Automatic Pre-Filled Syringe Plunger Rod Insertion and Labelling Machine

Get Price Quote

1 Unit (MOQ)

Automatic Pre-Filled Syringe Plunger Rod Insertion and Labelling Machine Automatic Pre-Filled Syringe Plunger Rod Insertion and Labelling Machine consisting of the main structure covered polycarbonate cabinet and SS 304 pipe, laminar airflow, filling head with individual servo motor, out-feed collection tray, vacuum system, pneumatic components, and electrical panel, AC Drive, PLC & HMI. Syringe Filling Machine & Stoppering Machine loaded on Stainless Steel in-feed hopper. A prefilled syringe manufacturing process machine tray can directly be loaded onto the PFS machine. Duly filled & stoppered syringes delivered on outfeed collection tray without hand touch.

Liquid Oral Processing Plant

2,000,000 - 4,000,000 Per Piece

1 Piece (MOQ)

Best Deals from Pharmaceutical Machines

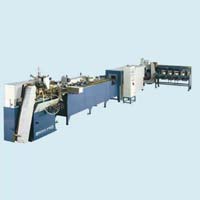

Pharmaceutical Automatic leaflet folder Leaflet Paper Folding Machine for pharma insert

Get Price Quote

2 piece (MOQ)

Stainless Steel Double Cone Blender

Get Price Quote

1 Piece (MOQ)

Gripper Type Automatic Rotary Ampoule Washing Machine

2,800,000 Per piece

1 piece (MOQ)

Input Specification Can accommodate different size of Ampoules with the help of change Parts. Special machines are available for other Size of containers on request. Ultrasonic provision for Pre-Cleaning is available on request.

Automatic Blister Packing Machine

Get Price Quote

With the aid of our experienced team, we are devoted towards manufacturing an exquisite range of Automatic Blister Packing Machine. Features: Low maintenance High operational fluency Enhanced service life

oral liquid filling machine

Get Price Quote

1 Piece (MOQ)

Pharmaceutical Dryer Machine

Get Price Quote

1 Piece(s) (MOQ)

semi automatic tablet counting machine

Get Price Quote

1 Piece (MOQ)

Pharmech Engineering Company is an ISO 9001: 2015 manufacturing company registered with D&B and Known for customized solutions in engineering, mainly for pharmaceuticals. The company also believes in constant improvement to bring out better, faster, and more economical machines in every category of machinery.TECHNICAL SPECIFICATIONS: Machine Structure Stainless Steel 304. Machine Size: Length-1000mm., Width-65Omm., Height-1100mm. Variable Speed Available. Product Wise Filling Quantity Can Be Saved In PLC For Regular Use Tablet / Capsule Per Hour Counting Approx 30,000. Depend On Tablet / Capsule Size And Shape ) Air Pressure Required 3 Kg. Approx. Approx Machine Weight: 150 Kg. Electric Power: Single Phase, 230 Volts.

Pharmaceutical Machine Parts

Get Price Quote

10 Piece(s) (MOQ)

We are offering a wide array of Pharmaceutical Machine Parts to patrons. They are made using high-grade raw material and modern machinery. Pharmaceutical Machine Parts are suitable for chemical and pharmaceutical industries. They can be availed from us in different sizes as per the clients’ needs. Owing to their accurate dimensions, compact design, high performance, easy installation, and low maintenance, our Pharmaceutical Machine Parts are widely demanded by consumers.

Vibro Separator Machine

65,000 Per Piece

1 Piece (MOQ)

automatic looping attachment mask making machine

Get Price Quote

fully automatic 3 ply disposable mask making machine with following specificationsfrom raw material to finished mask body1 steel frame work2..high stability and output3..automatic tension control system4..adjustable ultrasonic unit5..adjustable speed control system6 converter system7. auto elastic loop attachment system8. duel side elastic looping attachment. 9. synchronized with mask making unit10. servo motor driven11. pneumatic system integrated.12. separate ultrasonic system at each sealing section capacity 60-100pcs/minvoltage 220 vmachine working: automaticpower : 8 kwmachine weight 800 kg approx product size 17*9.5 cm

semi automatic capsule filling machine

875,000 - 1,350,000 Per Piece

1 Unit (MOQ)

Rapid Mixer Granulator

Get Price Quote

ampoule forming machine

Get Price Quote

We are pioneer manufacturers of glass ampoule forming machine (20 head) in india since last 35 years. We developed glass ampoule processing line in 2004. We exported more than 25 machines of 20 head ampoule forming in various countries which are running successful without any problem.

Tablet Dedusting Machine

Get Price Quote

It will be fixed under the outlet of tablet compression machine & it will be clean & polished all the tablets pherical vibratory system & give us polished & dust free trablets. Available with Brushing & without Brushing Model with MOC : SS 316.

Tablet Inspection Machine

Get Price Quote

Owing to the dedication of our diligent professionals, we have earned a reputed name in manufacturing, exporting and supplying the finest quality Tablet Inspection Machine. Under the strict guidance of our skilled professionals, our offered inspection machine is manufactured using quality tested components & cutting edge technology. Furthermore, the offered machine is highly acclaimed in pharmaceutical industries owing to its optimum functionality and robust construction. Features: Convenient design Easy to operate High output results NOTE : Technical details, specification & designs are subject to change without any prior notice.

