Automatic Toast Packing Machine

260,000 - 380,000 Per Piece

1 Piece (MOQ)

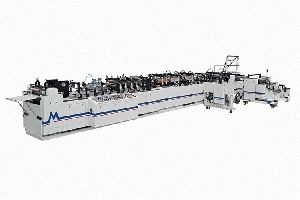

Stand Up Zipper Pouch Making Machine

4,251,000 Per Pack

1 Piece (MOQ)

FEATURES: One Master roll with shaft-less unwinder and Driven Tension control system Multiple sealing and cooling stations All stations are actuated by individual servo system to control seal and cool time Multiple Nip roller system to maintain even tension on the film Touch Screen PLC for setting of all parameters like size , sped , dwell time , temperature etc Servo actuated cutter system Auto conveyor system for easy collection of pouch

Best Deals from Pouch Packaging Machines

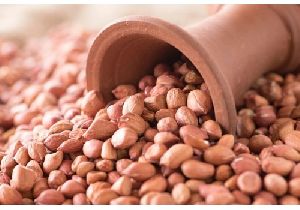

Peanut Seeds

Get Price Quote

Nutty, Delicious, Crunchy are a few terms that come in our mind when we think of Peanuts. These crunchy delights are not only rich in taste but also have various health benefits. Keeping this in mind, we are offering superior quality Peanut Seeds for high crop yield. We offer Peanut Seeds that are obtained from organic crops only.

Heat Shrink Tunnel Packaging Machine

45,000 Per Piece

1 Piece (MOQ)

Peanut Seeds

90 - 95 Per Kilogram

1000 Kg (MOQ)

Freshia is wellkown company for peanut manufacturer in india. We are working in this sector since long time. This is our 5th Generation who is working in this sector. We provide best service and quality material to our customer. We believe cutmore is God in every sector.

Peanut Kernels

Get Price Quote

Peanuts grow in a very fascinating manner. They actually start out as an above ground flower that, due to its heavy weight, bends towards the ground. The flower eventually burrows underground, which is where the peanut actually matures.The veined brown shell or pod of the peanut contains two or three peanut kernels. Each oval-shaped kernel or seed is comprised of two off-white lobes that are covered by a brownish-red skin. Peanuts have a hardy, buttery and "nutty" taste.While there are many varieties of peanuts, the ones most commonly found in the marketplace are the Virginia, Spanish and Valencia. Due to their high protein content and chemical profile, peanuts are processed into a variety of different forms, including butter, oil, flour, and flakes Peanuts are an excellent source of biotin. They are also a very good source of copper as well as a good source of manganese, niacin, molybdenum, foliate, vitamin E, phosphorus, vitamin B1, and protein.Specification: Bold - 50/55, 60/70, 70/80, 80/90 Java - 38/42, 50/55, 60/70, 70/80, 80/90, 90/100 Moisture - 7% Broken & Split - 1% Maz Damage & Imperfect - 1% Max Foreign Matter - 0.5 Max Packing: 10 Kg, 25 Kg, 40 Kg & 50 Kg , as per buyer requirement

Groundnut Kernels

Get Price Quote

In order to provide faultless products to the clients, we make sure that the inputs we use are of excellent quality. Thus, our experts keep a stringent check over the same. Our well-structured warehouse is properly maintained and installed with diverse amenities required for the safe storage of the products. Moreover, we keep on updating the unit for enhanced safety.

Semi Pneumatic Pouch Packing Machine

Get Price Quote

We are offering application:- the machine can pack namkeen, grains & pulses, tea, sugar, salt, masala, heena, kurkure, frymes, chees ball ,spices, detergent powder, milk powder, o.r.s. Powder, mahanadi, and any types of free flow powder and granules. Specification:- �filling capacity:- 5-20, 20-50, 50-100, 100-200, 200-500 grams (different types of machine) �filling accuracy:- ± 1.5% � sealing type:- centre seal � film size: - 40 - 350mm (width) : - 30 - 240mm (length) � packing material:- all type of heat sealable laminated film �speed:- 15 to 90 pouches per minute(depends on material flow density) � power :- ½ hp single phase ½ hp three phase �machine dimension :- 750mm(l) x 560mm(w) x 1750mm(h) �filling system:- volumetric cup filling �machine weight :- 350kg. (approx.) silent features:- � simple operation �all contact parts with product made of stainless steel �variable speed �easy to change pouch size & filling volume � digital photo electric controller & temperature controller �telescopic cup mechanism for micro adjustment � law maintains �automatic batch cutting system optional accessories:- �mechanical type batch coding � motorized type batch coding �gas flushing

