Pvc pulverizer machine

525,000 Per Piece

1 Piece (MOQ)

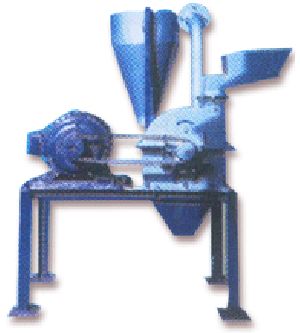

Grinding Pulverizer

Get Price Quote

A pulverizer is a mechanical device for the grinding of many different types of materials. For example, they are used to pulverize coal for combustion in the steam-generating furnaces of fossil fuel power plants. We are one of the largest Manufacturers and Suppliers of Grinding Pulverizer in India. Here are some of the specifications listed below : High precise pulverizing process of the material in micron size with impact effect. Main body (grinding chamber) made out of CI. It includes replaceable grinding liner / plates of different require shapes for different material. Metal trap would remove heavy foreign material. Automatic feeder having with variable speed star Feeder is provided for controlled feed. Rotor is made from thick plate fitted on main shaft. Hammers are hinged on it. It prevents breakage of hammers. Main shaft is supported by heavy-duty bearings fitted in dust tight housings. Whizzer is conical shaped having adjustable whizzer blades for adjust desire fineness in the range of 100-300 meshes, depending upon the material. Blower is heavy-duty long life bolted blade to get replace quickly.

Best Deals from Pulverizers

Spice Pulverizer

Get Price Quote

A specially designed hammer mill with cyclone and dust collector & dust collector system. to suit spice & like materials. Fineness may be changed of screen.

Mild Steel 2 in 1 Pulverizer Machine

21,000 Per Piece

1 Piece (MOQ)

Confider Industries stands as a beacon of excellence in the realm of food processing machinery, offering an extensive array of products tailored for both domestic and commercial applications. With a diverse portfolio comprising over 90 meticulously crafted machines, our company epitomizes innovation, reliability, and superior quality. From humble beginnings, we have grown into a globally recognized brand, catering to the needs of customers worldwide. At the heart of our success lies a relentless commitment to delivering top-notch products that exceed expectations. Every machine manufactured by Confider Industries undergoes rigorous quality control measures, ensuring precision engineering and durability. Whether it's a small-scale operation in a home kitchen or a large-scale industrial setting, our machines are designed to meet the diverse demands of modern food processing. One of the hallmarks of Confider Industries is our unwavering dedication to customer satisfaction. We understand that purchasing a food processing machine is an investment, and thus, we go above and beyond to provide unparalleled after-sales support. Our team of experts is readily available to assist customers through calls and video calls, offering guidance, troubleshooting, and technical assistance whenever needed. We believe in building long-lasting relationships with our customers, and our commitment to after-sales service reflects this ethos. Furthermore, Confider Industries takes pride in its global reach. With an extensive network of distributors and partners, our machines are delivered to customers across continents. Whether it's a bustling city in Asia, a remote village in Africa, or a thriving metropolis in Europe, our products have found their way into kitchens and food processing facilities worldwide. This global presence underscores our reputation as a trusted provider of food processing solutions on a global scale. Innovation is at the core of everything we do at Confider Industries. We continuously invest in research and development to stay ahead of market trends and technological advancements. Our team of engineers and designers work tirelessly to develop cutting-edge solutions that streamline processes, enhance efficiency, and elevate the overall user experience. From state-of-the-art automation technologies to eco-friendly designs, we strive to push the boundaries of innovation in the food processing industry. Sustainability is also a key focus for Confider Industries. We recognize our responsibility to minimize our environmental footprint and embrace sustainable practices throughout our operations. From sourcing materials responsibly to optimizing energy efficiency in our manufacturing processes, we are committed to fostering a more sustainable future for generations to come. In conclusion, Confider Industries stands as a beacon of excellence in the food processing industry, offering a diverse range of high-quality machines for domestic and commercial use. With over 90 machines in our portfolio, a global presence, and a steadfast commitment to customer satisfaction, we continue to set the standard for innovation, reliability, and excellence in food processing.

