hydro pneumatic systems

150,000 - 155,000 Per piece

1 piece (MOQ)

Hydraulic control panels it is Designed to operate Valve actuators, BOP's, Hydraulic Actuators and much more. The highly engineered equipment operates both offshore and onshore. Fully Integrated Compact design helps to reduce offshore footprint. Manual or PLC controlled. Custom designed units to client specifications.

Hydro Pneumatic Water Supply System

Get Price Quote

Best Deals from Pneumatic Conveying System

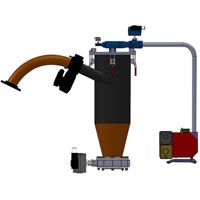

pressure conveying system

Get Price Quote

1 Set (MOQ)

Details: This ideal solution to convey PVC Compound from Cooler Mixer to storage Silo. Dust free operation. Highly efficient pressure conveying system by using reputed make brought out equipment. This pressure conveying system is design to give optimism output with noise free operation.

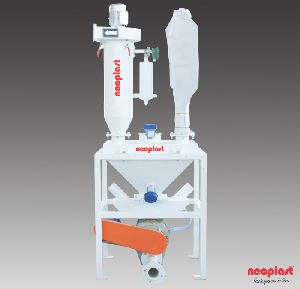

Pneumatic Conveying System

Get Price Quote

We are expert in robotize your procedure with pneumatic conveying on all kind of powder and granule materials a wide assortment of industry-particular applications in utilizing vacuum and pressure conveying on for putting away, bolstering, mixing, scaling, filtering, drying and dust collection systems. we are proficient to offer environment cordial arrangements in house material taking care of in industries. Our experience has given us information in passing on distinctive sort of materials furthermore planning custom manufactured Equipments. we are specializes in pneumatic conveying of dry bulk solids for the processing industries. System Types : Positive pressure systems Positive pressure dilutes stage pneumatic conveying systems are commonly utilized to pass on mass materials from a single source to one or numerous destinations, over longer separations and with a more prominent limit than conceivable utilizing vacuum frameworks. These systems use a positive removal blower with single or numerous downstream material section focuses, each of which meters product into conveying lines by method for a rotary airlock valve that keeps up the pressure differential between the encompassing air and that of the conveying line. Material and air blown through the line exit at single or different use focuses where they are isolated by method for a channel collector or cyclone separator, or encouraged specifically into procedure vessels that are vented to downstream dust collection devices. Pressure systems offer higher proficiency than vacuum systems, can pass on over longer distances, and can blow straightforwardly into procedure and storage vessels without the use of a rotary airlock valve. Vacuum systems Vacuum dilutes stage pneumatic conveying systems are generally employed for transporting material from different sources, for example, storage vessels, process equipment, trucks and railcars, to individual or numerous destinations. Not at all like positive pressure systems, vacuum systems permit simple get of materials from open containers using wands, and don't impart heat to the material. Since vacuum systems offer superior leak containment, they are frequently determined on the premise of cleanliness, especially when handling hazardous materials. Negative pressure is made by a positive displacement vacuum pump situated at the downstream end of the system. A material commonly enters the system via upstream rotary airlock valves, handheld get wands, and non-move through/ flood-feed pick-up adapters, and ways out the framework through filter receivers or cyclone separators that differentiate the material from the conveying air straightforwardly above process equipment, surge hoppers, storage vessels or other release points. In addition, vacuum conveying is suited to direct sustaining of blenders, reactors and other encased procedure vessels that are put under vacuum by a line terminating at a downstream bag house or other dust collection device, eliminating the requirement for individual receivers or cyclone over every discharge point. Our Pneumatic conveying system suitable for following material /powder/solids : ABS POWDER ACTIVATOR EARTH ALKALI CELLULOSE ALLIMINIUM FLORIDE BENTONITE BOPP BORIC ACID BREWERY FLAKES CALCITE CEMENT CERAMIC POWDER CHINA CLAY COAL POWDER / DUST COCOA BEANS COCOA POWDER CRUMB POWDER DEXTROSE DOLOMITE FELDSPAR FINE CHEMICALS FLY ASH FOUNDRY SAND GROUND ILMANITE HYDRATED LIME IRON OXIDE LEAD DUST LIME STONE MELAMINE MINERAL POWDER MONOHYDRATE PAINT PIGMENT PHARMA POWDER POLYTHENE CHIPS PP / HDPE PELLETS PRECIPITATED SILICA PVA PVC POWDER RICE HUSK ROCK PHOSPHATE SAN PELLETS SANDER DUST SAW DUST SILICA SAND SOAP NOODLES SODA ASH SODIUM SULPHATE STEEL GRIT STPP SUGAR TALC TITANIUM DIOXIDE WASTE COFFEE WASTE SPICES WHEAT BRAN WHEAT FLOUR

