Premix Ramming Mass

9 Per Kilogram

Cupola Ramming Mass

6 - 9 Per Kilogram

5000 Kilogram (MOQ)

Silica ramming mass, also known as acidic ramming mass or quartzite powder or quartz powder. Silica ramming mass is a product to be used in Coreless Induction Furnaces for melting of scrap to liquid steel. It is a dry lining refractory that can be used for all types of iron, steel, aluminium and foundries. Silica ramming mass is used for melting carbon steels with carbon content higher than 0.1 %. It is produced by calcining, crushing and grading of the white crystalline quartz containing 99.90 % of SiO2.

Best Deals from Ramming Mass

Acidic Ramming Mass

Get Price Quote

The role of Acidic Ramming Mass in steel melting through induction Furnace is very important. Due to its important property to with stand thermal shocks without developing any cracks due to interrupted power supply which is the case through out our country We have taken initiative to develop acidic ramming mass of high quality silica Quartz having heavy density.

Silica Ramming Mass

1 - 2 Per Kilogram

10 Ton (MOQ)

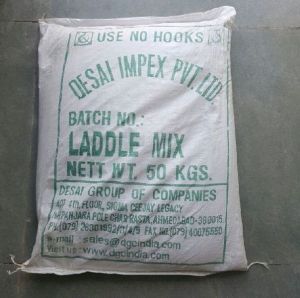

LADDLE MIX

Get Price Quote

Chrome enriched magnesite based ramming mass for making ladles of foundry. Plain water to be used as binder before pre-heating. Method to use: After mixing 3-4% of plain water, good compact ramming is required to be done, talking special care of the impact area which is the bottom. After completing the ramming process slow pre-heating is requied to be done for 3-5 hours (depending on the capacity of the laddle). There after laddle is to be kept in red hot condition for one hour.

INDUCTOCOAT

Get Price Quote

Material is to be used for giving coating to water cooled copper coil. Method to use: Homogeneous mixing is required to be done with 6-8% of plain water in order to get material in the form of paste. It is to be applied on coil. Drying can be done by putting 500 1000 watt bulbs insite the crucible.

Lining Machine Neutral Ramming Mass

Get Price Quote

Lining Compactness Increased Lining Life, Reduced No. of Sintering and Increased in Output Liquid Metal Uniform Strength throughout Furnace Crucible Reduce Man Power Reduce Lining Time