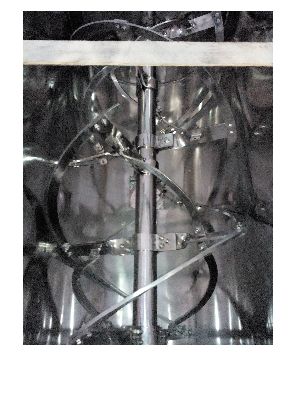

twin shaft paddle mixer

Get Price Quote

1 Piece (MOQ)

Our Twin Shaft Powder Mixer at Shree Engineering Services is the professional standard for any application requiring the homogenous mixing of two or more powders. As a prominent Twin Shaft Paddle Mixer Supplier, our Twin Shaft Paddle Mixers' unique design allows us to guarantee a uniform powder mix to our customers in very short cycle times. In short mixing times, we understand the crucial need for an even, consistent mix for our clients. This precise requirement is met by our Twin shaft paddle mixer. The Twin Shaft paddle mixer is comprised of two counter-rotating shafts with welded paddles. The paddles create "fluidization" by lifting the material up the centre of the mixer in weightless whirls. The particles have complete freedom of movement and collide with one another, resulting in a maximum level of homogeneity.

Double Cone Blender

235,000 - 1,250,000 Per Piece

1 Piece (MOQ)

Best Deals from Powder Mixers

Mixing Machine For Raw Material(Granules)

150,000 - 325,000 Per piece

1 piece (MOQ)

Granules Mixing Machine

120,000 - 250,000 Per Piece

Double Cone Blender

150,000 Per Piece

1 Piece (MOQ)

Ribbon Blender

75,000 - 500,000 Per piece

1 piece (MOQ)

double cone blender machine

75,000 - 1,450,000 Per Piece

1 Piece (MOQ)

Features The conical shape of both ends enables uniform mixing and easy discharge. All contact parts are made out of SS316 quality material. Maximum care has been taken to ensure safe operation of the unit. Safety reeling, overload protection and emergency shutdown features available. Mirror finish inside and outside the drum. Easy to load and unload the materials Low maintenance and enhanced durability

Venturi Powder Mixer

Get Price Quote

1 Piece(s) (MOQ)

Raw materials used in the production of our entire range are sourced from the reliable providers present in the market. Due to this, we guarantee quality products at buyer's end. The packaging procedure is supervised by our experts holding immense domain experience. Moreover, we make use of only quality packing material for ensuring complete safety of the orders during transit.

Jacketed Reactor

450,000 - 625,000 Per Piece

1 Piece (MOQ)

Ribbon Mixer Machine

360,000 Per Unit

1 Unit (MOQ)

High Speed Heater Cooler Mixer

Get Price Quote

1 Piece (MOQ)

In a High speed mixer. the heat generated due to friction is utilised for mixing, hence it's known as "Heater mixer". High speed mixers are used to mix solid to solid. liquid and pasty components. The Heating phase in a heater mixer - It is not only the shortest possible cycle time which is the decisive factor, but in many cases. the way in which iriction is introduced in to the product is ol lar greater importance.Features of High Speed Heater-Cooler Mixer Stainless steel vessel Vessel-highly polished surface inside. discharge plate blended into bottom dish Mixing tools-sell cleaning. adjustable in height specific to the material being mixed. simple design. armoured leading edges Robust. easily serviced and maintained construction Twin jacket Corrosion and abrasion resistance No deposits, crusts or pockets ol colour Fest and complete discharge of the mixed material Easy and perfect cleaning Optimum adaptability to each type and size of mixing batch Optimum dispersion and distribution of components Improved tool life Quick. easy dismantling and reassembling Long service life Low noise level Short maintenance and repair times For heating and cooling purposes Optional Features Optional Features Chopper with separate Programmable logic control Additional device for dispersion. especially for soit mixes Optimum adaptability to the process requirements Constant high quality of the mixed material Application R PVC S PVC Master Batches Anti Fab Master Batches

Ribbon Blender

25,000 - 500,000 Per piece

1 Piece (MOQ)

Stainless Steel Ribbon Blender Mixer

Get Price Quote

1 piece (MOQ)

500 Kg Double Cone Blender

150,000 Per Piece

1 Piece (MOQ)

Mass Mixer

Get Price Quote

We are a well known and trusted manufacturer, exporter and supplier based in Ahmedabad, Gujarat, offering Mass Mixer that is widely used in mixing of dry and wet materials for tablet granulation, powder, chemicals, food materials etc. The unique feature of the Mass Mixer is that they can easily and uniformly mix the sticky and difficult to mix materials too. Get these highly durable, accurate and low maintenance Mass Mixer at affordable prices. Prompt delivery is assured.

Mass Mixer Machine

100,000 - 200,000 Per Nos

1 Nos (MOQ)

Mass mixer machines are used for blending and mixing large quantities of materials, typically in the pharmaceutical, chemical, and food industries. Here’s a brief description: Function: Efficiently mixes bulk powders, granules, or other dry materials to ensure a homogeneous blend. The machine is designed to handle large volumes and achieve consistent mixing results. Operation: Typically features a rotating drum or container that tilts and rotates to mix the materials. The mixing action can vary from simple rotation to more complex agitator or paddle systems, depending on the design. Applications: Used for preparing mixes for tablets, capsules, granules, or other bulk products. It is also employed in industries like chemicals and food for blending ingredients.

