hdpe spiral storage tanks

Get Price Quote

Owing to our speedy distribution network, we are capable to render quickly and hassle free deliveries. Our company packs the entire range of products with superior-grade packaging material that is nontoxic and recyclable. Furthermore, the packaging prevents damage and ensures the product is kept safe. Application : Chemical & Process Fertilizers Petrochemicals Pulp & Paper Industries Pharmaceuticals Salt & Marine Food & Beverages Steel Industries Power Plants Water Treatment Plants Details : We Offer Material - HDPE Spiral Storage Tank, Polypropylene Spiral Storage Tank Temperature Range Up to - 25o C to 110o C. Various Type Of Tanks : Vertical Tank Vertical Flat Bottom Tank Vertical Open Top Tank Horizontal Tank Conical Bottom Tank Cone Bottom Tank Tank Capacity - 100 Litre, 250 Litre, 350 Litre, 500 Litre, 750 Litre, 1000 Litre, 1500 Litre, 2000 Litre, 3000 Litre, 3500 Litre, 5000 Litre, 7500 Litre, 10000 Litre, 12000 Litre, 15000 Litre, 18000 Litre, 20000 Litre, 25000 Litre, 30000 Litre, 35000 Litre, 40000 Litre, 45000 Litre, 50000 Litre, 60000 Litre.

Line Reactor

Get Price Quote

Line Reactor or Line choke or Inductor are put on the input or output of the motor control unit known as VFD (Variable Frequncy Drives) which protects VFD and motor from peak current. Line Reactor also reduce di/dt that is known as rate of rise of current. Reactor also helps to reduce the harmonic content in the current waveform. Reactor put on line side (input) is known as line reactor/choke and the reactor put on load side (output) is known as load reactor/choke. Line reactor/choke will reduce the voltage and current stress on the input rectifier of motor controlling unit (Variable Frequency Drive - VFD) which will increase reliability and life of VFD. Load reactor/choke generally used in the condition where too much long cable to connect motor with VFD. It will create parasitic capacitance effect which will harmful for motor and in some cases motor winding burns. In this case load reactor/choke will be a good and reliable solution. On the number of phases Line Reactor and Load Reactor classified in four categories. 1. Single Phase Line Reactor 2. Three Phase Line Reactor 3. Single Phase Load Reactor 4. Three Phase Load Reactor Any Reactor generally selected from motor power rating or current rating, % Impedance, Rated Voltage level. Features: Manufacturing Single Phase line/load reactors for 0.5HP to 7.5 HP VFD/motor or as per customers requirement Manufacturing Three Phase line/load reactors for 0.5HP to 500 HP VFD/motor or as per customers requirement Our reactors are known for quality and noise free operation Vacuum pressure impregnation We also manufacture the line reactor / choke / inductor as per customer requirement.

Best Deals from Pressure Vessels

filling vessels

50,000 - 100,000 Per Piece

1 Piece (MOQ)

stripping tank

Get Price Quote

1 Piece (MOQ)

Stripping tanks suitable to strip Nickel perforated rotary screens in horizontal/vertical way is fabricated from best quality polymer materials to withstand strong stripping chemicals. The whole unit of the tank is based of FRP coated legs. Suitable lid cover is provided for easy opening and closing of the tank. Drain valve is also provided completely assembled. Standard stripping tanks are suitable to strip the screens up to 3.5 mtr Long and 640, 820, 914, 1018, 1450 and 1680 mm repeat also. They can be customised on special request.

hdpe spiral storage tanks

Get Price Quote

We specialize in the production of "SPIRAL" Storage tanks designed for the international market, offering innovative thermoplastic storage solutions crafted through the fabrication of Spiral Pipe. Over the past two decades, our Spiral Tanks have become integral to the industrial sector, particularly in chemical storage applications. Our manufacturing capabilities extend to Spiral Storage tanks with capacities reaching up to 105 KL, constructed from high-density polyethylene (HDPE) and polypropylene (PP). These tanks are engineered to excel in high-temperature environments, demonstrating exceptional performance in a temperature range from -40°C to +100°C. Each tank undergoes meticulous fabrication using state-of-the-art imported welding equipment, ensuring a secure and reliable construction. The robust design of our tanks guarantees resistance to leaks, rust, chipping, or corrosion. They are built to endure extreme service conditions and harsh outdoor weather, offering unparalleled durability for a wide range of industrial applications.

