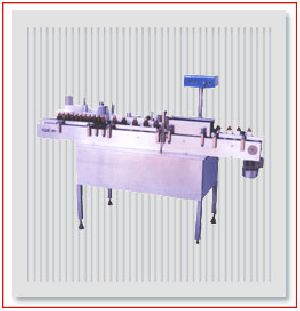

Wet Glue Labeling Machine

Automatic Wet Glue Labeling Machine Model for Vials and Bottles.Now, experience the experience of a No.1 Largest Labeling Machinery manufacturer, The latest and best with super smooth operation to suit every customers need from small scale to large scale multinationals.Operates with minimum mechanical moving parts resulting in best performance at very low maintenance. Wet Glue Labeling Machine with fully stainless steel finish with optionally AC Variable Freq. Drive Control system for smooth speed variation. Salient Features: Minimum Change over time is required from one size of container or label to another. In Built Counter and On Line Printing Device. Complete Stainless Steel Finish. Twin Label pickup System in single operation. Suitable for Overlap and Flag type Labelling Fully Gear Drive System.

...more

Wet Glue Labeling Machine

Wet Glue Labeler Machine is the fastest Wet Glue Labelling Machine ever developed in India to achieve very high production rate of Upto 400 Labels/Min. on Vial Line. Machine incorporates AC. Variable Freq. Drive System for smooth speed control. Latest Microprocessor controlled gluing system with unique twin label box design for constant delivery of labels at very high speed. Horizontal or Vertical Code over printing is possible with rubber stereos.ensures guaranteed output of 250-300 vials/min. for 2 ml. Vial. Salient Features: Provision of Safety System for stopping the machine in case a Bottle enters the safe zone to avoid damages to Products & Feed Worm. Provision of Drop Oilers for continuous lubrication. Twin Label Box System. No mechanical Label pick-up system.Only Vacuum operated 9/12 Label pick up cylinder ensures fast delivery of Labels with minimum rotation of Cylinder and also suits Very High Speed Labeling. Glue Saving 30% to 50% due to strip Gluing System. Elimination of Label Wastage - No Container No Label Device Glue Saving due to No Label No Gluing Device. Low Maintenance due to Fully Gear Drive System. Built in Safety Device for preventing damage to Container and Feed Worm. Easy Change Over System For Change parts of Bottle / Label Size. Least Change Over time for change parts. Vacuum Label Pickup system - No Label Finger. Easy to change label application height appx. 5 mm. Suitable for Overlap Labeling. Built-in Code-Over (Batch No., Price etc.) Printing Device.

...more

Wet Glue Bottle Labeling Machine

Fully Automatic High Speed Flat Bottle Labeling Machine Model is made for labeling on many kind of Flat bottles used by Breweries, Distilleries, Cosmetics and other industries. It had excellent flexibility to handle flat bottle at very high speed with great accuracy. The machine incorporates easy to use, simple online contact coding system to print Batch No., Price, Date of mfg. etc. on label in horizontal or vertical position. The machine also has completely stainless steel finish, No Bottle No Label system, No Label No Gluing and unique strip gluing system. Optionally A.C. Variable Speed Control, Pulse counter, Safety guard also available. Salient Features: Provision of Safety System for stopping the machine in case a Bottle enters the safe zone to avoid damages to Products & Feed Worm. Provision of Drop Oilers for continuous lubrication. No Finger system and Only Vacuum operated 3/6 Label pick up cylinder ensures fast delivery of Labels with minimum rotation of Cylinder and also suits Very High Speed Labeling. Glue Saving 30% to 50% due to strip Gluing System. Elimination of Label Wastage - No Container No Label Device Glue Saving due to No Label No Gluing Device. Low Maintenance due to Fully Gear Drive System. Built in Safety Device for preventing damage to Container and Feed Worm. Easy Change Over System For Change parts of Bottle / Label Size. Least Change Over time for change parts. Vacuum Label Pickup system - No Label Finger. Easy to change label application height appx. 5 mm. Built-in Code-Over (Batch No., Price etc.) Printing Device.

