Vibro Sifter

75,000 Per Piece

1 Piece (MOQ)

Gyro Separator

45,000 - 375,000 Per Nos

1 Piece (MOQ)

Best Deals from Pharmaceutical Processing Equipment

Stainless Steel Vibro Sifter

75,000 Per Piece

1 Piece (MOQ)

Salient Features : Stainless steel GMP construction with S.S.304 or 316 contact parts. Faster output at low power consumption. Double deck arrangement can be provided. Fitted with Vibro Motor. Provided lid for dust free operation. Easy to dismantle to clean screens.. Provided sieve with silicon sealing. Available in 20" Dia, 30" Dia, 36" Dia., 48" Dia size sieve model. Flame - proof electrical motor can be provided as option

Tablet Dedusting Machine

65,000 Per Piece

Application De-Duster is pharmaceutical processing equipment that removes the fine surface dust from tablets by using a vibratory effect. This machine can be linked directly to any type of high-speed tablet press. In Elevating Dedusterthere are vibrated uphill type sieves. The tablets enter the bottom inlet of perforated sieve from directly Tablet Press then they are gently vibrated and the tablet to move forward, upward, turning and rotating along the spiral up hill path of the perforated plate to outer at top of the sieve.Inspiral deduster there is vibrated spiral path perforated sieve. The tablets enter in centre of perforated sieve from directly Tablet Press then they are gently vibrated and the tablet to move forward, turning and rotating along the spiral path of the perforated plate to outer peripheries. Features All contact parts AISI 316 & non-contact parts AISI 304. Geometrically designed tablet route to ensure remove dust and burrs. Easy to install with all types of Tablet Press with an inline metal detector. Option for Spiral OR Elevating-Up hill type Deduster. Adjustable height. Easy and simple dismantle for cleaning of all contact parts. Design is cGMP – Current Good Manufacturing Practices compliance.

Vibro Sifter

45,000 Per Piece

Compression Testing Machine - Hand Operated

Get Price Quote

1 Piece(s) (MOQ)

We are offering compression testing machines conform to the requirements of is : 516 and other international standards like bs and astm. Latest design with hardchrome plate piston with new type of long life oil seal. Four pillar model is superior in design, reliability and accuracy in comparison to channel model. No welded parts. All joints reinforced with heavy nutbolt some of the salient features are : * high stability * self-aligning platen assembly. * gauges are calibrated in kilo newtons against certified proving rings. * suitable for testing cubes of various sizes * using special platens, bricks also can be tested.(extra cost) general specification loading unit. The loading unit consists of a cross-head and base with solid pillars supports connecting the base and cross-head firmly. The hydraulic jack is fixed to the base. The platen of the machine are hardened ground and polished the upper platen is provided with self-aligning action. To facililate testing of various size specimens. Spacer block provided. Pumping unit. The hydraulic pumping unit is manually operated the load is measured on bourdon tube type pressure gauge which is calibrated against certified proving rings. The pressure gauge is fitted maximum load pointer.

Vibro Sifter Machine

50,000 - 130,000 Per piece

1 Piece (MOQ)

Vibro Sifter Machine

45,000 - 950,000 Per Piece

1 Piece (MOQ)

Tablet Metal Detector

Get Price Quote

the tablet metal detector are basically used for detection of tablet and capsules and separate metal contaminated components without any interruption from a stream of capsules. A robust stainless steel reject flap is used by high speed electrical solenoid for clean rejection of contaminated waste. Best suited for high processing speeds and immediate product change. The tablet metal detection systems has unit that takes a small amount of length and is located before or after de-duster. With the use of tablet metal detector, it is feasible to detect stainless steel, ferrous and non-ferrous metals. features metal detector comes in a compact design and is mainly user friendly a non-corrosive detector with long lasting working life easy maintenance and smooth operation robust construction with higher sensitivity rapid operations with accurate outcomes the overall finish of the detector stands out to be rust free easy change electronic components easy cleaning possible led bar graph built tablet metal detector used for monitoring the amount of contamination automatic balance with adjustable sensitivity modular plug in card system used inside the tablet metal detector requires lesser space for installation compliable with the tablet press higher sensitivity towards various metals including the most rugged non-magnetic stainless steel, which is used for the built up of components.

