Curing Oven

Get Price Quote

1 Piece (MOQ)

Details : Heavy & Specially fabricated MS structure body. Electronic panel with temperature control system. 2 Hp standard blower for air circulation. Very easy door locking system. 6 kw heater for temperature control inside in box. (Up to 250 degree) 440 V (Three Phase) Connection.

Tray Dryer Oven

55,000 - 100,000 Per Nos

1 Piece (MOQ)

Best Deals from Overhead Conveyor Ovens

Cloth Drying Industrial Hot Air Blower

180,000 - 350,000 Per Nos

1 PIECE (MOQ)

Curing Oven

Get Price Quote

Owing to our capacity of meeting the exact requirements of the clients, we are supplying quality 2.16 Curing Oven. Our prime interest is to deliver a flawless range of products to the buyers. And in this concern, we make all arrangements in order to store the entire lot under safe environment.

Hot Air Circulating Oven

Get Price Quote

Hot Air Circulating Oven is one of the widely used Conditioning chamber or a medium of creating dry heat by heating the air inside it in various industries for various applications.

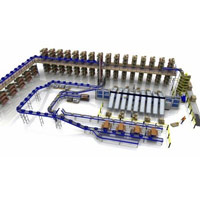

Hot Dip Galvanizing Plant

Get Price Quote

Planning & construction of tank system with fume exhaust system. Robust design of tank made out of Industrial Thermoplastic. Environment friendly Fume Extraction System, avoiding corrosion of surrounding steel construction, cranes and roof structure. Plastic Tanks available in flat pack modules (reduced volume) Heating and circulation system available. (optional) Tank made from Industrial Thermoplastic and welded with state-of-the-art hot gas extrusion welding process and stress relieved. Modules assembled and welded at site for easy transportation.

Hot Air Oven

14,500 - 150,000 Per Piece

1 Piece (MOQ)

air circulating oven

37,000 Per unit

hot dip galvanising plant

Get Price Quote

Plast World introduce ourselves as a Leading manufacturer, Supplier and exporter of a comprehensive range pickling tanks such as pickling plants for galvanizing tower , pickling plants for transmission tower, pickling plants for S.S. M.S. Pipes ,Tubes , Wire coils, Stripe etc.We design pickling Tanks that are used by galvanizing plants manufacturers for usage in high tension transmission Tower , poles, Pipe Cable Trays ,Grating , Guard, Tails, Railing and other steel items.

Tray Dryer Oven

Get Price Quote

Available in 24, 48, 96 & 192 Trays. Design is cGMP – Current Good Manufacturing Practices compliance. All contact parts AISI 316304 & non contact parts AISI 304 M.S. with painted. Highly effective uniform air re-circulating system by low speed fan. Inlet air filter and damper at inlet and exhaust air damper for air flow controls. Controls panel with Digital temperature controller and process timer controller. Mobile trolleys are provided which are used to load and unload the trays into the dryer.

air circulating oven

Get Price Quote

Effect of heat is very essential on all kind of odd plastic material. Air oven is used as conditioning chamber as well as to check the effect of heat on plastic product.

Batch Type Oven

400,000 Per Piece

Hot Air Oven

350,000 Per Piece

industrial gas ovens

100,000 Per Piece

Batch Type Ball Mill

Get Price Quote

We present special Batch Type Ball Mills to our clients. These Batch Type Ball Mills are known for the unique design and advanced technology that makes these Batch Type Ball Mills an efficient machine to work with. We manufacture these Batch Type Ball Mills with the best quality components for the desired performance and durability. Attributes : A versatile machine to pulverize even the hardest rocksGrinding and Liners made up of different hard material like Ceramic, Alloy steel, Granule brick etc available Suitable for : wet and dry grinding and mixing Application : CeramicQuartzPaintFeldspar Technical Specifications Model Volume in Ltrs. Cylinder Dimension *Production in Kg. / Hr. Dia. in mm.Length in mm.BMP-1001006406002 - 3BMP-2502506008003 - 5BMP-50050080010003 - 7.5BMP-75075085012505 - 10BMP-10001000100012507.5 - 15BMP-150015001250125010 - 20BMP-220022001250180015 - 30BMP-350035001500200025 - 50BMP-500050001800200030 - 60BMP-640064001800250040 -75BMP-11000110002400250050 - 100

Hot Dip Galvanizing Plant

3,200,000 Per Units

1 Units (MOQ)

Hot Air Oven

Get Price Quote

Temperature controller- Micro processor based double display PID controller Heating- Through high grade nichrome wire placed in the ribs of sides and bottom for uniformity Air circulation- Through aluminum blower fitted at the top at the back Temperature range- Ambient to 250°C Temperature least count- 0.1°C Accuracy- ± 0.5°C Timer- Micro processor based double display digital timer (Optional) Timer range- 999.9 Seconds, Minutes or Hours Safety MCB- Available on electrical panel Smoke ventilation- Installed on top of both sides Insulation- 70mm Thick Glasswool

Industrial Oven

Get Price Quote

Product Description : No literature can do justice to the vast range of Ovens and Dryers. Please contact us for a full exposition on the numerous types available. Each plant is individually designed to meet the specific requirements, related to process of the customer, fuel, method of job handling, safety requirements, through output etc. Key Attributes: » Mild Steel (Stainless steel above 350°C) » Mineral wool insulation material ( in conjunction with Ceramic fiber above 550°C) » Panel mounted control gear with optional Safety controls Manual or Powered door operation. » Sturdy Construction

Hot Air Oven

Get Price Quote

HOT AIR OVEN is amazing testing device which is designed elegant by the highly skilled engineers of Kant Plastology to perform different types of tests in various types of products at prescribed temperature. The internal stainless steel body retains three side heating zone to make perfect temperature equilibrium and it also has an air circulating blower which ensures even distribution of hot air inside the chamber. The apparatus has thick insulation to minimize the heat loss during test. The apparatus design is maintenance less and its operation is very user friendly.

Curing Oven for Rotary Screen

Get Price Quote

We are India’s notorious manufacture, supplier and exporter of curing oven, notably used in the printing industries to enact curing of the respective rotary screen. This curing oven is designed and engineered under strict observation to provide tight temperature tolerance and effective control for repeatable outcomes and homogenous airflow. Uniform curing of the respective rotary screen at low power consumption is what sets our range of the curing oven apart from competitors. The curing oven is developed in accordance with the set industry norms by performing strict quality controlled processes and performing rigorous testing ahead of shipment are the valuable reason for the unmatched thermal efficiency ensures uniform heat distribution throughout the work chamber as well as faster heating of the rotary screen. Incredibly fast heating, fast ramping, fast cool down rates, higher productivity, shorter cycles, consistent performance are the irresistible features of our curing oven making it a top performer in the market. Leveraging the experience we hold in the allied segment, we are well versed to manufacturer as per end user requirement, be it gas fired, electrically heated or indirect gas fired at the rock bottom prices. Prominent Features of Curing Oven for Rotary Screen: Best in class energy efficiency Sturdy construction Efficient thermal production Uniform heat distribution Lower recovery time Consistent performance