ribbon blander

Get Price Quote

Where a fine blending or mixing of material, with uniform output is required Ribbon Blenders are the best. The equipment is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 10000 litre. The design of the equipment also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. These blenders are also available with all contact parts of Stainless Steel. Construction : M.S. / M.S. - S.S Coating / S.S / Jacket Ribbon Blender Models Available : MS Blender MS. SS Coating Blender Jacket Blender Till Till Blender Ideal For: Mineral & Others Chemical Technical Products Dyestuffs Pigments Colours Fertilisers Metal Separation Insecticides / Pesticides

Agarbatti Powder Mixer Machine

17,500 Per Piece

Best Deals from Powder Mixers

Ribbon Blender

Get Price Quote

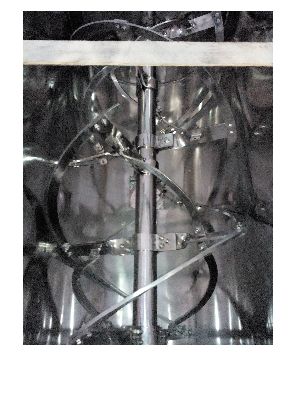

Based in Ahmadabad, Gujarat, we are known as one of the important manufacturers and suppliers of Ribbon Blender which are used for a homogenous mixture of powders and dry granules. Almost two third of the container should be filled with materials for proper mixture. Because of its unique shape and design, this product helps in perfect blending granules and dry powder and is used in various industries like pharmaceutical, cosmetic, food and chemical. The blender has a U shaft along with two spiral ribbons; one positioned within the other, so that material reaches every corner of the trough and has a perfect blend of linear and radial motion for fine powder. The agitator construction helps in triple mixing and efficient blending. Based on a SS/MS structure, this product has a double ribbon configuration which helps to discharge the material through a central bottom outlet. A valve, designed in the centre helps in the discharge procedure. The machine can also be fitted with a spray nozzle with pressure spraying system for spraying additives.

Granules Mixing Machine

Get Price Quote

These mixing machinery are made by using very high grade raw material which ensures hassle free work performance at its user end. These mixing machinery are widely finds its applications in various plastic processing industries. Features Stainless steel shell with super finished surface inside & outside. Rigid steel fabrication base. Emergency STOP facility. Timer controlled. Easy to clean maintained. Both side throat open facility.

Granule Mixer Cum Dryer

120,000 - 225,000 Per Nos

1 NOS (MOQ)

ribbon blender machine

200,000 Per Units

Ribbon Blender

25,000 - 500,000 Per piece

1 Piece (MOQ)

Double Cone Mixer

Get Price Quote

This is a unique mixer which has 2 cones on the ends and cylindrical in the middle portion. It has two supporting legs. The shaft is moving with the cone by a motor and pedestal support which is mounted on legs. Both the cones have lids which can be opened or closed for loading and unloading. The double cones and cylindrical body is made of stainless steel. D.C. Mixer has two major functionsa. Mixing of the ingredients kept inside the chamber, andb. Hydration of the Guar splitIn guar-gum industry, the D.C. Mixer plays important role as it gives better result in fast hydration which enables to get better flaking, soft pulverising and high viscosity of the powder to be produced.

Heater Cooler Mixer

800,000 Per Piece

Mixer Ribbon Blender

500,000 Per Piece

1 Piece (MOQ)

v cone blender

225,000 - 785,000 Per Piece

1 Piece(s) (MOQ)

Ribbon Blender

Get Price Quote

We are offering ribbon blender we have a state-of-the-art manufacturing facility, which helps us providing our clients with ribbon blenders. Ribbon blenders available size from 200 mm diameter to 2500 mm diameter in mild steel & stainless steel.

Incense Powder Mixing Machine

22,000 Per Piece

5 Piece(s) (MOQ)

Special Features : Contact parts made of customer requirement. Double Helical agitator with single speed for uniform dry mix and perfect wet mix. The general structure Ribbon Blender has non-contact parts made of customer requirement. The contact parts of the blender have a mirror finish.

Ribbon Blender

Get Price Quote

Model : 0.5 HP 100 HP 25 litter to 25,000 litter Capacity Direct Gear Drive , Counter Gear for load reduction Constraction : MS - MS / SS Coating – SS Material – Jeketared With and Without Counter Gear Ideal For : Pigment Colors - Minerals & Ores - Chemicals Technical Products Dyestuffs - Fertilizer - Insecticides - Pesticides Extra Material Handling Screw for loading & Unloading. HP required 2 HP 1440 Electric Motor 2 Nos. Capacity input and out material 75 kg per one minutes

Ribbon Mixer

Get Price Quote

All type of Blenders are available for Mixing i.e. Octagonal Shape, V Shape, Double Cone, Cage, Cone & Ribbon Blender in the MOC of Contact Parts S.S.316.