pressure conveying system

Get Price Quote

This Ideal solution to convey PVC Compound from Cooler Mixer to storage Silo. Dust free operation. Highly efficient pressure conveying system by using reputed make brought out equipment. This pressure conveying system is design to give optimism output with noise free operation.

Pneumatic Materials Handling System

Get Price Quote

Pneumatic Conveyor System

Get Price Quote

Pneumatic Conveying System

400,000 Per Piece

Pneumatic Conveying Systems

Get Price Quote

Shayona industries is engaged in the manufacturing and supplying of pneumatic conveying systems, which is designed in compliance with the clients’ requirements. Our pneumatic conveying systems has many unique features that make it hugely appraisable among clients. attributes : mandatory for horizontal and vertical transportation of powdercarefully designed as per the clients’ requirementsuser friendlyrobust constructionlong functional life applications : flour milldal millbesan millcorn flour millsoya flour millguargum plantmaize millrice mill

Pneumatic Conveying System

Get Price Quote

Jogeshwari Industries is a prominent Manufacturer, Exporter and Supplier of Pneumatic Conveying System. We offer the best quality Pneumatic Conveying System. Our Pneumatic Conveying System consists of 7 Lift Line and comprises of the following equipments : High Pressure fan type 900 mm diameter having redial blades dynamically balanced.H.P.15.2800 R.P.MAirlock type 200 mm rotor diameter C.I. body comprising of a rotor and the central shafting bused on ball bearings protected with the oil seals on both the side. Manufactured and machined on most uniform precision resulting optimum degree of separation in cyclone Air locks geared motor 0.75 H.PCyclone fabricated out of ms sheet made long cone streamlinedMain fold duct and delivery ductMaster cyclone all other accessories as hoppers, pipeline, inspection glasses, rubber sleeves, cloth bags. For the dust collector but without electrical motor and without gear boxes

Pneumatic Valve Testing System

Get Price Quote

Pneumatic Valve Testing System is a tailor made item and can be manufactured by taking into consideration client’s requirement. These systems can be designed for various types of valves. This system consists of Hydraulic Power Pack, Testing Panel, Testing Tables with Manual Jaws, Pneumatic Hydro testing Pumps.

Pneumatic System

Get Price Quote

Single stage, air cooled, heavy duty with air receiver. Pneumatic pipeline with pressure regulator, strainers, shut-off valves. Pipes are pre-installed in the module.

