18inch vibro sifter

35,000 - 75,000 Per piece

1 piece (MOQ)

1 HP Stainless Steel Flour Vibro Sifter

65,000 Per Piece

1 Piece (MOQ)

Best Deals from Pharmaceutical Machines

Rapid Mixer Granulator

850,000 Per Piece

1 Piece (MOQ)

Gyro Screen

45,000 - 375,000 Per Nos

1 Piece (MOQ)

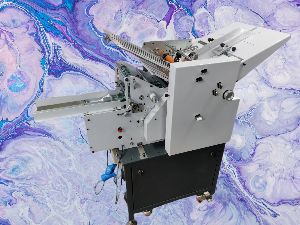

Pharmaceutical Paper Folding Machine

Get Price Quote

1 Piece (MOQ)

Pharmaceutical Centrifuge Machine

400,000 - 800,000 Per Piece

1 Piece (MOQ)

Model NTIM 1200 Tablet & Capsule Visual Inspection Belt Type Machine

Get Price Quote

1 Piece (MOQ)

TECHNICAL SPECIFICATION Machine Structure:S.S. - 304 Contact Parts: S.S.- 316 V/‘° PVC Endless Belt: Size - 205mm. Wide, 2mm. Thick ° Gear Motor: Bonfiglioli i z 1 r Machine Size: Height: 1250mm. Lenght: 1950mm. Width: 350mm Magnifier Sheet: 2 Nos , Size: 280mm x 220mm Tube Light (Led) :2 Nos, 1 Feet Lenght Speed: 1200 Tablet/Capsule Per Minute "/'AGN'FY'NG SHEET Power: 0.5 HP/3 Phase Dust Collector Unit OTHER FEATURES Machine Made From Stainless Steel-304 and Contact Parts are Made From Stainless Steel-316 About Conveyor Belt - Food Grade, Washable, Durable and Easy to Change Machine Hopper Capacity: 5 KG. to 10 KG High Quality Magnifying Sheets (3X) for Detect Every Defects on Tablet/Capsule Driving Roller Food Grade Rubber Coated 100%Top & Bottom Inspection for Tablet/Capsule Immediate Stoppage Foot Switch for Operator When Defective Tablet/Capsule are Identified

Vibro Sifter Machine

50,000 Per piece

1 piece (MOQ)

An SS (stainless steel) vibro sifter, also known as a vibro screen or vibrating sifter, is a type of equipment used to separate, classify, and filter powders, granules, and other bulk materials. It utilizes vibration to help achieve accurate and efficient screening. Here’s a detailed look at its features and applications: How It Works: Design: The vibro sifter typically consists of a circular screen or mesh mounted on a frame, with a vibrating motor or vibrator attached to the screen assembly. Vibration Mechanism: The vibrating motor generates vibrations that are transmitted to the screen. These vibrations cause the material to move across the screen and separate based on size, density, or other properties.

Rotary Tablet Press Machine

Get Price Quote

1 Piece (MOQ)

Pharmaceutical Dryer Machine

Get Price Quote

1 Piece(s) (MOQ)

Automatic Strip Packing Machine

450,000 - 1,250,000 Per Piece

1 Piece (MOQ)

Vibro Separator Machine

65,000 Per Piece

1 Piece (MOQ)

Syrup Filling Machine

500,000 Per piece

1 piece (MOQ)

Octagonal Blender

160,000 Per Piece

1 Piece (MOQ)

Octagonal Blender Machine

125,000 - 1,650,000 Per Piece

1 Piece (MOQ)

Features All contact parts are made of SS 316 and non-contact parts are made of SS 304. Highly energy efficient and compact machine GMP compliant machinery design Product container having discharge with butterfly valve and manhole. Superior safety features Easy to load and unload the materials Low maintenance and enhanced durability