...more

Vial Labeling Machine

Sticker Labeling Machine

The Om Bhagwati Labelling Technologies’s Automatic Vertical High Speed Sticker Labelling Machine Model SBSL-150-B, is one of the most user friendly. The Machine incorporates latest sophisticated Micro Processor Control Label Dispensing system with user friendly Sensing system for Label and Product. The Machine is suitable for Labelling on Round Bottle, Jars and other round objects. It is capable of Labelling up to 150 Products per minute depending on products diameter and label size.Machine is suited for Glass, Plastic, Aluminum, PET bottles / jars of Pharmaceuticals, Mineral Water, Food Products and Pesticides having bigger Label Height and Length. The Om Bhagwati Labelling Technologies’s Sticker Labelling Machine SBSL-150-B has its own unique single point synchronized speed control system. The Inbuilt Automated Label Length detection systems eliminates any need for manually feeding and storing of Label Length data in memory and retrieving the same every time for change of Label Size & re-starting the machine. The System thus saves valuable time, avoiding machine-down time, and helps achieve higher production. Machine can be supplied with Optional Toughened (Tampered) Glass or Acrylic Safety Cabinet. Machines having required all basic features as a standard fitment to match the current market needs and also saves cost and time.Built-In Unique Features : No Label Data Input/retrievals require for any Label Size No Change Parts for Product and Label size Synchronized speed of Label Dispensing, Conveyor and Pressing Device Virtually Maintenance free machine Easy to change label application height User Friendly Label Placing Adjustments Suitable for On-Line InkJet and Contact Coding System Suitable for Partial, Full Wrap Around and Overlap Labelling Built In A.C. Variable Frequency Drive System. Fully Stainless Steel finish Machine.

Power : 1.5 Amp.

...more

Tube Labelling Machine

This model is suitable for various dia. tubes i.e. 19 mm to 60 mm. The machine operates at the speed up to 60 tubes / min. Automatic feeding & air ejection system can also be provided for loading and un-loading of tubes. The machine comes with salient features like No tube - No label. Transparent film label can also be applied without eye - mark with the help of mechanical sensor. Tube Labelling Machine adopts advanced technology and high-powered components - small inertia stepper motor to reach the real perfect labelling. The system carries out high response and highly reliability by the professional approved program controller and stepper system, it carries out communication between machine and man by micro processor control panel, the precision of the main machine can during the process of the sending label control.

...more

Sticker Self Adhesive Labeling Machine

Sticker (Self-Adhesive) Labeling Machine Fully Automatic, User Friendly, Sticker (Self-Adhesive) Labelling Machine Mode, Suitable for Labeling on Vials, Bottles and other round objects.The Fully Automatic Sticker Labeling Machine incorporates latest sophisticated Micro Processor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system. Salient Features: No change parts for container and label size Built In A.C. Freq. Drive System Output 40 to 150 labels per minute Fully stainless steel finish Optionally online coding system Suitable for Wrap-around and Overlap Labeling

...more

Sticker Self Adhesive Labeling Machine

Sticker (Self - Adhesive) Labeling & Labeler Machine Fully Automatic, User Friendly, Sticker (Self - Adhesive)Labelling Machine with output upto300 Labels per minute. Machine suitable for labeling onVials and bottles, Ideal for Pharmaceutical unit having highproduction requirement. Salient Features: No change parts for container & label size. Fully stainless steel finish. Built-in AC. frequency drive system. Compatible with any type of inkjet and contract coding system

...more

Sticker Self Adhesive Labeler Machine

Fully Automatic, User Friendly, Sticker (Self-Adhesive) Labelling Machine Model. Suitable to apply accurate Labels on Single Side (Front or Back) of Flat/Oval/Square shaped products having PET, Plastic, HDPE, LDPE, Glass or any other surface. The Machine incorporates latest sophisticated MicroProcessor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system. OBMA series Sticker Labeling machines are 100% User Friendly, Virtually Maintenance Free and does not require Data Inputs for Label Size. Salient Features: No change parts for container and label size in standard shaped containers Precise Label Placement Accuracy Single Point on-line Speed Variation control system Built In A.C. Freq. Drive System Output upto 200 labels per minute. Fully Stainless Steel Finish including main machine frame Optionally online coding system

...more

Sticker Self Adhesive Labeling Machine

Sticker (Self-Adhesive) Labeler Machine Fully Automatic, User Friendly, Sticker (Self-Adhesive) Labelling Machine Mode, Suitable for Labeling on Bottles, Jars, Tins and other round objects. The Machine incorporates latest sophisticated Micro Processor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system. Salient Features: No change parts for container and label size. Built In A.C. Freq. Drive System. Output 40 to 100 labels per minute. Fully stainless steel finish. Optionally online coding system. Suitable for Wrap-around and Overlap Labeling