Double Cone Blender

Get Price Quote

OPERATIONThe Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. All the contact parts made out of stainless steel of required grade by customer. Two third of the volume of the Cone Blender is filled to ensure proper mixing. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. SALIENT FEATURESThe conical shape at both ends enables uniform mixing and easy discharge. All contact parts are made out of stainless 304 or 316 quality material, as required by customer. Maximum care has been taken to ensure safe operation of the unit. Manual rotating facility with hand wheel for inching. The same will be provided with ss cover & limit switch. ( In 200 Kgs. & above model ) Two nos. of safety road will be provided at back side. ( One LH side & one RH side ) Suitable size of butter fly valve at one end of the cone provided for material discharge & hole with openable cover provided at other end of the cone for material charging & cleaning. with 04 nos. of fixed buffels with mirror polished provided inside the cone. be mirror polished from the inside & outside & structure will be matt polished. All moving parts covered with SS304 covers. Safety guards made from SS304 pipes provided in front of the m/c with limit switch. Panel fabricated from SS304 material with facility of three phase indication, D.O.L. tarter, digital timer & Amp. Meter. As per customer requirement machine will be provided with left side drive or with right side drive. The conical shape at both ends enables uniform mixing and easy discharge. All contact parts are made out of SS304/316(as per customer requirement) quality material. Maximum care has been taken to ensure safe operation of the unit. Worm reduction gear use for speed reduction. Food grade rubber gasket will be used on both end of cone as well as in butterfly valve. Inside & outside of the cone will be polished to the mirror finished. General structure made out of SS304 and Polished to the matt / mirror finish ( as required by you ) in GMP Model. All safety guards & covers made out of SS304 in GMP Model. Hand wheel will be provided for manual tilting of cone. Safety guards provided with limit switch to not start the machine when safety guards are not in proper position.

SS Kitchen

Get Price Quote

Under the strict supervision of our experienced professionals, we are offering an innovative collection of SS (Stainless Steel) Scoop & Scraper that is highly demanded in pharma industries. Besides being delivered, this scraper is thoroughly tested by our quality experts ensuring its flawlessness. In line with clients' diversified requirements, we offer this scraper in various sizes, shapes and designs. The offered scraper is highly acclaimed by the clients for its durability and high strength. Features : Crevice free Contemporary design Smooth edges

double cone blender machine

75,000 - 1,450,000 Per Piece

1 Piece (MOQ)

Features The conical shape of both ends enables uniform mixing and easy discharge. All contact parts are made out of SS316 quality material. Maximum care has been taken to ensure safe operation of the unit. Safety reeling, overload protection and emergency shutdown features available. Mirror finish inside and outside the drum. Easy to load and unload the materials Low maintenance and enhanced durability

