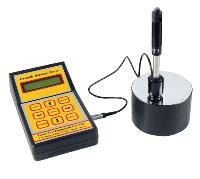

Poldi Hardness Tester

Get Price Quote

Insert the tapered end of the standard test bar after cleaning into the space provided between the ball and the plunger and slide it further beyond the tapered position. The test bat will thus be firmly gripped between the ball and the plunger pressed by a spring. The specimen to be tested be properly ground or filed and polished at the surface where it is to be tested to ensure accurate readings, With standard test bar inserted place the tester vertically on the specimen such that the ball touches the polished surface. Give a blow on the top of the plunger, with a hammer. The blow should not be very hard and should as vertical as possible. The blow will cause two indentations, one on the standard test bar and the other on the specimen. The diameters of these two indentations should be measured accurately with magnifier having, lease count of 0.1 mm provided with the machine. If the indentations so obtained are slightly elliptical, average diameter should be found out. The distance between the centers of any two indentations on standard test bar should be less than 15mm. If the bar is fully utilized it has to be replaced. The limiting indentation diameter on the standard test bar is 4.2mm

Poldi Hardness Tester

Get Price Quote

Manufacturer & Exporter of Poldi Hardness Tester & 8x Magnifier Lens type Poldi Hardness Tester. Our product range also comprises of Portable Hardness Tester, Digital Ultrasonic Thickness Gauge and Digital Coating Thickness Gauge.

Best Deals from Poldi Hardness Tester