O Rings (Viton)

10 - 150 Per Piece

Oil Wiper Rings

Get Price Quote

Oil Wiper rings are manufactured to effectively provide positive containment of lubricants within the crankcase. In addition to wiping rings, which essentially scrape liquid from the rod, most wiper packing also contain sealing rings to block gas pulsations or flow through the packing. Oil Wiper Rings are manufactured in several designs, including tangent cut unidirectional, tangent cut bi-directional and triple circle design. They are manufactured from Cast Iron, Bronze, Aluminum Alloy, Carbon, Stainless Steel & Teflon®. Oil Wiper Rings are available for rod sizes 1 1/2" to 8".

Best Deals from O Rings

Teflon O-Rings

Get Price Quote

We manufacture Teflon O-Rings which are used in Spray Drying Nozzle Body to prevent leakage of liquid from Nozzle Body. ADVANTAGES Improves life of Nozzle Body by preventing leakage of liquid

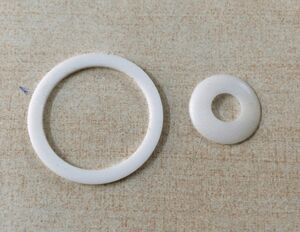

PTFE Ring

1 - 12 Per piece

500 piece (MOQ)

We are manufacturing wide range of ptfe rings, ptfe washer and ptfe gaskets. These products widly uses in valves industries, chemical industries, pharma industries and machine industries. These products are made in guidance of expert persons with high accurancy. Size Different size are available as per clints requirement. ( Up to 200mm OD) Materials Virgin and Filled like 25% Carbon, 25% Glass, etc.

PTFE back up ring

Get Price Quote

Back-up rings are normally supplied as a spiral of two turns. This enables the back-up ring to be opened with ease for fitting over a shaft, and ensures the 'O' ring is supported around its entire diameter. Single turn back-up rings can also be supplied, and these are usually endless to ensure good support. However, they can be scarf split if required, although we do not recommend this because extrusion can occur at the split.Smaller sizes of back-up rings are available only as a single turn. This is because spiral back-up rings need an inside diameter of 3mm or greater for machining purposes. Materials Our back-up rings are manufactured in either virgin PTFE, PEEK™ (from Victrex plc) or filled PTFE, depending on the application. Why use back-up rings? Back-up rings are installed to prevent extrusion of the 'O' ring. Two back-up rings - one either side of the 'O' ring in its housing - are needed when the application is double acting.They are normally recommended for applications where:Pressure of the fluid medium exceeds 10MPa, or'O' rings of low strength elastomer are used, or Adverse mechanical conditions prevail.

O-Rings

Get Price Quote

O-Rings, oil seals, Rubber Parts, Diaphragms, Bellows, pneumatic seal kits

O Ring

Get Price Quote

O Ring, Engineering Plastic, Pump Rings, Gaskets, Tapes

Rubber O Rings

Get Price Quote

Rubber O Rings, rubber mounting pad, Silicon Gasket, rubber v seal