PTFE O-Rings

Get Price Quote

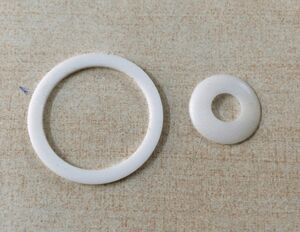

PTFE O-Ring is a mechanical product that is used as a joint that helps the machine work without any external disturbances. We manufacture these by different process of extrusion, moulding, etc. We supply and export these Rings In different inches and metric sizes. These are used in mechanised machines that fill the purpose of managing stress in the product and how this stress is to be applied on the machine. The company also makes available well-designed PTFE O-Rings. The range of PTFE O-Rings made available by the company is manufactured using quality materials and is hence, low on maintenance requirements. We offer PTFE O-Rings at the best prices in the market.Range : Manufacturing s per customer's specifications and drawings up to 1500 MM Dia. Available Grades Virgin PTFE 15% Peek PTFE 15 To 25% Glass Filled PTFE 25 To 35% Carbon Filled PTFE 15% Graphite Filled PTFE 40 to 60% Bronzed Filled PTFE 55% + 5% Bronzed + Molybdnum Disulphide Filled PTFE 15% + 5% Glass + MOS2 Filled PTFE

Ptfe O Ring

20 Per

Best Deals from PTFE O Rings

PTFE Ring

1 - 12 Per piece

500 piece (MOQ)

We are manufacturing wide range of ptfe rings, ptfe washer and ptfe gaskets. These products widly uses in valves industries, chemical industries, pharma industries and machine industries. These products are made in guidance of expert persons with high accurancy. Size Different size are available as per clints requirement. ( Up to 200mm OD) Materials Virgin and Filled like 25% Carbon, 25% Glass, etc.

Teflon O-Rings

Get Price Quote

We manufacture Teflon O-Rings which are used in Spray Drying Nozzle Body to prevent leakage of liquid from Nozzle Body. ADVANTAGES Improves life of Nozzle Body by preventing leakage of liquid

Teflon Rings

90 Per Piece

Ptfe O Ring

800 Per Kilogram

TEFLON PTFE O RING

Get Price Quote

For axial static face or flange-type applications. Resistant to practically all chemicals and to high temperatures.

Ptfe O Ring

Get Price Quote

PTFE O RING Still have questions about finding a standard or non-standard o-ring size? Feel free to either contact us with your questions or use our online o-ring size search. Easy to Order, Fastest Delivery When you are ready to get started, submit an online RFQ to receive a quote from our dedicated sales team within 24 hours. Most likely the size and compound you require is in our inventory of over 300 Million o-rings. You receive immediate shipments with no intermediate delays. Remember: With Apple Rubber, you buy direct. Standard O-Ring Material Applications We offer the following six (6) standard rubber materials in a range of durometer (Shore A) hardnesses to satisfy practically any service condition: Viton® / FKM: Fluorocarbon (Viton®) exhibits exceptional resistance to chemicals, oils, temperature extremes (-13°F to +446°F), low compression set, low gas permeability and excellent aging characteristics. Applications include: aircraft engines, automotive fuel handling systems, and chemical processing industries. FKM is also suitable for high vacuum applications. It is not recommended for exposure to ketones, alkalis, and Skydrol®fluids Custom compounds are available with improved chemical and low temperature resistance. Nitrile / NBR: Nitrile (Buna-N) is the most widely used elastomer due to its excellent resistance to petroleum products, operating temperature range (-40°F to +257°F) and one of the best performance-to-cost values. It's an ideal material for aerospace, automotive, propane and natural gas applications. Special Hydrogenated Nitrile (HNBR) compounds can improve resistance to direct ozone, sunlight, and weather exposure while increasing temperature range to +300°F. Ethylene-Propylene / EPDM: EPDM has outstanding resistance to heat, water and steam, alkali, mild acidic and oxygenated solvents, ozone, and sunlight (-40ºF to +275ºF); but it is not recommended for gasoline, petroleum oil and grease, and hydrocarbon environments. This popular rubber compound is usually the first choice for low torque drive belt applications. Fluorosilicone / FVMQ: Fluorosilicone (-75º to +400ºF) combines the good high and low temperature stability of silicones with the fuel, oil, and solvent resistance of fluorocarbons. FVMQ is unparalleled for aerospace fuel systems, auto fuel emission control systems and to meet or exceed government, military, aerospace, automotive, industrial and commercial specifications. However, due to relatively low tear strength, high friction and limited abrasion resistance of these materials, they are generally not used in dynamic applications. They are also not recommended for exposure to brake fluids, hydrazine, or ketones. Silicone / VMQ: In the Silicone family, you will find compounds which are superior as static seals in extreme temperature conditions. Standard compounds handle operating temperatures -85º to +400ºF. Silicone compounds are popular in food and medical applications because they are very clean and do not impart odor or taste. Special Phenyl silicones can be used down to -148°F. Neoprene® / CR: Neoprene (-40º to +250ºF) is reasonably priced and features good resistance to petroleum oils, ozone, sunlight and oxygen aging, relatively low compression set, good resilience and outstanding physical toughness. It is the preferred sealing material for the refrigeration industry because of its resistance to ammonia and Freon®. Let us know if you require materials to meet the following standards; UL, MIL, AMS, ASTM, FDA 21 CFR 177.2600, USP Class VI, or ISO 10993. We have many special compounds that can meet the specification you are looking for. Need help choosing an o-ring material? Try our new, Interactive Material Selection Guide. For assistance with o-ring size or material selection, contact us today.