Vibro Sifter Machine

Get Price Quote

1 Piece (MOQ)

Multi Mill Machine

Get Price Quote

1 Piece (MOQ)

Models available in Lab Model (1.0 HP ) regular Model (3.0 HP and Large Scale production Model (5.0 HP) Suitable for Milling of dry and wet cake and granules. cGMP Construction with Stainless Steel 316 or 316 L grade contact parts as per requirement. Wide range of screen sizes available from 0.5 mm to 12.0 mm hole sizes. It operates on the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to get the required size reduction. Material fed in the hopper, goes down to the processing chamber where it moves to the periphery and passes through the screen radially and tangentially. Finally the processed material gets collected in the container kept below the processing chamber. Out put and quality of the final product depends on three main factors shape of beaters (knife/impact edges). Continuous duty operation with Noise less and Maintenance Free performance. Unit mounted on wheel for ease in mobility. Direct drive unit available with Variable frequency drive. Flame proof / ATEX electrical available on demand. All validation documents will be provided in our format, along with the equipment. Wide application of Multi Mill in Pharmaceutical, API, Speciality Chemical and Powder processing industries.

Pre-filled Syringe Filling and Rubber Stoppering Machine

Get Price Quote

1 Unit (MOQ)

Pre-Filled Syringe Filling & Stoppering Machine Pre-Filled Syringe Filling Machine and Dental Cartridge Filling Machine, Pre Filled Syringe Stoppering Machine, Pre Filled Syringe Sealing Machine, Pre Filled Syringe Plunger Insertion Machine, and Pre Filled Syringe Labeling Machine consisting of the main structure covered polycarbonate cabinet and SS 304 pipe, laminar airflow, filling head with individual servo motor, out-feed collection tray, vacuum system, pneumatic components, and electrical panel, AC Drive, PLC & HMI. Syringe Filling Machine & Stoppering Machine loaded on Stainless Steel in-feed hopper. A prefilled syringe manufacturing process machine tray can directly be loaded onto the PFS machine. Duly filled & stoppered syringes delivered on outfeed collection tray without hand touch. Key Features The machine is manufactured or developed accordance with GMP standards. The structure is made of SS 304 or cladded with SS 304. Rigid vibration free construction for trouble free performance. Machine with out-feed trays for collection of syringe tub. All contact parts SS 316L and non-contact parts are SS 304. Machine suitable for different syringe size with help of change part and depends on characteristic of liquid. Servo with syringes synchronized system for filling Accuracy. Filling volume set with touch screen HMI. Pneumatically controlled Stoppering mechanism. Very easy & accurate electronic based volume setting of different pre-fill syringes. Zero Dripping filling stations. Diving system with the design of timer belt and Stepper Motor/pneumatic Control which has no Vibration and very smooth kind of filling, filling material must be Fill Centrally in the Syringe. Design of Nozzles and adjustment of flow rate is very useful for filling with minimum Air Bubble / foaming in the Syringes. Low air machine stop sensor. LAF stop machine stop sensor. Door interlocking system. A suitable expandable PLC with programming & 7” colour touch screen HMI. The Pharma grade silicon tubes are used for filling & CIP/SIP. There is a very less product change over time due to very less usage of mechanical parts. All liquid contact parts easily removable for cleaning and sterilization purpose. Machine with LAF which can maintain class 100 condition (OPTIONAL). Co eccentric nozzles for quick filling of liquids. For different heights of syringes, the whole assembly can be moved upwards & downwards. Production counter is given with password protection for daily track report. The faults can be detected on the PLC touch screen HMI and can be attended easily. The output speed can be appeared on HMI screen. Very less mechanical adjustment required due to the special design. User friendly and very less maintenance required. NITROGEN FLUSHING SYSTEM [OPTIONAL]: The filling unit has an inbuilt system for nitrogen flush. The unique dual filling nozzle flushes nitrogen before filling followed by filling operation. Most reliable & proven mechanical components such as pneumatics & CE certified electrical/electronic such as AC motor, AC Drives, PLC & HMI Touch screen, safety interlock & Sensors, MCB’s, relay etc.

Mild Steel Gyro Screen Machine

55,000 Per Piece

100 Piece (MOQ)

GMP Reactor

550,000 - 750,000 Per Piece

1 Piece (MOQ)