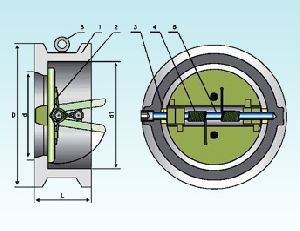

600 LB Wafer Cast Steel Check Valve

Appiicarit Standards Steel Check Valves API 594/API 6D Steel Check Valves ISO 14313 Steel Valves ASME B16.34 IN Face To Face ASME B16.10 End Flanges ASME B16.5 ButtWelding Ends ASME B16.25 Inspection and Test API 598/API 6D Design Descriptions One Piece Body Butterfly Swing Type Dual-plate Disc, Long-pattern Renewable Split Disc Horizontal Or Vertical Service Wafer Ends Available With Flanged Ends Materials Of Parts S. No. Part Name Carbon Steel ASTM Material 1/1/4cr-1/2 mo Low Temp Carbon Steel 1 Body A216-WCB A351-CF8M A352-LCB 2 Plate A216-WCB+CR13 A351-CF8M+HF A350-LCB+CR13 3 Stop Pin A276-420 A276-304 A276-420 4 Back Spring A313-304 A313-316 A313-304 5 Hinge Pin A276-420 A276-304 A276420 6 Eye Bolt2 Carbon Steel Dimensional Datas Of Ansi Class 150 LB NPS 2 2/1/2 3 0.4 6 10 12 14 16 in DN 50 65 80 100 150 200 250 300 350 400 mm L 2.38 2.62 2.88 3.12 5.38 6.5 8.38 9 10.75 12 in 60 67 73 79 137 165 213 229 273 305 mm D 4.38 5 5.75 7.5 10.38 12.5 15.62 17.88 19.25 22.12 in 110 128 147 191 264 318 398 455 490 562 mm d 2 2.5 3 4 6 7.88 9.88 12 13.25 15.25 in 51 65 80 102 152 200 250 305 337 387 mm D1 2.25 2.88 3.5 4.25 6.38 8.38 10.5 12.25 14 157.75 in 58 73 88 108 162 212 266 312 355 405 nun Wt 4 5 8 11 26 55 95 140 223 360 kg. Dimensional Datas Of Ansi Class 300 LB NPS 2 2/1/2 3 4 6 8 10 12 14 16 in DN 50 65 80 100 150 200 250 300 350 400 mm L 2.75 3.25 3.25 4 6.25 8.12 9.5 11.5 in 70 83 83 102 159 206 241 292 mm D 5.5 6.38 6.5 8 11.25 14 17 19.5 in 140 162 165 204 286 356 432 495 mm d 2 2.5 3 4 6 7.88 9.88 12 in 51 62 80 102 152 200 250 305 mm D1 2.25 2.88 3.5 4.25 6.38 8.38 10.5 12.25 in 58 73 88 108 162 212 266 312 mm Wt 8 11 14 20 42 84 145 220 kg.

...more

150 LB Wafer Cast Steel Check Valve

Appiicarit Standards Steel Check Valves API 594/API 6D Steel Check Valves ISO 14313 Steel Valves ASME B16.34 Face To Face ASME B16.10 End Flanges ASME B16.5 Butt Welding Ends ASME B16.25 Inspection and Test API 598/API 6D Design Descriptions One Piece Body Renewable Split Disc Horizontal Or Vertical Service Wafer Ends Available With Flanged Ends Range Of Materials S. No. Part Name Carbon Steel ASTM Material 1/1/4cr-1/2 mo Low Temp Carbon Steel 1 Body A216-WCB A351-CF8M A352-LCB 2 Plate A216-WCB+CR13 A351-CF8M+HF A350-LCB+CR13 3 Stop Pin A276-420 A278-304 A276-420 4 Back Spring A313-304 A313-316 A313-304 5 Hinge Pin A276-420 A276-304 A276-420 6 Eye Bolt2 Carbon Steel Dimensional Datas Of Ansi Class 150 LB NPS 2 2/1/2 3 4 6 8 10 12 14 16 18 20 24 in DN 60 65 80 100 150 200 250 300 350 400 450 500 600 mm L 2.38 2.62 2.88 2.88 3.88 5 5.75 7.12 7.25 7.5 8 8.62 8.75 in 60 67 73 73 98 127 146 181 184 191 203 219 222 mm D 4 4.88 5.38 6.75 8.62 10.88 13.25 16 17.62 20.12 21.5 23.75 28.12 in 103 122 135 173 220 277 337 407 488 512 547 604 715 mm d 2 2.5 3.25 4 6 8 10 12 13.75 15.75 17.75 19.75 23.62 in 51 65 80 102 152 203 254 305 350 400 450 500 600 mm D1 2.25 2.88 3.5 4.25 6.25 8.25 10.5 12.12 14 16 18 19.88 23.75 in 56 73 88 108 160 210 266 310 355 405 455 505 605 mm Wt. 2 3 4 6 13 25 39 54 80 117 138 163 331 kg. Dimensional Datas Of Ansi Class 300 LB NPS 2 2/1/2 3 4 6 8 10 12 14 16 18 20 24 in DN 50 65 80 100 150 200 250 300 350 400 450 500 600 mm L 2.38 2.62 2.88 2.88 3.88 5 5.75 7.12 8.75 9.12 10.38 11.5 12.5 in 60 67 73 73 98 127 146 181 222 232 264 292 318 mm D 4.25 5 5.75 7 9.88 12 14.12 16.5 19 21.12 30.38 25.62 30.38 in 110 128 147 179 249 305 359 420 483 537 594 652 772 mm d 2 2.5 3 4 6 8 10 1200 14 16 18 20 24 in 51 65 80 102 152 8.25 254 305 350 400 450 500 600 min D1 2.25 2.88 3.5 4.25 6.38 203 10.5 12.25 14 16 18 20 24 in 58 73 88 108 160 210 266 310 355 405 455 505 608 mm Wt. 3 4 6 8 18 31 51 77 117 190 200 265 410 kg.

