Permanent Magnetic Pulley

40,000 Per Piece

1 Piece (MOQ)

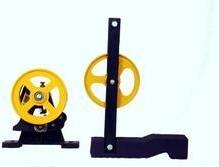

Top MRL Governor Pulley

Get Price Quote

For the utmost customer satisfaction, we are flexible in delivering the product range at the place agreed by the customers and that too in the set time. With the assistance of our packaging experts and advanced machines, we became capable of meeting the standard as well as customized packaging requirements of the clients.

Best Deals from Pulleys

diverter pulley

2,800 Per piece

1 Piece (MOQ)

diverter pulley

Magnetic Pulley

Get Price Quote

Our well-structured warehouse is properly maintained and equipped with modern amenities, thus assist us wholly in meeting bulk requirements of the customers. The packaging commences under the strict supervision of experts and other team members; they ensure that the products are packed sternly to circumvent loss during transit.

Timing Pulleys

Get Price Quote

Offers timing pulleys, v-belt pulley: these are manufactured from c.i. Upto 60", with or without taper lock bushes, statiscal and dynamic balancing is done aganist request. Available ex-stock in a, b, c & d sections.

Timing Belt Pulley

Get Price Quote

1 Piece(s) (MOQ)

Magnetic Pulley

Get Price Quote

Buy the best quality Magnetic Pulley that is the perfect outcome of the best practices and the innovative techniques. Working in close coordination with the genuine logisticians, we dispatch the products in the dedicated time.

Magnetic Head Pulley

Get Price Quote

Salient Features Bored and Keyed Hubs Maintenance Free

V Belt Pulley

Get Price Quote

We are offering v belt pulley.muratech engineering company is leading manufacturer of all types of timing pulley, poly 'v' pulley, flat belt pulley, v belt pulley. Precision v belt pulley (fenner type) : as per iso din bsw standards in a,b,c,d,e section with 1 to 20 grooves up to 80" (2000 mm) dia. With tlp without tlp. Mail: muracopower@hotmail.com info@muracopower.co.in visit: www.muracopower.co.in calls: 09825348476 09586823032

TOYOTA DOUBLE GRROVE PULLEY

400 - 600 Per piece

20 Piece (MOQ)

toyota double groove pulley is used in toyota airjet looms. i have full range of pulleys available.

magnetic drum pulley

Get Price Quote

With rich experience of this domain, we have established ourselves as a prominent manufacturer and supplier of Magnetic Drum Pulley. Widely used in ceramic and chemical industries, our offered magnetic tool is developed by experienced professionals using optimum grade raw material. In addition to this, we also customize this magnetic pulley in different sizes as per specific demand of the customers. Our offered Magnetic Drum Pulley is widely acknowledged and demanded in the markets owing to its reliable operation and optimum functionality. Features: Easy to fit Robust construction Resistant to corrosion

V Belt Pulley

Get Price Quote

We are offering v belt pulley. it was estabilised in 1982. We started this company to give high quality product and better service to customer. After that mayur industries understood that the raw-material for the machine is an important factor to improve the life of the machine.

Groove Pulley

Get Price Quote

We are known as foremost manufacturer, exporter and suppliers of supreme quality Split Type Groove Pulley that is made available in various customizations and control mechanisms. This groove pulley is developed with utmost excellence; the offered groove pulley is extensively demanded among various industries for its design quality. The groove pulley is properly inspected for its performance quality by our quality experts. Our honored customers can take this groove pulley in bulk quality within a given time frame.

Parmenent Magnetic Pulley

Get Price Quote

“KUMAR” manufacture a wide range of Rare Earth and Ferrite Magnetic Pulleys. These Pulleys are widely used to remove tramp iron mixed with the material moving on a conveyor belt. The permanent magnetic pulley is dual-purpose equipment used for protection of crusher Jaws or other machinery and also for purification and concentration of magnetic material from the mines. It has the widest application in food, chemical, ceramic, paper, coal handling, foundry operation and mining industry. The magnetism in a Permanent Magnetic Pulley is generated by internal assembly of magnets enclosed in non magnetic Stainless Steel shell. The steel shaft is extended on both sides. One side is provided with Key-way. The Pulleys have a face width of 50 mm to 100 mm more than the belt width. The magnetic strength of the pulley depends on the diameter and also quality of magnets used. Pulleys with Rare Earth Magnets can handle depths up to 300 mm. Pulley width is determined by width of conveyor belt to be used. Diameter depends on depth of material and speed of the conveyor. It can be designed to suit customer’s specific application.The magnetic Drum pulley replaces the drive pulley at the end of conveyor belts. In view of the wide variety of conveyor belt types, the drum pulley are supplied made to measure and ready for installation. As the figure clearly show, the magnetic head roller extracts the iron particles from the material flow and carries them to the underside of the belt where they are removed and collected. Head roller magnets for conveyor belt are supplied in permanent magnets.Features:(1) 304 stainless steel faces.(2) Removable mild steel shaft.(3) Four hub styles.(4) Flat face.(5) Keyway and set screws. Options:(1) Taper locks(2) Crowned face(3) Fixed shaft(4) Lagging(5) Stainless steel shaft

