Magnetic Destoner machine

125,000 Per piece

1 piece (MOQ)

Are you looking for a one-stop solution for finding a coveted Magnetic destroyer machine manufacturer online? Then you have landed on the right website, our company Royal Magnetics offers the best-quality Magnetic Destoner Machine. Ours is a promising enterprise offering Destoner Machine that aids in removing heavy containment from product line. We produce our superior-quality Destoner Machine is high in demand in industry food industry. Our comprehensive Destoner machine range includes magnetic rice destoner, grains magnetic destoner, magnetic Rawa destoner, etc. Our magnetic destoner machines are available in the automatic and semi-automatic range for our clients. Our product quality and attractive price have won us our client's trust and faith in our company. Based in Gujarat, we are a coveted manufacturer, supplier and exporter of varying industrial products within the country. Our destoner machines are easy to install and maintain adding to lower operation costs for our clientele. The user-friendly operation of our destoner machine has also gained the attention and trust of existing clients. Our Destoner Machine uses advanced technology for efficient containment scraping from our client's intended material. Our product comes equipped with high-intensity magnets to eliminate undesirable items like mud, stones, etc from the product stream. Our machine is designed for prompt cleaning of food items like grains, pulses, etc to ensure higher productivity for our clients. Our machines are designed for easy cleaning of food items with minimum breakage. The high speed and robust construction of the destoner machine have won accolades among our esteemed clientele. We also offer timely delivery of products right at our customer's doorstep within the promised timeframe. Our destoner machines are available in varying capacities to cater to the diverse industrial needs of our clients. Our product cutting-edge technology and commitment to quality have helped gained consideration market share in our industry. For more information about our Destoner machine range and pricing options, get in contact with our representatives today.

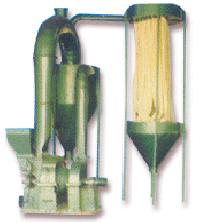

15 HP Double Stage Pulverizer With Motor

102,000 Per Piece

1 Piece (MOQ)

Confider Industries stands as a beacon of excellence in the realm of food processing machinery, offering an extensive array of products tailored for both domestic and commercial applications. With a diverse portfolio comprising over 90 meticulously crafted machines, our company epitomizes innovation, reliability, and superior quality. From humble beginnings, we have grown into a globally recognized brand, catering to the needs of customers worldwide. At the heart of our success lies a relentless commitment to delivering top-notch products that exceed expectations. Every machine manufactured by Confider Industries undergoes rigorous quality control measures, ensuring precision engineering and durability. Whether it's a small-scale operation in a home kitchen or a large-scale industrial setting, our machines are designed to meet the diverse demands of modern food processing. One of the hallmarks of Confider Industries is our unwavering dedication to customer satisfaction. We understand that purchasing a food processing machine is an investment, and thus, we go above and beyond to provide unparalleled after-sales support. Our team of experts is readily available to assist customers through calls and video calls, offering guidance, troubleshooting, and technical assistance whenever needed. We believe in building long-lasting relationships with our customers, and our commitment to after-sales service reflects this ethos. Furthermore, Confider Industries takes pride in its global reach. With an extensive network of distributors and partners, our machines are delivered to customers across continents. Whether it's a bustling city in Asia, a remote village in Africa, or a thriving metropolis in Europe, our products have found their way into kitchens and food processing facilities worldwide. This global presence underscores our reputation as a trusted provider of food processing solutions on a global scale. Innovation is at the core of everything we do at Confider Industries. We continuously invest in research and development to stay ahead of market trends and technological advancements. Our team of engineers and designers work tirelessly to develop cutting-edge solutions that streamline processes, enhance efficiency, and elevate the overall user experience. From state-of-the-art automation technologies to eco-friendly designs, we strive to push the boundaries of innovation in the food processing industry. Sustainability is also a key focus for Confider Industries. We recognize our responsibility to minimize our environmental footprint and embrace sustainable practices throughout our operations. From sourcing materials responsibly to optimizing energy efficiency in our manufacturing processes, we are committed to fostering a more sustainable future for generations to come. In conclusion, Confider Industries stands as a beacon of excellence in the food processing industry, offering a diverse range of high-quality machines for domestic and commercial use. With over 90 machines in our portfolio, a global presence, and a steadfast commitment to customer satisfaction, we continue to set the standard for innovation, reliability, and excellence in food processing.