...more

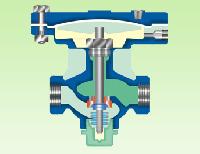

HP 290 Two stage Pressure Regulator

Technical Specification Fluid Material All gases corrosive or non-corrosive or those requiring high purity regulations complete with materials or construction. Max. Rated Inlet Pressure 6000 PSIG Outlet Pressure Range 1-25, 2-50, 10-200, 20-300, 100-600 Flow Capacity 0.06 Inlet Outlet Port Size 1/4", 3/8", 1/2" NPT/BSP Typical Application : High purity gas handling regulations of corrosive and specially semiconductor manufacturing epitaxial reactors diffusion furnaces research lab.

...more

600 LB Cast Steel Ball Valve

Design Descriptions Full. Port Design BB. Bolted Bonnet Split Body Three Piece Body for 12' &Above Trunnion Mounted Balt Type Fire Durable Construction Stopper Device ISO 5211 Mounting Pad Flanged or Butt Welding Ends Available with BG Operator Applicable Standards Steel Ball Valves API 608/API6D Steel Ball Valves ISO 14313 Fire Safe, API 607 Anti Statics Steel Valves ASME B16.34 Face To Face ASME B16.10 End Flanges ASME B16.5 Butt Welding Ends ASME B16.25 Inspection And Test API 598/API 6D Materials Of Parts No. Part Name Carbon Steel Stainless Steel 1 Body A216-WCb A351-CR8M 2 Bonnet A216-WCB A351-CR8M 3 Ball A1 82-F304 A182-F316 4 Stem A276-304 A276-316 5 Seat A105+ENP A182-F316 6 Seat Insert Glass Filled PTFE 7 Seat Spring A313-304 Inconel X-750 8 Seat 0-Ring N BR Vrton 9 Stem 0-Ring N BR Vrton 10 Bonnet Gasket Graphite+304 Graphtte+316 11 Bonnet 0-Ring NBR Vrton 12 Antistatic Spring A313-304 A313-304 A313-316 13 Lower Cover A216-WCB A182-F316 14 Bonnet Stud A193-B7 A193-B8 15 Bonnet Stud Nut A194-2H A194-2H A194-8 16 Trunnion A276-304 A276-316 17 Trunnion Bearing 304+ PTFE 304+ PTFE 316+PTFE 18 Gland Flange A216-WCB A351-CF8M 19 Gland Bott A193-B7 A193-B8 20 Stop Plate Carbon Steel Carbon Steel+Zn 21 Handla Carbon Steel Dimensional Datas Of Ansi Class 600 LB N PS 2½ 2 3 4 6 8 10 12 14 16 18 20 24 26 28 in DN 50 65 80 100 150 200 250 300 350 400 450 500 600 650 700 min 11.5 13 14 17 22 26 31 33 35 39 43 47 55 57 61 in (RF/BW) 292 330 356 432 559 660 787 838 889 991 1092 1194 1397 1448 1549 mm L2 11.62 13.12 14.12 17.12 22.12 26.12 31.12 33.12 30 39.12 43.12 47.25 55.38 57.5 61.5 in (RTJ) 295 333 359 435 562 664 791 841 762 994 1095 1200 1407 1461 1562 mm 7.12 7.62 8.5 9.5 21.25 25 26.12 31.12 31 36.38 38.75 44.5 46.62 52.5 57 in 180 193 215 241 540 635 665 790 790 925 985 1130 1185 1335 1450 mm W 14 16 20 20 24 24 24 24 32 32 32 32 32 32 32 in 350 400 500 500 600 600 600 600 800 800 800 800 800 800 800 mm Wt(kg .) 26 35 58 81 142 287 540 780 1000 1300 1700 2100 3400 3800 4500 BW 19 25 42 51 85 200 395 610 805 1010 1350 1656 2775 3125 3790 Dimensional Datas Of Ansi Class 900 LB NPS 2½ 2 3 4 6 8 10 12 14 16 18 20 24 in DN 50 65 80 100 150 200 250 300 350 400 450 500 600 mm 14.5 16.5 15 18 24 29 33 38 40.5 44.5 48 52 61 in (RF/BW) 368 419 381 457 610 737 838 965 1029 1130 1219 1321 1549 mm L2 1462 16.62 15.12 18.12 24.12 29.12 33.12 38.12 40.88 11.88 48.5 52.5 61.75 in (RTJ) 371 422 384 460 613 740 841 968 1038 1140 1232 1334 1568 mm 8.62 9.25 10.25 15.38 25.75 30.25 31.75 38 38.5 45 47 53.5 56 in 219 235 260 390 655 770 805 965 980 1145 1195 1360 1425 mm 20 20 20 24 24 24 24 32 32 32 32 32 32 in 500 500 500 600 600 600 600 800 800 800 800 800 800 mm Wt(kg.) 31 43 68 98 171 345 650 940 1205 1565 2050 2535 3950 BW 23 31 51 61 102 240 480 735 965 1215 1625 1995 3335