Steel Vibro Sifter

110,000 Per Piece

1 Piece (MOQ)

VSM30 Vibro Sifter Machine

70,000 Per Piece

1 Piece (MOQ)

Confider Industries stands as a beacon of excellence in the realm of food processing machinery, offering an extensive array of products tailored for both domestic and commercial applications. With a diverse portfolio comprising over 90 meticulously crafted machines, our company epitomizes innovation, reliability, and superior quality. From humble beginnings, we have grown into a globally recognized brand, catering to the needs of customers worldwide. At the heart of our success lies a relentless commitment to delivering top-notch products that exceed expectations. Every machine manufactured by Confider Industries undergoes rigorous quality control measures, ensuring precision engineering and durability. Whether it's a small-scale operation in a home kitchen or a large-scale industrial setting, our machines are designed to meet the diverse demands of modern food processing. One of the hallmarks of Confider Industries is our unwavering dedication to customer satisfaction. We understand that purchasing a food processing machine is an investment, and thus, we go above and beyond to provide unparalleled after-sales support. Our team of experts is readily available to assist customers through calls and video calls, offering guidance, troubleshooting, and technical assistance whenever needed. We believe in building long-lasting relationships with our customers, and our commitment to after-sales service reflects this ethos. Furthermore, Confider Industries takes pride in its global reach. With an extensive network of distributors and partners, our machines are delivered to customers across continents. Whether it's a bustling city in Asia, a remote village in Africa, or a thriving metropolis in Europe, our products have found their way into kitchens and food processing facilities worldwide. This global presence underscores our reputation as a trusted provider of food processing solutions on a global scale. Innovation is at the core of everything we do at Confider Industries. We continuously invest in research and development to stay ahead of market trends and technological advancements. Our team of engineers and designers work tirelessly to develop cutting-edge solutions that streamline processes, enhance efficiency, and elevate the overall user experience. From state-of-the-art automation technologies to eco-friendly designs, we strive to push the boundaries of innovation in the food processing industry. Sustainability is also a key focus for Confider Industries. We recognize our responsibility to minimize our environmental footprint and embrace sustainable practices throughout our operations. From sourcing materials responsibly to optimizing energy efficiency in our manufacturing processes, we are committed to fostering a more sustainable future for generations to come. In conclusion, Confider Industries stands as a beacon of excellence in the food processing industry, offering a diverse range of high-quality machines for domestic and commercial use. With over 90 machines in our portfolio, a global presence, and a steadfast commitment to customer satisfaction, we continue to set the standard for innovation, reliability, and excellence in food processing.

Vibro Sifter Machine

Get Price Quote

1 Piece (MOQ)

Double Cone Blender

235,000 - 1,250,000 Per Piece

1 Piece (MOQ)

Vibro Circular Vibrating Screening Machine

50,000 - 500,000 Per piece

1 Piece (MOQ)

Rubber Compression Machine

300,000 - 1,200,000 Per piece

1 Piece (MOQ)

Vibro Sifter

Get Price Quote

Vibro Separators are circular unitary gyratory screens used to separate mass composition of solids from solids, and for gradation of materials as per particle size, having wide range applications. The structuring of the machine has been designed in order to achieve the multiple plane vibration by suitable assembly of the specially designed Vibratory motor (constructed for this purpose) having eccentric weight at the top and bottom ends of the motor shaft. The motor is mounted vertically at the centre of the screening assembly, on a circular base by means of springs which allow the Unit to vibrate freely. The springs absorb the vibrations and prevent them to be transmitted on the floor. The top weight causes vibration in the horizontal plane which causes the material to move across the screen towards the Periphery. The lower weight acts to tilt the machine which causes vibration in the vertical tangential axis. The angle of lead of the lower weight with relation to the upper weight provides variable control of the screening pattern. Thus the material moves across the screen and also in the vertical and tangential planes enabling maximum screening.

Vibro Sifter

Get Price Quote

Our organization is one of the most reputed and efficient manufacturer and exporter of Vibro Sifter in Ahmedabad, Gujarat. A team of trained professionals verify the product. It is manufactured by making use of high grade components and growing technology. Vibro sifter finds application in pharmaceutical and chemical laboratories as it has a high degree of surface finishing. Checking arrangements are available with the product and faster output is ensured at low power consumption. Also, assembling and cleaning of the product is free from complications. Features : Double deck arrangement can be provided Faster output at low power consumption High Degree of surface finish All contact parts made of SS 316 as per GMP standard Easy dismantling and cleaning Unit Consists Of : Specially designed vibratory motor to run on 400/440 V, 3 phase, 50 cycles electric supply with adjustable eccentric weight at the center of the base plate of screening Screening unit consists of SS 304 / 316 screen sandwiched between SS 304 / 316 hopper and bowl with help of special clamp with gasket. This in turn is clamped to the base plate Option Available : Multi Deck screening GMP unit with SS 304 machine body base instead of MS Dust cover or lid for hopper assembly SS 316 contact parts Castor wheels for mobile unit Sample Availability: Yes Supplier Product Code : HE / 014

