Warp Beam Trolley

Manual and motorized beam lifting trolley Manual and automatic beam transportation trolley Battery operated High lift trolley Motorized double beam trolley Manual and automatic cloth roll carriers Cloth roll storage system Completely automatic vertical beam storage system Batching motions

...more

V wrap Creel machine

Sturdy structure arranged in 'V' configuration having two wings with a thirty five degree wing spread. High Tech non contact, Electronic Stop MotionIntegral Air Blowing Device Compensates the yarn tension of the creel and prevent the snarling at the time of machine stoppage. Both creel wings are equipped with yarn cutting assembly. Very suitable for all kind of yarn, from coarser to finest.

...more

Unrolling wrap Creel machine

Poly propylene / HDPE tapes require unrolling of the packages. PWP unrolling creel structure consists of length wise base frame with heavy duty column to support Bobbin peg and tension / brake assembly. Hard anodized aluminum package holder equipped with ball bearing on either side for smooth unwinding operation; as well as built in brake pulley with brake liner. Creel Capacity: Single or double tape execution800 up to 6200 ends (higher on request) Tension Assembly Tension assembly ensures uniform tension on tape during the beaming operation in equilibrium with the spring setting. Tension variation can be off set by application / release of brake shoe on the drum. Apart from individual tension adjustment on respective position, central adjustment by hand wheel per horizontal row is also available. On a machine stop, pneumatic brake applies immediately to stop each package position.

...more

Supertronic Sectional Warping Machine

New innovative separate warping and beaming structure Hydraulic disc brakesPitch control by servo drive Constant warping and beaming speed Lost end memory & auto stop during beaming Digital online display for desired process data Data storage and pattern selection

Country of Origin : India

Type : Sectional Warping Machines

Condition : New

Automatic Grade : Automatic

Warranty : 1year

...more

Single End Sizing Winder

Each module of 4 spindle having individual motor drive. Speed: 45mtr./min. to 350 mtr./min through A. C. variable speed drive. Yarn breakage is detected by non contact type sensor. Sized yarn gets dried on teflon coated double reel without shrinkage. Electrically operated heating system by automatic temperature control through temperature sensors. Two step roller system. Sponge roller assures stabilized starch permeation into yarn. Squeeze roller enables deep permeation to yarn. Cradle type cheese winder suitable for max. dia. of 250 mm. and maximum traverse of 150 mm. Sizing liquid circulation system through A.C. gear motor.Suitable for yarn count up to NelOO's.

...more

Simpletronic Sectional Warping Machine

Extremely robust separate warping and beaming structure Precise traverse movement through AC servo motor and drives Very effective caliper type hydraulic disc brakes on both sides Both side movable beaming structure Constant beaming tension with beam oscillation function Accurate length measuring with lost end memoryHandy remote panel for beaming related parameters Reverse/forward drum rotationPrinter interface to get all desired data Intelligent operational Panel having colour touch screen display for desired process data

...more

sectional warping machines

New innovative separate warping and beaming structure Hydraulic disc brakes Constant warping and beaming speed Lost end memory & auto stop during beaming Digital online display for desired process data Data storage and pattern selection

...more

Robowarp PB9 pneumatic leasing device

Leas insertion by 3 axis Robot No need to cut the section until end of warping Precise and quick yarn separation with optical monitoring Superb Flexibility with highest productivity. Ergonomically designed operation. Optimized yarn use. Perfect Wrap Quality Application of Feeler Roller (guided by Pneumatic closed loop A/c Servo Drive) on reed head-stock for precise, uniform, compact tidy warping. Optical monitoring of the thread separation at the warping reed during automatic insertion of the split cords (which are simply placed in the warping drum as part of the setting-up process) is extended in scope by the optical positional check of the separation slider. Laser-aided feed determination ensures highest warp quality and at the same time offering the possibility to carry out complicated samples by functional way. Cylindrical package build-up and the correct placement of the split cords, ensures perfect warp quality. Hgh tech Leasing Devices Fully automatic, fast and precise, new pneumatic leasing device is not fixed to the floor but is the part of the machine, and is located in the machine superstructure. By separating the thread guidance from the leasing reeds, this device provides the basis for optimized working when changing lots. A laser control allows the perfect separation of yarn during leasing. Leasing comb with eyelet board allows smooth yarn passage with a significant reduction in yarn break. Auto section tension control feature provides correct package built up over the warp width and a constant thread tension over warp length. Option of independent use from both sides of creel by reserve carriage for the 2nd series of combs, allows to prepare the next warp while the machine is working. Leasing combs perfectly designed for quick yarn insertion. Solid Structure The solid structure of machine allows installation in small space. The machine is equipped with strong and functional Cradle type beamer. Beam donning and doffing device are integral part of compact and ergonomic structure. The main data input console and functional buttons for warping and beaming operations are easy to access. Weaver Beams Entire machine operations are controlled by Multi-axis 'SIEMENS' high tech servo drives and motion sensors resulting in the finest quality weaver beams for all kinds of yams.