...more

1500 LB Cast Steel Ball valve

Design Descriptions Full. Port Design FuUl Port Design B. B. Bolted Bonnet Split Body Three Pieces Body For 12" & Above Trunnion Mounted Ball Type Anti Static Device Stopper Device ISO 5211 Mounting Pad Flanged Or Butt Welding Ends Available With Bg Applicable Standards Steel Ball Valves API 608/API 6D Steel Ball Valves ISO 14313 Fire Safe, API 607 Anti Statics Steel Valves ASME B16.34 Face To Face ASME B16.10 End Flanges ASME B16.5 Butt Welding Ends ASME B16.25 * Inspection And TEST API 598/API 6D Materials Of Parts No. Part Name Carbon Steel Stainless Steel 1 Body A216-WCb A351-CF8M 2 Bonnet A216-WCB A351-CF8M 3 Ball A182-F304 A182-F316 4 Stem A276-304 A276-316 5 Seat A105+ ENP A182-F316 6 Seat Insert Glass Filled PTFE 7 Seat Spring A,313-304 Inconel X-750 8 Seat 0-Ring NPR Viton 9 Stem 0-Ring NBR Viton 10 Bonnet Gasket Graphite+304 Graphite+316 11 Bonnet 0-Ring NBR Viton 12 Antistatic Spring A313-304 A313-316 13 Lower Cover A216-WCB A182-F316 14 Bonnet Stud A193-B7 A193-B8 15 Bonnet Stud Nut A194-2H A194-8 16 Trunnion A276-304 A276-316 17 Trunnion Bearing 304+PTFE 316+FTFE 18 Gland Flange A216-WCB A351-CF8M 19 Gland Bolt A193-B7 A193-B8 20 Stop Plate Carbon Steel Carton Steel +Zn 21 Handle Carbon Steel Dimensional Datas Of Ansi Class 1500 LB NPS 2 2½ 3 4 6 8 10 12 14 16 in DN 50 65 80 100 150 200 250 300 350 400 mm L/L1 14.5 16.5 18.5 21.5 27.75 32.75 39 44.5 49.5 54.5 in (R F/BW) 368 419 470 546 705 832 991 1130 1257 1384 mm L2 14.62 16.62 18.62 18.62 28 33.12 39.38 45.12 20.25 44.38 in (RTJ) 371 422 473 473 711 841 1000 1146 1276 1407 mm H 11.25 12 13.25 13.25 33.5 39.38 41.12 49.38 50_00 58.5 in 285 305 383 338 852 1000 1045 1255 1270 1485 mm W 20 20 24 24 24 32 32 32 32 32 in 500 500 600 600 600 800 800 800 800 800 mm Wt(kg.) 49 67 106 153 268 540 1020 1475 1885 2455 RF/RTJ 33 44 73 87 145 345 685 1050 1385 1735 BW Dimensional Datas Of Ansi Class 2500 LB NPS 2 21/2 3 4 6 8 10 12 14 16 in DN 50 65 80 100 150 200 250 300 350 400 mm L/L1 17.75 20 22.75 26.5 36 40.25 50 56 in (R F/BW) 451 508 578 673 914 1022 1270 1422 mm L2 17.88 21.25 23 26.88 36.5 40.88 50.88 56.88 in (RTJ) 454 540 584 683 927 1038 1292 1445 mm H 12 12.88 14.25 21.25 35.88 42.12 44 53 in 304 327 362 540 911 1070 1120 1345 mm W 20 24 24 24 32 32 32 32 in 500 600 600 600 800 800 800 800 mm Wt(kg.) 55 76 120 173 302 612 1150 1665 RF/FITJ 41 55 91 110 182 430 855 1315