v belts pulley

Get Price Quote

We are the prominent manufacturer and supplier of a broad range of V Belt Pulley that finds its wide uses in construction and logistics industries. We are involved in offering a quality assured range of belt pulley that is precisely designed under the supervision of qualified professionals. Furthermore, offered belt pulley is manufactured using quality assured raw material which is procured from trusted vendors. Our esteemed clients can avail this pulley from us in various dimensions at market-leading prices. SALIENT FEATURES : Excellent flexibility Impact resistance Excellent cover-to-ply adhesion Maximum load support Suitable for mechanical fasteners Very low permanent elongation Suitable for all types of cover grades

Magnetic Pulleys

Get Price Quote

We are offering magnetic pulleys have following features: 1. The magnetic pulleys can be installed easily at conveyor discharge. 2. they give complete magnetic protection over the entire face of the pulley for removing ferrous contaminants. 3. for different conveyors the magnetic pulleys of different sizes are available. 4. the pulleys either use ceramic magnets or powerful rare earth magnets.

magnetic drum pulley

Get Price Quote

The magnetic Drum pulley replaces the drive pulley at the end of conveyor belts. In view of the wide variety of conveyor belt types, the drum pulley are supplied made to measure and ready for installation. As the figure clearly show, the magnetic head roller extracts the iron particles from the material flow and carries them to the underside of the belt where they are removed and collected. Head roller magnets for conveyor belt are supplied in permanent magnets.

Rare Earth Magnetic Drum Pulley

Get Price Quote

we are offering Rare Earth Magnetic Drum Pulley. The magnetic Drum pulley replaces the drive pulley at the end of conveyor belts. In view of the wide variety of conveyor belt types, the drum pulley are supplied made to measure and ready for installation.

Magnetic Pulley

Get Price Quote

Manufacture a wide range of Rare Earth and Ferrite Magnetic Pulleys. These Pulleys are widely used to remove tramp iron mixed with the material moving on a conveyor belt. The permanent magnetic pulley is dual-purpose equipment used for protection of crusher Jaws or other machinery and also for purification and concentration of magnetic material from the mines. It has the widest application in food, chemical, ceramic, paper, coal handling, foundry operation and mining industry.

Magnetic Pulley

Get Price Quote

Head Pulley Magnets provide continuous self cleaning on products conveyed by belt. As product is conveyed along the belt it reaches the head pulley and enters the magnetic field where metal contaminants are attracted and held tightly to the belt surface. As the belt is conveyed around the magnetic pulley, metal contaminants are held in place until they pass through the magnetic field where they are safely discarded separate from the clean product. A diverter is typically installed below the pulley to direct the metal contaminants away from the cleaned product. Construction : 304 stainless steel face Bored and keyed hubs Permanent ceramic magnet material All welded rugged construction Keyed shafts Axial or radial pole magnetic circuit. Features : Available with or without shaft Several hub styles Lagged face Crowned face Taper lock hubs Stainless steel shafts High energy rare earth magnet material Custom sizes available Polarity options.

permanent magnetic drum pulley

Get Price Quote

The magnetic Drum pulley replaces the drive pulley at the end of conveyor belts. In view of the wide variety of conveyor belt types, the drum pulley are supplied made to measure and ready for installation. As the figure clearly show, the magnetic head roller extracts the iron particles from the material flow and carries them to the underside of the belt where they are removed and collected. Head roller magnets for conveyor belt are supplied in permanent magnets. The version with permanent magnets are fitted with powerful and An-Isotropic Hard ferrite Magnets /high intensity Rare Earth Nd-Fe-B Magnets and operate without the need for power supplies. The magnet system is available in two types: with Longitudinal polar field distribution for use with low levels of iron contamination and thin material layers, and with lateral polar field distribution for greater material thickness and larger iron particles.