2 Hp Semi Automatic Stainless Steel Pulverizer Machine

11,500 Per Piece

1 Piece (MOQ)

commercial and domestic pulveriser machine

11,000 - 18,000 Per piece

1 piece (MOQ)

Pulverizer Machine

Get Price Quote

TECHNICAL SPECIFICATION Model DISC SIZE MAIN MOTOR POWER IN HP OUTPUT IN LLDPE (ROTO GRADE) IN KG/HR OUTPUT IN RPVC IN KG/HR. FLOOR SPACE IN MM IRP-PLV-50 300 15 H.P. 40- 50KG/ HR 50- 60KG/ HR 2300X1300X3000 IRP-PLV-70 300 20 H.P. 60- 70KG/ HR 70- 80KG/ HR 2300X1300X3000 IRP-PLV-90 400 25 H.P. 85- 95KG/ HR 95- 115KG/ HR 2400X1400X3100 IRP-PLV-120 400 30 H.P. 110- 125KG/ HR 120- 135KG/ HR 2500X1500X3300 IRP-PLV-150 400 40 H.P. 130- 140KG/ HR 140- 150KG/ HR 2700X1600X3600 IRP-PLV-200 450 50 H.P. 180- 200KG/ HR 190- 210KG/ HR 2900X1600X3800 IRP-PLV-250 500 60 H.P. 225- 250KG/ HR 235- 255KG/ HR 2900X1600X3800 IRP-PLV-TM-300 500 75 H.P. 275- 300KG/ HR 285- 310KG/ HR 4200X1600X3800 IRP-PLV-TM-400 600 100 H.P. 350- 360KG/ HR 360- 370KG/ HR 4500X1600X3800

Micro Pulverizer

Get Price Quote

We are offering micro pulverizer. crushtech micro pulveriser is specially design for grinding the chemicals, food products and other materials. In micro pulveriser the screw feeder is given to force the materials which are light in density for grinding chamber. The chamber has hard steel liners has t type hammers which are specially design to ensures grinding and disintegration of the material simultaneously. It has the screen to pass the grinded material as per specific size in mesh or micron. advantages: - a compact and easy to maintain machine, especially suitable for operations where frequent change of raw material is required. - especially t shape hammers ensures grinding and disintegration of the material simultaneously. - screens for different mesh may be changed very easily. - low specific power consumption, increased production leading to faster return on the investments. - no rcc foundation is required if fixed on a specially designed avm pad frame - durable long life applications: crushtech micro pulverizers, can be used for a wide range of application e.g. Activated carbon, animal feeds, carbon black, chalk, cocoa, starch dyes, fine chemicals, gram flour, kaolin, pigments, sugar, etc.

Impact Pulveriser

Get Price Quote

We are among the distinguished names in the industry for manufacturing and supplying Impact Pulveriser, which is used for the powdering of substances by means of continuous hammering in pharmaceutical, chemical, fertilizer and food processing industries. The offered pulverizer is exceptional in performance and is ideal for heavy duty. It is resistant to abrasions and is available in various specifications.

MS Pulveriser 2 hp to 7.5Hp

17,600 - 48,000 Per

5 Piece (MOQ)

BHUMIKA FLOUR MILL. MS PULVERISER 2HP TO 7.5 HP AVAILABLE.

Pulveriser Machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering pulveriser machine.

Disc Pulverizer

Get Price Quote

Infeed hoper from ss 304(optional), Infeed screw to pulverizer chamber controls the infeed material in grinding chamber. The screw stops at 85% full load of main motor. The screw starts when the motor load decreases to 75%,Water cooling is provided to fix serration plate & bearing housing. The serrated grinding discsserrated segments(Round serrated disc in 6 to 8 pcs.) are from high chrome material duly hardened. We recommend use of segments over the use dics. The advantage of using segments over the disc is that wobbling can be controlled within 0.3 mm in face.(In our model plvr 450). This results in more production & wear out of segments in 23mm so that it can be resharpened for three times, HEAVY DUTY 'C' class of bearings are used in bearing housing. Bearing housing is from ms casting or from graded casting, The gap setting is done by inserting feeler gauge between fix & rotary serration segments from outside of the chamber,thus reducing down time, The gap setting is done by inserting feeler gauge between fix & rotary serration segments from outside of the chamber,thus reducing down time.