...more

150LB Cast Steel Ball Valve

Design Descriptions Full Port Design Split Body Three Pieces Body for 12 &Above Trunnion Mounted BaU Type Blow-out Proof Stem Fire Durable Construction Anti Static Device Stopper Device Flanged or Butt Welding Applicable Standards Steel Ball Valves API6D Fire Safe Anti Statics SteeL Valves ASME B16.34 Face To Face ASME B16.10 End Flanges ASME B16.5 Butt Welding Ends ASME B16.25 Inspection And Test API 598/API 6D Materials Of Parts No. Part Name Carbon Steel Stainless Steel 1 Body A216-WCb A351-CF8M 2 Bonnet A216-WCB A351-CF8M 3 Ball A182-F304 A182-F316 4 Stem A276-304 A276-316 5 Seat A105+ENP Al 82-F316 6 Seat Insert Glass Filled PTFE 7 Seat Spring A313-304 Inconel X-750 8 Seat 0-Ring NPR Vrton 9 Stem 0-Ring NBR Vrton 10 Bonnet Gasket Graphtte+304 Graphite+316 11 Bonnet 0-Ring NBR Vrton 12 Antistatic Spring A313-304 A313-316 13 Lower Cover A216-WCB A182-F316 14 Bonnet Stud A193-B7 A193-B8 15 Bonnet Stud Nut A194-211 A194-8 16 Trunnion A276-304 A276-316 17 Trunnion Bearing 304+ PTFE 316+ PTFE 18 Gland Range A216-WCB A351-CF8M 19 Gland Mt A193-B7 A193-B8 20 Stop Plate Carbon Steel Carbon Steel +Zn 21 Handle Carbon Steel Dimensional Datas Of Ansi Class 150 LB NPS 2 2½ 3 4 6 8 10 12 14 16 18 20 24 26 28 30 32 36 in DN 50 65 80 100 150 200 250 300 350 400 450 500 600 650 700 750 800 900 mm L 7 7.5 8 9.00 15.5 18 21 24 27.00 30.00 34.00 36.00 42.00 45 49 51 54 60 in (RF) 178 190 203 229 394 457 533 610 686 762 864 914 1067 1143 1245 1295 1372 1524 mm L1 8.5 9.5 11.12 12.00 18 20.5 22 25 30.00 33.00 36.00 39.00 45.00 49 53 55 60 68 in (BW) 216 241 283 305 457 521 559 635 762 838 914 991 1143 1245 1346 1397 1524 1727 mm H 7 7.5 8.25 9.25 20.88 24.62 25.62 30.75 31.00 36.25 38.25 43.38 45.25 50.75 55.12 64.12 70.88 80.75 in 177 190 210 235 530 625 650 780 790 920 970 1100 1150 1290 1400 1630 1840 2050 mm W 14 16 20 20 24 24 24 24 32 32 32 32 32 32 32 32 32 32 in 350 400 500 500 600 600 600 600 800 800 800 800 800 800 800 800 BOO 800 mm Wt(kg.) 15 19 27 38 81 140 160 205 260 390 510 750 1200 1400 1860 2100 2530 2970 BW 13.5 15.5 24.5 32.5 76 132 147 182 241 370 495 726 1125 1250 1640 1930 2390 2760 Dimensional Datas Of Ansi Class 300 LB NPS 2 2½ 3 4 6 8 10 12 14 16 18 20 24 26 28 30 32 36 in DN 50 65 80 100 150 200 250 300 350 400 450 500 600 650 700 750 800 900 mm L 8.5 9.5 11.12 12.00 15.88 19.75 22.38 25.5 30.00 33.00 36.00 39.00 45.00 49 5300 55 60 in (RF) 216 241 283 305 403 502 568 648 762 838 914 991 1143 1245 1346 1397 1524 mm L1 8.5 9.5 11.12 12.00 18 20.5 22 25 30.00 33.00 36.00 39.00 45.00 49 53 55 60 in (BW) 216 241 283 305 403 521 559 635 762 838 914 991 1143 1245 1346 1397 1524 mm H 7 7.5 8.25 9.25 20.88 24.62 25.62 30.75 31.00 36.25 38.25 43.38 45.25 50.75 55.12 64.12 70.88 in 177 190 210 235 530 625 650 780 790 920 970 1100 1150 1290 1400 1630 1840 mm W 14 16 20 20 24 24 24 24 32 32 32 32 32 32 32 32 32 in 350 400 500 500 600 600 600 600 800 800 800 800 800 800 800 800 800 mm Wt(kg.) 19 24 34 48 101 175 200 225 325 485 635 935 1500 1750 2450 2225 2870 BW 14 16 25 34 82 145 155 185 238 375 516 782 1280 1375 2180 1825 2260

