Web Aligner control system

The Web Aligner is a control system for automatically shifting the unwinded fabric. In this system, the basic unwind roll is mounted on a laterally moving body which is actuated by hydraulic cylinder which converts the stationery unwind into an automatic unwind guiding system.

...more

variable speed ac drive

Variable speed AC drive (Inverter drive) cutter heater + digital temperature control. Individual ink circulation system with each colour Auto start/stop of corona with line.

...more

Rotary Flexographic Printing Machine

Suitable for fabric of FIBC (flexible intermediate bulk container) / bags Printing medium : Instant dry ink Feeding : Hand-feed table topped with Formica sheet with synchronization mechanism with photo-polymer or rubber stereo. Accuracy of registration : +- 2 m.m. Print size : W-1270 / 1524 m.m. L-1371 / 1778 / 2031 / 2540 m.m. Number of colours : up to 4 colours Output : Maximum of 1200 bags per hour Power requirement : 1 to 7.5 H.P. (depending on no. of colours), 3.0, 380 / 440 vax, 50 / 60 HZ. With A.C. Variable speed, Programmable Counting meter, Inching facility, Conveyor protecting arrangement, E-stop, Flashing Beacon etc. Drive : 1 to 7.5 H.P.(depending on no. of colours), 3.0, 380 / 440 vac, 50 / 60 HZ, 1440 RPM, TEFC, IP 55, electric motor. Brief description : robust construction with CI machined side walls, mechanized adjustable feeding mechanism for synchronization with photo-polymer plate (rubber stereo); flexo plate cylinders fabricated from heavy plate, for mounting flexo-plate (stereo), Variable speed drive through frequency converter and painted with hammer tone finish.

...more

Ink Circulation Pump

Circulating pump has pump motor, S.S. colour storage tank. This unit will be connected with colour tray and this system will help to maintain uniform viscosity of the ink and variation in the colour shade is avoided to ensure uniform quality of the printing.

...more

Hydraulic Baling Press

Effective warehousing and economic transportation of finished goods are decisive factors in the economic operation of modern business processes. Baling of HDPE / PP Woven sack, Jute bags and laminated jute bags, Paper waste, Cotton, Coir Paddy straw etc. Is a major application for which NAVJIVAN Baling Press has been designed. As with all NAVJIVAN machines, ease of operation, minimum maintenance ad durability have been the prime criteria while designing these presses. As a result, these baling presses are simple, compact and robust. These presses are available with table sizes from L52” X W.35” to L.60” x W.42”, daylight 55” height maximum and different compressive forces from 15 ton to 35 ton.

...more

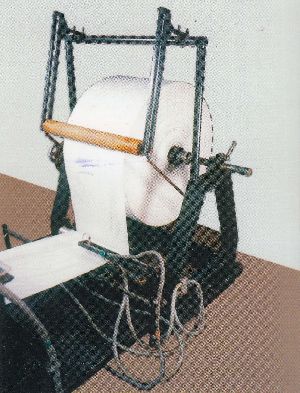

HDPE Woven Fabric Cutting Machine

SIMPLE AND STURDY CONSTRUCTIONThis machine will cut the HDPE woven fabric with electrically heated wire / strip and will simultaneously seal the edges. The machine is a unique spring tension arrangement to the wire / strip tight, resulting in sharp and uniform cutting.

...more

Corrugated Paper Flexographic Printing Machine

NAVJIVAN" designed multipurpose flexographic printing machine for printing kraft paper is unique and a masterpiece. It is equipped with statistically and dynamically balanced rolls and the gears of hobbing cut. Printing station is equipped with Anilox and Rubber rolls stainless steel ink ducts, inking and registration adjustment is given by means of screws. Flexographic printing system is used for transfer of image through photo polymer stereo of 2.8 mm and 4.6 mm thickness. Because we are devoted to enhancing our products to meet the needs of users, we make sure that each new model launched on the market possesses a high degree of technological maturity while guaranteeing a long service life. Precision manufacture of parts with close tolerances, test runs printed on every press before it leaves the factory - that is what makes NAVJIVAN's production facilities excel. Our top priority is to give our customers a machine for economical printing without sacrificing printing quality. Distinct Features : Prints through photo polymer stereos using water or solvent based inks. S are fixed by means of Double sided plaster. Flawless and distinct impression - instant drying. Easy operation and maintenance easy accessibility for cleaning. Economical for small lot printing. Simple and quick set up. Uniform spreading and controlled flow of ink. Draw rolls provided with pin setting arrangement to get print on exact position on all paper. Hand brake provided to release the eccentric pressure to get the paper / without printing if it feed wrongly. Commercial Features: Our motto is to contribute to the success of our customers by focusing on the specific conditions and requirements of individual customers. Products and services offered by us provide maximum value to customers in terms of performance, quality, flexibility and total economy. Technical Features: Controlled ink transfer is a key factor in high quality flexo printing. Prints through photo polymer stereos using water or solvent based inks. Easy set up leads to simple operation and maintenance. Economical for small lot printing. Draw rolls with registration setting arrangement to get print on exact position on all paper. Hand brake provided to release the eccentric pressure to get the paper without printing if it feed wrongly

