animal feed pellet machine

Get Price Quote

animal feed pellet machine

Get Price Quote

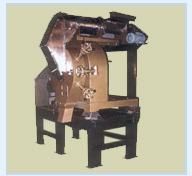

Animal feed pellet machine Twin shaft paddle type conditioner with two independent motors, magnet flanged inlet for steam and condensate removal arranged in S.S. Construction.DIE RING made out of EN – 353, pair of press Rolls made out of EN-8.

Best Deals from Feed Pellet Making Machine

pellet making machine

Get Price Quote

Basically the purpose of pelleting is to take a finely devised, some time dusty, unpalatable and difficult to handle feed material and by application of heat, moisture and pressure form it into larger particles. These larger particles or pellets are easier to handle, more palatable and usually result in improved feeding result when compared to mesh freed.

Pellet Mill

Get Price Quote

The remain material is to be sent to Pellet mill. Palletizing is a process to compact finely pulverized material into firm mass of a required shape and size by extruding it through a metallic ring die. Finely Elevator fed the material into the Pellet Mill through a feeder and then pressed into a rotating ring die with the help of two press rolls free to rotate on their respective shafts. The resulting pressure compresses the material and extrudes it through the holes in the die. Steam is mixed in the feed to decrease the friction and to better cohesion. High temperatures of steam results in gelatinization of raw starch present in Cattle ingredients.

Pellet Mill

Get Price Quote

Pellet Mill has a higher output per capital cost than any other pelleting machine on the market Pellet Mill has easy maintenance Pellet Mill is designed for silent smooth running Pellet Mill is meticulously engineered Long accumulated experience has gone into the Trumatic which is built to suit Dairy, Poultry Feed, Hog Feed, Oil Seed, Corn Wet Milling, Fish standard for continuous operation. This can be installed in an existing plant. The capacity depends on hole diameter of die, pellet thickness, speed of rotation. It's incorporate refinements are not found in any other pellet mill. Consists: Variable feeder, feed conditioner, permanent magnet, adjustable pellet cutter, oven loading mechanical fuse, easily operatable guard, big fly wheel, die holder assly., roll assly. Pellet Mill Specifications: No. Die Roll Output K.W. 1 305 x 110 148 50 2 420 x 160 205 110 3 520 x 190 250 160 4 660 x 190 302 200 5 850 x 295 390 250 6 900 x 295 408 250 Die Speed from 3.5 m/sec.

Spheronizer Machine

Get Price Quote

Spheronizer - Pellets Making, Extruder, Pelletize Uniform Spheronize pellets Process Application & Process : This machine is particularly designed for pharmaceutical, food and chemical laboratory small batch tests. Spheronizer enables uniform coating and accurate free flow filling into capsules drug applications within the pharmaceutical industry require consistent smooth surface particles, with a narrow size distribution. Spheronization helps to eliminate dust within the agro-chemical, pigment, and catalyst industries. This can reduce the risk due to toxic, environmental, and explosive hazards. It also improves processing consistency and productivity by using consistent free-flowing product and to reduce product settlement in transport of powder products prior to packaging. Spherodizer (also known as spheroinizers) provide a spherical product that is a more attractive as well as higher performing final granular product form than unspheronized. The Spheroinizers are implemented to produce uniform spheres for a wide range of technical as well as marketing driven reasons. Spheroidization can be used to improve the following: Limit dusting and fines generation Produce granule with a smooth surface Densify the surface for stability Minimize coating material necessary Increase flow ability Increase bulk density Narrow size distribution is controlled through the use of one of Prism's extruders such as Basket Extruder or Axial extruder to define the diameter of the feed material for the Spheronization Process. Feed material to the Spherodizer falls onto the high speed rotating chequered plate within the walls of cylinder of Spheronize of pellets. This plate contains many small sharply edged pyramids which cut the feed granulates to length at approximately 1 to 1.5 times their diameter. Centrifugal and gravitational forces create a mechanically fluidized ring of these particles which are impacting not only the plate but also each other and the walls with great velocity. With these impacts, they are reformed into spheres with a slight surface densification. Fines which were generated during the process are worked back into the spheres themselves leaving a very low dusting process with spheres which tend not to dust because of their slightly harder exterior and lack of corners. Variables for this Spheronization process include the formulation, the plate's pyramid sizes, the plate's rotational speed, and finally the time that the granules are allowed to stay inside the spheroinizers. Batch processing is typical for the requirements of pharmaceutical applications while the larger industrial Spheronization applications often employ the higher capacity cascade Spheronization method where granules are continuously moving through 2 or more Spherodizer bowls in a cascade layout to create the final spherical form required. Pharmaceutical spheroinizers are available with capacities from 0.25 Kg per batch to 60 Kg per batch. Industrial cascade spheroinizers with capacities to 100 Kg per batch are available. Salient Features : Capacities from 1 Kg to 100 Kg batch size for Industrial Productions. Designed as per cGMP - Current Good Manufacturing Practices & Non GMP STANDARD Model. Contact parts in AISI 316, AISI 304 or MS as desired by customer. Chequered plates are available with different pitch. AC Frequency Variable drives for chequered plate. Precise clearance between bowl and plate. Safety Features : Total drive transmission system enclosed Limit switch installed in the top lid ensure lid is closed Air pressure switch installed to ensure pressure is in limit. Limit switch installed at discharge to ensure product container underneath of discharge. Overload relay Protection and Emergency stop button

Wood Dust and Agro Waste Pellet Mill

Get Price Quote

Wood Dust and Agro Waste Pellet Mill, Double Stage Roll Crusher