...more

Swing Check Valve

Design NU-TECH cast steel valves are designed and manufactured to provide maximum service life and dependability. ALL check valves meet the design requirements of American Petroleum Institute standard API600 & API 6D. BS EN 13709 and generally, Conform to American Society of Mechanical Engineers standard ASME B16.34. VaLves are available in a compLete range of body/bonnet materials and trims. Available Modifications Fon "NU-Tech Cast Steel Valves Trim Changes End Connection Modifications Packing and Gasket Change Operator Mounting Handwheel Extensions Pressure Equalizing Customer Specified Coatings Weld End Bore Changes Oxygen & Chlorine Clearing & Packaging Eyebolt For 150Lb-8', 300Lb-8" 600Lb-6" • 900Lb-1500Lb/2500Lb-4"& over. Bolted cover. BC Welded cover & Pressure seal bonnet in services requiring frequent cycling or with high pressure/term perature variations. End Connection A choice of flanged, WO flanged or butt welding end for piping flexibiLity. Body to Cover Joint A male & female joint or tongue and groove joint is used 150Lb to 600Lb valves. Ring joint is used in the body to cover connection in 900Lb & higher rated valves. Range Of Materials Standard body/bonnet materials include nine grades of carbon, low alloy & stainless steels. For special applications they can be supplied in other grades of alloy & stainless steeL Threre's a full range of trim materials to match any service optional packing S, gasket materiaLs are available for a fulL range of service conditions. Outside Lever B Weigh All external hinge pin swing check valves 12" & smaller are available with an optional outside lever and weight, internal hinge available with all swing check valves. Seat Rign Separate heavy duty fulL ported rings for easy maintenance, Screwed or welded connection into body. Hcu Weighted Mechanical Accumulator This design can be used to either dampen or assist closing of the check valve disc depending on orientation. by using the hydraulic controL unit to buffer action the disc, the vaLve opens at lower flow rates.

...more

1500 LB Cast Steel Gate Valve

Applicable Standards Steel CheckValves BS EN 13709/API 600 Steel Valves ASME B16.34 Face To Face ASME B16.10 End Ranges ASME B16.5 Butt Welding Ends ASME B16.25 Inspection and Test API 598/API 6D Design Descriptions PSB, Pressure Seal Bonnet Rexible Disc, Fully Guided Renewable Seat Rings Ranged or Butt Welding Ends Materials Of Parts No. Part Name Carbon Steel ASTM Material 1/1/4cr-1/2 mo 1 Body A216-WCB A217-W06 2 Pres. Seal Bonner A216-WCB A217-WC6 3 Disc Al 05-HF A182-Fl1+HF 4 Hinge A2113-WCB A217-W6 5 Seat Ring Al 05-HF A182-F11+HF 6 Hinge Pin Steel Ring A276-304 7 Bonnet Gasket A276-420 30485 Ring 8 Adapter Ring Carbon Steel A276-420 9 Retainer Carbon Steel A276-420 10 Cover Carbon Steel Alloy Steel 11 Bonnet Stud A193-B7 A193-B7 12 A194-2H A194-2H A194-2H 13 Eye Bolt Carbon Steel Dimensional Datas Of Ansi Class 1500 LB NPS 2 2/1/2 3 4 6 8 10 12 14 16 in DN 50 65 80 100 150 200 250 300 350 400 mm L/L1 14.5 16.5 18.5 21.5 27.15 32.75 39 44.5 49.5 54.5 in (RF/BW) 368 419 470 546 705 832 991 1130 1257 1384 mm L2 14.62 16.62 18.62 21.62 28 33.12 39.38 45.12 50.25 55.38 in (RTJ) 371 422 473 549 711 841 1000 1146 1276 1407 mm H 9.5 10 13 14.75 18.88 23.5 26 29.12 30.88 32.88 in 240 256 330 375 480 595 660 740 785 835 mm Wt(kg.) 40 63 70 115 250 470 740 1100 1410 1600 RF/RTJ 29 47 49 84 152 310 470 710 910 1100 BW Dimensional Datas Of Ansi Class 2500 LB NPS 2 2/1/2 3 4 6 8 10 12 14 16 in DN 50 65 80 100 150 200 250 300 350 400 mm L/L1 17.75 20 22.75 26.5 36 40.25 50 56 in (RF/BW) 451 508 578 673 914 1022 1270 1422 mm L2 17.88 20.25 23 26.88 36.5 40.88 50.88 56.88 in (RTJ) 454 514 584 683 927 1038 1292 1445 mm H 17.75 13.25 13.75 15.12 19.5 24.62 28 35.62 in 275 335 350 385 495 625 712 905 mm Wt(kg.) 50 76 85 165 460 900 1300 1800 RF/RTJ 35 55 68 115 225 580 860 1150 BW

