woven sack tape plant

7,651,000 Per Unit

1 Unit (MOQ)

Voltage : 150 - 370 ( kw )

Driven Type : Automatic

Country of Origin : Made in India

...more

Woven Sack Bag Cutting Stitching Machine

One of the qualities driven firm we have been plighted in manufacturing, exporting and supplying high quality Woven Sack Bag cutting stitching machine. The offered machine is manufactured using high quality approved components by our highly skilled expert with the aid of cutting edge techniques. Available in different sizes and models this machine is highly demand by number of clients. The Woven sack bag cutting stitching machine is delivering to the customer with two servo motors. Nominal price are being offered on all our products. Features Easy operation Corrosion resistance Flexible No maintenance cost

...more

Two Extruder Blown Film Machine

3,553,000 Per Piece

1 Piece (MOQ)

Two Extruder Blown Film Machinery Prominent & Leading Manufacturer from Ahmedabad, we offer Two Extruder Blown Film Machinery, mulch film making two layer blown film plant and two extruder three layer aba blown film plant. Two Extruder Blown Film Machinery We are leading manufacturer and supplier of Two Extruder Blown Film Machinery to our clients. Products are designed under the direction of our domain experts using quality tested material and latest technology at well-equipped infrastructure unit. Two Extruder Blown Film Machinery Two Extruder Blown Film Machinery Suitable For All Kinds of High-Grade Film Packaging. For Its Good Barrier Property, Keeping Fresh, Well Protected Against Dampness, Frost Proof, Oxygen Insulation, Oil Resistant, This Film Can Be Widely Used In Light And Heavy Package, Such As All Kinds Of Fresh Fruit, Meat, Pickles, Fresh Milk, Liquid Beverage, Medical Supplies And Etc. However, it’s Not Made from Waste Plastic Raw Materials but from Plastic Granules Raw Material. Materials of Two Extruder Blown Film Machinery Polyethylene’s (HDPE, LDPE And LLDPE) Are The Most Common Resins In Use, But A Wide Variety Of Other Materials Can Be Used As Blends With These Resins Or As Single Layers In A Two Extruder Blown Film Machinery Structure. These Include Pp, Pa, Eva. In Some Cases, These Materials Do Not Gel Together, So Two Layer ABA Blown Film Plant Would Delaminate. To Overcome This, Small Layers Of Special Adhesive Resins Are Used In Between. Two Extruder Blown Film Machinery

Voltage : 146 - 194 ( kw )

Plastic Processed : Extruder

...more

Turrent Type BOPP Tape Slitting Rewinding Machine

1 Piece (MOQ)

Country of Origin : India

Certification : CE Certified

Color : Grey

Voltage : 110V

Condition : New

Rated Power : 1-3kw

Automatic Grade : Automatic

...more

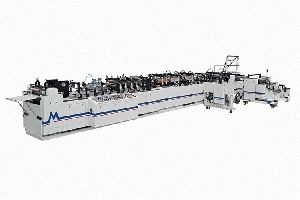

Three Side Seal Pouches

Three Side Seal Pouch Making Machine we are one of the pioneers in manufacturing and supplying a three side seal pouch making machine. These machines are manufacture from superior quality components and advanced machinery in accordance with the set industry standards. The center and three side seal pouch making machine is available in different design and sizes to meet various demands of our clients. Additionally, The Three side seal pouch making machine can be availed from us at market leading prices.

...more

Three Side Seal Making Machine

1,351,000 Per Pack

1 Piece (MOQ)

FEATURES of Three Side Seal Making Machine:- High Speed up to 150 strokes/min Servo Motor for Indexing and Accuracy Microprocessor Controlled with Digital Display Keyboard Setting for speed, Size & Count Backlit Display for Operating Parameters Photocell Control to Convert Printed Film Vertical Unwind stand Two Continuous Lateral Sealing Jaws One set Cross Sealing Jaws User Friendly Single Control Panel

Voltage : 110V

...more

Three Layer Blown Film Plant

5,651,000 Per Piece

1 Piece (MOQ)

Voltage : 146 - 194 ( kw )

Three Layer Blown Film Line

5,043,000 Per

1 Piece (MOQ)

FEATURES of Extrusion Mulch Film Machinery Exporter:- Energy efficient groove feed barrier extruder Haul-off Oscillating Tailor made winder depend upon application & automation requirement Advanced feature like PIB dosing system, internal bubble cooling. Extrusion Mulch Film Machinery Exporter

Voltage : 146 - 194 ( kw )

...more

THERMAL PAPER SLITTING REWINDING MACHINE

Our organization is engaged in manufacturing, exporting and supplying of Thermal / ATM Paper slitting rewinding machine which design sharp to meet the standards requirement of the clients. Our Paper Slitting Rewinding machines are engineered from superior grade parts and innovative technology in accordance with the defined industry norms.We ensure their high quality and robust performance these are being designed by our highly skilled professional ensuring their easy installation, high speed and very low maintenance cost. Additionally this Thermal Paper Slitting Rewinding machine can be availed from us as industry leading rates. Features Noise less Sturdy design High strength and high speed Low maintenance cost Special Features Having speeded up to max 240 mpm. Cut Thermal plain paper 40 GSM – 200 GSM Rewind on the single shaft like 5-8 rolls Very efficient machine The production rate 60,000-80,000meter in 8 hours.