...more

Single Side Sticker Labeling Machine

Single Side Sticker Labeling Machine OBSL-120F Fully Automatic, User Friendly, Sticker (Self-Adhesive) Labeling Machine Model OBSL-120F, Suitable to apply accurate Labels on Double Side (Front & Back) of Flat/Oval/Square shaped products having PET, Plastic, HDPE, LDPE, Glass or any other surface. The Fully Automatic Single Side Sticker Labeling Machine incorporates latest sophisticated Microprocessor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system. OBSL-120F Sticker Labeling machines are 100% User Friendly, Virtually Maintenance Free and does not require Data Inputs for Label Size. Salient Features: No change parts for container and label size in standard shaped containers Single Point on-line Speed Variation control system Precise Label Placement Accuracy Built In A.C. Freq. Drive System Output up to 150 labels per minute. Fully Stainless Steel Finish including main machine frame Optionally online coding system

...more

shrinkable label inserting machine

Shrinkable Label Inserting Machine (Applicator) Model No. SB-SLEEVE-30 GMP Model Bhagwati Shrink-Sleeve Labelling Machine high speed uses newest shrink technology with MMI and PLC base control panel. The bary centre and base have been accurately design, even use this machine with high speed for long time machine running still very stable and smoothly. Many model with all kind of speed selection from 50/minute to 200/minute and is suitable for wide range; it can be modified according to package's shape. Can meet, all kind of required no matter it is for cap or bottle. The machine is suitable for Pharmaceutical, food industries; it can be for health-food, medicines, Juices, Milk, Drinks, etc.Application:Beverage, Cosmetic, Dairy, Food & Pharma. Salient Features : The unit is made compact & versatile as per GMP norms. The structure of sleeve applicator and conveyor are made of SS 304 and the structure of tunnel is made from MS with powder coating. Rigid vibration free construction for trouble free performance. The SS 304 slat conveyor for proper product conveying. (For the processes of sleeve inserting and sleeve shrinking. Worm for the positive feeding.

Voltage : 220V/380V 50/60 HZ 3 PHASE

Power : 2.5KW

Material : PVC/PET/OPS

...more

Semi Automatic Wet Glue Labelling Machines

Power : 0.25 HP/ 414 v. / 3 Phase

Semi Automatic Self Adhesive Labelling Machine

Semi Automatic Vertical Type, User Friendly, Sticker (Self-Adhesive) Labelling Machine Mode OBMA-60, suitable for Labeling on Round Vials, Bottles and other round objects. The Machine incorporates latest sophisticated Microprocessor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system. Salient Features: No change parts required for container & label size. Output between : 40 to 80 labels per minute. Fully stainless steel finish. Optionally online coding system. Suitable for Wrap-round and Overlap Labeling

...more

Semi-automatic Labeling Machine

Semi-Automatic Labeling Machine Semi-Automatic Labeling Machine Model with optional Electronic Label Pick Up System. The machine is ideal for the customers requiring lower rate of production for round container, where Automatic Labelling machine are not Economical.Semi Automatic Labeling Machine Model , being the latest addition in the range of labelling machine. The machine is suitable for round Containers with the pack size of Appx. 30ml to 1/5 Ltr. appx., be they of Aluminium ,Composite, HDPE, Pet, Tin or Glass. Most important feature of the Labelling Machine is that it does not require any change parts for change in sizes of Container or Label. Salient Features: Compact Table Top Model for Ease in handling. No change parts required for changes in Size of Container & Label. Suitable for Glass/Plastic/Metal/Tin/Pet/Aluminium/Composite Containers, Tins, Jars and Bottles. Grooved and Brut shaped bottles can also be labelled. Suitable for Spot, Complete Wrap-Around and Over Lap Labelling where the length of Label is more than the circumference of the container. Minimum Glue Consumption due to special design of Glue Cylinder for Strip Gluing. Suitable for Pharmaceuticals, Food, Beverage, Distillery, Cosmetics, Pesticides, Chemicals, Agro Chemical and similar products.

...more

Semi Automatic Labeling Machine

Semi Automatic Labeling Machine OBSL-60 / Semi Automatic Labeler Machine Semi Automatic Vertical Type, User Friendly, Sticker (Self-Adhesive) Labeling Machine Mode OBSL-60, suitable for Labeling on Round Vials, Bottles and other round objects. The Semi Automatic Labeling Machine incorporates latest sophisticated Microprocessor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system. Salient Features: No change parts required for container & label size. Output between : 40 to 80 labels per minute. Fully stainless steel finish. Optionally online coding system. Suitable for Wrap-round and Overlap Labeling.