...more

600 LB Cast Steel Check Valve

Appucalle Standards Steel Check Valves API 6D Steel Check Valves ISO 14313 Steel Valves ASME B16.34 Face To Face ASME B16.10 End Ranges ASME B16.5 Butt Welding Ends ASME B16.25 Inspection and Test API 598/API 6D Design Descriptions BC, Bolted Cover Swing Type, Anti-rotation Disc Renewable Seat Rings Non-penetrate Disc Shaft Horizontal Or Vertical Service Ranged Or Butt Welding Ends Materials Of Parts No. Part Name Carbon Steel ASTM Material 1/1/4cr-1/2 mo 1 Body A2163NCB A2173AfC6 2 Cover A216-WCB A217-WC6 3 Disci A105-CR13 A182-F11+HF 4 Hinge A216-WCB A217-WC6 5 Fork Part A216-WCB A217-WC6 6 Seat Ring A105+CR13 A182-F11+HF 7 Hinge Pin A276-420 A276-304 8 Disc Washer Carbon Steel A276-304 9 Disc Nut Carbon Steel A194-7 10 Disc Nut Pln Carbon Steel A276-420 11 Gasket Spiral wound (Graphite+304) 12 Stud A193-B7 A193-B16 13 Stud Nut A194-2H A194-7 14 Eye Bott 2 Carbon Steel Dimensional Datas Of Ansi Class 600 LB NPS 2 2/1/2 3 4 6 8 10 12 14 16 18 20 24 in DN 50 65 80 100 150 200 250 300 350 400 450 500 600 mm L/L1 8 8.5 9.5 11.5 14 19.5 24.5 27.5 31 34 38.5 38.5 51 in (RF/BW) 203 216 241 292 356 495 622 966 787 864 978 978 1295 mm L2 8.5 9 10 12 14.5 20 25 28 31.5 34.5 39 39 51.5 in (RTJ) 216 229 254 305 368 508 635 711 800 876 991 991 1308 mm H 6 6.5 6.88 8 11.5 13.88 15.38 17 18.75 20.62 22.88 24.62 34.75 in 152 165 175 204 293 353 390 432 475 525 582 627 883 mm Wt(kg.) 24 35 44 70 125 207 310 460 615 945 1105 1495 1695 RF/RTJ 16 19 26 44 87 147 220 350 452 720 845 1160 1280 BW Dimensional Datas Of Ansi Class 900 LB NPS 2 2/1/2 3 4 6 8 10 12 14 16 18 20 24 in DN 50 65 80 100 150 200 250 300 350 400 450 500 600 mm L/L1 14.5 16.5 15 18 24 29 33 38 40.5 44.5 48 52 in (RF/BW) 368 419 381 457 610 737 838 965 1029 1130 1219 1321 mm L2 14.62 16.62 15.12 18.12 24.12 29.12 33.12 38.12 40.88 44.88 48.5 52.5 in (RTJ) 371 422 384 460 613 740 841 968 1144 1140 12.32 1334 mm H 9.5 10 11 12.5 18.12 22 24 26.5 32 32 33.5 38.75 in 240 256 278 320 460 560 610 675 815 815 850 985 mm Wt(kg.) 37 54 68 109 195 321 481 711 956 1468 1870 2316 RF/RTJ 21 25 34 58 115 194 290 461 597 950 1210 1533 BW

