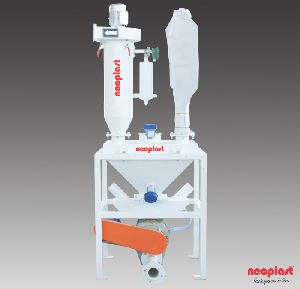

Hopper Loader Vacuum Conveying System with Online Sieving

Get Price Quote

1 Set (MOQ)

Details: Hopper Loader convey the material from silo mixer or any other storage arrangement. Various models to suit your extruder capacity. Dust free operation. Highly reliable level sensor to ensuring emptiness of material from Silo or extruder hopper. PlC operated state of the art electric control panel.

Hydro Pneumatic Water Supply System

Get Price Quote

Best Deals from Pneumatic Conveyors

hydro pneumatic systems

150,000 - 155,000 Per piece

1 piece (MOQ)

Hydraulic control panels it is Designed to operate Valve actuators, BOP's, Hydraulic Actuators and much more. The highly engineered equipment operates both offshore and onshore. Fully Integrated Compact design helps to reduce offshore footprint. Manual or PLC controlled. Custom designed units to client specifications.

Pneumatic System

Get Price Quote

We have gained recognition as an eminent enterprise, devotedly engaged in offering a broad range of Pneumatic Equipments. Backed by a team of experts, these equipments are manufactured using high grade components and advance.

Pneumatic Vacuum Conveyor

Get Price Quote

Pneumatic Conveying Systems

Get Price Quote

Shayona industries is engaged in the manufacturing and supplying of pneumatic conveying systems, which is designed in compliance with the clients’ requirements. Our pneumatic conveying systems has many unique features that make it hugely appraisable among clients. attributes : mandatory for horizontal and vertical transportation of powdercarefully designed as per the clients’ requirementsuser friendlyrobust constructionlong functional life applications : flour milldal millbesan millcorn flour millsoya flour millguargum plantmaize millrice mill

Pneumatic Conveyor System

Get Price Quote

Pneumatic Conveyor

Get Price Quote

1 Piece (MOQ)

Pneumatic Conveying System is a widely adopted means of transporting dry bulk material either by Vacuum or by Pressure of Air. Depending on the material to be conveyed, the air stream with specific velocity will carry the material to the final destination. Features And Benefits Free from contamination. Simple and user friendly. Speedy transfer.

pressure conveying system

Get Price Quote

This Ideal solution to convey PVC Compound from Cooler Mixer to storage Silo. Dust free operation. Highly efficient pressure conveying system by using reputed make brought out equipment. This pressure conveying system is design to give optimism output with noise free operation.

Pneumatic Conveying System

Get Price Quote

Jogeshwari Industries is a prominent Manufacturer, Exporter and Supplier of Pneumatic Conveying System. We offer the best quality Pneumatic Conveying System. Our Pneumatic Conveying System consists of 7 Lift Line and comprises of the following equipments : High Pressure fan type 900 mm diameter having redial blades dynamically balanced.H.P.15.2800 R.P.MAirlock type 200 mm rotor diameter C.I. body comprising of a rotor and the central shafting bused on ball bearings protected with the oil seals on both the side. Manufactured and machined on most uniform precision resulting optimum degree of separation in cyclone Air locks geared motor 0.75 H.PCyclone fabricated out of ms sheet made long cone streamlinedMain fold duct and delivery ductMaster cyclone all other accessories as hoppers, pipeline, inspection glasses, rubber sleeves, cloth bags. For the dust collector but without electrical motor and without gear boxes

Pneumatic Materials Handling System

Get Price Quote

Pneumatic Conveying System

400,000 Per Piece

Air Conveyor for bottle

Get Price Quote

Construction of S.S. matt finished body This is basically conveyor to feed pet, LDPE, HDPE empty bottles The bottles are hold by Neck Vibration Free, Jerk Free, Noise less construction with the help

Pneumatic Valve Testing System

Get Price Quote

Pneumatic Valve Testing System is a tailor made item and can be manufactured by taking into consideration client’s requirement. These systems can be designed for various types of valves. This system consists of Hydraulic Power Pack, Testing Panel, Testing Tables with Manual Jaws, Pneumatic Hydro testing Pumps.

vacuum transfer system

Get Price Quote

Vacuum tablet press loading systems are furnished as complete, ready-to-operate systems for mounting on customers’ presses. Available for single or dual hopper tablet presses The loader eliminates manual scooping of product and messy dumping or mishandling. Draw material directly from drums, boxes, storage containers, process vessels.Thus Vacuum Loading reduces the manual labor intensity,to eliminate the dust pollution to ensure the production line with GMP.