Best Deals from Processing Plant

Milk Pump(Fabricated Pump)

3,500 - 22,931 Per piece

5 Piece (MOQ)

Vibrating Sieve

Get Price Quote

1 Piece (MOQ)

Peanut Shelling Machine

Get Price Quote

Features : Peanut sheller machine is the ability to replace manual modern machinery and equipment, and is the great help to the brand masses of farmers. The capacity of peanut sheller in an hour is 300-400Kg Peanut sheller machine can separate the seed and husk cleanly. When shell the peanut/groundnut, what we get is seed. They can be as seed to sow directly. The most important is that peanut/groundnut can not be damaged. The peanut sheller machine is a best choice for farmers. This kind of peanut sheller machine has been wildly used.

belt color sorter

Get Price Quote

Founded in 2004 at Ahmedabad, APS Industries are leading and renowned company dedicatedly engaged in manufacturing and supplying admirable quality of Belt Color sorter to the consumers at budget-friendly rates. We are offering a variety of creative and innovative belt color sorter making us a leading Belt Color Sorter Suppliers. Our products are manufactured using ultra-modern machines ensuring hassle-free performance at reasonable prices. We have a team of highly skilled professionals who are using the latest technology to ensure that products are manufactured and supplied as per desired quality standards. We have gained a huge client base due to our products and are known as an excellent belt color sorter manufacturer. Our products run automatically and have a warranty of 5 years with a capacity of 100kg/hr.

Butter Milk Pouch Packing Machine

Get Price Quote

We offered automatic buttermilk pouch packing machine. automatic buttermilk pouch packing machine is widely used in dairy industries. automatic buttermilk pouch packing machine is very compact and easy to operate. automatic buttermilk pouch packing machine is working on gravimetric timer base filling system, which system give us very accuracy filling and less spoile of pouch. Product details : Driven Type Electric Capacity (pouch per hour) : 1200 / 2200 (High Speed) Pouch Capacity : 200 Ml to 1 Liter Machine Power 0-1 HP Specifications : Brand: packtech Power Consumption: 1/2h.p. Machine Type: automatic

vibro sieve

120,000 - 250,000 Per Piece(s)

1 Piece(s) (MOQ)

Mahaveer Vibro screen (MVS) we are manufacturer of Vibro screen machine (gyro screen) last 15 years of existence. Manufacturer, trader and exporter

Double Stage Pulverizer Machine

11,200 Per Piece

1 Piece (MOQ)

Peanut Butter Machine

Get Price Quote

AP Industries are one of most reliable manufacturer & supplier of Peanut butter machine in India. Our industries are also inducing Automatic Double Grindering System for smallest maicron peanut butter in Peanut Butter machine India. We are able to manufacture, supply and export superior quality Peanut Butter Machine. We are offered machine Which especially designed by a team of highly skilled & experienced professionals using optimum quality raw material sourced from reliable market vendors. We are attaching Double grindering system in this machine so create paste easy and fast in machine. Some industry likes hotels ,restaurant, carters ,food process industry which are regular use fresh peanut Butter every day are more useful machine . peanut Butter machine is work fast so save labor cost and time in industries. Peanut Butter machine for operating must be use Grindering Blade and power. Machine design is compact size so customer is easy adjusting in processing area. AP Industries are manufacturing machine different capacity of Peanut Butter Machine.

vibro sieve

Get Price Quote

Bhalani Industries manufacturer of Vibro Sieve. Vibro Sieve is Vibratory or Gyratory Sieving Machine designed on the principle of gyratory motion generated by vibro motor. For the purpose of maintaining the quality of powders and liquids, the use of Vibro Sieve has gone mainstream. They are also known as Vibro Screen, Gyro Screen, Vibating Screen, vibrating sifters, vibro sieves or control sieves and are incredibly well suited for size-based operation of multiple material.

vibro sieve

175,000 Per Piece

Cashew Electrical Oven Dryer

55,000 Per Piece

Namak Para Making Machine

120,000 Per Piece

1 Piece (MOQ)

Magnetic Destoner

Get Price Quote

Working PrincipleIn Magnetic Destoner separator, a short conveyor belt envelopes the magnetic roll and a tensioning ideal roll. A suitable feeder discharges materials on the belt. The ferromagnetic and paramagnetic particles adhere to the belt while the nonmagnetic particles flow freely off at the end of the conveyor.Features Magnetic Rolls available in 75(3 inches) & 100mm(4 inches), 150mm(6 inches) , 200mm (8 inches), 240mm(9.5inches) diameter. & widths up to 2000mm. A 0.5 HP, variable speed DC/AC geared motor drive adjustable from 0 to 280 RPM drives the roll. Vibratory feeder provided with high quality unbalanced vibratory motors. Abrasion resistant endless conveyor Belts with a thickness of 0.35mm is provided for the Machine. Salient Features Vibratory Feeder with controls provided for Feeding. The high efficiency of the iron separation system. Abrasion resistant endless conveyor belt with a thickness of 0.35mm is provided for the Machine. Multi-stage system up to 6 stages is available. Different Magnetic Strengths are available: 8,000 Gauss 10,000 to 11,000 Gauss Magnetic Destoner is used for Cleaning and Processing for various types of Grains Rice Cleaning Wheat Cleaning Corn Cleaning Pulses Cleaning Spices Cleaning Seed Cleaning Semolina Cleaning Chilli Flakes Sesame Cleaning Cumin Cleaning Fennel Seed Cleaning Magnetic Destoner is also used for various applications below After Gravity Separations At discharge of Bucket Elevators At first break in Flour Mill It is installed in Buhler Flour Mill For cleaning live Discharge of all cleaning machines In auto cleaning machines ApplicationsOur Magnetic Destoner machines are mostly used in various industries like minerals applications such as abrasive, refractory and ceramic raw material beneficiation, alumina, silica, carbide, magnesite, quartzite, etc. Glass raw materials cleaning silica and quartz, feldspar, dolomite, etc.Ultra high purity quartz cleaning, graphite upgrading, manganese ore beneficiation, bauxite upgrading, diamond ore beneficiation, selective separation of garnet/ilmenite/rutile, zircon, beneficiation of iron ore, recovery of metals from slag, removal of ferrous silicates from limestone, magnesite etc.Also, our magnetic destoners are also used for food processing industries which can remove mud balls from wheat, rice, sesame, semolina, cumin, fennel, chilly flakes and many other food products.Testing FacilitiesLive working of a machine will be demonstrated at our workplace. A small sample of around 5-10 Kgs. of material can be tested free of cost and performance of our machine can be demonstrated.