Pressure Vessels

Get Price Quote

The Pressure Vessel, we supply, is reckoned for its safe design and heavy duty performance. These vessels are constructed to carry materials at assorted pressures. The multi-layered walls of the container ensure the much safer storage of the materials. Features: Precision made High pressure handling Industrial application

Chemical Reactor

Get Price Quote

1 Piece(s) (MOQ)

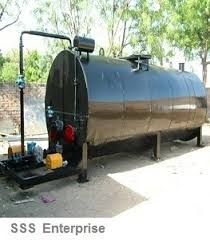

Bitumen Tank

180,000 - 225,000 Per Piece

1 Piece (MOQ)

Dipping Tank

Get Price Quote

We are manufacturer of dipping tank with new "u" profile and new german technology. Dipping tank manufacture according pollution control norms. all type of dipping are possible in this tank.

Low Pressure Air Receiver Tank

Get Price Quote

Syrup Tank

Get Price Quote

We are offering Syrup Tank

Puf Sandwich Panel

Get Price Quote

A renowned Manufacturer of PUF Sandwich Panels, Shreeji Polyfiber also supplies these PUF Sandwich Panels all over the country. Polyurethane foam of the highest quality is used in the manufacturing process of PUF Sandwich Panels which are available at the market leading prices. Warehouses [cold], Refrigerated Truck Bodies, Dairy Industry etc. are some of the applications of PUF Sandwich Panels. Features Compact & Construction friendly Water proof Termite proof Light weight Cost & Energy savings Easy installation Low maintenance Very good thermal insulation properties [-11OoC TO +110oC] Eco friendly (CFC free) Used in Govt. Institutions and departments Civil construction industries Insulation industry Cold storage Heavy duty electrical insulation industries Hospitals Chemical industries Pharmaceutical industries Hotel industries Dairy industry

Stainless Steel Vessel

Get Price Quote

Compliant with the international quality standards, our Vessels are produced using high-grade stainless steel and the latest technology. Therefore, our Stainless Steel Vessels are sturdy, durable, rust resistant and robust. Further, they have high tensile strength. To get the Vessels in Stainless Steel at rock bottom prices, contact us. Located in Ahmedabad, Gujarat, India, we are the top-notch Manufacturer, Exporter and Supplier of Stainless Steel Vessel.

Bitumen Tank

300,000 Per Piece

Polypropylene Chemical Tank

15 Per Litre

1 Piece (MOQ)

Chemical Storage Tank

100,000 Per Piece

02 Piece (MOQ)

Chrome Flush Tank Handle

Get Price Quote

Polo Plastic Flush Tank Handle Made In Premium Plastic Designed for Premium Users, No Compromise In Quality Single Pieces Box Packing

Pressure Vessel

Get Price Quote

Bitumen Storage Tank

280,000 - 300,000 Per Piece

SINGLE CHAMBER EXTRA COOLING SPRAY TANK

Get Price Quote

Single Chamber Extra Cooling spray tank is used for an additional cooling of pipes for higher output pipe extrusion line Standard Features : Tank with Mild Steel construction Mechanical seal spray pump with high head and high flow rate Fixed on jacking screws Appropriate working platform with aluminium chequred plate 1 .5" x 1 nos. Inlet connection Easily cleanable spray nozzles Optional Features : Tank with Stainless Steel construction Precise water level control system with visual manometer Water temperature control with thermostat and solenoid valve All piping Including spray pipe with stainless steel lnsulation on outer side of the tank Pipe support with central height adjustment Dual disc type water filter in spray pumps with 200m mesh (manual back flushing) Glycerine filled pressure gauge on disk type water filter to see blockage of filter

spiral tanks

Get Price Quote

Eminence make Spiral Conveyor is designed with a uniform slope, the Spiral Conveyor insures smooth operation without disturbing the product. A continuously moving table top chain gently elevates or lowers the product. We can Make what you want.