...more

Poly beamer

Rigid structure with side frames supporting beam carriages Independent Motorized Beam Carriages with heavy duty ball bearing facilitate accommodation of warp beam having different width 3 Roller feeding system consists of Synthetic rubber coated Delivery roller Safe and smooth beam donning / doffing 10" Touch screen display with color graphics provides user friendly controls

...more

narrow fabric needle loom

Prashant texmach is leading manufacturer of complete range of narrow width machinery. Various machinery include Needle loom Needle loom with jacquard Drum warping machine Winding and finishing machine Selvedge warping machine Measuring and winding machine Rubber covering machine Continuous dyeing and finishing for tapes and ribbons

...more

Narrow Fabric Machine

Prashant texmach is leading manufacturer of complete range of narrow width machinery. Various machinery include Needle loom Needle loom with jacquard Drum warping machine Winding and finishing machine Selvedge warping machine Measuring and winding machine Rubber covering machine Continuous dyeing and finishing for tapes and ribbons

...more

Long Chain Beamer ( MRB-7200 )

Low profile height allows easier access to the comb and provides improved observation. Fabricated side cabinets with sealed doors provide a lint free ventilated environment for electronics.Functional operator controls grouped in one control panel improves operator performance. Equipped with frequency controlled AC drive designed for a gear-in speed of 500mpm. Beam drive is direct from the motor to the beam drive spindle by means of a poly-V belt. Movable foot operated START/STOP switch located along the front of the beamer for operator convenience.Three quick-acting pneumatic brakes are provided to prevent broken ends from being wound into the warp beam.Each brake is individually set and controlled for precise adjustment and synchronization.Loading/Unloading of the beam is accomplished by simple operator control which extends and retracts the tail-stock bearing support.Predetermined counter sets the yarn length for each beam and automatically activates an indicator light to signal the operator that a lease string is approaching.Lease string detector automatically stops the machine before a lease string reaches the comb.Comb mounted behind the carrier roll facilitates warp yarn adjustment from side to side and width adjustment.Chromium-plated flattening bar is located behind the comb to support the yarn sheet at the desired height.

...more

Lasertronic Plus Sectional Warping Machine

Robust separate warping and beaming structure. Hightech cradle type Beaming structure. Extremely effective air cooled hydraulic disc brakes. Constant beaming tension with beam oscillation function. Three servo systems for warp table traverse motion, warp table cross motion and machine head stock motion in synchronization with each other. Yarn Built-up through Laser Sensor Kick Back type Feeler Roller for Compact Beam Programmable Leasing Device Section Tension Control Reverse/Forward Drum Rotation

...more

Laser Sensor Extremely robust separate warping machine

Yarn Built-up through Laser Sensor Extremely robust separate warping and beaming structure. Movable beaming structure on both side. Extremely effective air cooled hydraulic disc break. Constant beaming tension with beam oscillation function.Three servo system for warp table traverse motion, warp table crossMotion and machine head stock motion in synchronization with each other.Ball screw for high precision warping. Linear guide for under carriage movement. Kick Back type Feeler Roller for Compact Beam Programmable Leasing Device Section Tension Control Reverse/Forward Drum Rotation

...more

Festooning Machine

International Standard machine, ideally suitable for packing of elastic tape in carton box. Quick setting for different tape width. Electroonic sensor, pre-set digital length counter. The machine is attached with Feeding, Measuring and Detangling Divice.