Impact Pulverizer

Get Price Quote

Our pulvisers are of Impact type – versatile grinding unit of solid and robust construction capable of continuous operation of multipurpose grinding mills of soft to medium hard minerals and chemicals. Pulverisers cater the need of the mineral industries to achieve the fineness of the finished product to 60 mesh to bulk passing through 350 mesh, depending on the extent of particular material being handled. Fine grinding is achieved by compression, shear, abrasion, attrition and impact of Hammers on the materials against the replaceable radial liners. High efficiency Cyclone Air Separator is also provided to separate the Pulverised materials from air which is recalculated in the Grinding Chamber to have completed the close circuit grinding action. Excess air coming in the system is bled off through Dust Collector. The system consists of: Auto Feeding Arrangement. High Efficiency Cyclone. Air Separator. Complete Duct Line. Dust Collector with Bags. Anti Vibrating Pads with Adjustable structural rail for motor (oprtional) Impact Pulveriser Star Features: Strong suction Of Centrifugal Blower through Whizzer Classifier. Whizzer Classifier consisting blades with tips tapered to suit the degree of Whizzer Cone, gives better classification Of particle sizes. Easy Adjustment given to control fineness by clamping whizzer blades at a suitable position. Entire wearing portion consists of Grinding Chamber, Whizzer Cone and Centrifugal Blower which are lined with suitable wear resistant replaceable liners to suit the material's hardness and abrasivity. Compact Design & Dust Free Operation. Dynamically balanced all rotating parts t minimizing the friction losses and vibration. Application; Minerals Such as Bauxite, Bnetonite, Gypsum, Calcite, china clays etc. Spices such as turmeric , wheat etc., Herbs, Coconut shell, Wood Saw dust, Marine Feeds Carbon & Graphite, Coal, Coke etc. Pharmaceutical & Herbs raw materials. Chemicals and Pigments, detergents , Ferro Alloys Fertilizers, Fillers, Insecticides, and Pesticides etc.

Impact Pulveriser

Get Price Quote

The Techno Wings brand impact pulveriser meets most capacity requirements. It lend themselves to a wide degree of adjustment with finesse of the finished products ranging from about 60 mesh to bulk passing through 300 mesh depending to a considerable extent on the particular materials being handled. It combines grinding, classifying and conveying all in one single unit. It grinds with easy, economy and safety offering a wide range of particle sizing of any non-abrasive material, hard or soft from granular to finest dust up to 300 meshes. Operating principle of impact pulveriser The techno wings impact pulveriser consists of and encased rotor-carrying swing hammers, whizzed classifier for finesse regulation and blower fan mounted on a solid shaft. Raw material from the feed hopper enters manually or automatically roll feeder and as the feeder and as the feeder pockets rotate spills into the grinding chamber. The impact to the hammers on the feed material against the liner plates reduces it into fine powder. The ground material carried towards the whizzed classifier for clarification and the finesse regulators (whizzed classifier) and returns to the grinding chamber for further grinding reject the oversize particles. Classified material then conveyed into the cyclone for collection and bagging. A dust collector provided in the system for ensuring dustless operation and no loss of ground powder. Key features of impact pulveriser Unique and reliable design The impact series pulverisers are highly effective as well as nonstop continuous pulverizing process. Compact size. Dust free operation. Ideal for dry crushing. Increased production leading to faster return on the investments. Hardened &fully machined salving type beaters thus less wears &tears. All rotating parts are dynamically balanced for reducing friction losses and noise. Standard accessories of impact pulveriser Impact pulveriser's &motor pulley Suitable numbers of cotton balloons. Anti vibrating foundation stand with adjustable rail for motor Extra accessories of impact pulveriser Suitable totally enclosed fan cooled single or three phase sq. Cage motor as per is: 325{(special power can be accommodated): 110/220/380/415 volts, 50/60 Hz ,3 phase} Suitable starters, main switch, ampere meter, capacitor for three phase V belts Contacting parts stainless steel 304 / 316 can be accommodated. Application of impact pulveriser The techno wings impact pulveriser are used for a wide range of application e.g. Agricultural, chemicals, carbon &graphite, coal, coke, coconut shell &wood saw dust, clay, dye stuff &pigments, detergents, ferro alloys fertilizers, fillers, food products, herbs &spices, insecticides and pesticides, katha, marine feeds, minerals, plastics, pharmaceuticals, resins, wheat, turmeric, bangle grams, dehydrated Onion, Dehydrated Garlic, pulses, peas, sandalwood, Snuff, etc.

