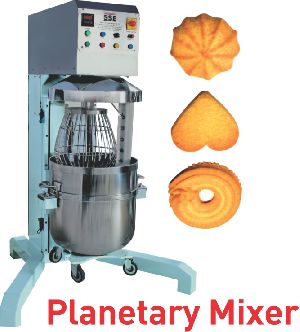

Imported Planetary Mixer

Get Price Quote

1 Piece (MOQ)

Note : Electricity Mode Power Supply 220 Volts 50Hz or 440 Valts 50 Hz as Per Order Accessories : Dough Hook Whisk Mixing Paddle Features : Copper Driver Motor Three Speed Three Fonction Whit Hook, Ball, Beat Oil Bath Gear Box Belt Transmission With Safety Guard S.S. Body Material

planetary mixer machine

1,500,000 Per Piece

1 Piece (MOQ)

Best Deals from Planetary Mixer

Planetory Mixer

Get Price Quote

SPECIAL FEATURESRange of models to suit working volume 60, 100, 115, 200, 350, 600, 1000, 1500 & 2000 Liters for OINTMENT / CREAM / LOTION / PASTE / TOOTH PASTE. All contact parts are made out of S.S.304 quality material.(SS316 provided on demand on extra cost) Compact design requires comparatively smaller floor space. Lowering and lifting movement achieved through motorized drive in 140 & 200 liters model & hydraulic lifting system from 350 liters to 2000 liters size models. (In 60 & 100 liters models product container moving up & down manually. Motorised system can be provided on demand on extra cost, if required.) In all other bigger size models product container remain fixed and mixing drives comes up and down by means of mechanical or hydraulic system. Castore wheel mounted product container for the ease of mobility.(This facility available from 60 liters to 350 liters model only.) Container with fixed legs above 350 Liters model. Hence no facility of mobility of container. A high-speed emulsifier (Homoginizer) will be provided at the center axis, in 140 liters model and above capacity model only.(It can be interchangeable with disperser & necessary assembly provided with m/c) In-Line Homoginizer also provided on demand, if required. Double stirrer & SS scraper with PTFE blades for better mixing of the material.( In 140 Liters & above model only ) Single stirrer with scrapper in 60 & 100 Liters model. Planetory motion of the stirrer ( beaters ) enables faster and better mixing of the material at a considerable lesser time. As stirrer is a top driven and sealing doesnt comes in contact with product, there isnt any black particle contamination problem. Water / steam circulation jacket for mixing bowl, to heat or cool the mix during operation in OINTMENT MIXER only. (Water jacket recommended only in 60 to 350 litres model. Steam heating recommended in 600 litres to onward all models. Jacket also made out of mild steel in Standard Model & SS304 in GMP Model.) SPECIAL FEATURESAll non contact parts (general structure)made out of mild steel and claded with SS304 or crome plated or made out of SS304 in GMP Model. Contact parts are polished to the mirror finished and non contact parts are polished to the matt finished in GMP Model. All safety guards & covers made out of SS304 material in GMP model & made out of mild steel & painted in standard model. General structure & all non contact parts are made out of Mild Steel & same will painted in Standard Model. Fixed type product container in 600 litres and above capacity models. Heater with temperature controller for heating facility. (For 60 / 100 / 200 / 350 litres OINTMENT MIXER only) 100 % utilisation of machine can be possible due to facility of change of extra product container. (In 60 to 350 litres model only) Vacuum facility provided on demand for de airation during mixing in Gel product. (For OINTMENT MIXER only) Insulation will be provided on jacket of container. (For OINTMENT MIXER only ) as a optional facility. Material discharge from bottom. Flush bottom valve provided for material discharge in 350 litres and above model only. (For OINTMENT MIXER only) M/C provided with Light glass, Sight glass ,material inlet, air suction valve for vacuum, CIP port facility. (For OINTMENT MIXER only) All connection of valve, light glass, sight glass will be triclover ended. Sampling port provided in 600 litres & above model. Flush bottom type valve in 600 litres & above model. All moving parts are enclosed with safety guards. OPTIONALSS316 product contact parts instead of SS304. Vacuum system for deairation during mixing. (For gel products) Variable speed drive for main agitators motor and emulsifier motor. Vacuum Pump Set. Flameproof model. "PLC" based operating panel for automation. Hydraulic lifting system in 60 to 200 litres model, instead of mechanical lifting system. APPLICATIONIdeal for mixing of Pharmaceutical powders, ointments, creams, lotions, pastes, tooth paste, cosmetics, food and confectioneries, rubber and rubber compound, colours and pigments, PVC & plastic material, ceramics, pesticides, insecticides, adhesives, metal powder, resins etc. etc.

Planetary mixer

Get Price Quote

The Planetary mixer is a machine ideal for collaborating wet and dry materials. It is a mixing assemble where the agitation pattern is of the planetary nature. The machine works on a homogeneous mixing action i.e. suspensions and semisolids. The Planetary Mixer Machine performs all the tasks like mixing, heating, cooling, vacuuming and homogenizing functions within one machine. This is a vacuum type planetary mixer which is used for mixing of ointments, wet mass, dry powders etc. The agitation assembly rotates around itself and also travels in a circular motion, thereby resulting in through mixing of the materials. Characteristic features The contact parts made up of AISI 316 and non contact parts S.S.394 Simple to mount machine is compact in structure and design It consists of a double anchor blade with planetary rotation for extremely efficient shearing force. The top lid of the machine is mounted with a motor operated lifting device. Product container is castor wheel mounted for easy load and unload to the machine. The machine has a rigid drive with planetary gear and reduction gear box Equipped with a dual speed motor for both slow and fast mixing action. The scrapper is made from teflon. Process of operation The anchor type agitator rotates in the anticlockwise direction. The paddle revolves in clockwise direction with planetary motion. The paddle generates a disturbance in the normal circular motion and dampen the vortex formation. The planetary action and mixing blade have dual speed. Moreover, the adjustable scrapers prevents the building of stagnant film between the vessel and the agitator. This ensures the efficient transfer of heat to the product during heating and cooling. The speed of the agitator and the counter paddle is adjustable. The mixing container is completely closed for efficient heating and cooling. The mixing container has been designed to operate under vacuum so that the mixing can be done in isolation from air.

Planetary mixer

Get Price Quote

1 Piece (MOQ)

Planetary mixer

275,000 Per Set

1 Set(s) (MOQ)

Planetary mixer

Get Price Quote

Our name features among the topmost manufacturers, exporters and suppliers from Ahmedabad, Gujarat. We provide supreme quality Planetary Mixer which comprises of finely polished stainless steel vessel, shafts and blades along with a tough gear box. The outstanding performance and high efficiency of Planetary Mixer along with cost effective pricing and timely delivery has made us extremely popular in the global market.

planetary mixers mass mixers

Get Price Quote

planetary mixers mass mixers, Pp Standard Blue Filter Housing

Planetary mixer

Get Price Quote

Bakery Machinery

Planetary mixer

Get Price Quote

bakery machinery spare parts, Slicer Machine

Planetary mixer

Get Price Quote

Bakery Oven

double planetary mixers

Get Price Quote

double planetary mixers, Continuous Fluid Bed Dryers

Planetary mixer

Get Price Quote

concrete laying canal paver, hydraulic sweeping machine

Planetary mixer

Get Price Quote

Rolling Mill