Fluid Bed Top Spray Granulation

Get Price Quote

Granulation Granulation is one of the most important unit operations in the production of pharmaceutical oral dosage forms. However, there are many different technologies each having different strengths and weaknesses. Granulation is often required to improve the flow of powder mixtures and mechanical properties of tablets. Granules are usually obtained by adding liquids binder or solvent solutions. Larger quantities of granulating liquid produce a narrower particle size range and coarser and harder granules, i.e. the proportion of fine granulate particles decreases. The optimal quantity of liquid needed to get a given particle size should be known in order to keep a batch-to-batch variations to a minimum. Wet granulation is used to improve flow, compressibility, bio-availability, homogeneity, electrostatic properties, and stability of solid dosage forms. The particle size of granulate is determined by the quantity and feeding rate of granulating liquid. Wet granulation is used to improve flow, compressibility, bio-availability, and homogeneity of low dose blends, electrostatic properties of powders, and stability of dosage forms. Granulator process solutions involve smaller particles adhering to each other in order to grow larger particles or agglomerates. Particle size is critical in a granulator process solution because if the particles are too large or too small they do not have the product characteristics important to produce light powders into high density free-flowing granulates. There are many variables in controlling a granulator process, ranging from feed rate of the granulator liquid to the resonance time of the granulator chamber. All of these parameters affect the particle size in different ways. With an on-line sensor, the particle size is measured instantaneously and continuously in real time helping to monitor and control the granulator process. Granulation methods: Fluid Bed Top Spray Granulation High Shear Granulation Fluid Bed Top Spray Granulation The fluid bed granulation process also known as agglomeration involves suspending particulates in an air stream and spraying a liquid from the top down onto the fluidized bed. Particles in the path of the spray get slightly wetted and become tacky. The tacky particles collide with other particles and adhere to them to form a granule. Granulation can be performed using fluid beds fitted with spray nozzles. It is possible to have completely closed material handling by a closed linking with upstream and downstream equipment. Also, fully automatic cleaning in fluid beds using stainless steel filters now compares favorably with what is possible in a single pot. There are two different modes of fluid bed granulating: • Dry Stage: In Dry stage granulation, the particles only require a slight wetting to become tacky and stick to each other. The granulating solution is applied at a rate less than or equal to the evaporation rate. Thus the particles remain "dry" through the entire process. • Wet Stage: In Wet stage granulation, the particles require significant wetting before they become tacky enough to stick to each other. The granulating solution is applied at a rate higher than the evaporation rate until the particles build up enough moisture to granulate. The characteristics of the particles when wet and the type of granulating solution being used will determine which mode of granulating is most appropriate. While Dry stage is more common, Wet stage granulating allows for denser products.

pvc pipe extruder machine

900,000 Per

Best Deals from Plastic Machine

plastic pipe extruder

1,750,000 Per Piece

Plastic Stool Mould

Get Price Quote

We have emerged as the leading manufacturer and supplier of a wide variety of Plastic Stool Mould. The offered stool mould is manufactured by our adroit professionals using premium quality raw material and cutting-edge technology. The offered stool mould is available with us in different sizes to meet the diverse needs of the clients. This superior quality stool mould is offered at very nominal rates within the promised time frame. Features: Durability Sturdy construction Corrosion resistance

PLASTICS SHEET WELDING MACHINE

300,000 Per Piece

Plastic Bottle Cap Molding Machine

1,500,000 Per Piece

Plastic Bag Making Machine

Get Price Quote

The Plastic Bag Making Machine, delivered by us, has high-quality colour code tracker, which makes the sealing and cutting length more accurate. This machine is known for its advanced features that make it more efficient.

PLASTICS SHEET WELDING MACHINE

Get Price Quote

This heavy duty plastics sheet finishing machine is for finishing the welded part. The machine is pneumatically controlled with impulse sealing system. SALIENT FEATURES Pneumatically operated Impulse heat sealing system Sealing jaw of 60” length Digital timer with thump wheel switch and indicator Heating Element fitted in both upper and lower jaws PLASTIC SHEET FINISHING MACHINE Cardcan Finishing Machine

Plastic Berrel Grinding Machine

Get Price Quote

mild steel agglomerate machine

200,000 Per Piece

plastic cap sealing machine

Get Price Quote

The semi automatic cap sealing machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine.