2 IN 1 PULVERISER MACHINE

Get Price Quote

Savariya specializes in the Manufacture of High-Quality Pulveriser & Masala Machinery Our company has the inclination to have sound business ties and will very much appreciate to receiving your valued inquiries. We are committed to render you better services with prompt attention at all the times. We manufacture and supply a Range of flourmills machine, Pulveriser Machine & Masala Machinery. Which are used in the grinding of wheat, spices, pulses, salt and all kinds of grains. These are developed to provide superior processing capabilities and deliver fine outputs in form of quality flour. We have been capable to offer the broad range of Machinery is designed using by making use of high proven wires, motors, etc, coupling with the modern technology. This Machinery is highly demanded in the market, owing to its superb features. Machine Detail’s : Micro fine Grinding. Bigger size feeding hopper. Extra masala hopper for bigger size masala grinder. Without stone , gear, pulley & V-Belt. Special rotor for grinding. Easy to operate, move, clean with smaller floor space, No foundation required. Motor protecting over load MCB switch provided Micro feeling regulator. Low power consumption & Higher average, owing to heavy duty ele, motor made of silicon stamping. Heavy duty aluminum chamber. Maintenance & dust-free operation. No wastage during grinding process. Rotating parts are fully balanced for smooth operation Construction materials consist of S.S., M.S. & aluminum or eles as per requirements of Customers.

Laboratory Pulveriser

Get Price Quote

Laboratory Pulveriser is a disc type grinder, designed for grinding material to produce a fine mesh sample in one operation. It is a self contained grinder furnished with a rotating disc having a planetary movement in a vertical plane. This feature gives added life to the wearing parts and delivers a product to uniform fineness. The pulverizer will reduce 1 pounds sample of quartz type material to 100 mesh in 1 minute. Maximum feed size is 1/4 inch Grinding is done between two discs one of which is stationary and the other reolving eccentrically at high speed. The apparatus is supplied with heat treated disc of 7 inches in diameter adjustment of size of product may be made by use of a convenient hand wheel while the machine is in operation or at rest. A self locking device holds the hinged grinding chamber in place and affords easy and quick access to the grinding chamber for removal of ground samples and for cleaning. The Laboratory Pulverizer is supplied complete with a 3 HP motor, starting switch, V-belt pully drive and mounting electrical requirements are 440 volts 3 phase A.C.

Food Pulverizer

15,000 Per Piece

PULVERIZER

Get Price Quote

Pulverizer Machine

Get Price Quote

In order to fulfill the changing demands of our clients, we are offering a quality range of Pulverizer Machines. Clients can avail these machines along with heavy duty angle channels and graded castings from us at industry-leading prices. There is an Its electric motor, which is mounted below the machine. With the help of different size perforated sheets the desired powder size can be obtained by the clients. Our professionals ensure that these machines are delivered at their preferred destination within the promised time.

Micro Pulverizer

Get Price Quote

We manufacture micro pulverizers in various sizes and models. Our micro pulverizing equipments grinds easily any type of granular to finest dust up to 300 mesh.