Ptfe O Ring

Get Price Quote

Still have questions about finding a standard or non-standard o-ring size? Feel free to either contact us with your questions or use our online o-ring size search. Easy to Order, Fastest Delivery When you are ready to get started, submit an online RFQ to receive a quote from our dedicated sales team within 24 hours. Most likely the size and compound you require is in our inventory of over 300 Million o-rings. You receive immediate shipments with no intermediate delays. Remember: With Apple Rubber, you buy direct. Standard O-Ring Material Applications We offer the following six (6) standard rubber materials in a range of durometer (Shore A) hardnesses to satisfy practically any service condition: Viton® / FKM: Fluorocarbon (Viton®) exhibits exceptional resistance to chemicals, oils, temperature extremes (-13°F to +446°F), low compression set, low gas permeability and excellent aging characteristics. Applications include: aircraft engines, automotive fuel handling systems, and chemical processing industries. FKM is also suitable for high vacuum applications. It is not recommended for exposure to ketones, alkalis, and Skydrol®fluids Custom compounds are available with improved chemical and low temperature resistance. Nitrile / NBR: Nitrile (Buna-N) is the most widely used elastomer due to its excellent resistance to petroleum products, operating temperature range (-40°F to +257°F) and one of the best performance-to-cost values. It's an ideal material for aerospace, automotive, propane and natural gas applications. Special Hydrogenated Nitrile (HNBR) compounds can improve resistance to direct ozone, sunlight, and weather exposure while increasing temperature range to +300°F. Ethylene-Propylene / EPDM: EPDM has outstanding resistance to heat, water and steam, alkali, mild acidic and oxygenated solvents, ozone, and sunlight (-40ºF to +275ºF); but it is not recommended for gasoline, petroleum oil and grease, and hydrocarbon environments. This popular rubber compound is usually the first choice for low torque drive belt applications. Fluorosilicone / FVMQ: Fluorosilicone (-75º to +400ºF) combines the good high and low temperature stability of silicones with the fuel, oil, and solvent resistance of fluorocarbons. FVMQ is unparalleled for aerospace fuel systems, auto fuel emission control systems and to meet or exceed government, military, aerospace, automotive, industrial and commercial specifications. However, due to relatively low tear strength, high friction and limited abrasion resistance of these materials, they are generally not used in dynamic applications. They are also not recommended for exposure to brake fluids, hydrazine, or ketones. Silicone / VMQ: In the Silicone family, you will find compounds which are superior as static seals in extreme temperature conditions. Standard compounds handle operating temperatures -85º to +400ºF. Silicone compounds are popular in food and medical applications because they are very clean and do not impart odor or taste. Special Phenyl silicones can be used down to -148°F. Neoprene® / CR: Neoprene (-40º to +250ºF) is reasonably priced and features good resistance to petroleum oils, ozone, sunlight and oxygen aging, relatively low compression set, good resilience and outstanding physical toughness. It is the preferred sealing material for the refrigeration industry because of its resistance to ammonia and Freon®. Let us know if you require materials to meet the following standards; UL, MIL, AMS, ASTM, FDA 21 CFR 177.2600, USP Class VI, or ISO 10993. We have many special compounds that can meet the specification you are looking for. Need help choosing an o-ring material? Try our new, Interactive Material Selection Guide. For assistance with o-ring size or material selection, contact us today.

Ptfe O Rings

Get Price Quote

Ptfe O Rings, gasket bush, ptfe oil seals, Rubber Parts, V Rings, v seal

Ptfe O Rings

Get Price Quote

Ptfe O Rings, Water Cool Condenser, Wirtgen Track Pad, Submersible Bearings

Ptfe O Rings

Get Price Quote

Ptfe O Rings, Ptfe Products, teflon washers, PTFE Washers