Ribbon Blender

380,000 Per Piece

1 Piece(s) (MOQ)

The Mahavir ribbon blender are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. The dimensions and configuration of the ribbons in ribbon blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. The design of the Mahavir ribbon blender can in corporate features required for a customer's product or process such as: wear resistance, corrosive resistance, vacuum filling and discharge arrangements, special shaft seals, heating/cooling jackets. Ribbon blender is available in sizes 100-8000 litters in Stainless Steel 304, Stainless Steel 316 and Mild Steel Construction.

double cone blender machine

Get Price Quote

To mix the dry powder and granules homogeneously, the double cone blender machine is used. It is a versatile and an efficient blender machine used in various industries like pharmaceutical, food, chemical and cosmetic products. The capacity of the double cone blender machine is 10 kgs, 25 kgs, 50 kgs, 100 kgs, 200 kgs, 300 kgs, 500 kgs. HOW TO OPERATE : The wisely design conical shape of the machine is proven better for the uniform mixing and easily discharge. All quality contact parts are made of the S.S. 304 THE SPECIAL FEATURES : Both ends are of conical shaped, ideal for the easy discharge and uniform mixing. All quality contact parts are made of the S.S. 304 On both of the side the two nos. of safety roads are provided The butterfly valves are provided at one end of the cone. It is help in material discharge and other end of the cone for the material charging cleaning. The shaft of 04 nos. of fixed buffers Inside of the cone is mirror polished Outside of the cone is matt polished Safety guards are with limit switch All moving parts and safety guards are of S.S. 304 The panel is of S.S. 304 The panel is provided with D.O.L. tarter, digital timer, Amp meter and three phase indication For the speed reduction, the worm reduction gear is provided. On the both end of the cone, the food grade rubber gasket is given

Double Cone Blender

Get Price Quote

The double cone blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as healthcare, food, chemical, cosmetics, detergents, fertilizers and plastics. Product Description Ideal for Mixing of powder and homogeneous lubrication of granules. Double cone blender is provide safety guard with limit switch interlocked to motor For higher capacity model. Available capacity 5 kg. to 1000 kgs. Automatic loading & unloading facilities provided. All parts made it S.S material is used for ss304 / 316 / 316L. It can be used to pharmaceutical,food,chemical and cosmetic product

ribbon blender screw conveyor

Get Price Quote

Cone Blender

Get Price Quote

All type of Blenders are available for Mixing i.e. Octagonal Shape, V Shape, Double Cone, Cage, Cone & Ribbon Blender in the MOC of Contact Parts S.S.316.

Ribbon Blender

560,000 Per Piece

Heater Cooler Mixer

800,000 Per Piece

Ribbon Blender Mixer

110,000 Per Piece

1 Piece (MOQ)

Mass Mixer

Get Price Quote

Salient Features: All contact parts are made of SS 304 (SS 316 optional) Thrust bearings are provided to carry rigid and thrust load. Easy for cleaning and operating. Interlocked acrylic dust cover for inspecting the mixing process. The tilting device provided for easy unloading of the material. Salient Features:- Mass Mixer - SS 304 Pharmaceutical Mixing Machine All contact parts are made of SS 304 (SS 316 optional) Thrust bearings are provided to carry rigid and thrust load. Easy for cleaning and operating. Interlocked acrylic dust cover for inspecting the mixing process. The tilting device provided for easy unloading of the material.

Double Cone Blender

Get Price Quote

Ribbon Blender

Get Price Quote

Mild Steel Ribbon Blender

50,000 - 500,000 Per piece

1 PIECE (MOQ)

Ribbon blender are used for all dry foods products, nutraceuticals, protein powder mixes, dry juice mixes, chemicals, fertilizer, insecticides, colorants, resins and polymers. The moderate shear of the ribbon or paddle naturally breaks down lumps and agglomerates. Ribbon blenders are extremely efficient and economical.

Double Cone Blender

100,000 - 300,000 Per Piece

1 Piece(s) (MOQ)

Silent Features : The conical shape at both end enables uniform mixing and easy discharge The cone is statically balanced which protects the gear box and motor from any excessive load. Powder is loaded into the cone through a wide opening and discharged through a butterf Depending on the characteristic of the product, paddle type baffles can be provided on the shaft for better mixing, uniform blending and de-agglomeration Flame proof electricals can be provided as optional. Dust free bin charging system ensures minimum material handling.

ribbon blander

Get Price Quote

Where a fine blending or mixing of material, with uniform output is required Ribbon Blenders are the best. The equipment is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 10000 litre. The design of the equipment also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. These blenders are also available with all contact parts of Stainless Steel. Construction : M.S. / M.S. - S.S Coating / S.S / Jacket Ribbon Blender Models Available : MS Blender MS. SS Coating Blender Jacket Blender Till Till Blender Ideal For: Mineral & Others Chemical Technical Products Dyestuffs Pigments Colours Fertilisers Metal Separation Insecticides / Pesticides