pulley

Get Price Quote

500 Piece (MOQ)

Heavy Duty Power Winch Machine

700,000 - 1,000,000 Per Piece

Mild Steel Timing Pulley

400 - 900 Per Piece

1000 Piece (MOQ)

V-belt Pulley

Get Price Quote

100 Piece (MOQ)

Permanent Magnetic Pulley

40,000 Per Piece

1 Piece (MOQ)

motorised chain pulley

Get Price Quote

We are the top Chain Pulley Block Hoist manufacturer of India. Our products are accessible in diverse load bearing capacities. These are accessible in manual as well as electrical varieties and employ sturdy chain as the lifting medium. The load is elevated by the pulley by means of chain.These are designed and fabricated with cutting-edge technologies as well as high grade raw material in adherence to the industrial norms. We quality test our products so as to offer only flawless high performance products to our clients. We offer them in diverse specifications with features such as Rust & corrosion resistance, Extensive chain life, precisely designed pendent controller, high reliability, Easy installation& maintenance as well as user-friendly

Chain Pulley Block

9,000 Per Piece

1 Piece (MOQ)

Chain Pulley Block offered are high performance based chain pulley blocks and provide for improved functional performance. Specifications : Comes in compact size and light weight finish Provide for durable service usage High efficiency with small pulling effort at full load conditions Safe in operations and needing low maintenance Require low headroom that allows optimal use of space Lifting chain support in 3m length Works as portable lifting device easily operated by hand Suitable for use in factories, farms, construction sites Also used in docks for lifting cargos, and loading and unloading goods Can be conveniently attached to trolley Superior durability in service

Concrete Mixer Brake Pulley

1,200 Per Piece

100 Piece (MOQ)

Timing Belt Pulleys

Get Price Quote

Timing Pulley

Get Price Quote

Timing pulleys are the specialized type of pulleys, which have distinctively designed teeth or pockets outside the diameter of the instrument body. Timing pulley manufacturers ensure that the timing teeth perfectly engage into the metal belt holes while the timing pockets grip lugs on the metal belt’s inner circumference. It is noteworthy to mention that the teeth and pockets are used only for the timing purpose and have no role to play in power transmission.Timing pulley is made up of light-weighted materials like cast iron, aluminium and plastic and is widely used in the textiles and automobiles industrial segments.Timing pulley suppliers ensure that the belt creep is reduced to the minimum possible level. Apart from this, side flanges are provided in order to prevent the side movement of the belt when it is rotating. Leading Timing Pulley Manufacturer in AhmedabadYou can select a timing pulley based on parameters like diametrical pitch, power transmission requirements, speed ratio needed, the diameter of the driver and driven pulley, the distance between the diver and driven pulley, etc. to name a few. The tooth shape of the timing pulley is either trapezoidal or curvilinear and it manufactured on shaping machines. In case of plastic timing pulley, however, it created by finch molding plastic as per the required tooth shape.At UMA Engineering, you can find an extensive range of superlative timing pulleys in varied sizes and models. Our timing pulleys are manufactured using high-quality raw material and are in-line with the international standards- lightweight and high accuracy product line further puts us on top in the least of leading Timing pulley manufacturers of Ahmedabad, Gujarat. Advantage of Timing Pulley:- High Torque Carrying Capacity Robust Construction No Slipping between the belt and pulleys High strength Power Transmission at a Constant Speed Corrosion Resistance Low Noise & Vibration Long Durability

Magnetic Pulley

100,000 Per Piece

1 Piece (MOQ)

We are one of the leading Manufacturers, Suppliers, Distributors of this highly commendable range of Magnetic Pulley The magnetic head pulley replaces the drive pulley at the end of conveyor belts. In view of the wide variety of conveyor belt types, the magnetic pulley are supplied made to measure and ready for installation. As the figure clearly show, the magnetic head roller extracts the iron particles from the material flow and carries them to the underside of the belt where they are removed and collected. The version with permanent magnets are fitted with powerful and An-Isotropic Hard ferrite Magnets /high intensity Nd - Feb Rare Earth Magnets and operate without the need for power supplies. The magnet system is available in two types: with Longitudinal polar field distribution for use with low levels of iron contamination and thin material layers, and with lateral polar field distribution for greater material thickness and larger iron particles. Finally as the belt leaves the magnetic pulley, the magnetism dissipates and the unwanted contamination falls from under the belt into a separate receptacle.

Folding Bed

1,000 - 1,500 Per Piece

100 Piece (MOQ)

Chain Pulley Block

4,130 Per Piece

5 Piece (MOQ)

Manitou Hydraulic Winch

Get Price Quote

1 Piece (MOQ)