...more

Thermal Paper Slitting Machine

1 Piece (MOQ)

Rated Power : 1-3kw

Driven Type : Elecric

Warranty : 1year

...more

tarpaulin making machine

6,561,000 Per Piece

1 Piece (MOQ)

Type : Tarpaulin Making Machine

Voltage : 220V

Automatic Grade : Automatic

Power : 1-3kw

Warrenty : 1 Year

Brand Name : Ocean International

...more

T Shirt Bag Making Machine

Ocean international is one of the pioneers for manufacturing, exporting a wide different range of T-shirt Bag making machine. The bag is sealed and cut using hot needle for auto stacked simple to pack. We manufacture this T shirt bag making machine in various specification and models in order the meet the requirement of our valuable clients. Using this Bag making machine you can bunch of 50 bags blocked together by using online punching press. Additionally, we are offering this bag making machine to our Valuable clients at market leading prices. Features Easy to adjust the bag length and generation speed Fully automatic and safe to operate Servo motor for indexing and accuracy More production saves man power and time Auto punch system

...more

Synthetic String Sutli Making Machine

2,173,000 Per Piece

1 Piece (MOQ)

Voltage : 25 - 91 ( kw )

Weight : 4 Ton

Surface Type Slitting Rewinding Machine

651,000 Per Piece

1 Piece (MOQ)

Voltage : 5hp

Stretch Film Slitting Rewinding Machine

Owing expertise in this domain we are one of leading manufacturer, exporter and supplier of Stretch Film Slitting Rewinding machine. The whole machine controlled by proper ways, is safe and solid under right operation. The programmed cutting blade is made by proficient apparatus crushing production line. The Stretch Film Slitting Rewinding machine is controlled by autonomous of recurrence converter which can modify speed rapidly and viably guarantee the rewinding machine pressure easily, perfectly and energy saving. As our Rewinding machine are used in varied industries. In addition, our Stretch Film Slitting Rewinding machine can be available at market leading prices. Features Easy to use Sturdy construction Highly flexible, high quality Solid Stretch ability , Low maintenance cost Energy saving Technical Specification Max Diameter of materials: Diameter 800mm Max rewinding diameter for 4 Shaft exchange of Diameter 150mm Min cutting diameter 12mm Machine speed of 0 to 180m/min

...more

Stretch Film Making Plant

3,551,000 Per Piece

1 Piece (MOQ)

Voltage : 145 ( kw )

Weight : 10 Ton

Size : 25 X 15 X 12 ( L X W X H ) feet

...more

stretch film making machine

3,551,000 Per Piece

1 Piece (MOQ)

Weight : 10 Ton

Driven Type : Automatic

Stand Up Zipper Pouch Making Machine

4,251,000 Per Pack

1 Piece (MOQ)

FEATURES: One Master roll with shaft-less unwinder and Driven Tension control system Multiple sealing and cooling stations All stations are actuated by individual servo system to control seal and cool time Multiple Nip roller system to maintain even tension on the film Touch Screen PLC for setting of all parameters like size , sped , dwell time , temperature etc Servo actuated cutter system Auto conveyor system for easy collection of pouch

Voltage : 110V

Condition : New

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

Warrenty : 1year

...more

Slitting Rewinding Machine

By means of the profound knowledge we embrace in the slitting rewinding technology, we are thriving in the converting industries for equipping productive solution concerning heavy duty slitting applications of large industries. This range of the slitting machine is made adopting cutting edge web guiding technology that delivers excellent webbing operation, imperative for the successful execution of the unwinding and rewinding. The equipped pneumatic brake with the unwinding roll enables controlling the tension, as the tension of the machine is decisive for consistent slitting process and successful execution of stretchy and thin materials. The every equipment incorporated with the provided heavy duty slitting rewinding machine is quality tested by a team of the quality analyst before being combined in the one unit and hence is assured of supremacy under heavy duty operations.