Storage Vessels

95,000 Per Piece

1 Piece(s) (MOQ)

We manufacture Hoppers and Silos of varying sizes as per the storage requirement of the customer. These are used in construction sites, cement and fly-ash storage, agro food industries etc. for Bulk Storage of material and have Vertical orientation for easy discharge of the stored contents. Various bin bottom designs are available, again depending on the flow properties of the material and the desired silo withdrawal method. Single or multiple steel hoppers, flat bottoms and custom mass flow designs can be provided.

Ointment Manufacturing Vessel

225,000 Per Units

1 Piece (MOQ)

HDPE Spiral Tank

10 - 15 Per Piece

1 Piece (MOQ)

Capacity : 0.5 KL to 100 KL Available Diameters : 300 mm to 4000 mm [in mm : 300, 350, 460, 500, 560, 600, 700, 800, 900, 1000, 1200, 1400, 1500, 1600, 1750, 1840, 1900, 2100, 2000, 2200, 2400, 2550, 2700, 3000, 3300, 3600, 4000 ] Length : Upto 6000 mm. even longer on special request. MAX FIBER INDIA, based in Ahmedabad, is a leading manufacturer of HDPE Spiral Tanks with a capacity range of 0.5 KL to 100 KL. These tanks are available in diameters from 300 mm to 4000 mm and lengths up to 6000 mm, with longer sizes available upon request. Supplying across India, the tanks are designed for high durability, corrosion resistance, and chemical storage applications.

Autoclave Stirred Tanks

Get Price Quote

We hold expertise in manufacturing, exporting & supplying Autoclave Stirred Tanks from Gujarat, India. We are equipped with our in-house production unit for fabricating superior quality Autoclave Stirred Tanks. Customers can rely on us for handling small or bulk orders of Autoclave Stirred Tanks and ensuring their delivery within postulated time. Details: A final formulation-cum-blending tank is usually employed during filling of sterile liquid formulations. However, when conventional formulation tanks are used, the shop floor manager is confronted with the following challenges- How do I maintain sterile suspensions in well-mixed condition during the formulation process? How do I transfer the formulation aseptically, into & out of the formulation tank? How do I sterilize the various components of the formulation tank, especially the agitator assembly? Even if all the above operations are possible, will they be easy to carry out? The solution to all the above problems is the range of autoclavable stirred tanks & pressure vessels manufactured by us. The tank is sterilized in an empty condition inside an autoclave large enough to hold the tank. It can be autoclaved in vertical or horizontal orientation, without causing damage to the agitator. After autoclaving, the motor is fitted & the product is aseptically transferred into the tank under stirring. The product can be maintained in this condition during the entire filling process. The impeller is located as low as possible in the tank, so that only a negligible amount of product is left unstirred, & that too at the very last stages of the batch.

Stainless Steel Vessel

Get Price Quote

Our product range includes a wide range of Stainless Steel Vessel such as 1. Pressure Vessel 2. Chemical Vessel 3. Reaction Vessel 4. Pharmaceutical Vessel.

Reaction Vessels

Get Price Quote

We are offering reaction vessels. Reaction vessel is made according to customer’s specific requirements in different sizes, shapes, with without jackets, various types of agitators, with limpet coils. They are designed and fabricated to match the optimum process conditions of temperature and pressure with efficient mixing application. Reaction vessels are widely used in liquid formulation, solid liquid mixing in chemical, food, pharma & paints industries.

High Pressure Vessels

100,000 Per Piece

10 Piece(s) (MOQ)

Pressure Vessel

1 - 200,000 Per

1 Litre (MOQ)

Bitumen Tank

Get Price Quote

We are the main supplier of this product.