VSM48 Vibro Sifter Machine

120,000 Per Piece

1 Piece (MOQ)

Confider Industries stands as a beacon of excellence in the realm of food processing machinery, offering an extensive array of products tailored for both domestic and commercial applications. With a diverse portfolio comprising over 90 meticulously crafted machines, our company epitomizes innovation, reliability, and superior quality. From humble beginnings, we have grown into a globally recognized brand, catering to the needs of customers worldwide. At the heart of our success lies a relentless commitment to delivering top-notch products that exceed expectations. Every machine manufactured by Confider Industries undergoes rigorous quality control measures, ensuring precision engineering and durability. Whether it's a small-scale operation in a home kitchen or a large-scale industrial setting, our machines are designed to meet the diverse demands of modern food processing. One of the hallmarks of Confider Industries is our unwavering dedication to customer satisfaction. We understand that purchasing a food processing machine is an investment, and thus, we go above and beyond to provide unparalleled after-sales support. Our team of experts is readily available to assist customers through calls and video calls, offering guidance, troubleshooting, and technical assistance whenever needed. We believe in building long-lasting relationships with our customers, and our commitment to after-sales service reflects this ethos. Furthermore, Confider Industries takes pride in its global reach. With an extensive network of distributors and partners, our machines are delivered to customers across continents. Whether it's a bustling city in Asia, a remote village in Africa, or a thriving metropolis in Europe, our products have found their way into kitchens and food processing facilities worldwide. This global presence underscores our reputation as a trusted provider of food processing solutions on a global scale. Innovation is at the core of everything we do at Confider Industries. We continuously invest in research and development to stay ahead of market trends and technological advancements. Our team of engineers and designers work tirelessly to develop cutting-edge solutions that streamline processes, enhance efficiency, and elevate the overall user experience. From state-of-the-art automation technologies to eco-friendly designs, we strive to push the boundaries of innovation in the food processing industry. Sustainability is also a key focus for Confider Industries. We recognize our responsibility to minimize our environmental footprint and embrace sustainable practices throughout our operations. From sourcing materials responsibly to optimizing energy efficiency in our manufacturing processes, we are committed to fostering a more sustainable future for generations to come. In conclusion, Confider Industries stands as a beacon of excellence in the food processing industry, offering a diverse range of high-quality machines for domestic and commercial use. With over 90 machines in our portfolio, a global presence, and a steadfast commitment to customer satisfaction, we continue to set the standard for innovation, reliability, and excellence in food processing.

NT48 Vibro Sifter

90,000 Per Piece

1 Piece (MOQ)

Best Deals from Pharmaceutical Processing Equipment

Vibro Circular Vibrating Screening Machine

50,000 - 500,000 Per piece

1 Piece (MOQ)

Double Cone Blender

90,000 - 265,000 Per Piece

1 Piece (MOQ)

Cone Powder Blender - Double Cone Blender machines is best efficient and most versatile equipment's for powder mixing of API and pharmaceutical, chemicals powder and granules, food powder blender and products homogeneously. Our Double cone blender machine effective volume for optimums homogeneity approx between 35-70% gross volume powder. The conical shape at both ends enables uniform mixing and easy discharge. All contact parts of Double Cone Blender are made out of stainless 304 or 316 quality material, as required by customer. Maximum care has been taken to ensure safe operation of the unit. Manual rotating facility with hand wheel for inching. The same will be provided with ss cover & limit switch. ( In 200 Kgs. & above model ) Two nos. of safety road will be provided at back side. ( One LH side & one RH side ) Suitable size of butter fly valve at one end of the cone provided for material discharge & hole with openable cover provided at other end of the cone for material charging & cleaning. One shaft with 04 nos. of fixed buffels with mirror polished provided inside the cone. Cone will be mirror polished from the inside & outside & structure will be matt polished. All moving parts of Double Cone Blender covered with SS304 covers. Safety guards made from SS304 pipes provided in front of the m/c with limit switch. Panel fabricated from SS304 material with facility of three phase indication, D.O.L. tarter, digital timer & Amp. Meter. As per customer requirement machine will be provided with left side drive or with right side drive. The conical shape at both ends enables uniform mixing and easy discharge.

Vibro Sifter

Get Price Quote

We make use of the quality basic material in the production of the entire range. The material is thoroughly checked by our quality experts before procurement from vendors. With us, payment transactions will always remain secured, as we have adopted modern payment procedures that guarantee instant and hassle-free transactions.

Vibro Sifter

Get Price Quote

Our organization is one of the most reputed and efficient manufacturer and exporter of Vibro Sifter in Ahmedabad, Gujarat. A team of trained professionals verify the product. It is manufactured by making use of high grade components and growing technology. Vibro sifter finds application in pharmaceutical and chemical laboratories as it has a high degree of surface finishing. Checking arrangements are available with the product and faster output is ensured at low power consumption. Also, assembling and cleaning of the product is free from complications. Features : Double deck arrangement can be provided Faster output at low power consumption High Degree of surface finish All contact parts made of SS 316 as per GMP standard Easy dismantling and cleaning Unit Consists Of : Specially designed vibratory motor to run on 400/440 V, 3 phase, 50 cycles electric supply with adjustable eccentric weight at the center of the base plate of screening Screening unit consists of SS 304 / 316 screen sandwiched between SS 304 / 316 hopper and bowl with help of special clamp with gasket. This in turn is clamped to the base plate Option Available : Multi Deck screening GMP unit with SS 304 machine body base instead of MS Dust cover or lid for hopper assembly SS 316 contact parts Castor wheels for mobile unit Sample Availability: Yes Supplier Product Code : HE / 014