...more

Semi Automatic Cartooning Machine

To increase the production and efficiency, we have specially designed Semi Automatic Cartooning Machines. Our Semi-automatic cartooning machine speeds up the cartooning process in every possible way. The horizontal semi-automatic cartooning machine manufactured by us is ideal for pharmaceuticals. It is also suitable for a wide range of bottles, containers pouches, blister packs, etc. Thus we are famous exporters of it from India.. This Cartoning machine is suited to handle such items as tubes, blister strips, bottles, vials, ampoules, droppers, inhalers, film rolls, bearings, soaps and many other products falling within the wide range of the machine either individually or in combination. Automatic Cartoning Machine draws the carton from a magazine & opens the carton, Inserts product and closes the carton by tucking in the flaps. This Cartoning machine is suited to handle such items as tubes, blister strips, bottles, vials, ampoules, droppers, inhalers, film rolls, bearings, soaps and many other products falling within the wide range of the machine either individually or in combination. Applications this machine can successfully be used for Cartoning Tubes, Cosmetics, Soaps, Bottles, Ampoules, Vials, Bearings, Blisters or any other rigid products that goes into a unit carton. Multi packs of more than one product in a unit carton can also be handled in this Cartoning Machine. Leaflet insertion: An automatic insertion of pre-folded leaflets is also possible with an leaflet pre-insertion device.

...more

Bottle Labeling Machine

Self Adhesive Vial & Bottle Labelling Machine Model : OBSL-300 Om Bhagwati Labelling Technologies India's market leader in design and manufacture of self adhesive Labelling machinery for the packaging industry.Since Om Bhagwati Labelling Technologies is pioneered the development of Labelling machinery and its technology has grown to be a market leader working with many blue chip companies world wide. Our machinery is sold within many varied industries such as: pharmaceutical, toiletries, cosmetic, beverage and food etc. OBSL-300 Automatic Self Adhesive Vertical Labeling Machine is used for labeling of round container which are previously filled and sealed. No change parts are required for change over of container size. Machine conveyor will receive container from in feed turntable, it will be separated by the feeding roller assembly to maintain the pre determined space between the two container according to the label length and container diameter. Label is placed on the container immediately when it will be sensed by the container sensor, it ensures instant adhesive of label's edge. Then it passes through the pressing unit resulting in precise registration and crease-free application. It does not require any change parts for change in container diameter or label sizes. It can handle the diameter range from 20 MM to 90 MM and label height from 10 MM to 115 MM, change over can be done with in few minutes, label height from bottom can be also adjustable for different kind of containers Salient Features: A total CGMP model High Production Speed up to 300 containers/min and other higher model can give up to 300 containers/min. S.S. 304 Construction. Accurate label placement. Micro processor Control System. Full Pharmaceutical & Packaging security package system. Secondary Pressing unit. Any kind of printing device can be accommodated with machine. Imported Gear Motor for Conveyor & Pressing unit Imported Gear Box for Conveyor & Pressing unit A.C. Frequency Drive for main drive In built Speed Indicator & Counter Stepper Motor with Controller Imported Sensor for Label & Containera.. Specially designed machine useful to Apply labels on Round Products (full body or partial Labeling)as well as on Flat / Oval products (Single side labeling) b.. Any type products can be accommodating like Aluminium, Glass, Plastic & etc. c.. No change parts required due to special designed mechanism

...more

self adhesive sticker labeling machine

Self Adhesive Sticker Labeling Machine OBHSL 150 The Automatic (Horizontal) Sticker Labeling Machine with Automatic Feeding Hopper, is one of the most user friendly. It is capable of labeling up to 150 units per minute depending on products and label size. The fully automatic self adhesive sticker labeling machine is suitable for labeling on Inhalers, Ampoules, Vials and many kind of small diameter round objects. It had excellent flexibility to handle small size of labels and products. It has its own unique single point synchronized speed control system.The in-built automated label length detection systems eliminates any need for manually feeding and storing of label length data in memory and retrieving the same every time for change of label size & re-starting the machine. The system thus saves valuable time, avoiding machine-down time, and helps to achieve higher production. Salient Features: No label data input/retrievals require for any label size No change parts for label size Single pot on-line speed variation control Synchronized speed of label dispensing, conveyor and pressing device Virtually maintenance free machine User friendly label placing adjustments Self protected against voltage fluctuations Suitable for on-line Ink-Jet and Contact Coding System Suitable for partial, full wrap around and overlap labeling Built in A. C. variable frequency drive system Fully stainless steel finish machine and also frame structure

Power : 1.2 Amp.