Automatic Pouch Packing Machine

Get Price Quote

Aseptic Liquid Filling Machine

Get Price Quote

Description Aseptic Liquid Filling Machine is made in pleasing matt finished stainless steel materials. The basic unit consists of turntable, Stainless Steel Stat conveyor belt, unique eccentric pre-gassing, filling and post-gassing. Highly efficient and precision built Stainless Steel 316L Syringes, non- toxic synthetic rubber tubing and easy reach compact panel. The minimal distance between filling and stoppering units reduces the risk of contamination. The machines are designed for operation in a sterile area and for use under laminar flow protection. The un-scrambler itself has been redesigned to eliminate dead ends and difficult-to-clean spots. Salient Features Suitable for the filling Volume of 2ml to 250ml. Piston pump/Peristaltic pump aseptic filling. Filling accuracy of ±0.5% to ±1%. No cross contamination. Easy to validate filling system for small/large batch production. All Contact Parts Made from Stainless Steel 316L & framework by Stainless Steel 304. Variable A.C. frequency drive for speed adjustment. Digital Vial Counter for counting production output. In-feed Turn Table/ Unscrambler for automatic feeding of objects. On-line Mechanism. “No Vial - No Filling” System. “No Vial - Machine Stop” System. IQ/OQ documentation can be provided. PLC system with Graphical User Interface. (Optional) Process Operation The incoming dry vial (sterilized & siliconised) are fed through the unscrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of Stainless Steel 316L construction and both, glass as well as Stainless Steel syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided for ''No Vial-No Filling'' operation. Syringes are mounted on eccentric block and driving through bottom main gear box. Volume can be either increased or decreased by increasing or decreasing stroke length of piston as per filling size. Syringes is having non return valve for sucking and delivering situation to avoid volume variation. Liquid will reach to filling nozzles through silicon transparent pipe. Nozzle will be having Up and Down movement with help of cam mechanism and it will come down when vial will be hold by starwheel for filling operation and starts filling when it starts to move up and after completion of filling operation, starwheel delivers six vials together on conveyor for rubber stoppering operation. Stoppering unit consist of Starwheel, Vibrator unit and Bowl. The sterilized and siliconised rubber stoppers stored in the vibrator bowl moves vertically to the rubber stopper chute. The vial is hold firmly by starwheel, which will be in continuous rotary motion and vial which is coming from filling unit get in to starwheel and move in rotary direction along with starwheel, during movement it will pick up the rubber stopper from the exit end of the chute and rubber stopper will be pressed by fix single pressing roller, which is spring loaded. Then vial further move on conveyor and collected on out feed starwheel for next sealing operation.

Vertical Door Packing Machine

Get Price Quote

Standard Features PLC based control panel with 4 line LCD display from "MITSUBISHI" - JAPAN. Stainless steel housing. No sharp edges. Easy to wipe. Cutout of toughned glass to view the packaging process from the top. Base conveyor with teflon rollers for easy movement of the product. Adjustable height of the base conveyor for products having different heights. Entirely made from stainless steel, cast aluminium & other non ferrous materials. Oil mist separator to remove the oil mist from vacuum pump exhaust. Manual vacuum stop button for liquids & semi liquids. Can be conveyorised for higher output. Useful for moulded vacuum packaging for brick shaped packs. Optional Features Inert Gas Flushing Unit. StainlessVaccum & gas sensor control for accurate level of vaccum & gas. Cutout Gas pressure monitoring device for nitrogen & carbon dioxide. "BUSCH" (Made in Germany) Vacuum Pump. Vibrating table for compaction of the material to be packed. Infeed & discharge roller conveyor for easy movement of product or mould. All stainless steel mould & formers to get the perfect brick shape for moulded vacuum packaging.

Automatic Water Soluble Fertilizer Packing Machine

Get Price Quote

scrubber packing machine

55,000 Per Units

de blister machine

58,000 Per Piece

1 Piece (MOQ)

Pouch Packing Machine

2,000 Per Piece

1 Piece (MOQ)

Dry Fish Vacuum Packing Machine

380,000 Per Piece

1 Piece (MOQ)

Milk Pouch packing machine

Get Price Quote

1 Piece(s) (MOQ)

We are a quality-centric company and thus, we make sure that the packaging is done under the strict supervision of experts and professional. We make use of the finest packaging material and thus, keep our products safe from the external factors. According to your convenience, to pay for an order, our company can settle on a method of payment. We are familiar with online and offline payment methods. We only want to make payment safe and secure for you.

spices filling machine

11,200 Per Piece

1 Piece (MOQ)

Automatic Electric Heat Shrink Tunnel Machine

350,000 - 750,000 Per Piece

1 Piece (MOQ)

Welcome to Technogen Enterprise, the industry-leading manufacturer of the Automatic Electric Heat Shrink Tunnel MODEL: TGEHT-100, designed to provide efficient and precise shrink sleeve labeling on the body of round plastic containers. Our machine is compatible with a wide variety of sleeve labels made from PVC, PP, PETG, and OPS films, ensuring versatility in your labeling applications. Achieve impressive speeds of up to 100 containers per minute, depending on the size of the container. The Automatic Electric Heat Shrink Tunnel Machine features a robust AISI 304 make Slat conveyor for smooth feeding of the containers. The speed of the conveyor can be adjusted through the provided speed port on the operating panel, giving you control over the labeling process. For labeling, the sleeve label is manually placed on the plastic container, and together they are put on the conveyor. As the containers enter the tunnel, the machine utilizes sets of Pin heaters to heat the air inside, creating the perfect environment for label shrinking. Additionally, the shrink tunnel contains two blower assemblies, facilitating forced convection heat transfer. This ensures uniform heating around the traveling containers inside the tunnel, resulting in flawless and perfectly shrunk labels adhered to the containers' body. Trust in Technogen's Automatic Electric Heat Shrink Tunnel Machine for consistent and high-quality shrink sleeve labeling. Streamline your labeling operations and elevate the efficiency of your packaging process with our cutting-edge technology. Choose Technogen Enterprise for top-of-the-line labeling solutions. Contact us now to explore the full potential of our Automatic Electric Heat Shrink Tunnel MODEL: TGEHT-100 and experience superior performance and reliability. Upgrade to precision and efficiency with Technogen today! Automatic Electric Heat Shrink Tunnel Features : CGMP MODEL Heating is taking place based on forced convection method Machines work with variety of sleeve label made from PVC, PP, PETG and OPS films. 2 set of blowers to assist the uniform distribution of superheated air. Superior Pin heater in order heat the air to superheated level Temperature controller in order to control the temperature.

Pillow Packing Machine

83,000 Per Piece

1 Piece (MOQ)