...more

Slitter Rewinder Plant

651,000 Per Piece

1 Piece (MOQ)

Machine Features: Most Versatile, Model Providing Combination of Duplex Center Cum Surface Rewind System Constantly Flawless Slit Rolls by Providing Center Driver Drum to Maintain. Fixed Minimum Distance Between Slitting and Rewind Point Constant Line Speed Causes Constant Tension Rolls Two Rewinding Shafts Carried on Swinging Arms are Center Driven Through Adjustable Slipping Clutch Counter Balance System to Adjust the Pressure Between Rewind Reels and Center Drum Suitable for off Caliper / Slippery / Stretchy Material In Special Case, Rewinding Shaft can be Supplied with Provision of Individual Different Slip Assembly for each Slit Reels Slitting Methods as per Customer Requirement Like: Scissor Cut/Crush Cut (Circular Knives) / Razor Blade Slitting System Side Frame Construction of Ribbed Anti Vibration C.I Body Rewind – Central Drum or Duplex type Dynamically Balances Drive Rollers Trim Separation by Air Blower of 1.0 HP AC Motor Line Speed up to 100 – 200 Meter /Min. Depending on the Thickness of the Materials & Operating Conditions Customized Roll Handling System for Enhanced Production & Ergonomic Safety AC Drive System Applications of Slitter Rewinder Plant:-Used in Paper Mill & Paper Tube Making PlantSlitting of all Types of Material Like Plastic, Paper, PVC, Stretch Film, BOPP Film, PET Film, Paper Board, Film Ribbon, Micro Tape, Fax Roll, Cling Film, Duct Tape, Mask Tape, Rubber, Tarpaulin, Tube, Flexible Packaging , Aluminum Foil, LDPE Film, Non-Woven Fabric, Adhesive Tape, Ice Cream Cup Paper, Nylon Fabric, Coated Paper, Laminated Film, Etc.

Type : Slitting Rewinding Machine

Certification : CE Certified

Weight : 100-1000kg

Color : Grey

Voltage : 110V

Rated Power : 1-3kw

Automatic Grade : Automatic

Driven Type : Elecric

...more

Single Two Color Rotogravure Printing Machine

Certification : CE Certification

Weight : 60 kg

Warranty : 1 Year

...more

Single Layer Blown Film Machine

2,051,000 Per Piece

1 Piece (MOQ)

Driven Type : Electrical

Material : LD,HM,BIODEGRADABLE

Voltage : 146 - 194 ( kw )

...more

Side Sealing Machine

As one of the eminent organization we are offering high quality Side Sealing machine which are well known for its solid structure with simple operation. This Sealing machine is manufactured by our experience professional by using high quality crude materials and advanced technology. The side sealing bag making machine is known for its features like sturdy construction, excellent performance, Hassle free functioning etc. The Side sealing machine is widely used in packaging industries our offered machine is available in various specification like semi and Automatic side sealing machine to meet various requirement of the clients. Features Hassle free functioning Sturdy and strong construction Easy maintenance High speed up to 300 strokes/min.

...more

Side Seal Bag Making Machine

As one of the eminent organization we are offering high quality Side Sealing machine which are well known for its solid structure with simple operation. This Sealing machine is manufactured by our experience professional by using high quality crude materials and advanced technology. The side sealing bag making machine is known for its features like sturdy construction, excellent performance, Hassle free functioning etc. The Side sealing machine is widely used in packaging industries our offered machine is available in various specification like semi and Automatic side sealing machine to meet various requirement of the clients.

...moreOpening Hours

Perfect solutions for manufacturing different product types and for various industrial applications are highly required in all manufacturing companies. And manufacturing companies usually choose these solutions considering the quality and price. Production of only superior quality products taking place at our unit and affordable rate being put on each product is what we are guaranteeing at Ocean International. Incepted in the year 2007, Ocean International is a professionally managed company that is involved in manufacturing, supplying, and exporting a superlative range of industrial machines, industrial plants, and industrial lines that are widely used across different industrial sectors.

The company is based in Ahmedabad (Gujarat) and has maintained a huge customer base not only in India but also in various overseas countries. We, at Ocean International always keep ourselves focused on maintaining our quality standards consistently so as to stay ahead of our competitors in the market.

We are supported by a technologically advanced manufacturing unit that is outfitted with the latest machinery. This helps us in producing products of high quality in a large volume while matching international quality standards. We keep a close eye on our entire production process and ensure strict quality analysis must be done on all of our manufactured products in order to ensure their preciseness and prevent any sort of error in them. We are supported by a team of highly skilled and experienced individuals that is undeniably an indispensable part of our company. With the cooperation of our employees, we are operating with proper management and adroitly catering to the demands of our valuable customers.

100% Quality assurance & customer satisfaction guarantee, personalized services, and competitive pricing policy are the major essences that drive our company’s success for years.