...more

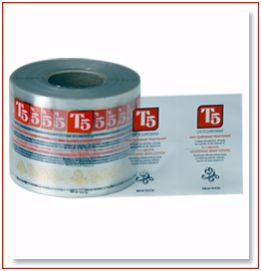

Self Adhesive Labels Rolls

We are glad to introduce ourselves as manufacturers of Self Adhesive labels Rolls . We combine our past experience of 20 years in Pre-Press with professional team of labeling and labels experts to fulfill any labeling requirement. Our labeling solutions are at par with the best in the world with High Speed "NILPETER" (USA) servo flexo combination printing machine , capable of printing with UV as well as Water Based Inks. We offer high quality world class labels in all types of substrate such as Paper, PP, PE, clear on clear with eight colors printing and value additions to your label such as Inline coating/Varnish, Emboss effect, Perforation, Cold / Hot foiling, Lamination, Reverse printing and many more.We assure high quality, most attractive & cost effective labels for industries such as Pharmaceutical Self Adhesive labels Rolls, FMCG Self Adhesive labels Rolls, Liquor Self Adhesive labels Rolls & Beverage Self Adhesive labels Rolls, Apparel Self Adhesive labels Rolls & Textile Self Adhesive labels Rolls, Chemicals Self Adhesive labels Rolls, Lubricants Self Adhesive labels Rolls, Airlines Self Adhesive labels Rolls etc.

...more

Self Adhesive Ampoule Vial Labeling Machine

Self Adhesive Ampoule/Vial Labeling Machine Salient Features: Suitable for wrap around labeling on Ampoules / Tubular vials or any other thin dia. Containers.Conveyorised tray loading and tray Collection system Spot wrap around system for accurate labeling.Star wheel with spring loaded rollers to take care the variation in dia. in case of 400 speed model.Available with latest Digital SERVO technology to achieve higher speed.

Weight : 450 kgs

...more

powder filler machine

Automatic Single Head Auger Type Dry Syrup Powder Filling Machine is a compact model used for filling of Dry Syrup Powder into bottle. The incoming dry bottle (sterilized and siliconised) are fed through the infeed Turn Table with suitably guided on the moving delrin flat conveyor belt at the required speed for feeding. Filling head is mounted on machine top plate. When bottle reaches to the filling station, it will be hold by the pneumatic bottle holder. Immediately it will be sensed by the bottle sensor as soon as it gets the signals from sensor magnetic clutch starts to rotate which is mounted on auger shaft. It will fill the desire amount of powder to the bottle through auger, where rotation time is previously saved in PLC control. After filling of bottle pneumatic piston goes back and release the bottle to move on conveyor. The main advantage of this machine is Pneumatic bottle holding system is directly connected with Auger rotation, so till bottle get filled with powder as per set value, pneumatic system will not going to release the bottle. Total Compact cGMP model. All parts and assemblies coming in contact with powder and rubber stopper are made of S.S.316 and easily removable for mandatory Autoclaving/ Sterilization. “NO BOTTLE, NO FILL” System eliminates wastage of costly powder. Conveyor driving is through High quality imported Gear motor Machine speed can be adjusted by A.C. Frequency drive, which is time saving. Machine is provided with delrin conveyor belt to avoid sticking of vial on conveyor. Pneumatic bottle holding system is connected with auger rotation, which eliminateschances of bottle transfer before completion of filling operation. Total PLC control for the machine. No change parts are required for any change in bottle diameter from 30 to 120 ml. Imported Gear Motor for Conveyor drive. A.C. Frequency drive for Conveyor drive. “No Bottle, No Filling” System. PLC control for machine. Pneumatic bottle holding system.

...more

OBSL-150 Labeling Machine

Fully Automatic, User Friendly, Sticker (Self-Adhesive) Labeling Machine Mode OBSL-120 (S), Suitable for Labeling on Vials, Bottles and other round objects. The Fully Automatic Labeling Machine incorporates latest sophisticated Micro Processor Controlled Stepper Motor Drive, Fiber Optic Label and Container sensing system. Salient Features: No change parts for container and label size Built In A.C. Freq. Drive System Output 40 to 150 labels per minute Fully stainless steel finish Optionally online coding system Suitable for Wrap-around and Overlap Labeling

...more

Label Printing Machine

We are offering Label Printing Machine

Power : 0.25 HP/ 414 v. / 3 Phase

Printing Machinery

Be first to Rate

Rate ThisOpening Hours