...more

150LB Cast Steel Check Valve

Appiicarit Standards Steel Check Valves API 6D Steel Check Valves ISO 14313 Steel Valves ASME 81634 Face To Face ASME B16.10 End Flanges ASME B16.5 Butt Welding Ends ASME B16.25 Inspection and Test API 598/API 6D Design Descriptions Bc, Bolted Cover Swing Type, Anti-rotation Disc Renewable Seat Rings Non-penetrate Disc Shaft Horizontal Or Vertical Service Flanged Or Butt Welding Ends Materials Of Parts S. No. Part Name Carbon Steel ASTM Material 1/1/4cr-1/2 mo 1 Body A2113-WCB A217-WC6 2 Cover A216-WCB A217-WC6 3 Disc 1 Al 05-CR13 Al 82-F1 1 +HF 4 Hinge A216-WCB A217-WC6 5 Fork Part A216-WCB P21 7-W6 6 Seat Ring A105+CR13 Al 82-F11 +HF 7 Hinge Pin A276-420 A276-304 8 Disc Washer Carbon Steel A276-304 9 Disc Nut Carbon Steel A194-7 10 Disc Nut Pln Carbon Steel A276-420 11 Gasket Spiral wound (Graphite+304) 12 Stud A193-B7 A193-B18 13 Stud Nut A194-2H A194-7 14 Eye Bolt 2 Carbon Steel Dimensional Datas Of Ansi Class 150 LB NPS 2 2/1/2 3 4 6 8 10 12 14 16 18 20 24 26 28 30 36 in DN 50 65 80 100 150 200 250 300 350 400 450 500 600 650 700 750 900 mm L/L1 8 8.5 9.5 11.5 14 19.5 24.5 27.5 31 34 38.5 38.5 51 51 57 60 77 in (RF/BW) 203 216 241 292 356 495 622 966 787 864 978 978 1295 1295 1448 1524 1956 mm L2 8.5 9 10 12 14.5 20 25 28 31.5 34.5 39 39 51.5 in (RTJ) 216 229 254 305 368 508 635 711 800 876 991 991 1308 mm H 6 6.5 6.88 8 11.5 13.88 15.38 17 18.75 20.62 22.88 24.62 34.75 37 37 38.62 48 in 152 165 175 204 293 353 390 432 475 525 582 627 883 940 940 980 1220 mm Wt(kg.) 14 20 25 40 71 118 177 263 353 542 632 855 970 1600 1600 1990 2760 RF/RTJ 10 12 17 29 57 96 143 227 295 468 552 755 831 1420 1420 1760 2230 BW Dimensional Datas Of Ansi Class 300 LB NPS 2 2/1/2 3 4 6 8 10 12 14 16 18 20 24 26 28 30 36 in DN 50 65 80 100 150 200 250 300 350 400 450 500 600 650 700 750 900 mm L/L1 10.5 11.5 12.5 14 17.5 21 24.5 28 33.00 34.00 38.5 40 53 53 59 62.75 82 in (F1F/BW) 267 292 318 356 445 533 622 711 838 864 978 1016 1346 1346 1499 1594 2083 mm L2 11.12 12.12 13.12 14.62 18.12 21.62 25.12 28.62 33.62 34.62 39.12 40.75 53.88 54 60 63.75 in (RTJ) 283 308 333 371 460 549 638 727 854 879 949 1035 1368 1372 1524 1619 mm H 6 6.5 6.88 8 11.5 13.88 15.38 17 18.75 20.62 22.88 24.62 34.75 35.88 37 38.62 48 in 152 165 175 204 992 353 390 432 475 525 582 627 883 910 940 980 1220 mm VVt(kg.) 16 23 29 46 82 136 204 302 405 625 730 985 1115 1465 1840 2290 3180 RF/RTJ 11 13 18 31 61 103 155 245 315 503 593 812 895 1205 1525 1895 2395 BW

...more

Solenoid Control Valve 600

The 600 series solenoid control valve is classified in two categories (1) Globe and (2) Angle type. The valve is a self-contained unit consists of a diaphragm operated main valve with two solenoid pilot valves. The first (globe) will permit main valve to open when de-energized. The solenoid pilot valve may be activated by pressure, temperature, clock, and float. Etc. other features are available on custom basis. Additional Relief/Sustaining Function-600 601-Solenoid on/off 602-High Capacity 603-Booster Pump Control 604-High capacity with control Max. Range : 0-300 psig Specifications Pressure Ratings : Class: 150-300 # Standard Materials : 150-400 mm, ASTMA 216 Gr. WCB & Alloy Steel Temperature Range : -40 to 90 deg.C. Media : Any Liquid Services

...more

Solenoid Control Valve

Specifications * Pressure Ratings : Class: 150-300 # * Standard Materials : 150-400 mm, ASTMA 216 Gr. WCB & Alloy Steel * Temperature Range : -40 to 90 deg.C. * Media : Any Liquid Services