...more

Flexographic Printing Machine

With the goal of presenting Flexographic Printing Machines of the latest technological concepts, NAVJIVAN has come out with a range of answers. Our intensive research and development into the needs and expectations of our customers, thrust for innovation and improvements and our vast engineering expertise, have resulted in flexographic printing machine of different configuration and capabilities -single colour to four colour prints of designes, - different printing widths, from 28” to 110’ and printing length from 54” to 102”, - high accuracies in colour-registration plus minus 2 m.m., - different type of material to be printed, - ink circulating system, - anilox roller based / rubber stereo based image transfer, -digital counting for production data, AC variable speed drive mechanism with push button starter. Because of availability of different options, right investment decisions can be taken. Features: Flexographic Printing Machines of the latest technological concepts Flexographic Printing Machines of different configuration and capabilities Single colour to four colour prints of designs Range of printing widths from 28” to 110” Range of printing length from 54” to 102” High accuracies in colour Registration plus minus 2 m.m., Different type of material to be printed, Ink circulating system, Anilox roller based image transfer Rubber stereo based image transfer, Digital counting for production data, AC variable speed drive mechanism with push button starter.

...more

corona treater equipment

The equipment consists of a high voltage (HV) high frequency (HF) generator, output transformer and an enclosed station. The HV/HF between the electrodes and the di-electric covered roller generates a continuous shower of ionized air (corona). Power from the generator increases the kinetic energy of the ions. The nascent oxygen generated due to the bombardment of these ions changes the molecular structure of the woven sack fabric surface. Oxygen breaks down into Ozone and nascent oxygen as per the equation

...more

Both Side Printing Machine

Specification Both Side Printing Machine - New Double-Usage Printing Machine for HDPE/PP Woven bags, Jute & Non-Woven Bags. (Model NV-3252B) Description The machine is developed for the new century woven bags used printing machine configuration is created by high technique precision and modern design. It has the colours accuracy of+- 2 mm. The machine is assembled by one set of bags feeding platform, bags sides’ turn-over unit, begs collection units. Robust construction with CI machined side walls, mechanised & adjustable feeding mechanism for with photo-polymer plate (rubber stereo); flexo plate cylinders fabricated from heavy plate, for mounting flexo-plate (stereo), variable speed drive through frequency converter and painted with hammer tone finish. Apart from the above machine will be equipped with following: All print cylinders will be Push and rotate design. Brush rolls are provided for stereo cleaning. To maintain ‘kiss touch’ between stereo and ink roller (or anilox roller) to prevent damage to and ink roller. It is achieved by rotating hand wheel. Transport printing blanket with tracking strip for high precision and printing. Highly accurate bag side turnover cylinder. Hydraulic feeding table. The machine is guarded and covered to ensure safety measures. No need for foundation because of its bulk manufacture. Features: The machine has one step control for stop machine. Printing speed : 41 pc/minute (One-step two sides printing, two workers) Max Printing material size: 34: x 54” Max Printing area : 32” x 52” Printing available : two sides & 5 colors with following options o3 + 2, 3 + 1, 3 + 0, 1 + 1 Motor Power : 3.77 KWAC variable drive, programmable counting meter, inching facility, conveyor protecting arrangement, E-stop, flashing Beacon etc. Machine size : (L x W x H) All the main electronic parts are having “CE” marking. Inverter : control Technique Contract breaker, contractor, and push button : SHNEIDER made Ball bearing : ZKL, Czechoslovakia. Note : Depending upon the Customer’s requirement, the machine can be manufactured with printing options of 4 + 4 and 3 + 3 also.

...more

Automatic Heat Cutting Machine

State-of-the-art Heat Cutting machine to heat-cut laminated unlaminated woven fabric out of HDPE/PP into uniform pieces of equal length. The printed fabric is taken from the rear side of the machine. The cutting time is controlled and can be adjusted exactly to the specifications of the fabric, thus the quality and thickness of the fabric is maintained. The temperature of heating element can also be varied through supply voltage to heating element. The cut pieces are then taken to the stacker through automatic conveyor.

...more

Anilox Roller

The Anilox Roll is made from steel. Machine engraved and protected with hard wear resistant coating. The function of the Anilox Roll is to draw supply of ink from the rubber roll and deliver consistently a very controlled and predetermined volume of ink on the stereo. Since the roll delivers exactly the required quantity of ink for printing, high quality of printing is ensured.

...moreBe first to Rate

Rate ThisOpening Hours