Moulding Machine Assembly

Get Price Quote

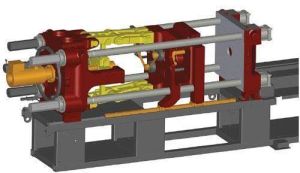

biaxial rotomoulding machine

Get Price Quote

We are Supplier and Manufacturer by Biaxial Machine Exporter, Biaxial Rotomoulding Machine, Bi-axial Machine ,Bi-axial Moving Oven Type Rotational Moulding Machine for NK Industries Ahmedabad, India. Biaxial Rotomoulding Machine NK Industries Provides Biaxial Rotomoulding Machine, Biaxial Rotomoulding Machine, Bi Axial Moving Type Machine, Rotomoulding, Supplier in India.

Best Deals from Plastic Machine

Plastic Recycling Plant

12,500,000 Per Piece

Two Layer Blown Film Extrusion Lines

Get Price Quote

Two Layer Blown Film Extrusion Lines with the best combination of technology and performance. These low investment, power efficient, high - speed plants can give processors the competitive edge and quick return on their investment. Two layer blown film Line has a great demand in global market for its wide range of packaging products that can be produced from it. Two layer blown film machine is an economical solution to create moderate barrier films for shopping bags, crop covers, carry bags used in textile sector, etc. It consumers low power and when it comes to return on investment, packaging industry can made good and fast profit. Similarly, two layer blown film line materials can also be produced from this single plant. TWO LAYER PLANT APPLICATION - Film for Shopping Bags- Film for Liners- Stretch Film - Shrink Film- Lamination Film - Biodegradable Film

plastic machinery spare parts

Get Price Quote

General feature:- User friendly Fully auto microprocessor based technology Best quality of product Easy to operate

230 V Plastic Testing Apparatus Machine

250,000 Per Unit

1 Unit (MOQ)

SKE-EP Glass Edge Grinding Polishing Machine

205,000 Per Piece

1 Piece (MOQ)

SKE-EP(2HP)SHAPE GLASS HAND EDGE PROCESSING HPRIZONTAL(8X4 FT) BALL ROLLERS TYPE MACHINE ,3 WHEELS ON A SPECIAL SINGLE MOTOR SHAFT FOR 1-6/8 FITS ALL SHAPES GLASS EDGE GRINDING,HALF /FULL ROUNGING WITH CHANGING WHEELS AS PER THK.& PROCESS. SKE-EP(2HP)straight Line and Shapes Glass Hand Grinding , C- Polishing with Changing Wheels Size and Process Wise .machine with Rollers On Plate and Scrolling Special Rolles Strips with Rubber Ball 8x4 Fits Horizontal Heavy Duty 50x50 Mm Square Pipes Structure.2 Hp S/p or 3/ph Special Motor with 3 Wheels On the Same Shaft to Up and Down When Using Rough,Fine & Polish Wheel with Out Changing.with Water Collecting Tray,Tank Pump Electrical Penal Board are Atteche with Machine. Machines are Available in Different Sizes Smaller and Biger as per Your Requirements On Order. Additional Information: Production Capacity: 700 /1000 R.FIT PER DAY Delivery Time: 30 DAYS Packaging Details: WOODEN/PLASTIC AND JUTE

TARPAULIN SLITTER REWINDER MACHINE

Get Price Quote

Tarpaulin Slitter Rewinder Machine made, Tarpaulin Rolls are used for making different types of bags, window curtains, roof coverings, etc. After making Jumbo Roll & Laminating the Tarpaulin, our Tarpaulin Slitter Rewinder Machine comes into use. Nowadays, Tarpaulin Fabric is being used for all different types of applications. In the Tarpaulin Industry, big width Tarpaulin Fabric is slitted into small parts to carry forward the same for different applications.

Single Screw Extruder

Get Price Quote

Single Screw extruder offered by us finds application in Single Screw Extruder that is extensively used in cable industry in form of cable sheath and insulation as these have superior electrical as well as mechanical properties of PVC material. These extruder aids in arriving at better compounds with lower manufacturing costs involved.