Magnetic Pulley

Get Price Quote

Head Pulley Magnets provide continuous self cleaning on products conveyed by belt. As product is conveyed along the belt it reaches the head pulley and enters the magnetic field where metal contaminants are attracted and held tightly to the belt surface. As the belt is conveyed around the magnetic pulley, metal contaminants are held in place until they pass through the magnetic field where they are safely discarded separate from the clean product. A diverter is typically installed below the pulley to direct the metal contaminants away from the cleaned product. Construction : 304 stainless steel face Bored and keyed hubs Permanent ceramic magnet material All welded rugged construction Keyed shafts Axial or radial pole magnetic circuit. Features : Available with or without shaft Several hub styles Lagged face Crowned face Taper lock hubs Stainless steel shafts High energy rare earth magnet material Custom sizes available Polarity options

Conveyor Pulley

Get Price Quote

We manufacture a wide range of Conveyor Pulleys with laining which are used for hassle-free conveyor operations. Our range caters to the needs of various industries, and is known for its high quality and cost effectiveness. We fabricate these pulleys keeping into view the accurate dimension and excellent durability. We also have competence to offer them as per the demands of our industrial clients.

permanent magnetic drum pulley

Get Price Quote

The magnetic Drum pulley replaces the drive pulley at the end of conveyor belts. In view of the wide variety of conveyor belt types, the drum pulley are supplied made to measure and ready for installation. As the figure clearly show, the magnetic head roller extracts the iron particles from the material flow and carries them to the underside of the belt where they are removed and collected. Head roller magnets for conveyor belt are supplied in permanent magnets. The version with permanent magnets are fitted with powerful and An-Isotropic Hard ferrite Magnets /high intensity Rare Earth Nd-Fe-B Magnets and operate without the need for power supplies. The magnet system is available in two types: with Longitudinal polar field distribution for use with low levels of iron contamination and thin material layers, and with lateral polar field distribution for greater material thickness and larger iron particles.

Deflection Pulleys

Get Price Quote

We are the renowned manufacturer of premium quality Defecting Pulley. This pulley is designed using finest quality material and sophisticated technology in compliance to set industrial norms. It is used in various mechanical devices and machines to reduce tension and friction. We offer this pulley in various specification and deliver within promised time frame. Clients can avail this pulley from us as per their requisites. Specifications: Category: HDN 64UA-0010 Features: Low maintenance Easy to install Smooth functioning

elevator pulley

Get Price Quote

We are into manufacturing and supplying a complete range of Elevator Pulley. Supported by heavy concrete beams, these machines are hold extensive vibration dumping properties. These products are manufactured using high-grade raw material procured from the reliable vendors of the market in accordance to international quality standards. Owing to excellent quality, high tensile strength, longer service life, these products are widely acclaimed by the customers.Features: Durability Accurate dimensions Seamless finish Low maintenance

shaft pulley

160 Per Piece

100 Piece (MOQ)

Split Pulley

Get Price Quote

We are known as foremost manufacturer, exporter and suppliers of supreme quality Split Type Groove Pulley that is made available in various customizations and control mechanisms. This groove pulley is developed with utmost excellence; the offered groove pulley is extensively demanded among various industries for its design quality. The groove pulley is properly inspected for its performance quality by our quality experts. Our honored customers can take this groove pulley in bulk quality within a given time frame.

Drum Pulleys

Get Price Quote

OGI offers Drum Pulleys using a minimum 1/2" rim, 1-1/4" end discs, and 1/2" center discs, as well as an additional center disc. Each Quarry Duty Drum Pulley features a two piece rolled rim, which has been fabricated on either of our flat or custom crowned roll machines. The rims are trimmed and hydraulically seated around the heavy end discs to ensure maximum concentricity. Once the pulley is formed, OGI utilizes a double or triple pass submerged arc weldment to ensure optimum connection of its individual components. Features •12" to 60" diameter •1/2" thru 1" Rims •1 1/4" and Heavier End Discs •1/2" Center Plates •Full Depth Hub/Bushings •Double Sub-Arc Weldments •Several Hub/Bushing System Available

Timing Belt Pulley

50 Per Piece

10 Piece(s) (MOQ)

Complete range of Transmission belt pulleys that meet highest quality standards. It includes Classical, HTD, Metric in various sizes, with or without taper/keyless bushings with different width diameter, materials, torque, shapes & drives for almost all kinds of machineries. Details : Model - TNC 770 x 4000 (Heay Duty Lathe) Specifications - 500mm Diameter x 4000mm Length Model - DX 200, Jyoti Make Specifications - 200mm Diameter x 500mm Length Model - ZFWZ – WMW Make Model - F06, TOS Make Model - HL SC, QuaTech Make Job Capacity upto 400mm , 5 modules Job Capacity upto 200mm, 2 modules Job Capacity upto 600mm, 10 Module Job Capacity upto 500 mm, 6 Modules Job capacity upto 70mm, 1.25 Module