...more

fabric machine

Needle loom Needle loom with jacquard Drum warping machine Winding and finishing machine Selvedge warping machine Measuring and winding machine Rubber covering machine Continuous dyeing and finishing for tapes and ribbons

...more

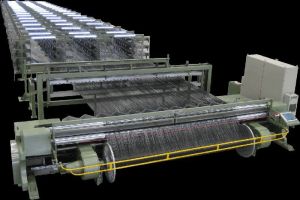

CB warp Creel

A perfect warp can only be produced when the tension of each end is constant irrespective of warping speed, package diameter or type of yarn. We offer highly sophisticated warp creel which is a technological innovation to meet highest standard for preparing PERFECT BEAM which in turn helps improve your weaving efficiency. Creel CB The threads are drawn through the slim tensioner profiles made from galvanized steel for durability and smooth finish. The yarn from package is drawn out through two pairs of discs and three guide eyelets arranged in a straight line for extremely easy and simple threading of the yarn by a hook. Tension is activated by high precision dual acting stainless steel spring element. This positive tensioning device ensures precise and uniform tension control. Motorised centrally controlled tensioners to get equal tension at both sides of the creel. We provide separate PLC on creel, which will interface with main PLC under close loop controls. (Standard with Lasertronic Model) Continuous rotating tensioner by central drive to minimise any fluff accumulation in sideways and ensures uniform tension. Creel CFD Sturdy and modular construction having strong base with tubular supports Self compensating tensioner ensures equal yarn tension irrespective of size of package diameter. The spring element installed in a special oil bath which dampens the surge while drawing yarn. Very precise tension regulation at different speed and at any winding density. At the entry, big disc controls the ballooning of the yarn. Each vertical row of tensioners are centerally adjusted. The movable tensioner frames facilitate, to adjust optimum ballooning distance between package and tensioner. The scale is provided over the hand wheel for equal adjustment on both the sides of creel. Suspended tensioner frames allows to clean the floor space conveniently. Both the side of creel tensioners are adjusted centrally with a push buttons by a Servo Motor for precise setting of equal tension. (Standard with Lasertronic Model)

...more

Beam Trolley

Prashant Ferber is leading supplier of beam trolley, cloth roll storage, automatic beam storage as well as batching motion. Various warp beam trolleys include Manual and motorized beam lifting trolley Manual and automatic beam transportation trolley Battery operated High lift trolley Motorized double beam trolley Manual and automatic cloth roll carriers Cloth roll storage system Completely automatic vertical beam storage system Batching motions

...more

Beam to Cone Winder

Ideal solution of preparing Cheese or Cone from Indigo Dyed Warp beam Suitable for Knit or Shirting Denim Fabrics Leasing zone with stop motion.Rigid and heavy duty structure Monitoring of beam unwinding and package windingAC Servo motors ensuring uniform & regulated winding speed through out the process. Servo System helps for precise synchronizationWaxing device is a standard feature ensuring even distribution of wax7" Touch Screen for monitoring the process and functionality of the machine with fault diagnosis.

...more

Beam To Beam Rolling Machine

Very much ideal for preparing small lots of same pattern fabrics with several colours in warp sheet To enhance the weavers beam quality Reduction in yarn wastage for small lot sizing Increased loom efficiency

...more

Ball Warper

MPI-881 In-Line Creel Accommodates wide range of package sizes. Equipped with various tension devices ranging from post and disc to electronic. Available stop motions include drop wire, motion sensing and optical sensing. Automatic traveling cleaner or lint fans. Transfer magazine, Swing gate, Trolley or Nonmagazine type creel available. MBW-4800 Ball Warper Heavy-duty flame cut steel side frames and cross members. Stainless steel doffing platform eliminates potential damage to the ball. Equipped with frequency controlled AC drive designed for a gear-in speed of 500 MPM. Rubber covered drive/bed rolls minimize yarn damage and ensures silent operation. Light weight trumpet carrier reduces noise and traverse mechanism wear. Aircraft type pneumatic brake used for quick response. Low mass yarn carrier is chain and sprocket driven on dual shafts for reduced vibration and noise. Servo motor and drive used to alter the rope-winding pattern. It facilitates to set the optimum traverse speed and allow for change of the traverse speed. This helps to reduce vibration as the ball warp is built up with increase in diameter. Traverse drive speed has absolute synchronization with drive rolls. Standard air cylinders are used for loading the ball, thus reducing maintenance and simplifying the pneumatic circuit. Ergonomically design of the ball warp hooks simplifies the automated doffing process. All controls enclosed in console for protection from dust and contamination.

...more

Creel Warping Machine

Machine Tool

wrapping machine

Be first to Rate

Rate ThisOpening Hours