...more

Separate Closing Speed Controls Check Valve

The 700 series Non-slam check valves are diaphragm actuated. The higher downstream pressure enters the valve cover thru a control tube and the valve closes. Additional Relief/Sustaining Function-200 701R-No speed control 701-01R-No closing speed 701-02R-Opening speed 701-03R-Separate adjustable opening and closing speed (4" & smallest) 701R-Separated opening and closing speed (6" & large) Specifications Pressure Ratings : Class:150-300 # Standard Materials : Stainless Steel Size : 150-400 mm Temperature Range : -40 to 90 deg.C. Main valve Body & Cover : ASTMA 216 Gr. WCB & Alloy Steel Media : Any Liquid Services

...more

Separate Closing Speed Controls Check Valve

We offer separate closing speed controls check valve. specifications * pressure ratings : class:150-300 # * standard materials : stainless steel * size : 150-400 mm * temperature range : -40 to 90 deg.c. * main valve body & cover : astma 216 gr. Wcb & alloy steel * media : any liquid services

...more

Self Regulating Valve 523

Technical Specification Valve Size 2", 3", 4" Rating 150# to 300# Temperature 180 C Maximum Inlet Pressure Max. 300 PSIG Valve FunctionSelf RegulatingAccessories Pressure reducing, up stream-down stream controlcontrol, emergency on/off, back pressure controlHigh pressure regulator pneumatically operatedblind pressure controller Body Globe style with model 523 Material • Body - C.S. & Alloy Steel • Trim - C.S. & Alloy Steel

...more

Safety Relief Valve Open Bonnet

* spring loaded safety relief valve * full lift pop type design * open bonnet with cap & liver * close bonnet with liver * close bonnet with packed liver.

...more

Safety Relief Valve Open Bonnet 501

Technical Specification Inlet Size 1" x 2" through 10" x 12" ANSI Flanged Material C.S./CF8/CF8M/Alloy Steel Inlet Rating ANSI Class 150# to 2500# Orifice Size Sizes D Through T Temperature Range -450 F to 1500 F Pressure 5 to 3000 PSIG Spring loaded safety relief valve Full lift pop type design Open bonnet with cap & liver Close bonnet with liver Close bonnet with packed liver

...more

H 500 Safety Relief Valve

Built in conformance to ASME code section / API for air, gas, steam and liquid service Technical Specification

Valve Size : 1/4

Material : C.S./CF8/CF8M/Alloy stell flat seats for easy maintenance

...more

C 501 Safety Relief Valve

Technical Specification Inlet Size 1" x 2" through 10" x 12" ANSI Flanged Material C.I./C.S./CF8/CF8M/Alloy Steel Inlet Rating ANSI Class 150# to 2500# Orifice Size Sizes D Through T Temperature Range -450 F to 1500 F Pressure 5 to 6500 PSIG Spring loaded safety relief valve Full lift pop type design Open bonnet with cap & liver Close bonnet with liver Close bonnet with cap Close bonnet with packed liver Metal seat Stallited nozzle & dics Soft seat with PTFE & Viton Bellows seal safety relief valve

...more

Safety Relief Valve 500

Built in conformance to ASME code section / API for air, gas, steam and liquid service Technical Specification

Valve Size : 1/2

Material : C.S./CF8/CF8M/Alloy stell flat seats for easy maintenance

...more

Safety Relief Valve

Built in conformance to ASME code section API for air, gas, steam and liquid service

...more

Remote Air Operated Valve

Loading pressure - either air or inert gas - is applied to tge tope of the diaphragm by the loader to open the main valve against the valves spring and inlet pressure. After the valve is open, more loading pressure is applied to the top of the diaphragm to keep the valve open while building up the desired reduced pressure under the diaphragm and to restore equilibrium under flow conditions.

...more

Remote Air Operated PRV 45

Technical Specification Inlet Body Size 1/4", 3/8", 1/2", 3/4", 1", 11/2", 2" NPT/BSP Body C.S./Brass/Alloy Steel Diaphragms Seats Neoprene/Buna-N/302 ST. ST. Standard Metal Trims S.S./Brass Inlet Pressure 0 to 500 psig Outlet Pressure 0 to 300 psig Loading pressure - either air or inert gas - is applied to tge tope of the diaphragm by the loader to open the main valve against the valves spring and inlet pressure. After the valve is open, more loading pressure is applied to the top of the diaphragm to keep the valve open while building up the desired reduced pressure under the diaphragm and to restore equilibrium under flow conditions. Reduced pressure from the down stream piping system is applied to the bottom of the metal diaphragm through an external impulse line.

...more

Pressure Sustaining Valve

Specifications * Pressure Class : 150 & 300 # * Temperature Range : -40 to 90 deg.C. * Media : Any Liquid Services * Material : Body & Cover : ASTMA 216 Gr. WCB & Alloy SteelG

...moreBe first to Rate

Rate ThisOpening Hours