Pneumatic Corner Cutting Machine

Get Price Quote

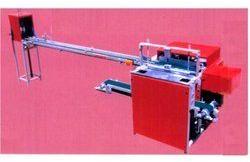

Air Pneumatic Core Cutting Machine

Get Price Quote

RK CC AIR PNEUMATIC CORE CUTTING MACHINE Core Cutting Machine. Air pneumatic core cutting machine. Multiple Core cutting, printed label core, sticker label roll core. Specifications Automatic Pneumatic Core Release System Core Cutting with Pneumatic Operational As Per Requirement Size Core Cutting Attachment 1 HP Single Phase Motor With Machine Core size 25mm, 38mm and 75mm Core Shaft Size 500mm Working 450mm

Best Deals from Pneumatic Cutting Machine

Automatic Pneumatic Cutting AND Stamping Machines

Get Price Quote

With firm commitment to quality, we are manufacturing and supplying a comprehensive range of Fully Automatic Pneumatic Cutting & Stamping Machines. These are extensively used to cut soap bar from the plodder at equal lengths, which cut the soap to billets and stamp the essential logo. All the pneumatic components used in these machines are janatics/airmax. These are specially designed with flexibility for quick change over system between pack sizes. Moreover, these are one, two and three soaps cutting together with this machine. There Are 1 Soap, 2 Soap & 3 Soap are cutting together with this Machine. There are starting the Machine when the Soap is Coming.The automatic Soap cutting and stamping machine is used to cut soap bar from the plodder, cut the Soap to billets and stamp the necessary logo. Features The primary cutter cut the bars from the plodder at equal lengths. Bars are conveyed to cutting and stamping machine through a conveyor. The Machine is provided with a cutting frame to cut the bars. The trimming waste is taken out by a conveyor and fed to the inclined belt conveyor for cutting waste recycling. All the pneumatic components are JANATICS/AIRMAX make. The machine is designed with the flexibility for quick change over system between pack sizes. User-friendly system to very lengths of bars. Power Required in KW 220/Volts, Single Phase Dimensions 14 (L) x 3.5 (W) x 5 (H) Feet Air Compressor 2 H.P Contact Parts SS/MS

pneumatic cutting machine

Get Price Quote

Sheet metal cutting comes under the category of metal working. metalworking is craft and practice of working with metals to create individual parts, assemblies, or large scale structures. the term covers a wide range of work from large ships, bridges and oil refineries to delicate jewelry. it therefore includes a correspondingly wide range of skills and the use of many different types of metalworking processes and their related tools. the sheet metal cutting process is a main part of the all industries. normally the sheet metal cutting machine is manually hand operated one for medium and small scale industries. automation in the modern world is inevitable. any automatic machine aimed at the economical use of man, machine, and material worth the most. in our project is solenoid valve and control timing unit is used for automation. the sheet metal cutting machine works with the help of pneumatic double acting cylinder. the piston is connected to the moving cutting tool. it is used to cut the small size of the sheet metal. the machine is portable in size, so easy transportable automation can be achieved through computers, hydraulics, pneumatics, robotics, etc., of these sources, pneumatics form an attractive medium for low cost automation. the main advantages of all pneumatic systems are economy and simplicity. automation plays an important role in mass production.