Masala Mixture Machine

190,000 - 200,000 Per 100kg

We are manufacturer masala mixture machin ..its use for ( chemical mixting/ powder mixting/ masala mixting) SHREE HARI ENGINEERING WORKS WHATSAPP:- 6351510076

Cashew Nut Peeling Machine

Get Price Quote

Cashew Peeling Machine,Which is used To Remove the Outer skin of Cashew Kernels.An ISO 9001-2008 Certified APS Industries is One of the Manufacturing Of Cashew Nut Peeling Machine With Up To 97% Accuracy or Up To 2% Breaking Ratio of Kernels. Capacity - 40/80/120 Kg Per Hour Power - 4KV Three Phase low Breaking Cost of Kernals High Production Rate computerized Controlling System.

Cashew Nut Cutting Machine

85,000 Per Piece

soft drink processing plant

Get Price Quote

Soft drink processing plant Mineral water plant process the normal water from natural source or from the municipality etc. and convert it to Pure Mineral water which is now a days very much popular among the health conscious people all around the world.

sheller machine

Get Price Quote

Flour, Maize, Beans, Herbs, Cereals, Non- abrasive, All types of cereals, Herbs Pulses, Grains, Tobacco, Dry Chemicals, Herbs, Cereals, Non- abrasive Material etc. Highest feature results with regard both to quantity and quality. Very low Power consumption because of the Emery Stones runs with double roller bearings.

Gyratory Sieving Machine

Get Price Quote

Vibromatic Industries Vibro screen (gyro screen) is Vibratory or Gyratory Sieving Machine designed on the principle of gyratory motion generated by vibro motor. Gyratory motion is the most effective method for screening. Vibro screen are driven by vertically mounted vibratory motor having eccentric weight at the top & bottom end of the shaft. At the time of Motor rotation top weight causes vibration in Horizontal plane whereas the rotation of bottom weight causes tilt & vibrations in vertical plane. By changing their lead angle, various spiral-screening patterns are obtained to suit different application. "VIBROMATIC" vibro screen provides optimum screening & assures maximum feed-rate & efficiency. Vibro screen is also known as gyro screen, vibrating screen, vibro sifter, vibro grader, rotary screen, etc... APPLICATION Vibromatic Vibro screen Use in solid-solid, solid-liquid separation in different type of industries. Food Industry Oil Industries Pharmaceuticals Bulk Foods Minerals Plastics Paper Others Agro Products Chemical Industry Metal Powder Refractory Ceramics Spices Sugar SALIENT FEATURE Increased accuracy and material control – Full material flow on up to 4 sieve decks Higher screening capacities – up to 50% more compared to a conventional vibro separator Improved cleanability – Hygienic open frame design providing improved cleaning

Cashew Nut Peeling Machine

Get Price Quote

we are manufacturer of all type of food processing machinery with good quality or good product. cashew nut peeling machine capacity-30/50/100 kg per hour power consumption 3 phase

Vibro Sifter Machine

40,000 Per Piece

1 Piece (MOQ)

kandap machine

Get Price Quote

On off device to control functions of the striking bars provided.Machine remains operational even when the striking bars are stand still.A special device to tighten V belts.Chilly, Shikakai, Turmeric, Supari, Ayurvedic Herbals and others alike materials could be ground on the machine.The taste of the materials after being ground on this machine remain in tact.

Pressure Gauge

2,450 Per Piece

1 Piece (MOQ)

Cashew Dryer Machine

55,000 Per Piece

1 Piece (MOQ)

Cattle Feed Machine

45,000 Per Piece

Impact Pulverizer

Get Price Quote

We are offering impact pulverizer. An extra heavily constructed machine designed to pulverize even rocks & minerals of medium hardness. Fineness ranging between 100 mesh to 300 mesh (150 to 50 microns) and in some cases upto 500 mesh.

Sieving Machine

Get Price Quote

SingleDouble Deck Vibrating Screening Machines are designed for screening of powders. These machines are simple and robust in construction.Available in Screen size of 1500 x 600mm,1800mm x 800mm, 2500mm x 800mm. Special sizes as per customer specifications are also manufactured.

Milking Machine

35,000 Per Piece