Ribbon Blender

150,000 - 7,500,000 Per piece

1 Piece (MOQ)

Mass Mixer Machine

Get Price Quote

Manufacturer & Supplier of Mass Mixer Machine. Our product range also comprises of Filling And Sealing Machine, Pharmaceutical Equipment and Bottle Inspection Machine. With rich industry experience, we are fabricating, exporting and supplying a wide gamut of Wet Mixing Machine. These are fabricated as per the defined quality norms using best quality raw material and technology. Our range is acknowledged in the industry due to their optimum performance and durability. Moreover, our clients can avail these at market leading prices. Features :- Thrust bearings are provided to carry rigid and thrust load Easy for cleaning and operating Interlocked acrylic dust cover for inspecting the mixing process The Tilting device provided for easy uploading of the material

Mass Mixer Machine

Get Price Quote

APPLICATION : The mass mixture machine is specially made for the mixing of the dry and damp materials. The machine is very suitable to the tablet granulation. The machine is provided with powerful-geared drive and the mixing paddle make mass mixer. The machine is very efficiently mixing the material. It is proven an ideal mixture machine to mixing even the sticky ingredients. The two speed machine can customize as per requirement of the clients. CONSTRUCTION : The mass mixture machine provided by following components S.S. 304 mixing drum Mixing paddles Mixing drum body M.S. fabricated body carrying motor Gearbox starter The contact parts are of S.S.316 CONTACT PARTS : SS316 FEATURES : easy cleaning facility The transparent poly-carbonate dust cover with inter locking system. On opening of the cover, the machine stops functioning. The safety device is provided with the machine. To make easy unloading, the tilting device is provided with the machine. The machine is specially design to make self-adjusting sealing arrangement to ensure no black particles can enter into the mixing drum.

double cone blender machine

Get Price Quote

suitable for rapid mixing of all types of free flowing powders and granules. The uniform, multidimensional offset arrangement of the cone ensures good mixing it is made from high quality stainless steel to prevent from rust & corrosion. It is easy to load and discharge materials in double cone mixer as its servers as excellent batch mixer machine. Provision is made for steam, chemicals, and hot water arrangements as required by customer. Available in all capacities ranging from 10 liters to 4000 liters. Chain drive arrangement provides minimum slippage and maximize load bearing capacity. salient features:- double cone blender, octagonal batch mixer, powder/granules mixing machine suitable for rapid mixing of all types of free flowing powders and granules. the uniform, multidimensional offset arrangement of the cone ensures good mixing it is made from high quality stainless steel to prevent from rust & corrosion. it is easy to load and discharge materials in double cone mixer as its servers as excellent batch mixer machine. provision is made for steam, chemicals, and hot water arrangements as required by customer. available in all capacities ranging from 10 liters to 4000 liters. chain drive arrangement provides minimum slippage and maximize load bearing capacity.

cooler mixer

Get Price Quote

We offer Cooler Mixer. Perfect height to dia ratio of vassel. Precise Peripheral speed of mixing tool. Least down time, so payback period is higher Unmatched Pneuma seal Capsule Technology. Proper design of impeller. Computerized balancing of rotating parts. Best quality material of all key components. Unique design of bottom & discharge valve. Very prompt after sales services. Experience of manufacturing highest number of high speed mixers.

Granules Mixing Machine

Get Price Quote

High efficient high speed Mixer designed to generate heat due to friction. The high speed Mixers are used to mix granules with pigment paste or pigment powder or different colored granules for uniform blending.The high speed mixer achieves heat while working is important to blend the pigment paste and polymer powder uniformly.Moisture free blending and compounding with additives in different controlled temperatures, Process control timer switch to set and monitor process, Twin jacket for heating and cooling Timer control for energy saving, Heavy duty bearing housing for trouble free working

Ribbon Blender

Get Price Quote

We are offering ribbon blender. The design of the reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass. Application in: food, pharma, chemical, minerals, guar gum starch cellulose etc.

Ribbon Blender

560,000 Per Piece

Ribbon Blender

380,000 Per Piece

1 Piece(s) (MOQ)

The Mahavir ribbon blender are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. The dimensions and configuration of the ribbons in ribbon blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. The design of the Mahavir ribbon blender can in corporate features required for a customer's product or process such as: wear resistance, corrosive resistance, vacuum filling and discharge arrangements, special shaft seals, heating/cooling jackets. Ribbon blender is available in sizes 100-8000 litters in Stainless Steel 304, Stainless Steel 316 and Mild Steel Construction.