plastic extrusion machines

Get Price Quote

Shree Laxmi Engineering Works has developedPlastic Extruder machine based on more than 30 yrs.of experience in plastic Processing machinery. These plasticextruder machine and plants incorporate many silent features togive long & trouble free operation. The superior design ensures high output at low operating costs. • Processing machines• Plastic processing machines• Plastic processing equipment

Plastic Washing Plant

Get Price Quote

Tea strainer plastic injection moulding machine

1,700,000 - 3,500,000 Per piece

1 Piece (MOQ)

We are manufacturer and exporter of rotary type plastic injection moulding machine which is used for tea strainer. 1 no to 4 number 4 cavity mould and cycle time is 15 second. We have installed 20 machines and mould for tea strainer in india and overseas.

Moulding Machine Assembly

Get Price Quote

Plastic Bag Making Machine

Get Price Quote

We are engaged in manufacturing Plastic Bag Making Machine, which has a regular alarm on getting the set value. The plastic bag making machine is equipped with an anti-static bar, which helps in the better productivity.

plastic machinery spare parts

Get Price Quote

plastic machinery spare parts, electric motor parts

Automatic Ampoule Plastic Rondo Tray packing Machine

Get Price Quote

AUTOMATIC AMPOULE PLASTIC RONDO TRAYS PACKING MODEL: AHRP 40U Suitable for “U” type plastic trays Basic units consist of a rondo tray hopper, a denesting station, a product hopper, a rotary filling stations, an inserting wheel, and controls switches. The machine should be used for Ampoules to be packed in rondo trays for which it has been fitted with. The nested trays are placed directly in the rondo tray hopper in the same position as received from the suppliers. Filled and labeled ampoules are placed in the product hopper in vertical position. Now, operate the machine for a short time, by pressing inching Push Button with a view to obtain uniform packing of ampoules in to rondo trays.. The dog chain moves out each pair of nested rondos and transfers them to the denesting station where they are separated and positioned face up. The rotary transfer wheel picks up a preselected number of ampoules and drops them in the rondo flutes. The ampoules next are firmly inserted in to the flute of the rondo by means of the inserting wheel. Direction Of The Operation Will Be Left To Right. Machine occupies very little floor space as compare to hand packing. Machine occupies very little floor space as compare to hand packing. Very simple in operation. Size changes take less than fifteen minutes and require no special tools. Machines efficiency allows short runs and frequent changes. If ampoules placement found satisfactory, the machine is put into operation. Now push green push button for continuous operations. Size of Ampoules: The machine used to pack Ampoules from 10mm to 17mmin diameter in to rondo trays in the horizontal position . The height of the round Ampoules should be proportional to the diameter. In the event of unusual height, kindly get the Ampoules examined at our works before putting the machine into operation. Size of rondo trays. The machine is suitable for following dimensions of the rondo trays.

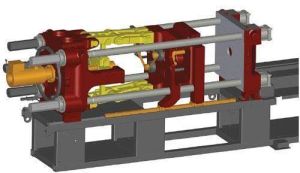

hydraulic screen changers

Get Price Quote

The Hydraulic Screen Changers manufactured, exported and supplied by us are suitable for reprocess kind of extrusions like RP Plants, Filler and Master batch Plants, Compounding Plants etc. where highly contaminated kind of materials are processed. These are highly demanded by our clients and are provided by us at market leading prices within the stipulated time period. Features : Steel body for long lifeLeakage frees performanceBuilt-in heaters give fast heating and retaining superior temperature Comes with energy efficient and most power full Power PackHole-to-hole screen changing can be quickly accomplished without wasting productionCompact, operator friendly & easy to install with low maintenance and low cost spare partsEnsures Quality processing, high product quality and reduced waste materialsThe special chrome and nickel plating gives high protection against wear & tear

biaxial rotomoulding machine

Get Price Quote

We are Supplier and Manufacturer by Biaxial Machine Exporter, Biaxial Rotomoulding Machine, Bi-axial Machine ,Bi-axial Moving Oven Type Rotational Moulding Machine for NK Industries Ahmedabad, India. Biaxial Rotomoulding Machine NK Industries Provides Biaxial Rotomoulding Machine, Biaxial Rotomoulding Machine, Bi Axial Moving Type Machine, Rotomoulding, Supplier in India.