Pneumatic System

Get Price Quote

Single stage, air cooled, heavy duty with air receiver. Pneumatic pipeline with pressure regulator, strainers, shut-off valves. Pipes are pre-installed in the module.

Pneumatic Powder Transfer System

200,000 Per Piece

01 Piece (MOQ)

Vacuum Powder Conveying, Transfer System

Get Price Quote

APPLICATION & PROCESS : The Vacuum transfer system is unique dry material transfer system for dust free and avoid to human touch. The vacuum transfer system is used in Pharmaceutical, Food, Agro Chemical, Sugar Industries and chemical. The system is use full for inline milling, sifting, blending, loading and unloading. The principle of vacuum transfer has been proven to be a better way to move many types of material and a giant step over manual handling. The technology exists for moving virtually any material that can be pulled through a hose or tube. The system is consisting of Blower, Vacuum receiver system with filter, cyclone filter and Pipe. The vacuum conveying systems designed specifically for the direct charge loading of blenders, mixers, sifter, milling, reactors or any vessel capable of withstanding a vacuum. The vacuum system can be provided mobile type with lifting provision to move one room to another room for loading and loading any machine. SALIENT FEATURES : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Capacity available 100 Kg to 5000 Kg/hr. Can be used for transfer of products having bulk densities up to 1.0gm/cc. Total Discharge no Retention. No segregation or degradation of Product. No tool required for opening & cleaning. Transfer can be completely automatic to avoid the manual handling of the material.

Pneumatic Conveying System

Get Price Quote

We provide a spectrum of pneumatic conveying system also known as vacuum conveying systems that is fabricated using finest quality raw material. Our efficacious gamut takes less floor space and is easy to integrate into manufacturing environment.

Pneumatic Conveyors

Get Price Quote

Each design from Pneucon undergoes a stringent check to ensure that the end result is what is required and the material used in the manufacture of each of our pneumatic conveying systems is of the best quality and meets all the required industry standards in quality grading. The pneumatic conveying belts are also used by the food industry and meet all the checks required to work with various food products as well. Our systems have achieved so much reliability that we are now the leading name for Pneumatic Conveying System Manufacturer in India and this is what is guaranteed when you choose us

Pneumatic Conveyors

Get Price Quote

Precious Pneumatic Conveying Systems are designed to convey dry powder or grains from one place to another, which may a combination of horizontal as well as vertical conveying, even through some intricate path. While conveying material it may be lifted from one or more than one place and similarly may be dropped at one or at many places.

Vacuum Conveyor

Get Price Quote

Our firm expertize in providing our clients with an expansive range of Vacuum Conveyor. These systems are widely used for transferring the material from material dumping station to vacuum silo. For this purpose, these systems are mounted on top of the lid of high speed heater mixer. Available with conveying capacity of approx. 3000 Kg./hour, these systems are provided with anti dust reverse jet cleaning system for dust free environment. Moreover, these systems are offered in varied specifications to meet the diverse industrial applications.suppliers in ahmedabad Vacuum Conveyor.

Pneumatic Vacuum Conveyor

Get Price Quote

We manufacture of pneumatic systems and support equipment for conveying, weighing and batching of dry materials inclduding Vacuum Conveying Systems for Bulk Dry Powders , Vacuum Conveying System: Direct Charge Blender Loading , Mobile Vacuum Conveying Systems ,Potassium Permanganate & Dry Chemical Vacuum Conveying , Vacuum Conveying Systems , Batch Weighing Systems , Bulk Bag Unloader , Bulk Bag Loader ,Bag Dump Stations , Bag Compactors ,Flexible Screw Conveyors , Aero-Mechanical Conveyors , Industrial Vacuum Cleaners, Central Vacuum Systems with output available up to 5000 kg per hours. More than 100 models different types of vacuum transfer system for powder , pharmaceutical vacuum transfer system , powder transfer equipment, vacuum conveying system and design, vacuum conveyor belt system , vacuum transfer chemistry, vacuum conveyor design, pneumatic powder transfer system ,vacuum system, mobile vacuum system, centralized vacuum system ranging form R&D to high speed commercial model of single & three phase with instrumentation and automatic weight control models. Many new capabilities were built for the Domestic & International Customers with successful installation & services.