Fluid Bed Top Spray Granulation

Get Price Quote

Granulation Granulation is one of the most important unit operations in the production of pharmaceutical oral dosage forms. However, there are many different technologies each having different strengths and weaknesses. Granulation is often required to improve the flow of powder mixtures and mechanical properties of tablets. Granules are usually obtained by adding liquids binder or solvent solutions. Larger quantities of granulating liquid produce a narrower particle size range and coarser and harder granules, i.e. the proportion of fine granulate particles decreases. The optimal quantity of liquid needed to get a given particle size should be known in order to keep a batch-to-batch variations to a minimum. Wet granulation is used to improve flow, compressibility, bio-availability, homogeneity, electrostatic properties, and stability of solid dosage forms. The particle size of granulate is determined by the quantity and feeding rate of granulating liquid. Wet granulation is used to improve flow, compressibility, bio-availability, and homogeneity of low dose blends, electrostatic properties of powders, and stability of dosage forms. Granulator process solutions involve smaller particles adhering to each other in order to grow larger particles or agglomerates. Particle size is critical in a granulator process solution because if the particles are too large or too small they do not have the product characteristics important to produce light powders into high density free-flowing granulates. There are many variables in controlling a granulator process, ranging from feed rate of the granulator liquid to the resonance time of the granulator chamber. All of these parameters affect the particle size in different ways. With an on-line sensor, the particle size is measured instantaneously and continuously in real time helping to monitor and control the granulator process. Granulation methods: Fluid Bed Top Spray Granulation High Shear Granulation Fluid Bed Top Spray Granulation The fluid bed granulation process also known as agglomeration involves suspending particulates in an air stream and spraying a liquid from the top down onto the fluidized bed. Particles in the path of the spray get slightly wetted and become tacky. The tacky particles collide with other particles and adhere to them to form a granule. Granulation can be performed using fluid beds fitted with spray nozzles. It is possible to have completely closed material handling by a closed linking with upstream and downstream equipment. Also, fully automatic cleaning in fluid beds using stainless steel filters now compares favorably with what is possible in a single pot. There are two different modes of fluid bed granulating: • Dry Stage: In Dry stage granulation, the particles only require a slight wetting to become tacky and stick to each other. The granulating solution is applied at a rate less than or equal to the evaporation rate. Thus the particles remain "dry" through the entire process. • Wet Stage: In Wet stage granulation, the particles require significant wetting before they become tacky enough to stick to each other. The granulating solution is applied at a rate higher than the evaporation rate until the particles build up enough moisture to granulate. The characteristics of the particles when wet and the type of granulating solution being used will determine which mode of granulating is most appropriate. While Dry stage is more common, Wet stage granulating allows for denser products.

HDPE Film Slitting Rewinding Machine

Get Price Quote

wood profile extrusion line

Get Price Quote

Located in Ahmedabad(India), we are a high-flying name when it comes to quality-centralized and cost effective products. We give our patrons the choice to make payments online or offline. Our company understands the concerns of its customers. Therefore, we make sure our payment options are safe.

Hydraulic Plate Screen Changer

100,000 - 300,000 Per Piece

Avail from us the Hydraulic Plate Screen Changers in plenty of models, at astoundingly low prices. Used in wide range of applications in extruding plants, these Hydraulic Plate Screen Changers assure durability, advanced design, hassle-free use, quick filter change and other valuable features. Feel free to place desired quantity orders with us. We are the significant Supplier of the Hydraulic Plate Screen Changer from Gujarat.More About Hydraulic Plate Screen Changer : There is less effect on extrusion work when using Hydraulic Plate Screen Changer to filter change. It can be applied to most plastic or rubber extrusion work. Normally rapidity of changing from 4 to 5 seconds per times, depending on the size of the filter The distance between screw and breaker plate can stay 10 mm recently, thereby reducing the possibility of polymer degradation. The screw can pulled out through the screen changer after removed the breaker plate, suitable for single extrusion and co-extrusion production line. Model : 90,100,120,180,200,225,250 Output : 90 to 450 KGSHR Heating : 1 to 8 KW Special Features : Round breaker plate design with maximum melt filtering area Melt filter cavity as per client requirement Leakage proof screen changer due to close clearance tolerances Imported sealing design in input & output melt flow path Smooth operating for changing filters from one station to another thru hydraulic power pack station Melt temperature measuring provision Melt pressure measuring provision for safe & in time operation Advantages : Simple & quick operation 2.simple & quick filter changing 3. Low heating load consumption Saving labour 5. Low maintenance cost 6. Low wastage of material Application : Suitable for variety macroviscosity melt of extrusion line. Including sheet extrusion, extrusion coating, profile tube extrusion, compounding extrusion, cable extrusion, flexible pipe extrusion, lab extrusion, eva, thermosol etc.

Automatic Ultrasonic Plastic Welding Machine

Get Price Quote

Plastic Injection Molding Machine

Get Price Quote

we are offering plastic injection Molding Machine injection Molding Machine injection Molding Machine pet preform injection moulding machines r-pvc & c-pvc injection moulding machines thin wall injection moulding machines servo motor driven injection molding machines chillers view all... vertical injection moulding machines liansu extrusion machines auxiliaries equipment for plastic processing

Plastic film extruder

900,000 Per Piece

Plastic Granule Machines

900,000 - 2,000,000 Per Set

1 Set(s) (MOQ)

Plastic Film Slitting Rewinding Machine

415,000 Per AUnit

1 Set (MOQ)

Different types of Plastic Materials are used for different type of applications like, PVC, LDPE, HDPE, BOPP Film, etc. After Printing in Rotogravure or Flexo Machine or Extruded materials, our Plastic Film Slitting Rewinding Machine comes in use for Slitting of all types of material. We have been successfully Manufacturing, Exporting & Supplying all types of Plastic Film Slitting Rewinder Machine since last 25 years from Ahmedabad, Gujarat, India. With more than 1400 installations all over India and overseas like Saudi Arabia, UAE, Dubai, Sharjah, South Africa, Nigeria, Ghana, Congo, Kenya, Zambia, Sri Lanka, Bangladesh, Malaysia, Pakistan, Nepal, Russia, Thailand, Indonesia, Brazil, Colombia, Venezuela, Argentina, Mexico, Canada, etc. We are winner of 3 times National Award and 2 times International Award for Quality manufacturing.

plastic auxiliary machineries

Get Price Quote

plastic auxiliary machineries, Auxiliary Equipment, Hot Air Dryer

pvc pipe extruder machine

900,000 Per