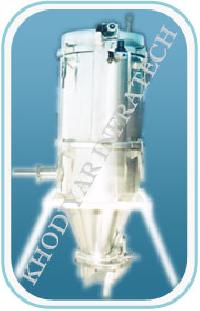

Pneumatic Conveying System

Get Price Quote

khodiyar infratech offers high quality pneumatic conveying systems and equipment for the food, pharmaceutical, chemical and packaging industries. dust free stainless or mild steel vacuum systems dense phase vacuum systems for fragile and pre-mixed product sophisticated controls positive pressure lean phase systems specialized powder handling for non free flowing products turnkey systems abrasion resistant systems high accuracy multi material weighers the p-series filtered receivers are specially designed for use with powders and friable materials in sanitary applications from pick-up spike to piping to receivers and vacuum pumps, khodiyar infratech offers a wide range of equipment for pneumatic conveying needs, whether for automated refill of feeding systems or as standalone conveying applications. The following list describes the varied elements available from khodiyar infratech for building a complete conveying system for loss-in-weight feeder refill (pictured in the diagram above). material pick-up : from pick-up spike to piping to receivers and vacuum pumps, khodiyar infratech offers a wide range of equipment for pneumatic conveying needs, whether for automated refill of feeding systems or as standalone conveying applications. The following list describes the varied elements available from khodiyar infratech for building a complete conveying system for loss-in-weight feeder refill (pictured in the diagram above). conveying line : connect one or multiple material picks up stations to a vacuum receiver. To ensure blockage-free conveying, diverter valves (4) and line clearance valves (5) are available in addition to the piping. vacuum receivers : various models of central (7) and self-contained receivers are available to separate the material from the conveying air stream, alternating between suction and discharge modes of operation. sequence & vent valves : sequence & vent valves (8) allow the air stream to bypass and vent the vacuum receiver during the discharge cycle. pump packages : vacuum pump packages include the pump -- regenerative blower (9), sliding vane or rotary lobe blower (10) -- to produce the air stream as well a bypass valve (11) to allow the pump to run while no receiver is conveying and a secondary filter (12) to protect the vacuum pump from entrance of foreign bodies. controls : hcu/hsu control and operator interface are available to control a single central or self-contained unit. To control the sequence of a multi-component system plc controls (13) are available which are programmed to suit the client’s process. Siemens, mitsubishi and allen bradley plc controls are available.

Pneumatic System

Get Price Quote

Material can be conveyed in dilute phase through suspension in pipe line, regardless of the particle size, shape or density. It is often referred to as suspension flow because the particles are held in suspension in the air as they are blown or sucked through

Hydro Pneumatic Pressure Boosting System

Get Price Quote

We are engaged in the business of developing Hydro Pneumatic Pressure Boosting System. An automatic pressure controlled pump and a pressure tank which include an air filled poly-ether-urethane (PEU) bladder are the parts of our Hydro Pneumatic Pressure Boosting System. In the Hydro Pneumatic Pressure Boosting System, the pressure tank compresses water pumped in it and pressurizes the bladder, which turn to maintains the desired pressure within the whole water system with PLC controlled. We offer Hydro Pneumatic Pressure Boosting System at the best prices in the market.

AQUAPACK Hydro-Pneumatic Pressure

Get Price Quote

FEATURES & BENEFITS Ideal for pressure boosting without overhead tanks. Constant pressure at all distribution points. Low energy consumption. Wide range. Simple installation. Continuous water supply due to standby pumps. Low noise, tuff & reliable. Fully factory assembled & tasted. Also available VFD controls for power saving solution. Prompt on site service support.

Pneumatic Conveying System

Get Price Quote

We provide a spectrum of pneumatic conveying system also known as vacuum conveying systems that is fabricated using finest quality raw material. Our efficacious gamut takes less floor space and is easy to integrate into manufacturing environment.

Pneumatic System

Get Price Quote

1.Single stage, air cooled, heavy duty with air receiver. 2.Pneumatic pipeline with pressure regulator, strainers, shut-off valves. 3.Pipes are pre-installed in the module.

Pneumatic System

Get Price Quote

Each design from Pneucon undergoes a stringent check to ensure that the end result is what is required and the material used in the manufacture of each of our pneumatic conveying systems is of the best quality and meets all the required industry standards in quality grading. The pneumatic conveying belts are also used by the food industry and meet all the checks required to work with various food products as well. Our systems have achieved so much reliability that we are now the leading name for Pneumatic Conveying System Manufacturer in India and this is what is guaranteed when you choose us

Pneumatic Lint Conveying System

Get Price Quote

Pneumatic Transport System for Lint from D.R.Gins to a Post Cleaner Machine : With the help of this system contamination of lint is avoided. The system also helps in removal of dust, leafy particles and short fibers from good cotton. Studies have shown that use of such system improves the grade of cotton. › Pneumatic Transport System from Post-Cleaning machine to Lint Halls : The system generally comprises of Material Transport fan, duct line and stationery condensors in the Lint Halls. This reduces labour dependance and also prevents contamination of Ginned Lint. The stationary condensors additionally contributes in removal of dust, leafy particles and short fibers. › Pneumatic Transport System from Post-Cleaning machine to Lint Halls to Press : Presently we can offer systems to transport lint from the lint halls to an area adjacent to the press with a capacity of 160-180 Kilos within 2 to 3 minutes depending upon the requirement.