Horizontal Ribbon Blender

Get Price Quote

Horizontal Ribbon Blender gives very best result for combining of dry powdered & granules as a result of design and form of the mixing ribbon and product jar. It can provide for Pharmaceutical, Meal, Chemical and Cosmetic products etc. The HORIZONTAL RIBBON BLENDER is a proficient and resourceful blending machine and is very useful for homogeneous mixing of dry granules & powders. Roughly about two third of the volume of the container of Horizontal Ribbon Blender is filled to make certain that it is mixed properly. The Horizontal Ribbon Blender Manufacturer offers the most excellent outcome as far as mixing of dry powder and granules is concerned because of the design and shape of the container. It is very apt for Pharmaceutical, Food, Chemical and Cosmetic products processing. Material charged via the top part port/ports are put on the top cover to charge the material. It also aids in venting the air. A discharge valve is given at the bottom part at center of the container. The discharge height can be altered according to the necessity, thus the material is discharged in the extra container directly. Thus there is zero material handling time needed for discharge and the operation is totally dust free. We produce brilliant quality of Horizontal Ribbon Blenders and our product is very apt for mixing, grinding, granulation and homogenizing procedures. Features: The shape of container along with mixing stirrer allows sufficient continuous movement towards powder / granules result in good quality. All contact elements of Horizontal Ribbon Blender are created from SS 304/SS 316 top quality material Maximum care may be taken to ensure safe operation in the Horizontal Ribbon Blender Inching service for stirrer regarding discharge of materials Full cover at the top side of the container Discharge height as per client requirement Operating panel provided for safe operation of Horizontal Ribbon Blender Centrally located material Discharge valve Dust proof top cover with window provided

Double Cone Blender

Get Price Quote

Operation: The Double Cone Blender Is An Efficient And Versatile Machine For Mixing Dry Powder And Granules Homogeneously. Two Third Of The Volume Of The Cone Blender Is Filled To Ensure Proper Mixing. Double Cone Blender Can Be Used For Pharmaceutical, Food, Chemical And Cosmetic Products Etc. Capacity: Our Double Cone Blender Is Available In 10 Kg., 25 Kgs., 50 Kgs., 100 Kgs., 200 Kgs., 300 Kgs., 500 Kgs. Capacity Salient Features: All Moving Parts Of Double Cone Blender Are Covered With SS304 Covers Safety Guards Made From SS304 Pipes Provided In Front Of The M/c. Panel Of Double Cone Blender Is Fabricated From SS304 Material With Facility Of Three Phase Indication, D.O.L. Tarter, Digital Timer & Amp Meter. As Per Customer Requirement Double Cone Blender Machine Will Be Provided With Left Side Drive Or With Right Side Drive. The Conical Shape At Both Ends Enables Uniform Mixing And Easy Discharge All Contact Parts Are Made Out Of SS304/316(as Per Customer Requirement) Quality Material Maximum Care Has Been Taken To Ensure Safe Operation Of The Unit. Food Grade Rubber Gasket Will Be Used On Both Ends Of Cone As Well As In Butterfly Valve. Inside & Outside Of The Double Cone Blender's Cone Will Be Polished To The Mirror Finished. (All Safety Guards & Covers Made Out Of SS304 In GMP Model As Required By You) In GMP Model The Conical Shape Of Both Ends Enables Uniform Mixing And Easy Discharge Suitable Size Of Butter Fly Valve At One End Of The Cone Provided For Material Discharge & Hole With Open Able Cover Provided At Other End Of The Cone For Material Charging & Cleaning. One Shaft With 03 Nos. Of Fixed/ Detachable Buffers With Mirror Polished Provided Inside The Cone.

dry mixer

Get Price Quote

Blenders are used for mixing, lubricating and blending in Pharmaceutical, Nutraceutical, Food, Chemical, cosmetics, ceramics, pesticide, plastics and other Allied industries The Double shape blenders have long two corner of product container for more rubbing and tumbler effect to the material for fast and homogenizing mixing. It can perform homogenously dry mixing of free flowing powders, granules requiring low shearing force, Mixing and Blending of particles with rapid intermixing of particles irrespective of varying specific gravities. The material is loaded into the double cone blender drum. The double blender is tumbles the material in the container and spread out. The mixing is achieved in 5 to 15 minutes with better homogeneity.

Granules Mixing Machine

100,000 - 165,000 Per 100 kg to 150 kh

Ribbon Blender

Get Price Quote

Ribbon blender is used for uniform, homogeneous and quick mixing of powders and semi-wet materials of different densities by specially designed helical ribbon agitator. It can be used for Pharmaceutical, Food, Chemical, Dyestuffs & Pigment etc. For Pharmaceutical Industries, Ribbon Blender is called as Mass Mixture. Uni-Mech manufactures Continuous type and Batch type Ribbon Blenders. Uni-Mech also designs Ribbon Blenders for Chemical Reactions with Heating & Cooling applications. Ribbon Blender Design Range : Capacity range: 5 liters to 15000 liters Material of Construction: Various grades of Stainless Steel, Mild Steel, Hastelloy (cGMP model is also available). Special Features : Homogeneous Mixing Dust Free Operation Easy Handling & Operations Top Charging & Bottom Discharge through Butterfly Valve / Sliding Gate

Double Cone Blender

Get Price Quote

A Double Cone Blender for the easy loading and discharge of the materials. Entire body of the Mixer Rotates and does not allow a single particle of the mass to stay at one place. The mass continuously tumbles and mixes. Double Cone Blender is unique equipment especially suitable for the small to medium capacities. The sizes of Double Cone Blender available are 50 liters to 3000 liters. Application In: Food, Pharma, Chemical, Minerals, Guar Gum / Starch / Cellulose etc