Double Cone Blender

Get Price Quote

Our range of premium quality and highly efficient Double Cone Blender is widely used in Food, Chemicals, Cosmetics and Pharmaceutical industries. This equipment is designed with electric control panels, enclosed rigid drive with reduction gear box, charging hole with hinged lid etc. The Double Cone Blender is immensely popular in market for being compact, offering excellent blending and three side accessibility. We are a renowned manufacturer, exporter and supplier in Ahmedabad, Gujarat offering Double Cone Blender at reasonable rates while ensuring timely delivery.

Inline Vibro Sifter

Get Price Quote

Ranked among top suppliers of Inline Vibro Sifter, we can provide the product at economical prices. We have hired a team of professionals who work in complete adherence with the industry norms to deliver the best quality products to our valued patrons.

Compression Testing Machine

30,000 Per Piece

1 Piece(s) (MOQ)

Standard Accessories The Machine can be supplied with NCCBM Calibration certificate at an extra cost. The Machine can also be supplied with 2 or 3 pressure Gauges of 100 KN, 250 KN and 500 KN for testing lower strength cubes or smaller size cubes. Optionally, the machine can be supplied with digital load indicator and load cell in place of Pressure Gauge at an extra cost.

Vibro Separator

Get Price Quote

Salient Features Flour and semolina mills Feed mills Seed cleaning plants Works on cereals cleaning and calibration centers. Aluminum Industries Sand Material

Vibro Sifter

85,000 - 150,000 Per Piece

1 Piece (MOQ)

A vibro sifter machine that is exclusively used in Pharmaceutical & food industries. This sifting machine is manufactured as per the highest standards that meet cGMP norms. The Vibro Sifter machine works on the principle of gyratory vibrations. The material is separated based on its particle size. Once the motor gets energized, vibration is caused in the screen/sieve making the material travel across the sieves according to its particle size. Salient Features Compact and versatile design Sturdy and vibration free design Easy to operate Less maintenance Durable Application Sifter Industry Pharmaceuticals FMCG Beverages

30INCH SS VIBRO SIFTER

50,000 - 60,000 Per PIECE

1 PIECE (MOQ)

Vacuum Rubber Compression Molding Machine

1,500,000 Per Unit

1 Unit (MOQ)

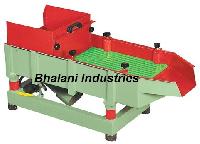

Vibro Separator

Get Price Quote

We are offering vibro separator. bhalani vibro separators are dewlapped to separate ceramic media, parts and water by screening. Vibro seprator is powered by foot mounted vibratory motor. This range of vibro separator is known for saving time and labour as compared to the manual screening. These products are known for their sturdiness and reliability. Separation screen will be fitted with nylon perforated for effective separation of ceramics and parts. All the contact parts are mild steel suitably protected against corrosion. The top screen is removable type & can be replaced for screening of different material. features simple construction & maintenance free. accurate separation & easy to operate. can be added in continues production system rugged heavy duty special vibratory motor.

vibro screening machine

Get Price Quote

Gyrator screen is useful and impart for solid liquid, screening. The motor rotations vibration to an entire screen assembly mounted on the springs, which gives material desperation, stirring and movement due to rotary multi plane motion given by Heavy duty vibration Motor, Feed material continously moves in horizontal motion on Vibro Screen surface as per Loop pattern. The vibratory screens are used to separate materials by partical size, shapes and small amount of oversize material. We are manufacturing the Machine in Single, Double & Tripple Deck Type with cover to avoid dusting.Flange mounted dust-tight 1440 R.P.M. unbalance vibration elec. motor, Manufactured in mild steelS.S.construction, Replaceable wire mesh screen frame with quick changing of wire mesh screens, Right or Left-hand outlets, Ball tray decks to reduce screen plug blinging

Vibro Sifter

100,000 Per Piece

1 Piece (MOQ)