Vibro Separator

Get Price Quote

Salient Features Flour and semolina mills Feed mills Seed cleaning plants Works on cereals cleaning and calibration centers. Aluminum Industries Sand Material

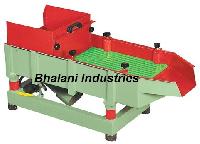

Vibro Separator

Get Price Quote

We are offering vibro separator. bhalani vibro separators are dewlapped to separate ceramic media, parts and water by screening. Vibro seprator is powered by foot mounted vibratory motor. This range of vibro separator is known for saving time and labour as compared to the manual screening. These products are known for their sturdiness and reliability. Separation screen will be fitted with nylon perforated for effective separation of ceramics and parts. All the contact parts are mild steel suitably protected against corrosion. The top screen is removable type & can be replaced for screening of different material. features simple construction & maintenance free. accurate separation & easy to operate. can be added in continues production system rugged heavy duty special vibratory motor.

Compression Testing Machine

30,000 Per Piece

1 Piece(s) (MOQ)

Standard Accessories The Machine can be supplied with NCCBM Calibration certificate at an extra cost. The Machine can also be supplied with 2 or 3 pressure Gauges of 100 KN, 250 KN and 500 KN for testing lower strength cubes or smaller size cubes. Optionally, the machine can be supplied with digital load indicator and load cell in place of Pressure Gauge at an extra cost.

Double Cone Blender

Get Price Quote

Salient Features Ldeal for mixing of powders and homogeneous lubracation of granules. MOC SS 304/316/316L. Safety gusrds provided with limit switch interlocked to motor for higher capacity modal. Available capacities 5kg to 1000kgs. Automatic Loading & unloding facilites provided.

Vacuum Rubber Compression Molding Machine

1,500,000 Per Unit

1 Unit (MOQ)

Double Cone Blender

Get Price Quote

Our range of premium quality and highly efficient Double Cone Blender is widely used in Food, Chemicals, Cosmetics and Pharmaceutical industries. This equipment is designed with electric control panels, enclosed rigid drive with reduction gear box, charging hole with hinged lid etc. The Double Cone Blender is immensely popular in market for being compact, offering excellent blending and three side accessibility. We are a renowned manufacturer, exporter and supplier in Ahmedabad, Gujarat offering Double Cone Blender at reasonable rates while ensuring timely delivery.

Vibro Sifter Machine

40,000 Per Piece

1 Piece (MOQ)

Laboratory Scoop

Get Price Quote

Double Cone Blender

Get Price Quote

The Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. The effective volume for optimum homogeneity is between 35-70% of gross volume. The SLANT double cone design eliminates dead sports, which occasionally occur in conventional double cone mixer. It can be used for pharmaceutical, food, chemical and cosmetic products etc. Dry powder mixing for tablets and capsule formulations Dry granules sub lots mixing to increase the batch size at bulk lubrication stage of tablet granules.

vibro screening machine

Get Price Quote

Gyrator screen is useful and impart for solid liquid, screening. The motor rotations vibration to an entire screen assembly mounted on the springs, which gives material desperation, stirring and movement due to rotary multi plane motion given by Heavy duty vibration Motor, Feed material continously moves in horizontal motion on Vibro Screen surface as per Loop pattern. The vibratory screens are used to separate materials by partical size, shapes and small amount of oversize material. We are manufacturing the Machine in Single, Double & Tripple Deck Type with cover to avoid dusting.Flange mounted dust-tight 1440 R.P.M. unbalance vibration elec. motor, Manufactured in mild steelS.S.construction, Replaceable wire mesh screen frame with quick changing of wire mesh screens, Right or Left-hand outlets, Ball tray decks to reduce screen plug blinging

Vibro Sifter

Get Price Quote

VIBRO SIFTER 30’’ MACHINE :- Compact vibratory design for high speed & dust free sieving. Noiseless and maintenance free machine ll contact parts and screen made of S.S.-304 (S.S.-316 optional) Low power consumption compared to reciprocating vibratory system Easy dismantling and cleaning of contact parts. Machine available with flame proof and double / triple deck options

Double Cone Blender

Get Price Quote

Incorporated with most advanced techniques, the Double Cone Blenders are superlative for mixing dry powder and granules homogenously. The blender is highly preferable in a number of industrial blending applications due to its easy functioning, cleaning, discharging and contamination absence. These blenders is designed in slant double cone design by making use of optimum grade materials and sophisticated techniques to make sure excellent dead spot elimination. It is integrated with no moving blades, which minimizes the particle's size reduction during blending. We are providing our precious patrons a precision-engineered Double Cone Blender.Known for its anti-corrosive properties, it has fetched high demands in the market. Offered blenders are ideal to be used for the purpose of mixing dry powder and granules homogeneously. To ensure the same, we manufacture the parts of these cone blenders using stainless steel, sourced from the most eminent vendors of the industry.

Vibro Sifter Machine

Get Price Quote

We are leading manufacturer and supplier of vibro sifter machine from last 10 years. We manufacture high-quality vibro sifters machine which are circular gyratory screens used for separating composition of solids, liquid from solid and for gradation of materials as per particles sizes. Mostly our vibro shifters used for separating wanted elements from unwanted materials. Our Vibro Screen or Vibro Sifter or Circular/Gyrator Vibro Screen Machine has slow noise, high efficiency performance, innovative design and exacting standard fully closed structure. It can used in grain, powder and liquid material screening and filter. Operating and cleaning is quick and easy of our vibro shifters making this range of shifting machines perfect for all processing industries. Major Benefits of Vibro Sifter: Low Maintenance Improved Cleanability Superior Performance

Vibro Sifter

100,000 Per Piece

1 Piece (MOQ)