700 Kg Double Cone Blender

250,000 Per Piece

1 Piece (MOQ)

Model-240 Double Track Blister Packing Machine

575,000 Per Piece

1 Piece (MOQ)

tablet packaging machine

550,000 Per Piece

Technical Data • Product Pack : Tablet, Capsules , Soft Gelatine Capsules • Material Uses: Nontoxic thermo formable transparent or opaque Pvc. Pvc with Pepvdc coating. • Lidding Materials: Hard aluminium foil with heat seal able inquire or pvdc coating. • Additional Advantage: Suitable for surgical product, disposable needles, syringes, scalp vein, IV cannula set, vial, ampoules etc. Advantage • Fully automatic blister pack machine. • Contact heating system. • Customisation of machine on special request for cell, any special product • No air compressor required. • Optional Pneumatic Sealing system. Salient Features • Simple and convenient operation. • Ease of maintenance. • Delivery as per committed services • Prompt & immediate efficient after sales services. • Optional equipment as per requirement. • Infinitely variable speed. • INBUILT CHILLING PLANT

gyro screen machine

Get Price Quote

Gyratory motion is the most effective method for screening. It causes 100% rotary motion and causes dispersion stirring & stratification of material to be sifted. Feed material constantly flows in Horizontal motion along a loop pattern on Vibro screen surface.gyro screen machine provides optimum screening & assures maximum feed-rate & efficiency.

pharmaceutical blender

150,000 - 500,000 Per Piece

1 Piece (MOQ)

150 Blister Packaging Machine

Get Price Quote

We are engaged in manufacturing and supplying a wide variety of 150 Blister Pack Machine. These products have many features like sturdy construction, minimal maintenance, easy operation, energy efficiency and longer service life.

Double Cone Mixer

Get Price Quote

This is a unique mixer which has 2 cones on the ends and cylindrical in the middle portion. It has two supporting legs. The shaft is moving with the cone by a motor and pedestal support which is mounted on legs. Both the cones have lids which can be opened or closed for loading and unloading. The double cones and cylindrical body is made of stainless steel. D.C. Mixer has two major functionsa. Mixing of the ingredients kept inside the chamber, andb. Hydration of the Guar splitIn guar-gum industry, the D.C. Mixer plays important role as it gives better result in fast hydration which enables to get better flaking, soft pulverising and high viscosity of the powder to be produced.

double cone blender machine

Get Price Quote

To mix the dry powder and granules homogeneously, the double cone blender machine is used. It is a versatile and an efficient blender machine used in various industries like pharmaceutical, food, chemical and cosmetic products. The capacity of the double cone blender machine is 10 kgs, 25 kgs, 50 kgs, 100 kgs, 200 kgs, 300 kgs, 500 kgs. HOW TO OPERATE : The wisely design conical shape of the machine is proven better for the uniform mixing and easily discharge. All quality contact parts are made of the S.S. 304 THE SPECIAL FEATURES : Both ends are of conical shaped, ideal for the easy discharge and uniform mixing. All quality contact parts are made of the S.S. 304 On both of the side the two nos. of safety roads are provided The butterfly valves are provided at one end of the cone. It is help in material discharge and other end of the cone for the material charging cleaning. The shaft of 04 nos. of fixed buffers Inside of the cone is mirror polished Outside of the cone is matt polished Safety guards are with limit switch All moving parts and safety guards are of S.S. 304 The panel is of S.S. 304 The panel is provided with D.O.L. tarter, digital timer, Amp meter and three phase indication For the speed reduction, the worm reduction gear is provided. On the both end of the cone, the food grade rubber gasket is given

single punch tablet press

Get Price Quote

Tablet Machine Single Punch from our side is used in the production of a number of different tablets. Our offered products are fully capable of making different shape and size of tablets. Their power, dimension and weight is in accordance to the current industry standards. These machinery are fully capable of changing the size of the same at any level of production. The implementation of the sophisticated engineering and advanced technology makes our machinery the best in the marketplace.

fluid bed granulator

Get Price Quote

Fluid Bed Processing involves drying, cooling, agglomeration, granulation and coating of particulate materials. It is ideal for heat sensitive and non heat sensitive products in Pharmaceuticals, Biotech, Nutraceuticals, Cosmetic, Chemicals, Biochemical, Food, Dairy, Confectionery, Agrochemical, Herbals, Ceramics, Detergents and Pharma Institutes. The Fluid Bed system have a bed of solid particles which are fluidized by passing a stream of air upward through a specially designed perforated sheet. The upward velocity of air is so maintained so as to slightly lift the solid particles and set them in motion. This motion can be utilized to bring about mixing as well as forward movement of the solids particles. The air is heated and the process hot air evaporates the fluid and dries the solids. Fines get agglomerated to larger granules particles thus providing large size

Automatic Tablet Counting and Filling Machine

1,200,000 Per Piece

Tablet, Capsule Filling Machine

Get Price Quote

we are offering tablet and capsule filling machine. we have become a renowned manufacturer of tablet & capsule filling machine that is widely appreciated by our clients for easy operations and high rate of production with minimum rejection and variation. these tablet & capsule filling machine can easily fill powders, pellets in all sizes.the is having easy operating system and user friendly with very compititive cost. long lasting. the machine is capable for output 60 bottlesminute. the main feature of the machine is best output of the machine.

Double Cone Mixer

Get Price Quote

We offer double cone mixer. This continuous mixer is use for solid-solid and solid-liquid mixing for medium to large production on continuous basis. This mixer has a single or double shaft with adjustable mixing paddles. In horizontal mixer the mixing purpose can be solved with interned impact and up-down movement. The output production range of this mixer is 100 kgs. To 20000 kgs. Application in: chemical, minerals, fertilizers, cement, guar gum starch cellulose etc.