Pneumatic Conveying System

Get Price Quote

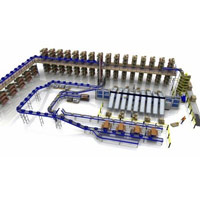

Khodiyar infratech offers high quality pneumatic conveying systems and equipment for the food, pharmaceutical, chemical and packaging industries. dust free stainless or mild steel vacuum systems dense phase vacuum systems for fragile and pre-mixed product sophisticated controls positive pressure lean phase systems specialized powder handling for non free flowing products turnkey systems abrasion resistant systems high accuracy multi material weighers the p-series filtered receivers are specially designed for use with powders and friable materials in sanitary applications. Material pick-up : from pick-up spike to piping to receivers and vacuum pumps, khodiyar infratech offers a wide range of equipment for pneumatic conveying needs, whether for automated refill of feeding systems or as standalone conveying applications. The following list describes the varied elements available from khodiyar infratech for building a complete conveying system for loss-in-weight feeder refill (pictured in the diagram above). For more details about pneumatic conveying system visit us at : http:www.khodiyarinfratech.compneumatic-conveying-system.html

Pneumatic Conveying System

Get Price Quote

» AIR HANDLING ENGINEERING is an art, please consult us for your specific air handling needs. General Information: » Pneumatic Conveying Systems can be tailor made to suit exact requirements of any bulk material to be conveyed. The system is enviro-friendly. » Can offer suction conveying, low pressure conveying, high pressure conveying depending upon the typical nature of the product, conveying rate and the distances » Can design and offer a system which can be fully manual, semiautomatic and fully automatic. Features: » Can handle materials like flour of all types, dextrose, clay powder, coal dust, soda ash, plastic pellets, grits, powders, Soya meal/beans, catalysts of all types & sizes, LDPE / HDPE pellets, wood chips, groundnut, paper, plastic & laminate » Specialists in catalysts loading / unloading for refineries and fertilizer plants. Details required for Quotation: » Application » Kind of Material » Specific Density Of Material : Vertically » Conveying Distance : Horizontally

Pneumatic System

Get Price Quote

1.Single stage, air cooled, heavy duty with air receiver. 2.Pneumatic pipeline with pressure regulator, strainers, shut-off valves. 3.Pipes are pre-installed in the module.

vacuum transfer system

Get Price Quote

Design is cGMP – Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Capacity available 100 Kg to 5000 Kghr. Can be used for transfer of products having bulk densities up to 1.0gmcc. Total Discharge no Retention. No segregation or degradation of Product. No tool required for opening & cleaning. Transfer can be completely automatic to avoid the manual handling of the material Fully automatic system, with timing controls and automatic air blow back system for filter cleaning. Vacuum Blower and cyclone filter can be installed in out side production area. Avoids product waste, loss and contamination. Easy to clean and wash of contact parts. Option for Inline Milling, Sifting with Blender and Loading material to RMG, Tablet press& Vessel.

Pneumatic Conveying System

Get Price Quote

Pneumatic Conveying System Manufacturer Powders, granules and other dry bulk materials are transferred through an enclosed horizontal or vertical conveying line in Pneumatic Conveying System. All kinds of manufacturing industries and processes need different kinds of Pneumatic Conveying System and Shree Techno Engineers are pleased to have the best and the most extensive scope of these frameworks. Various types of enterprises require diverse determinations with regards to these pneumatic transports and we have a remark all prerequisites. Our transport frameworks are utilized as a part of businesses as differed as pharmaceuticals, concoction ventures, and different nourishment enterprises and even in the bundling business. The quality and precision of our passing on frameworks are based on a strong establishment of devotion to customer fulfillment and with the most recent refreshed innovation. Our group of authorities and specialists are industry specialists and can plan the best pneumatic frameworks as well as guarantee that the highlights suit the individual customer too. This has additionally guaranteed our name in the rundown of regarded names for Pneumatic Conveying System India.

AQUAPACK Hydro-Pneumatic Pressure

Get Price Quote

FEATURES & BENEFITS Ideal for pressure boosting without overhead tanks. Constant pressure at all distribution points. Low energy consumption. Wide range. Simple installation. Continuous water supply due to standby pumps. Low noise, tuff & reliable. Fully factory assembled & tasted. Also available VFD controls for power saving solution. Prompt on site service support.

dense phase conveying systems

Get Price Quote

In dense phase conveying two modes of flow are recognized. One is moving bed flow, in which the material is conveyed in dunes on the bottom of the pipeline, or as a pulsatile moving bed, when viewed through a sight glass in a horizontal pipeline. The other mode is slug or plug type flow, in which the material is conveyed as the full bore plugs separated by air gaps. Dense phase conveying is often referred to as non-suspension flow.